排污活门10101000系列

一、名称

WASTE DRAIN VALVE ASSEMBLY

排污活门

二、件号

10101000CA,10101000C-A,10101000CG,10101000C-G,10101000CH,10101000C-H,10101000CJ,10101000C-J,10101000CA1,10101000C-A-1,10101000CJ1,10101000C-J-1,10101000CJ2,10101000C-J-2,10101000CM,10101000C-M,10101000CN,10101000C-N,10101000CR,10101000C-R,10101000CB,10101000CJ3,10101C739,10101C758

三、章节号

38-30-01

四、适用机型

B757

五、系统

38 WATER/WASTE

水/污水

六、安装位置

机身下部

七、部件原理

1. DESCRIPTION AND OPERATION

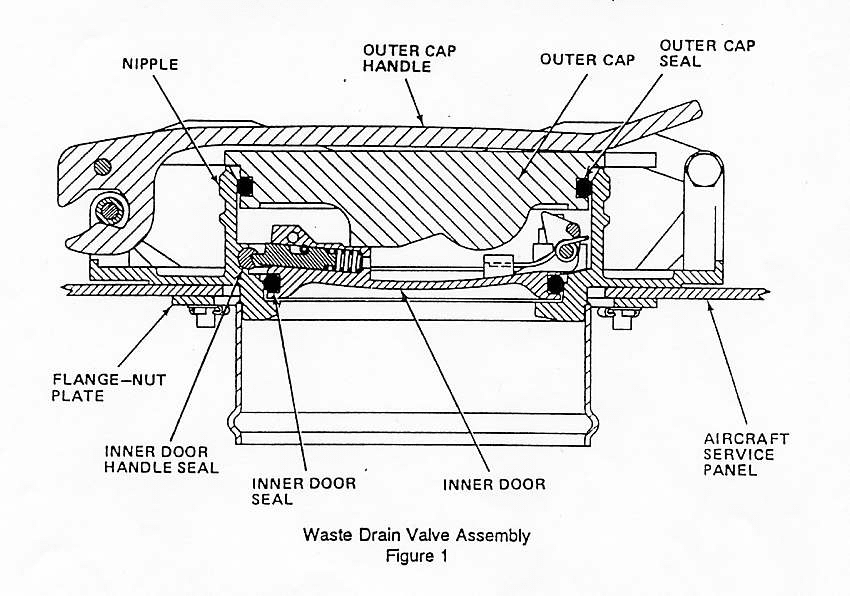

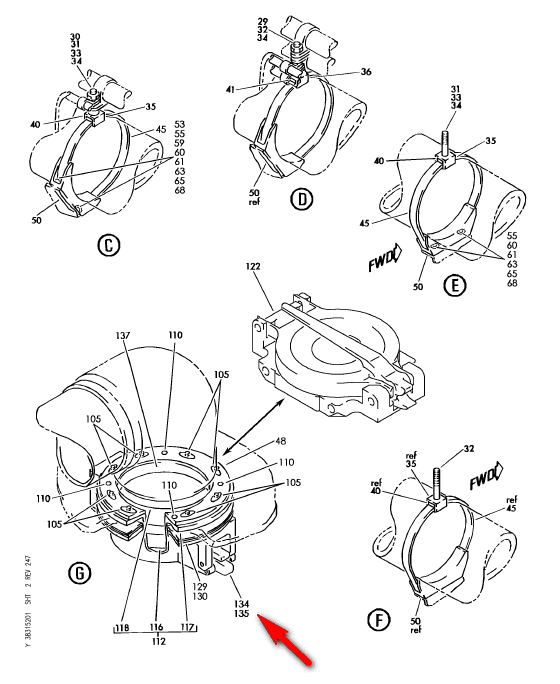

A. Description (See Figure 1)

(1) The waste drain valve assemblies are composed of a nipple assembly and, except for the 10101000CB, -J, -J-1,-J-2,J3, N, 10101C739 and 10101C758 units, a flange-nut plate for mounting, and a label as applicable.

(2) The nipple assembly is composed of a hinged outer cap with a seal to provide an external seal and a latch handle controlled inner door with O-ring to provide an internal seal. With the inner door closed and the outer cap closed, a double seal is provided.

1. 说明和操作

A. 说明 (见图 1)

(1) 排污活门组件由一个管嘴组件和一个法兰螺母板(10101000CB、-J、-J-1、-J-2、J3、N、10101C739 和 10101C758 部件除外)组成,法兰螺母板用于安装,并附有适用的标签。

(2) 管嘴组件由一个带密封圈的铰链外盖和一个带 O 型圈的自锁手柄内门组成,前者提供外部密封,后者提供内部密封。在内门关闭和外盖关闭的情况下,可提供双重密封。

B. Operation

(1) The waste drain valve is a manually operated valve. The outer cap is opened and a coupling attached to the nipple. The inner door is then opened allowing for waste disposal.

(2) Upon completion of waste disposal, the coupling is removed and the outer cap is manually closed which automatically closes and seals the inner door.

B. 操作

(1) 排污活门为手动操作活门。打开外盖,将接头连接到管嘴上。然后打开内门,进行排污。

(2) 废物处理完毕后,取下接头,手动关闭外盖,内门自动关闭和密封。

八、工作参数

Leading Particulars

Proof Pressure

Valve :25 psig (172.4 kPa)

Inner Door :17 psig (117.2 kPa)

Outer Cap :17 psig (117.2 kPa)

九、在飞机系统中的工作原理及其互联

Functional Description

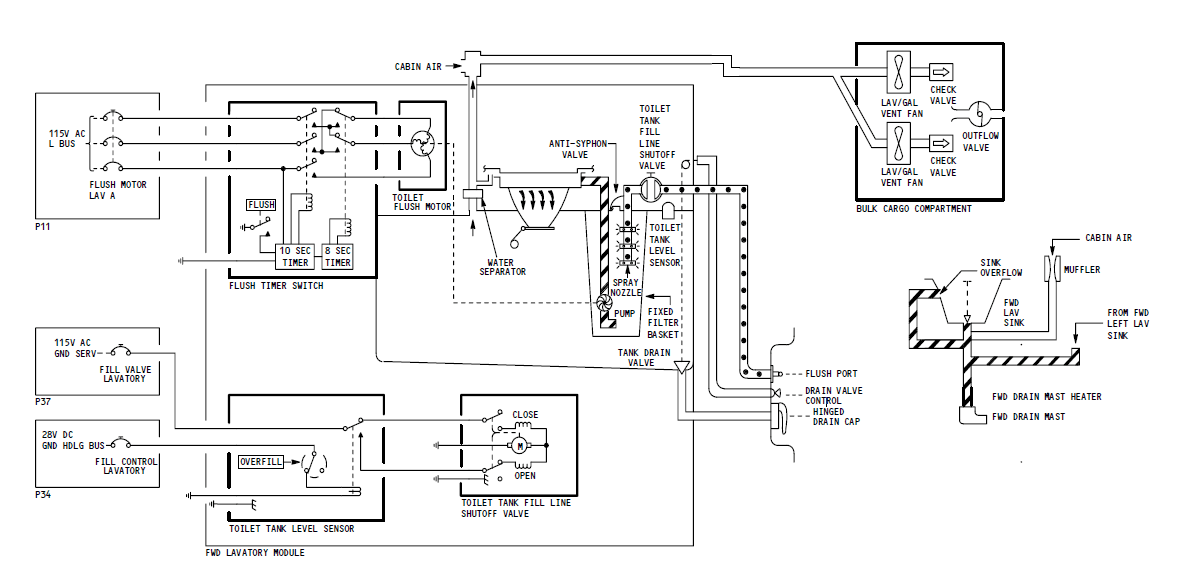

(1) The toilet flushing cycle is started when the flush timer handle is depressed. This provides power to the flush motor which operates the pump. Filtered water is pumped into the toilet bowl until the flush timer cuts power to the flush motor (about ten seconds).

(2) When ground power is applied, the fill/shutoff valve opens. During servicing, the valve closes if the liquid level in the tank reaches three inches from the top of the tank. The valve reopens when the liquid level drops 0.5 |.25 inches. The valve closes when ground power is removed.

功能说明

(1) 当按下冲水计时器手柄时,马桶冲水循环开始。这就为冲水电机提供了动力,从而使水泵运转。过滤水被泵入马桶,直至冲水计时器切断冲水电机的电源(约十秒钟)。

(2) 当接通地面电源时,加水 / 关断活门打开。在勤务期间,如果水箱中的液面达到距水箱顶部三英寸的高度,活门会关闭。当液面下降 0.5 |.25 英寸时,活门重新打开。切断地面电源后,活门关闭。

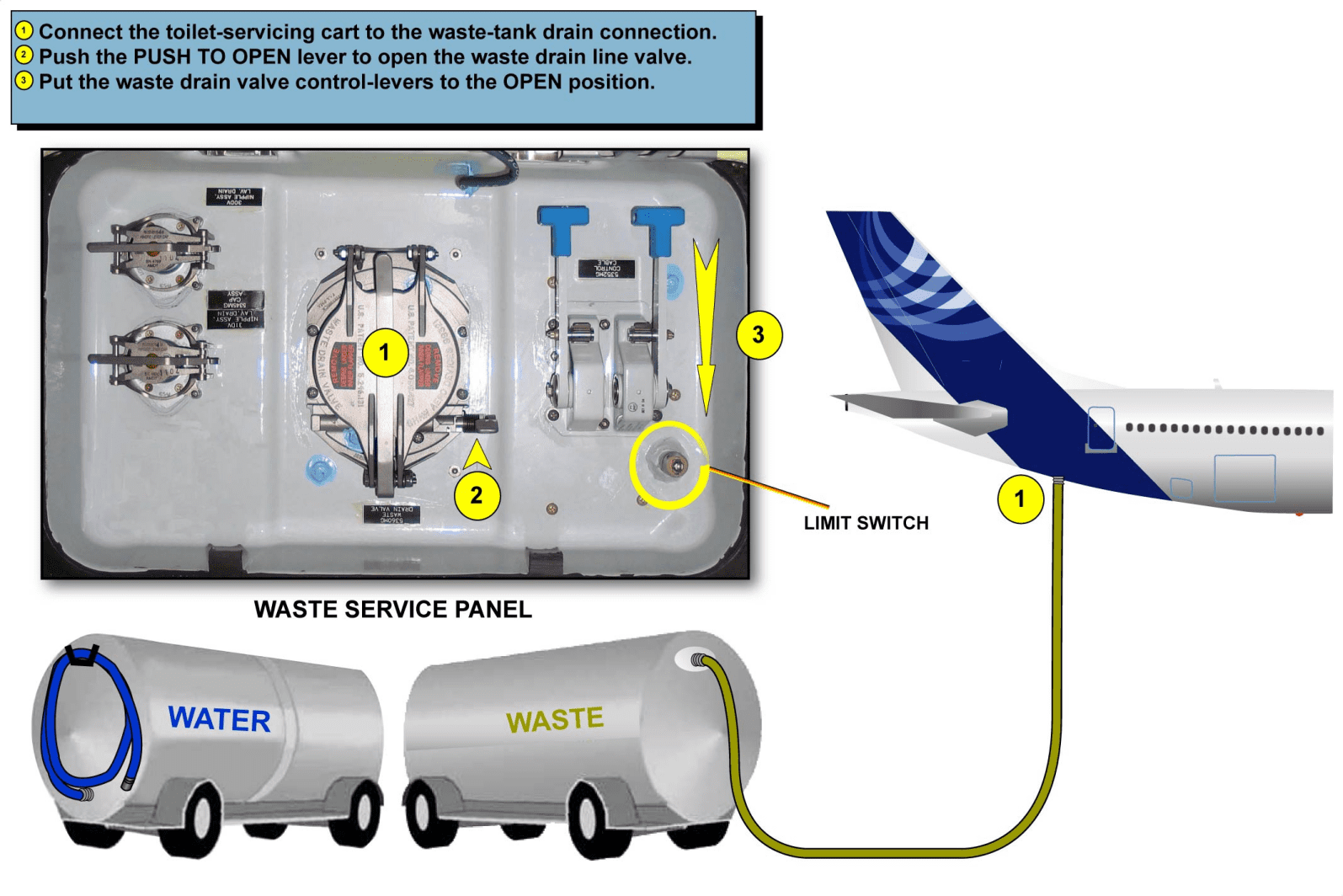

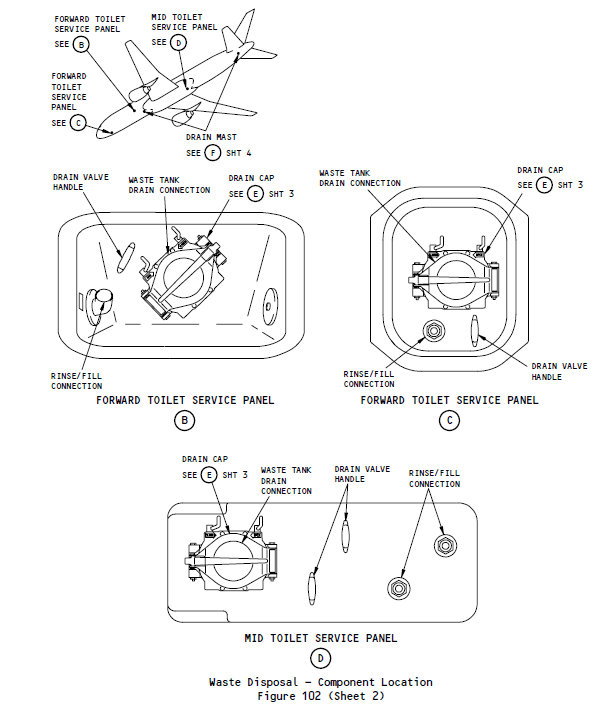

地面人员可以从下部机身的污水勤务面板来接近真空马桶系统。污水勤务面板上装有污水管接头和排放活门手柄。另外,还装有一个冲洗接头用于勤务结束后进行水箱的冲洗。

在污水管的排放口上通常装有一个排放堵盖。排放堵盖上装有一个安全活门,这个安全活门可以防止排放活门故障后造成的污染物泄漏。在排放污水之前,必须将管道从污水车连接到排放口,然后再打开安全活门。

要排放污水箱的水,必须拉动相应水箱的排放活门手柄。通过钢索打开排放活门。当拉动手柄时,排放活门就会打开,污水通过重力作用流到污水车里。在排放活门打开的同时,监控活门位置的临近电门就会断开真空发生器的供电,以防止其在勤务期间工作。

十,系统介绍

General

A. The standard capacity potable water system is used on airplanes with the recirculating toilet systems. The standard capacity potable water system has a 60 gallon water tank which stores fresh water. The system supplies water to the galley units and lavatory wash basins.

B. The storage and distribution components of the potable water system, store, distribute, and drain fresh water. The potable water tank is in the compartment aft of the bulk cargo compartment.

C. Each galley and lavatory has water shutoff valves above the floor. The valves allow any one unit or combination of units, to be isolated while the rest of the units remain operating. The lavatory wash basins each have a faucet with hot and cold water. The faucets are self venting. This allows automatic bleeding of air from the system, and allows draining the system without opening the faucet.

D. Most of the water distribution system is flexible teflon hose with a reinforced fiber covering. Metal fittings and connectors are used at junctions and line replaceable units. Distribution lines route from below the water tank to above the cabin ceiling. The lines enter galleys and lavatories from above at Doors 1, 2, and 3, and from below at Door 4.

E. The water heaters provide hot water to the wash basins in each lavatory. Each lavatory has a water heater in the supply line to the wash basin faucet.

F. Potable water quantity indicators show ground service personnel and the flight crew how much water is in the potable water tank. The water quantity sensing system sends quantity signals to the water quantity indicators.

G. The potable water tank is pressurized to force water from the tank to the lavatories and galleys. The pressurization system includes an air compressor, air filters, pressure relief valve, and pressure switch. Bleed air from the pneumatic system provides additional pressurization.

概述

A. 标准容量饮用水系统用于飞机上的循环式厕所系统。标准容量饮用水系统有一个 60 加仑的水箱,用于储存淡水。该系统为厨房设备和厕所洗手盆供水。

B. 饮用水系统的储存和分配组件用于储存、分配和排放淡水。饮用水箱位于散货舱后部。

C. 每个厨房和厕所地板上方都有水关断活门。这些活门可将任何一个单元或单元组合隔离,而其余单元仍在运行。厕所洗脸盆各有一个冷热水龙头。水龙头具有自排气功能。这样可以自动排出系统中的空气,并在不打开水龙头的情况下排空系统。

D. 大部分输水系统都是柔性聚四氟乙烯软管,外覆强化纤维。在连接处和可更换的管路装置上使用金属配件和连接器。分配管路布线从水箱下方一直延伸到机舱天花板上方。水管从上方的 1 号、2 号和 3 号门进入厨房和厕所,从下方的 4 号门进入厨房和厕所。

E. 热水器为每个厕所的洗脸盆提供热水。每个厕所都有一个热水器,通过供水管道通向洗脸盆龙头。

F. 饮用水水量指示器向地面服务人员和机组人员显示饮用水水箱中的水量。水量感应系统向水量指示器发送水量信号。

G. 对饮用水箱进行加压,以便将水从水箱强制输送到厕所和厨房。加压系统包括空气压缩机、空气过滤器、泄压阀和压力开关。气动系统的引气可提供额外的加压。