介绍INTRODUCTION

1. How to Use This Manual

怎么使用手册

A. General

通用

(1) This publication gives maintenance instructions for the equipment shown on the Title page.

本出版物提供标题页所示部件的维护说明。

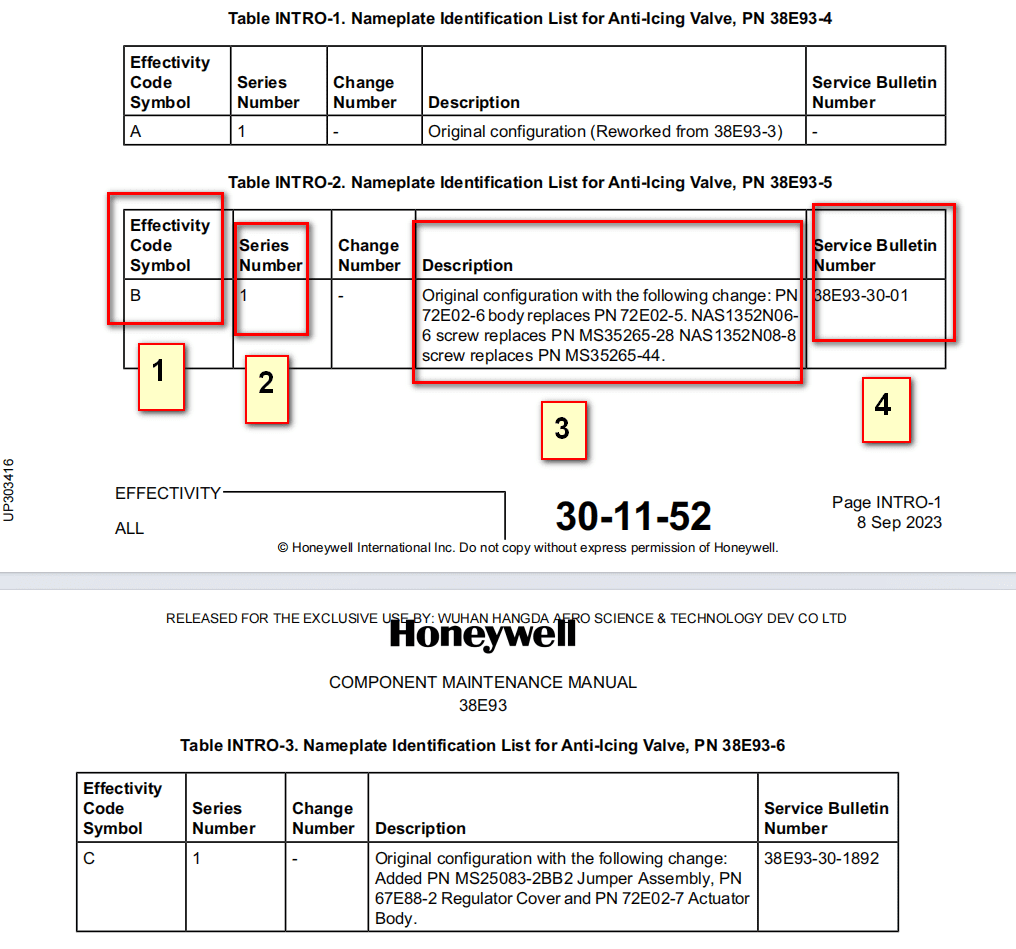

(2) Refer to Table INTRO-1 thru Table INTRO-3 for Nameplate Identification data.

铭牌标识数据请参见表 INTRO-1 至表 INTRO-3。

(a) The configuration of the equipment is shown by the part number, dash number, series number, and change number stamped on the identification plate. Compare this data with the data shown in Table INTRO-1 thru Table INTRO-3.

部件的构型由铭牌上印制的件号、破折号、序号和改装号显示。将这些数据与表 INTRO-1 至表 INTRO-3 中的数据进行比较。

(b) A part number, a service bulletin number (Pre SB, Post SB), or an effectivity code symbol identifies the special procedures or illustrations necessary for each configuration. The procedures and illustrations not identified are applicable to all the configurations of the equipment.

件号、服务通告编号(Pre SB、Post SB)或有效代码符号标识了每种构型所需的特殊程序或插图。未标识的程序和插图适用于设备的所有构型。

(c) The effectivity coding system identifies the differences between unit configurations.

有效代码系统可识别部件构型之间的差异。

①Modifications to the basic unit make it necessary to re-identify the unit. For example: PN 123456-1 becomes PN 123456-2.

对原部件进行改装后,有必要重新标识部件。例如 PN 123456-1 变为 PN 123456-2。

②Each different part number and dash number has its own effectivity code.

每个不同的零件号和破折号都有自己的有效代码。

③In the text, if no effectivity codes or part numbers are shown, then the procedures are applicable to all the configurations of the unit.

在文本中,如果没有显示有效代码或件号,则程序适用于该部件的所有构型。

④In the text, if one or more effectivity codes or part numbers are shown, then the procedures are applicable only to the related configuration of the unit.

在文本中,如果显示了一个或多个有效代码或件号,则该程序仅适用于部件的相关构型。

⑤Table INTRO-1 thru Table INTRO-3 shows the part number and effectivity code for each unit.

表 INTRO-1 至表 INTRO-3 显示了每个部件的件号和有效代码。

(3) Standard maintenance procedures that technicians must know are not given in this manual.

本手册未给出技术人员必须了解的标准维护程序。

(4) This publication is written in agreement with the ATA Specification.

本手册的编写符合 ATA 规范。

(5) Refer to the Special Tools, Fixtures, and Equipment and Consumables tables in each section before the start of maintenance or repair procedures.

在开始进行维护或修理程序之前,请参考各节中的专用工具、夹具和设备及消耗品表。

(6) An explanation on how to use the ILLUSTRATED PARTS LIST is given in the Introduction to that section.

如何使用图解零件清单的说明在该部分的介绍中给出。

(7) Honeywell recommends that you do the tests in TESTING AND FAULT ISOLATION before you disassemble the unit. These tests can show the condition of the unit or most possible cause of a malfunction. If a malfunction occurs, repair as necessary.

霍尼韦尔建议您在分解部件前进行 “测试和故障隔离 “中的测试。这些测试可显示部件的状况或故障的最可能原因。如果出现故障,请进行必要的修理。

(8) Warnings, cautions, and notes in this manual give the data that follows:

本手册中的警告、注意和注释提供了以下数据:

– A WARNING gives a condition or tells personnel what part of an operation or maintenance procedure, which if not obeyed, can cause injury or death

警告给出了一种情况,或告诉人员操作或维护程序中的哪个部分,如果不遵守,可能导致人员伤亡。

– A CAUTION gives a condition or tells personnel what part of an operation or maintenance procedure, which if not obeyed, can cause damage to the equipment

注意给出了一种情况或告诉工作人员操作或维护程序中的哪一部分,如果不遵守,可能会导致设备损坏

– A NOTE gives data, not commands. The NOTE helps personnel when they do the related instruction.

注释提供的是数据而不是命令。注释有助于工作人员执行相关指令。

(9) Warnings and cautions go before the applicable paragraph or step. Notes follow the applicable paragraph or step.

警告和注意事项放在适用段落或步骤之前。注释在适用段落或步骤之后。

B. Observance of Manual Instructions

遵守手册说明

(1) Make sure that you carefully obey all safety, quality, operation, and shop procedures for the unit.

务必认真遵守部件的所有安全、质量、操作和车间程序。

(2) All personnel who operate equipment and do maintenance specified in this manual must know and obey the safety precautions.

操作本手册规定的部件和进行维护的所有人员必须了解并遵守安全预防措施。

C. Symbols

符号

(1) The symbols and special characters are in agreement with IEEE Publication 260 and IEC Publication 27. Special characters in text are spelled out.

符号和特殊字符与 IEEE Publication 260 和 IEC Publication 27 一致。文本中的特殊字符均为拼写。

(2) The signal mnemonics, unit control designators, and test designators are shown in capital letters.

信号助记符、单元控制代号和测试代号用大写字母表示。

(3) The signal names followed by an “*” show an active low signal.

信号名称后的 “*”表示低态有效信号。

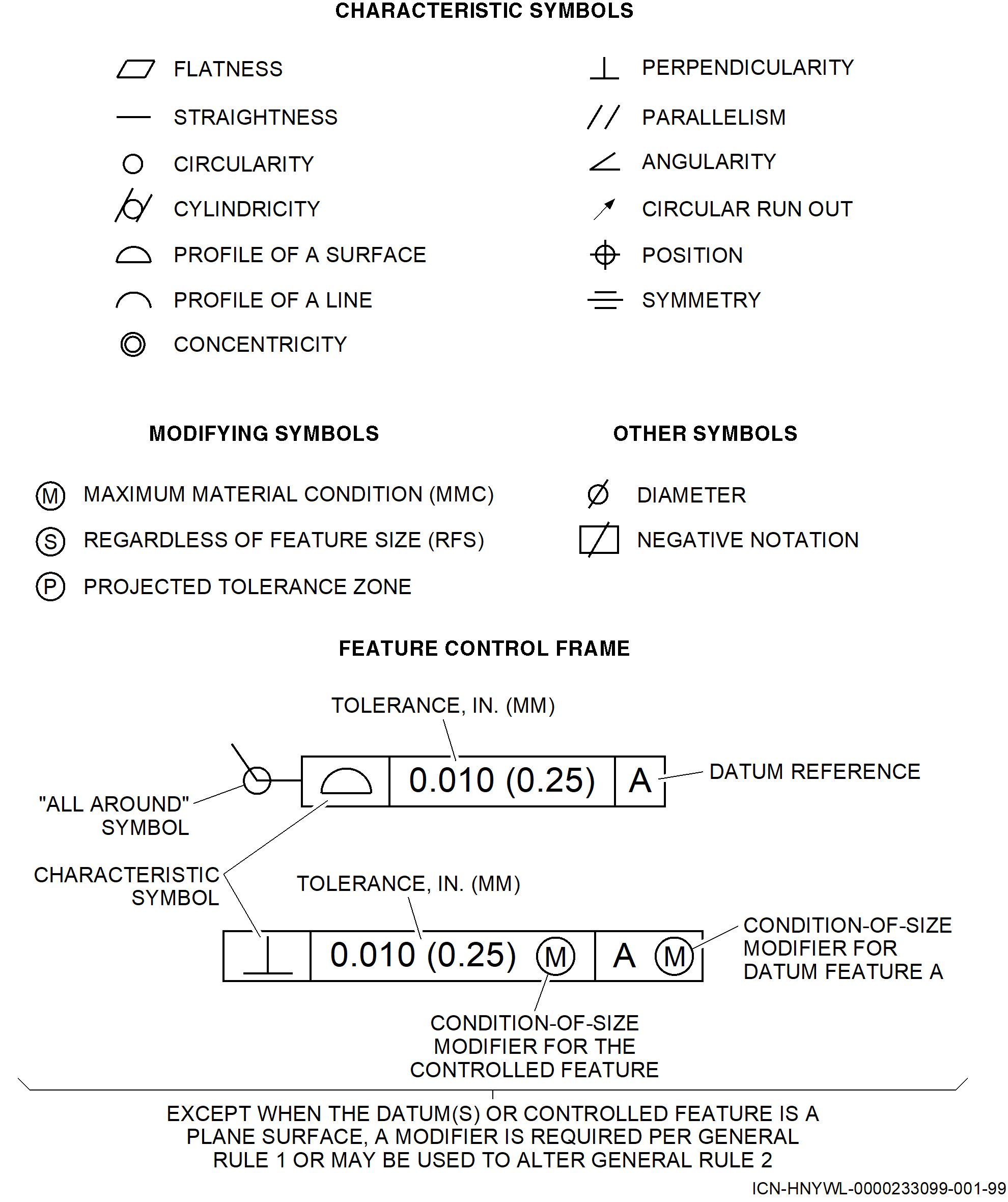

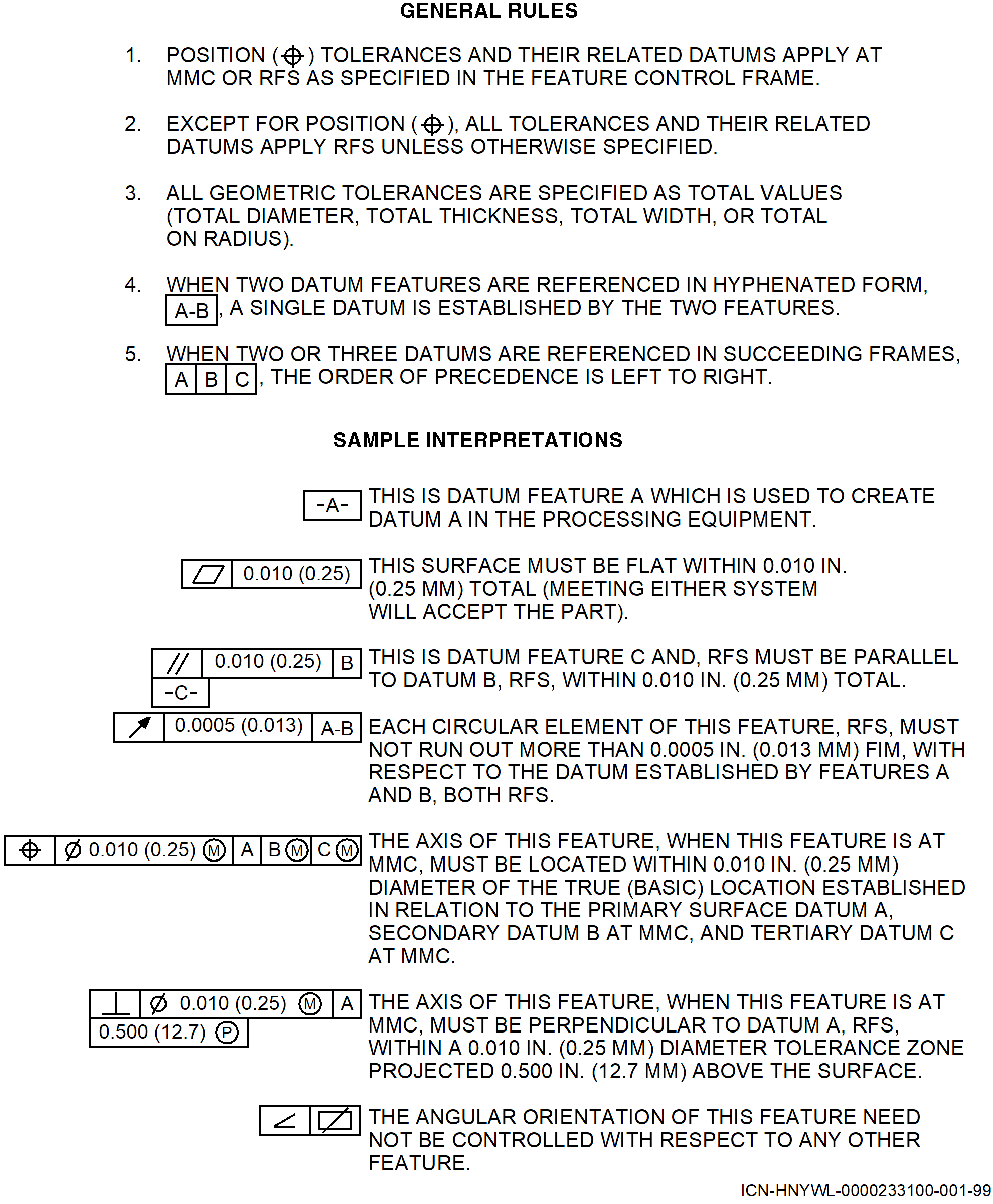

(4) Some figures in this manual incorporate standard geometric characteristic symbols. Refer to Figure INTRO-1 for the geometric characteristic symbols.

本手册中的某些图包含标准几何特性符号。有关几何特性符号,请参阅图 INTRO-1。

Figure INTRO-1. (Sheet 1 of 2) Geometric Tolerance Symbols

Figure INTRO-1. (Sheet 2 of 2) Geometric Tolerance Symbols

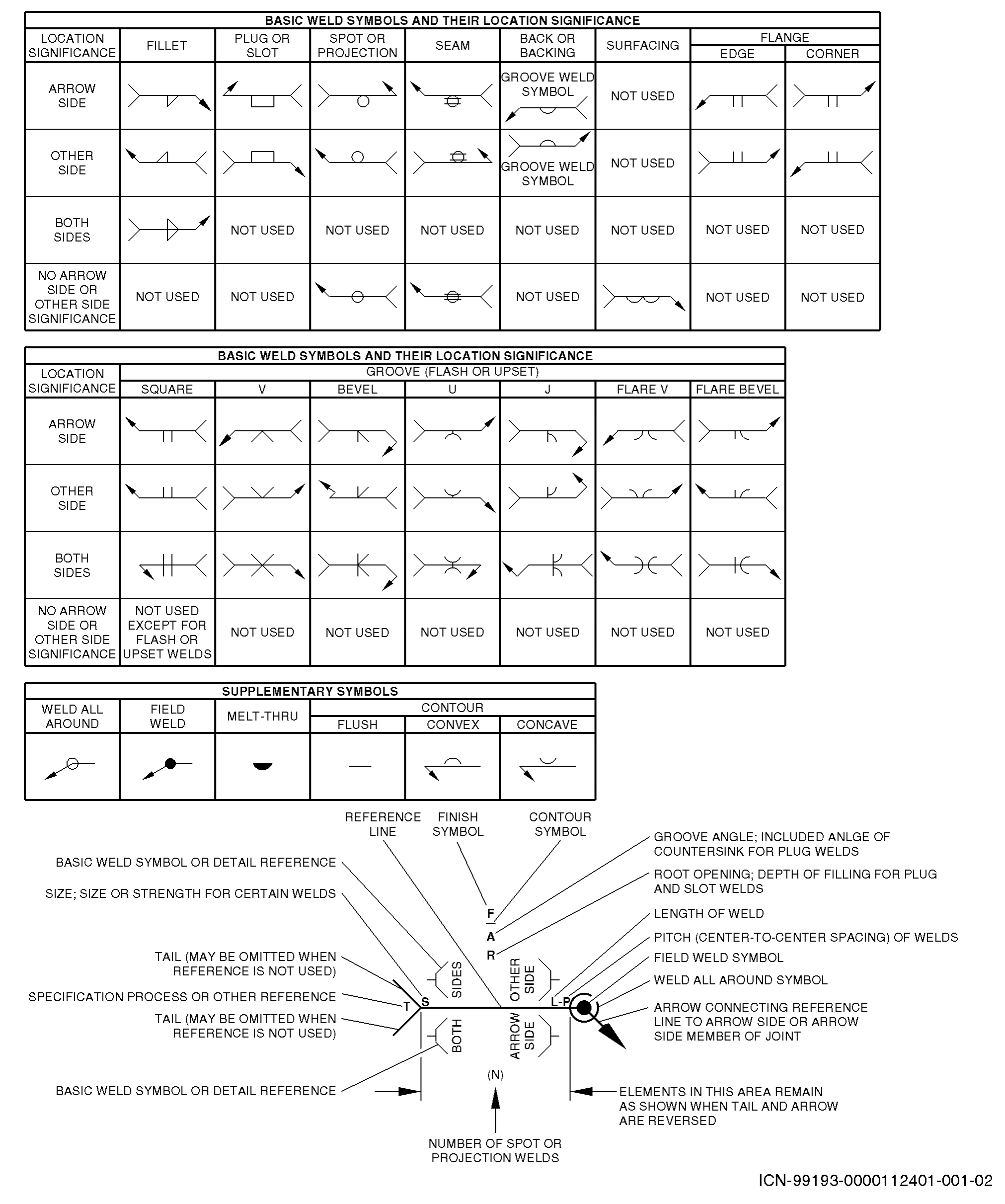

(5) Some figures in this manual incorporate standard weld symbols. Refer to Figure INTRO-2 for the weld symbols.

本手册中的一些图包含标准焊接符号。有关焊接符号,请参阅图 INTRO-2。

Figure INTRO-2. Weld Symbols

D. Units of Measure

测量单位

(1) Measurements, weights, temperatures, dimensions, and other values are expressed in the USMS followed by the appropriate SI metric units in parentheses. Some standard tools or parts such as drills, taps, bolts, nuts, etc. do not have an equivalent.

测量值、重量、温度、尺寸和其他数值均以 USMS 表示,括号内为相应的 SI 公制单位。某些标准工具或零件,如钻头、丝锥、螺栓、螺母等,没有等效的单位。

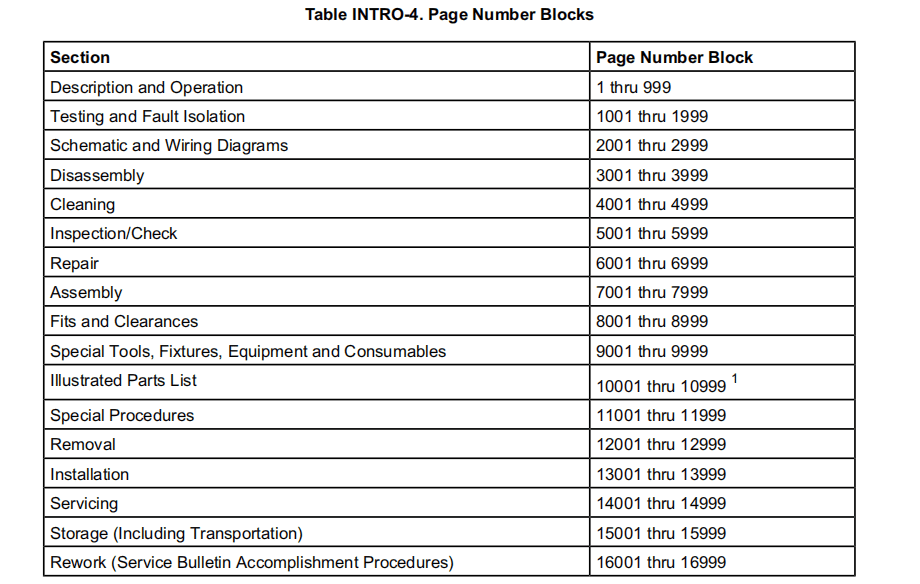

E. Page Number Block Explanation

页块说明

(1) The data in this manual is divided into sections. A standard page number block system is used. Page number blocks are shown in Table INTRO-4.

本手册中的数据按章节划分。采用标准页码块系统。页码块如表 INTRO-4 所示。

F. Illustration

插图

(1) Some of the exploded view illustrations shown in the ILLUSTRATED PARTS LIST section are also referenced in the DISASSEMBLY, CLEANING, INSPECTION/CHECK, REPAIR, ASSEMBLY, and/or FITS AND CLEARANCES sections of this manual.

在本手册的分解、清洁、检查、修理、组装和 / 或配合与间隙章节中,也参考了图解零件清单(IPL)中的某些爆炸图。

(2) Illustrations that support the individual items are shown by the item nomenclature, and in parenthesis, the item number followed by the basic figure number, i.e. washer (90, IPL Figure 1). Item numbers refer to the same IPL figure until a different IPL figure is specified.

支持单个项目的插图用项目命名法表示,括号内为项目编号,后跟基本图号,如垫圈(90,IPL 图 1)。在规定不同的 IPL 图之前,项目编号指的是同一 IPL 图。

(3) Supplemental illustrations use a suffix number to the basic figure number. For example, if Figure 5001-5 is used, it signifies that it is an illustration of the item identified by index number 5 in Figure 5001.

补充插图使用基本图号的后缀数字。例如,如果使用图 5001-5,则表示它是图 5001 中索引号 5 所标识项目的插图。

(4) If a code symbol (Code _____), part number, or Service Bulletin Number (Pre SB _____ or Post SB _____) is before the illustration title, it is applicable to a specific unit.

如果插图标题前有代码符号 (代码 _____)、件号或服务通告编号 (Pre SB _____ 或 Post SB _____),则表示该插图适用于特定的部件。

(5) Illustrations with no specific designation are applicable to all units.

没有具体说明的插图适用于所有部件。

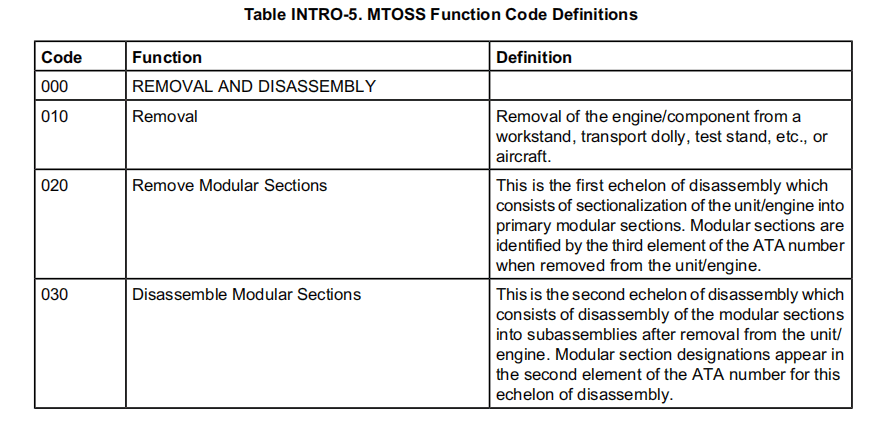

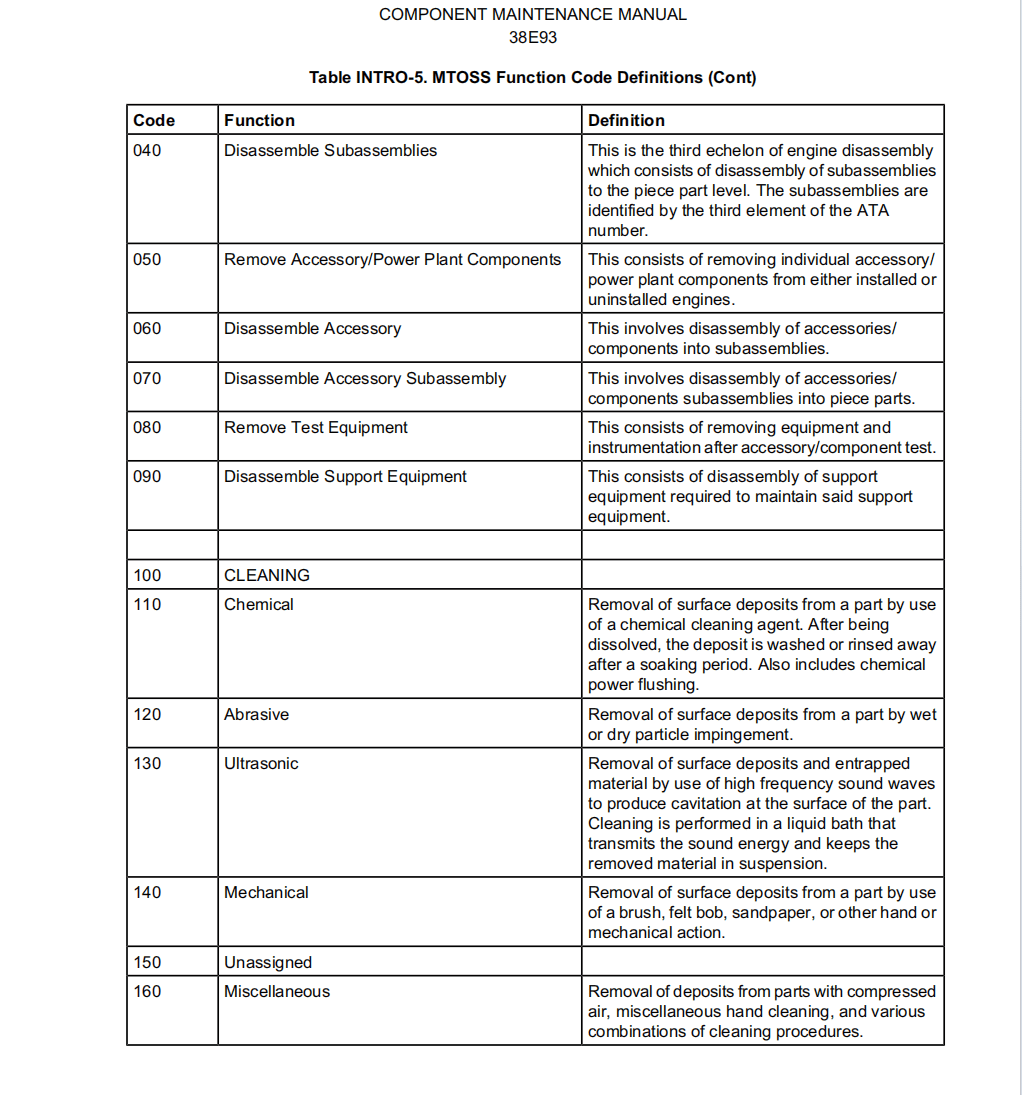

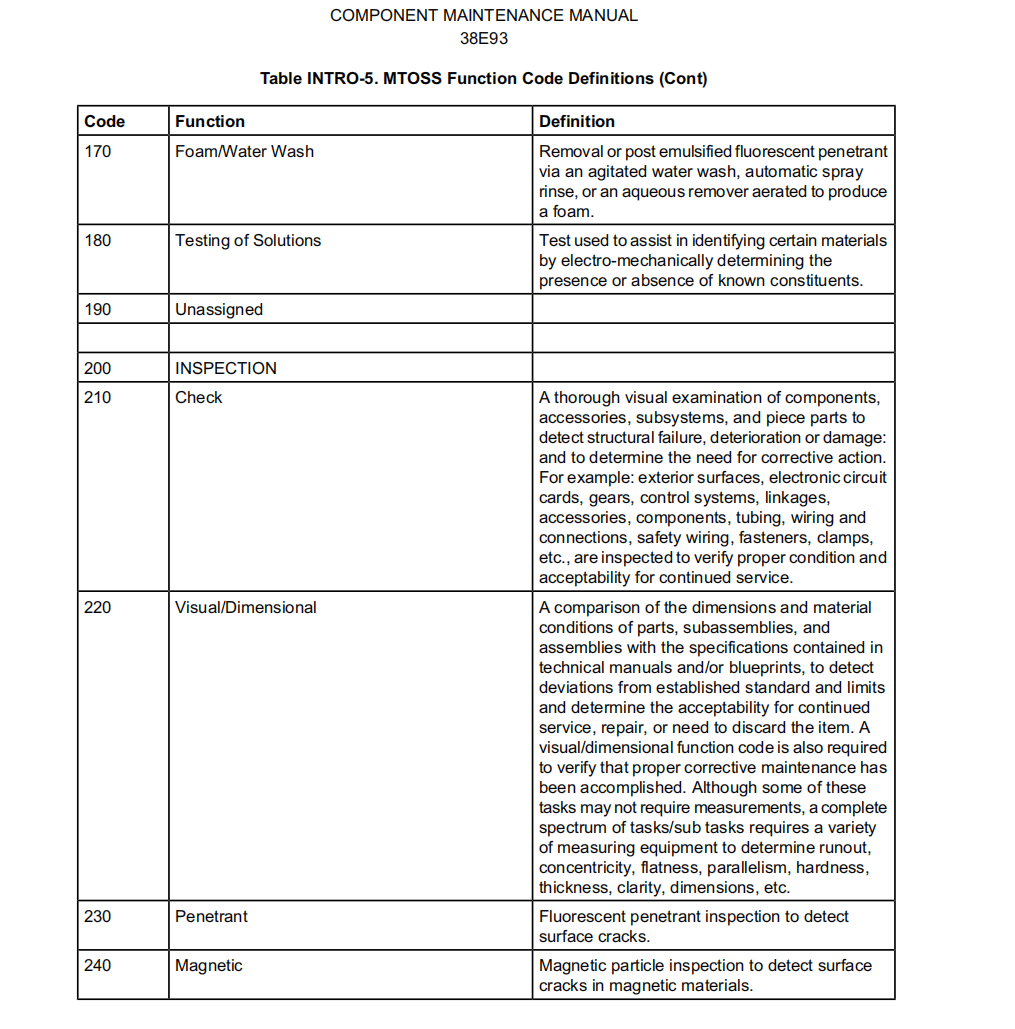

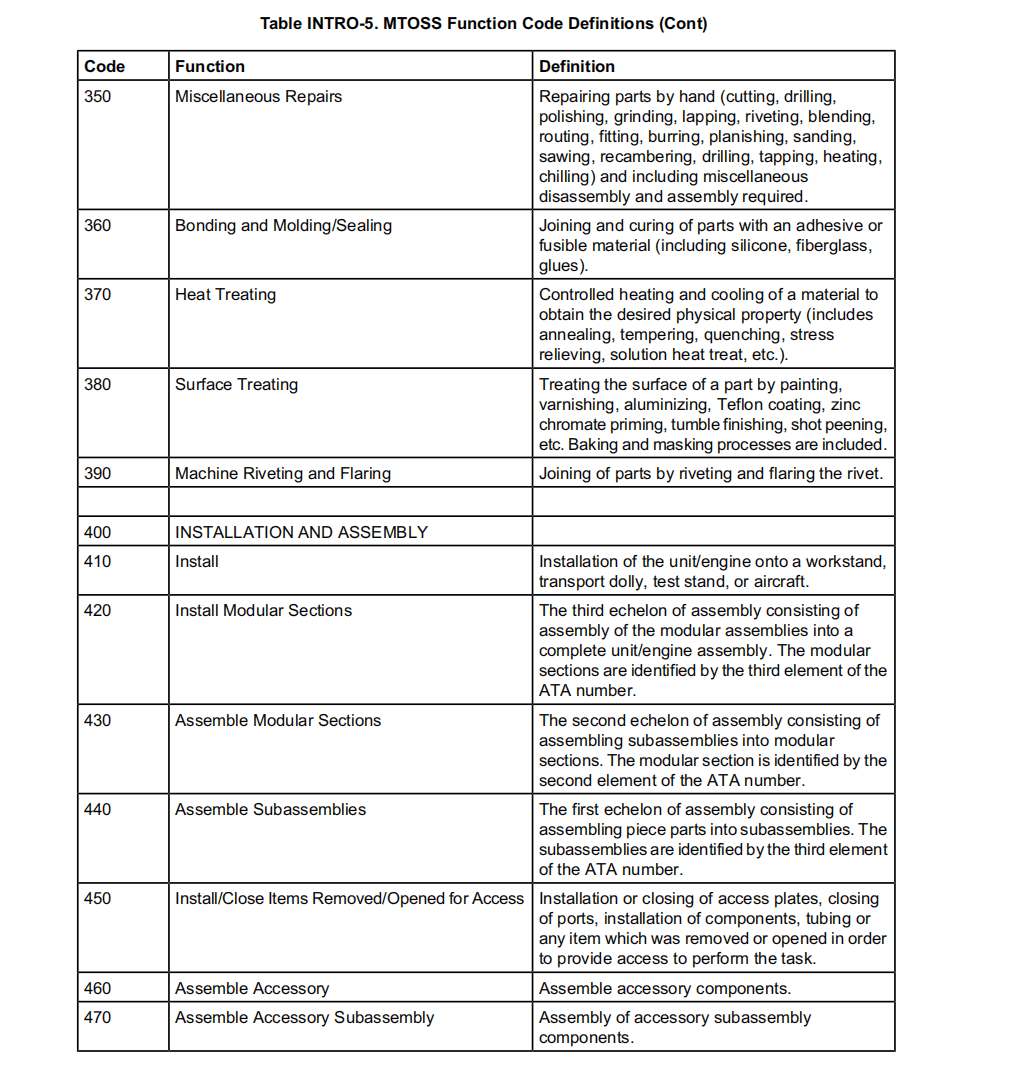

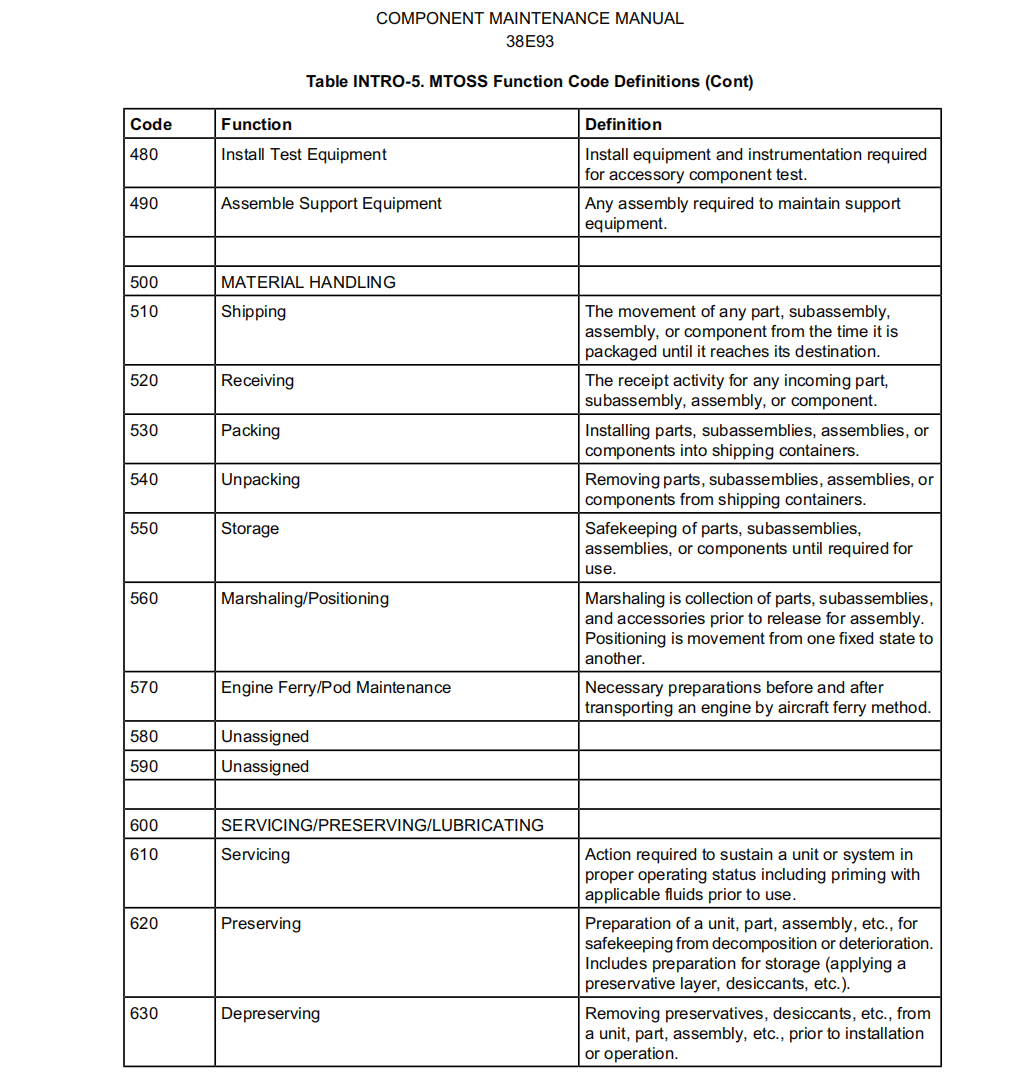

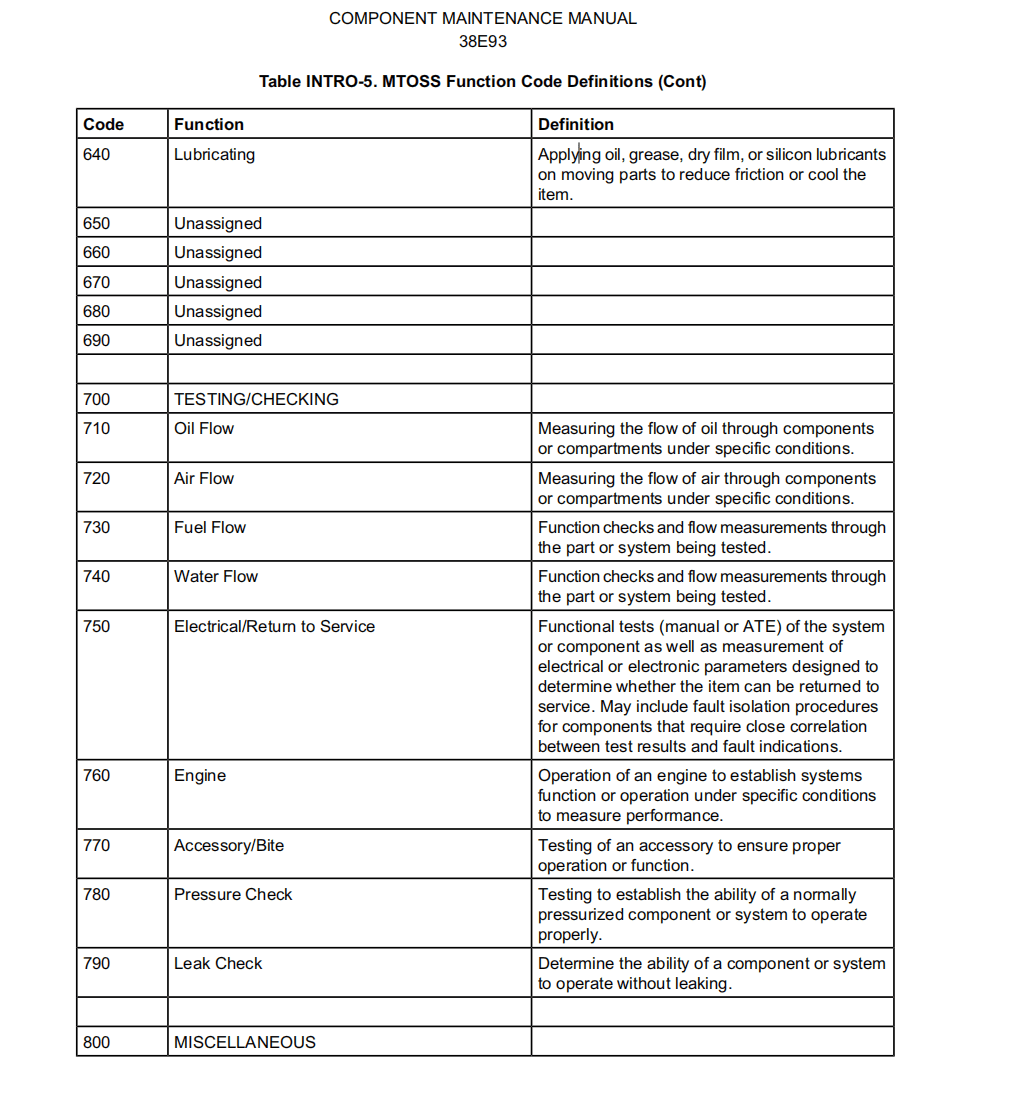

G. Application of Maintenance Task Oriented Support System (MTOSS)

维护任务导向支持系统(MTOSS)的应用

(1) In accordance with the ATA Specification 2200, this publication uses a Maintenance Task Numbering System which make the maintenance procedures in this manual compatible with an automated shop environment.

根据 ATA 规范 2200,本手册采用维护任务编号系统,使手册中的维护程序与自动化车间环境兼容。

(2) The system uses standard and unique number combinations to identify maintenance tasks and subtasks.

该系统使用标准和唯一的编号组合来标识维护任务和子任务。

(3) The MTOSS structure is the logical approach to organizing maintenance tasks and subtasks. The MTOSS numbering system includes the ATA Chapter-Section-Subject number as well as a function code and unique identifiers. The purpose of incorporating the MTOSS numbering system is to provide a means for the automated sorting, retrieval, and management of digitized data.

MTOSS 结构是组织维护任务和子任务的逻辑方法。MTOSS 编号系统包括 ATA 章-节-主题编号以及功能代码和唯一标识符。采用 MTOSS 编号系统的目的是为数字化数据的自动分类、检索和管理提供一种方法。

(4) Section and Sub-section Numbering System

章节和子章节编号系统

(a) All procedures in this publication have TASK and SUBTASK numbers at key data retrieval points. The numbers provide the following:

本出版物中的所有程序在关键的数据检索点都有 TASK 和 SUBTASK 编号。这些编号提供以下信息:

– Identification of the hardware (part or parts) primary to the TASK

TASK 的主要硬件(零件)标识

– Identification of the maintenance function applied to the part or parts

识别适用于零件的维护功能

– A unique identifier for a set of instructions (known as TASK or SUBTASK)

一组指令(称为 TASK 或 SUBTASK)的唯一标识符

– Identification of alternate methods and configuration differences that change the procedure applied to the TASK

识别改变适用于 TASK 程序的替代方法和构型差异

– Identification of airline changes to a TASK or SUBTASK.

识别航空公司对任务或子任务的变更

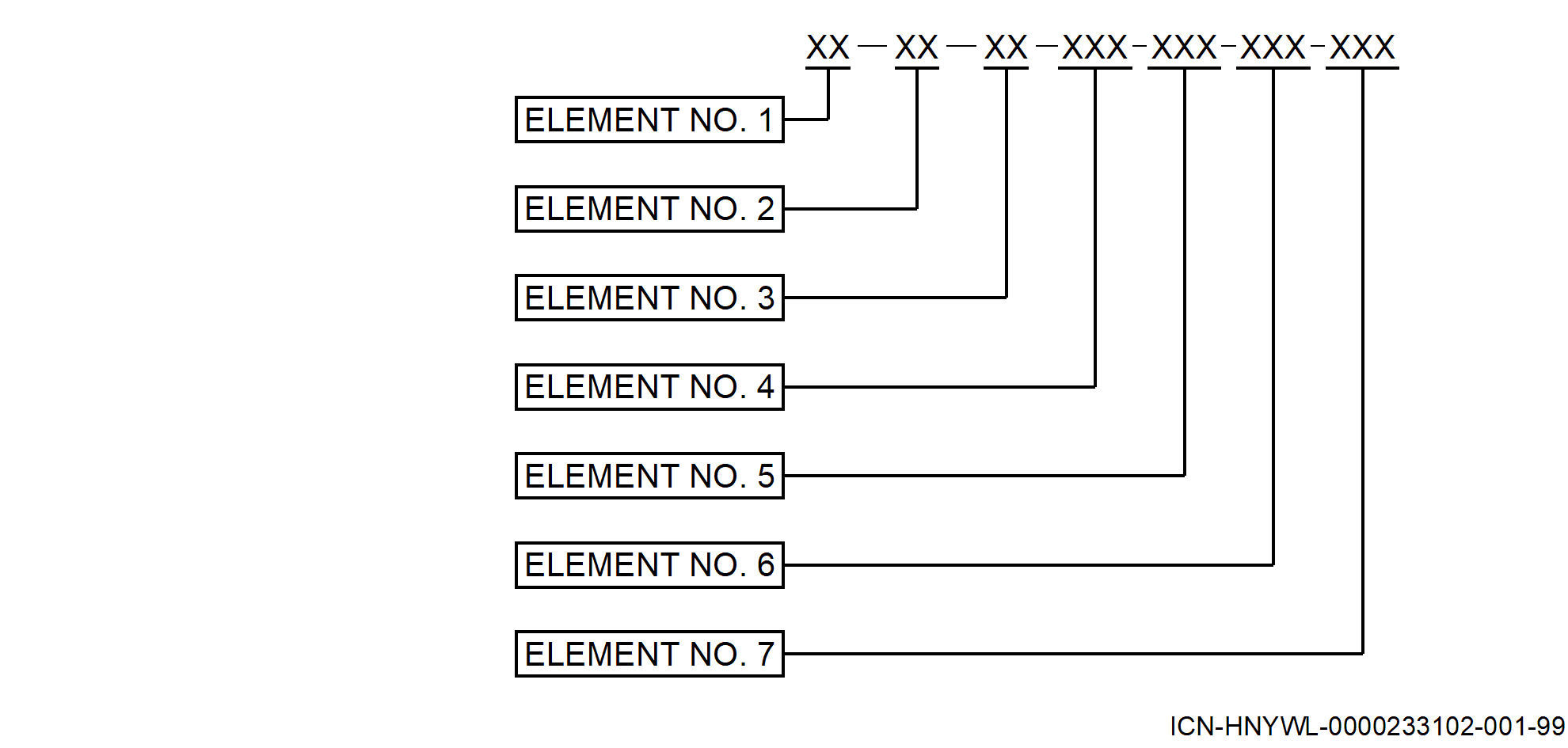

(5) Components of Task and Subtask Number

任务和子任务编号的组成部分

(a) The numbering system is an expansion of the ATA three-element numbering system. The number has seven elements. The first five elements are necessary for each TASK or SUBTASK. The sixth and seventh elements are applied only when necessary. Refer to Figure INTRO-3.

编号系统是 ATA 三元素编号系统的扩展。编号有七个元素。前五个元素是每个任务或子任务所必需的。第六和第七元素仅在必要时使用。参见图 INTRO-3。

(b) Elements 1, 2, and 3 identify the ATA Chapter-Section-Subject number of the pageblock.

元素 1、2 和 3 标明分页块的 ATA 章-节-主题编号。

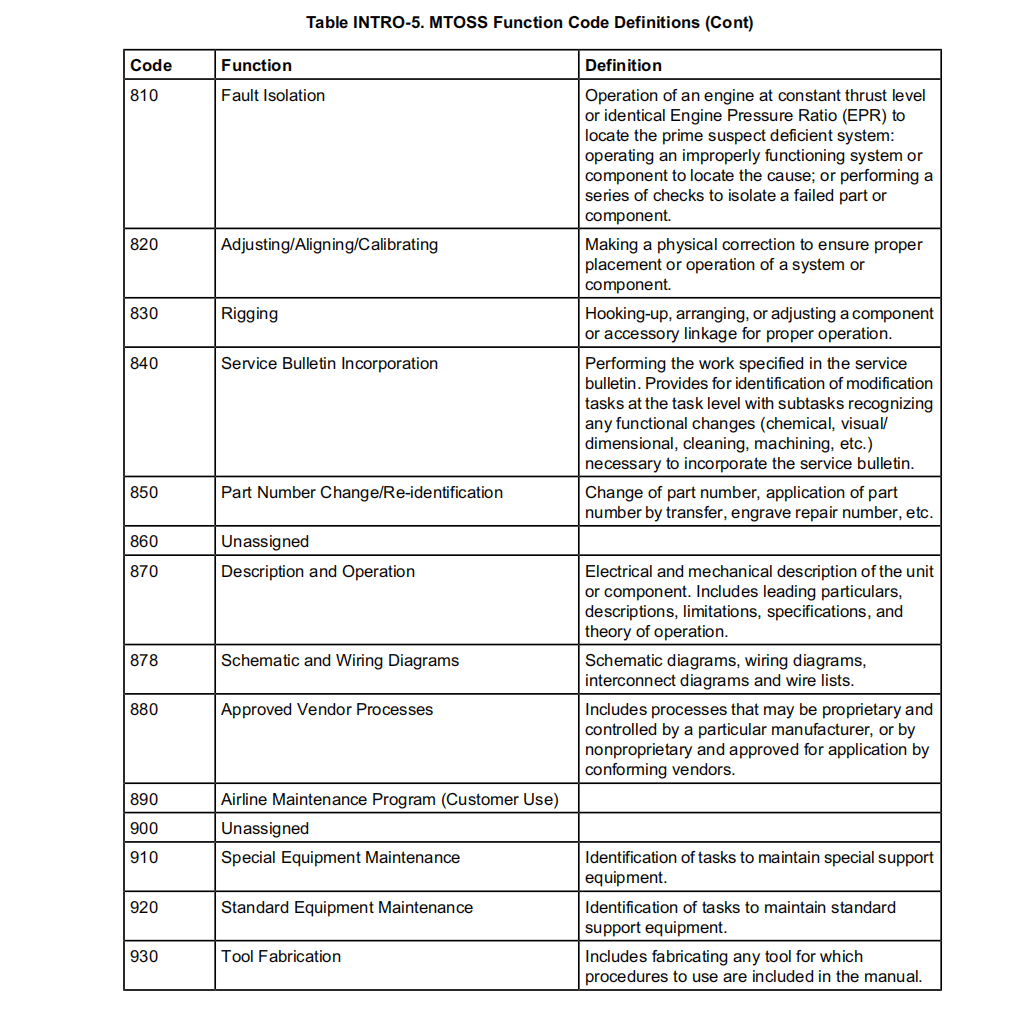

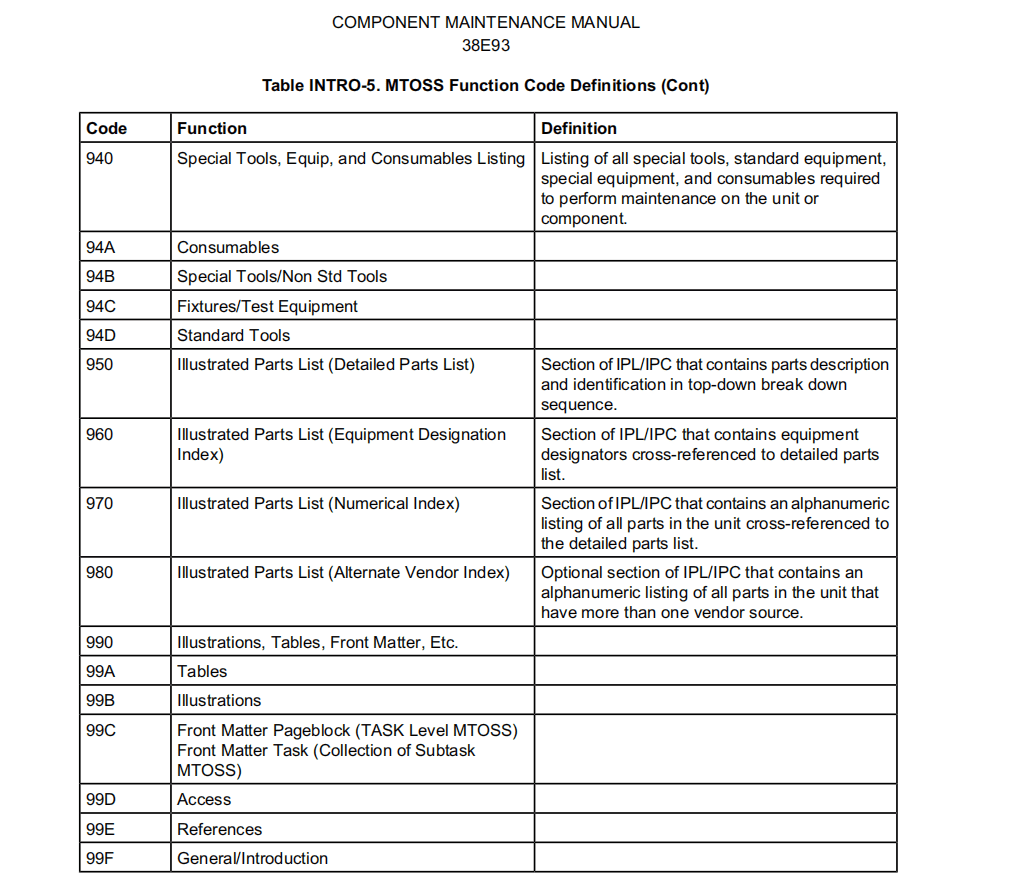

(c) Element 4 defines the maintenance function being performed. This element is a three position element. The third position is zero filled when further definition is not required. If required, the manufacturer will use the numbers 1 thru 9 or letters A thru Z, excluding the letters I and O. Refer to Table INTRO-5.

元素 4 定义正在执行的维护功能。该元素有三个位置。当不需要进一步定义时,第三个位置为零。如果需要,制造商将使用数字 1 至 9 或字母 A 至 Z,但不包括字母 I 和 O。

(d) Element 5 provides a unique identification for each TASK or SUBTASK number which is similarly numbered through the first four elements.

元素 5 为每个 TASK 或 SUBTASK 编号提供唯一标识,其编号与前四个元素类似。

– TASKS are numbered from 801 thru 999

– 任务编号为 801 至 999

– SUBTASKS are numbered from 001 thru 800.

– 子任务编号为 001 至 800。

(e) Element 6 is a three position alphanumeric element used for identification of differences in configurations, methods or techniques, variations of standard practice applications, etc.

元素 6 是一个三位字母数字元素,用于识别构型、方法或技术的不同,以及标准施工应用的变化等。

(f) Element 7 provides coding of those tasks or subtasks that have been changed by the customer (e.g., those tasks or subtasks accomplished by an outside repair source).

元素 7为客户更改的任务或子任务提供编码(例如,由外部修理来源完成的任务或子任务)。

Figure INTRO-3. MTOSS Code Positions

2. Component Maintenance Levels

部件维护级别

A. General

通用

(1) This CMM contains one or more component maintenance levels for repair. The component maintenance levels of repair are shown below as specified in the ARINC Report 663.

本CMM包含一个或多个修理组件保养级别。根据 ARINC 报告 663 的规定,组件修理维护等级如下所示。

(2) Component maintenance level 1 is maintenance operations with an end result of determining LRU serviceability. No maintenance action is performed to repair the LRU.

组件维修级别 1 是以确定 LRU 可维护性为最终结果的维修操作。在修理 LRU 时不执行任何维护操作。

(3) Component maintenance level 1 is limited to RTS testing and configuration confirmation of the LRU, including all software loading as necessary for RTS and the pre-loading of field loadable software.

组件维护级别1仅限于对 LRU 进行 RTS 测试和构型确认,包括 RTS 所需的所有软件加载和现场可加载软件的预加载。

(4) Component maintenance level 2 is maintenance operations with an end result of restoring LRU serviceability. Maintenance procedures are limited to the replacement of subassemblies.

组件维护级别2是以恢复 LRU 可使用性为最终结果的维护操作。维护程序仅限于更换组件。

(5) Component maintenance level 2 embodies those activities necessary to:

组件维护级别2包含以下必要活动:

– Fault isolate to the defective subassembly

– 将故障隔离至有缺陷的子组件

– Replace such subassemblies

– 更换此类子组件

– Return the LRU to service.

– 使 LRU 重新投入使用。

(6) Component maintenance level 2 includes programming, calibrations, alignments, tuning, etc., necessary to return the LRU to service without the replacement of basic parts.

组件维护级别2包括编程、校准、校正、调试等,这些工作是在不更换基本零件的情况下使 LRU 重新投入使用所必需的。

(7) Component maintenance level 3 is maintenance operations with an end result of restoring a LRU or a subassembly to serviceability. Maintenance includes repair of the LRU and or its subassemblies by any and all repair processes, including but not limited to, replacement of defective basic parts such as processor chips, transistors, or chassis mounted parts.

组件维护级别3是以恢复 LRU 或子组件的可用性为最终结果的维护操作。维修包括通过任何及所有修理程序修理 LRU 及其组件,包括但不限于更换有缺陷的基本零件,如处理器芯片、晶体管或底盘安装零件。

(8) Component maintenance level 3 embodies those activities necessary to:

组件维护级别3包括以下必要活动:

– Fault isolate to the basic part level

– 将故障隔离到基本零件级

– Replace/repair such parts

– 更换/修理此类零件

– Return the LRU or subassembly to service.

– 将 LRU 或子组件返修至可用状态。

(9) Component maintenance level 3 includes all programming, calibrations, alignments, tuning, etc., necessary to return the LRU/SRU to service.

部件维护等级3包括将 LRU/SRU 返修至可用状态所需的所有编程、校准、对齐、调整等。

(10) If the service location does level 3 repairs, it must have the equipment identified in Table 9001 or the equivalent alternative(s).

如果维修地点进行级别3的修理,则必须具备表 9001 中确定的设备或同等的替代设备。

3. Acronyms and Abbreviations

缩略语

A. General

通用

(1) The abbreviations are used in agreement with ASME Y14.38.

缩写词的使用与 ASME Y14.38 一致。

(2) Acronyms and non-standard abbreviations used in this publication are as follows:

本出版物中使用的缩略语和非标准缩略语如下:

Table INTRO-7. List of Acronyms and Abbreviations 缩略语清单 |

||

|

AN |

Army – Navy |

陆军 – 海军 |

|

ARINC |

Aeronautical Radio, Inc |

航空无线电公司 |

|

ASME |

American Society of Mechanical Engineers |

美国机械工程师协会 |

|

ATA |

Air Transport Association |

航空运输协会 |

|

CAGE |

Commercial and Government Entity |

商业和政府实体 |

|

CMM |

component maintenance manual |

部件维护手册 |

|

CRES |

Corrosion Resistant Steel |

抗腐蚀钢材(不锈钢) |

|

DPL |

Detailed Parts List |

详细零件清单 |

|

EDI |

Equipment Designator Index |

设备代号索引 |

|

FAA |

Federal Aviation Administration |

美国联邦航空管理局 |

|

GEM |

ground equipment manual |

地面设备手册 |

|

GPO |

Government Publishing Office |

政府出版办公室 |

|

IEC |

International Electrotechnical Commission |

国际电工委员会 |

|

IEEE |

Institute of Electrical and Electronics Engineers |

电气和电子工程师学会 |

|

IPC |

Illustrated Parts Catalog |

图解零件目录(有插图的零件目录) |

|

IPL |

Illustrated Parts List |

图解零件清单(有插图的零件清单) |

|

LRU |

Line Replaceable Unit |

航线可更换部件 |

|

MS |

Miltary Standard |

军用标准 |

|

MTOSS |

Maintenance Task Oriented Support System |

维护任务导向支持系统 |

|

NAS |

National Aerospace Standards |

国家航空航天标准 |

|

NHA |

Next Higher Assembly |

更高级组件 |

|

Nm |

Newton Meter |

牛米 |

|

No. |

number |

数,编号 |

|

PN |

part number |

件号 |

|

RTS |

Return to Service |

返回至可用状态 |

|

SB |

service bulletin |

服务通告 |

|

SI |

International System of Units |

国际单位制 |

|

SPM |

Standard Practices Manual |

标准施工手册 |

|

SRU |

shop replaceable unit |

车间可更换零件 |

|

TR |

temporary revision |

临时修订 |

|

USMS |

United States Measurement System |

美国测量系统 |

|

VAC |

volts alternating current |

交流电压 |

|

in. |

Inches |

英寸 |

|

lb |

Pound |

磅 |