发动机防冰活门65E63

一、名称

ANTI-ICING VALVE ASSEMBLY

防冰活门组件

二、件号

65E63-2

三、章节号

30-21-11

四、适用机型

A330

五、系统

30 ICE AND RAIN PROTECTION

防冰防雨

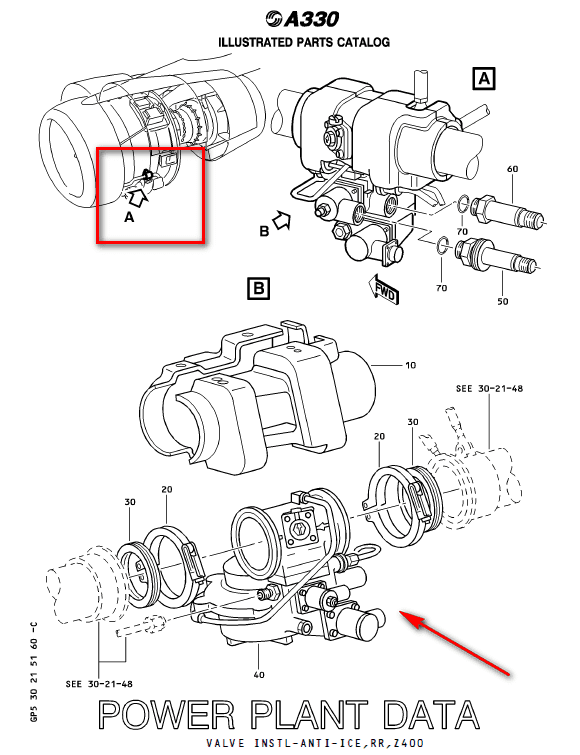

六、安装位置

发动机

七、部件原理

Operation

工作

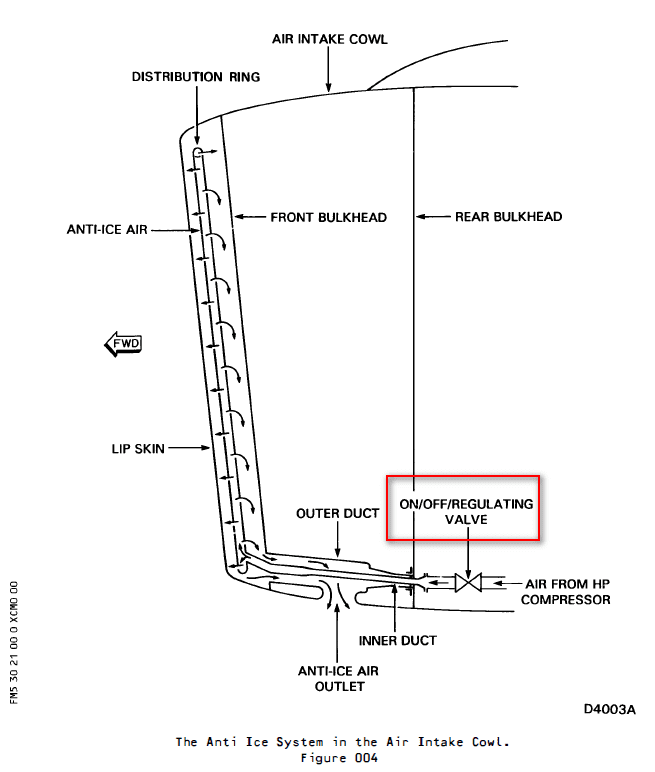

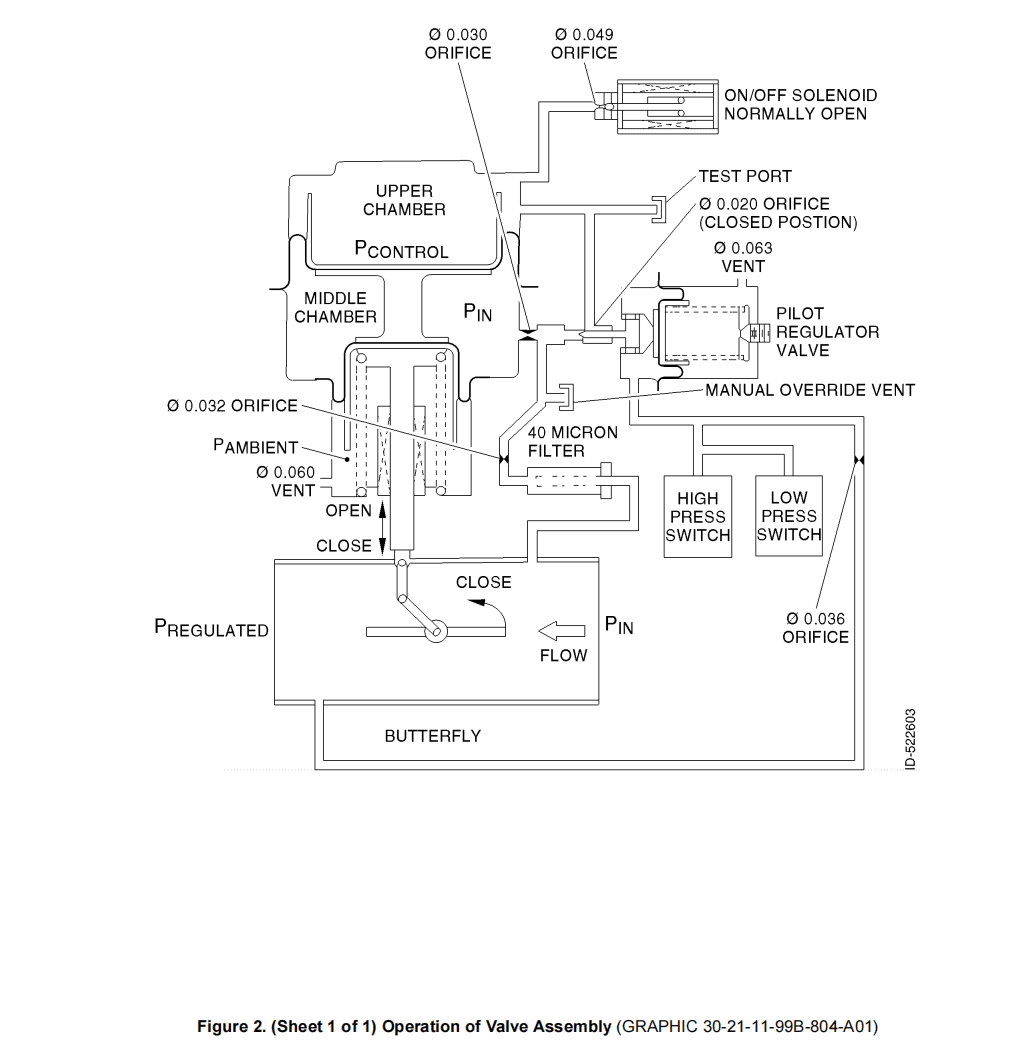

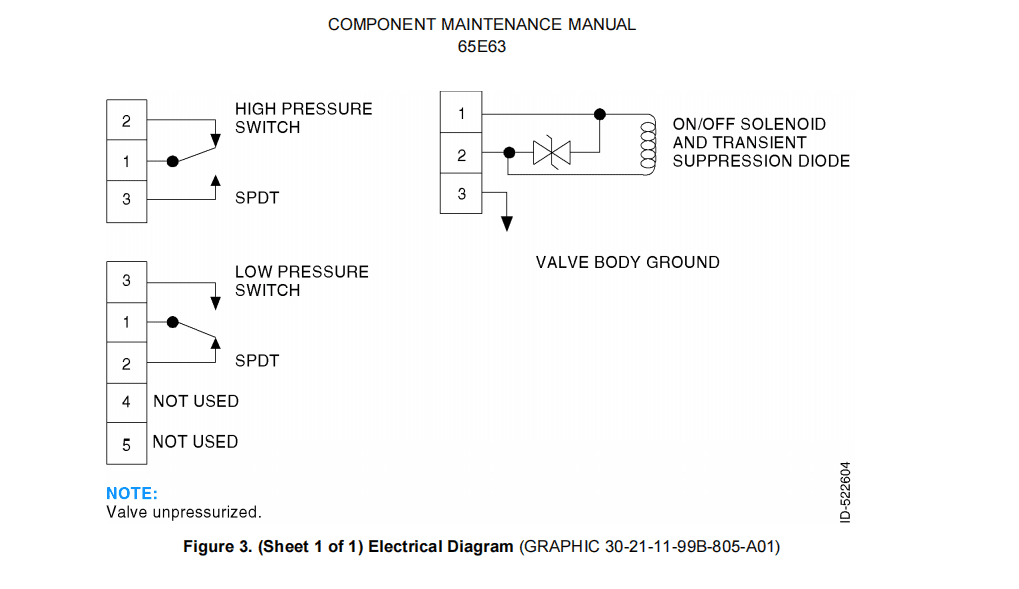

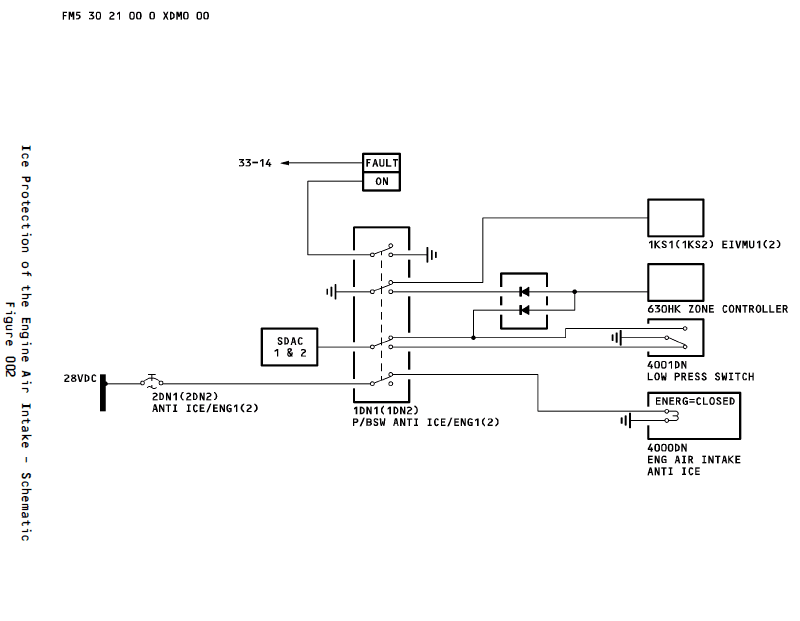

(1) Refer to Figure 2 and Figure 3.

参阅图2和图3。

(2) The valve assembly has a butterfly valve which is usually open. When the solenoid has no electrical power, air pressure in the middle actuator chamber is almost equal to the inlet pressure. The pilot regulator valve diaphragm feels downstream pressure and adjusts the inlet pressure to the upper (control) chamber. This pressure goes through the solenoid valve orifice to the outside air. This adjusted pressure controls the position of the actuator and the butterfly. When the downstream pressure changes, the pilot regulator valve increases or decreases the control pressure which changes the butterfly position. This keeps the correct adjusted (downstream) pressure in the duct.

活门组件有一个蝶板,通常处于打开状态。 当电磁阀无电时,中间作动器腔的气压几乎等于入口压力。 先导调节阀膜片会感受到下游压力,并调节上部(控制)腔的入口压力。 该压力通过电磁阀限流孔连通外部空气。 调整后的压力可控制作动器和蝶板的位置。 当下游压力发生变化时,先导调节阀会增大或减小控制压力,从而改变蝶板的位置。 这样就能在管道中保持正确的调节(下游)压力。

(3) When the solenoid valve is energized and the inlet pressure is more than 9.5 PSIG (65.5 kPa), the air pressure in the middle and control actuator chambers will be equal. The actuator will then hold the butterfly closed.

当电磁阀通电且入口压力超过 9.5 PSIG (65.5 kPa) 时,中间腔和控制作动器腔的气压将相等。 作动器将保持蝶板关闭。

(4) Indication of the valve assembly operation is given by two downstream pressure switches. With no downstream pressure, the two switches are off. The low pressure switch is on (the valve is open) for pressures more than 6 PSIG (41.4 kPa). The high pressure switch is on at 87 PSIG (599.8 kPa). This shows that the adjusted pressure is too high. Both switches are used for failure detection and maintenance warnings.

活门组件运行的指示由两个下游压力开关给出。 无下游压力时,两个开关断开。 压力超过 6 PSIG (41.4 kPa) 时,低压开关接通(活门打开)(即开关作动)。 高压开关在87 PSIG (599.8 kPa) 时接通(即开关作动)。 这表明调整后的压力过高。 这两个开关都用于故障检测和维护警告。

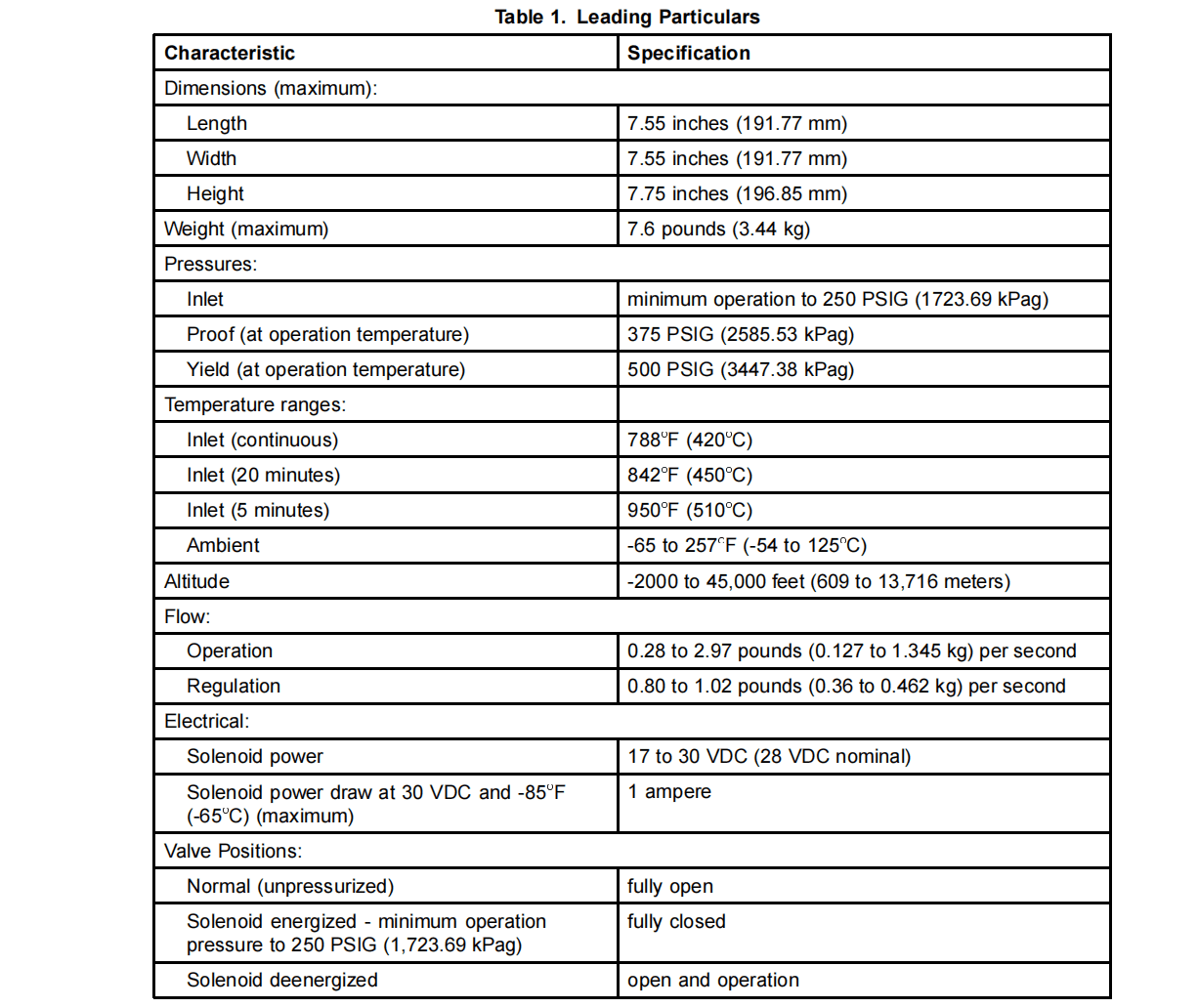

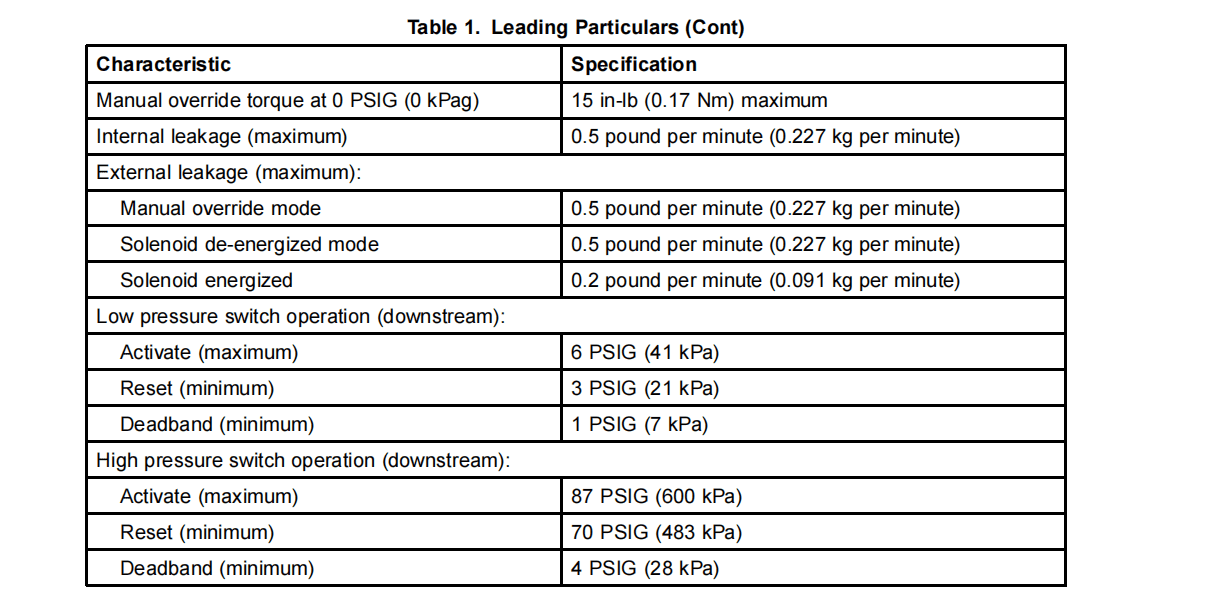

八、工作参数

九、在飞机系统中的工作原理及互联

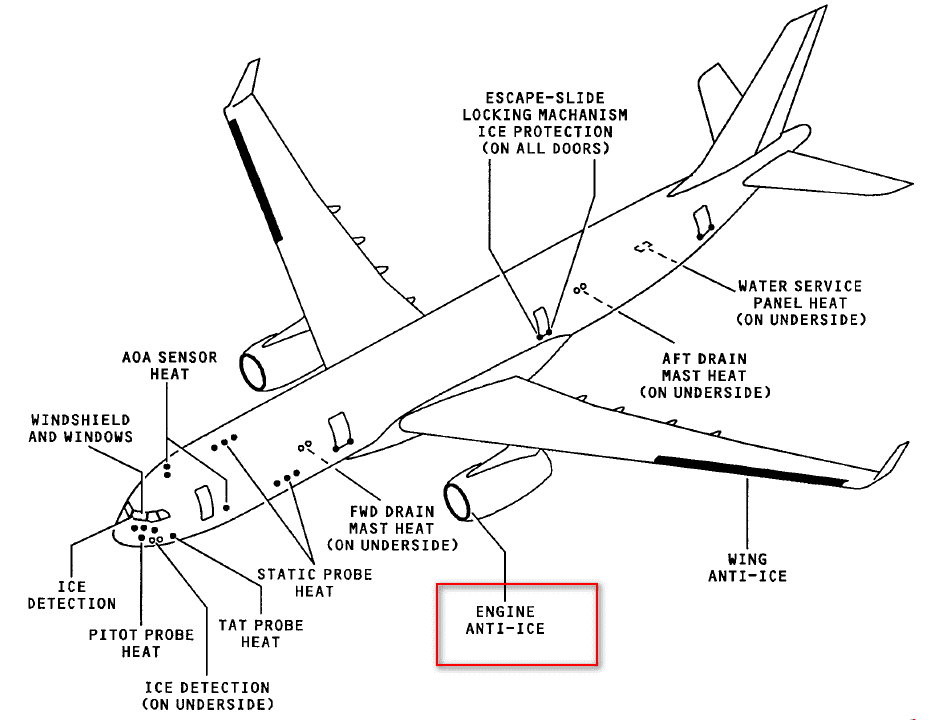

The ice and rain protection system lets the aircraft operate, without restrictions, in conditions of ice or heavy rain.

The areas heated with hot air are:

– the leading edge slats 4, 5, 6 and 7 on each wing

– the engine air intakes.

防冰防雨系统可使飞机在结冰或大雨的条件下不受任何限制地运行。

用热空气加热的区域有

– 每个机翼上的前缘缝翼 4、5、6 和 7

– 发动机进气口。

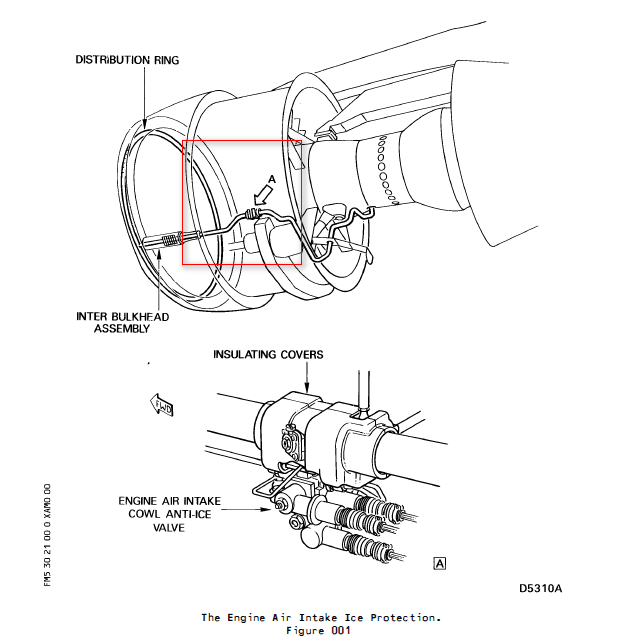

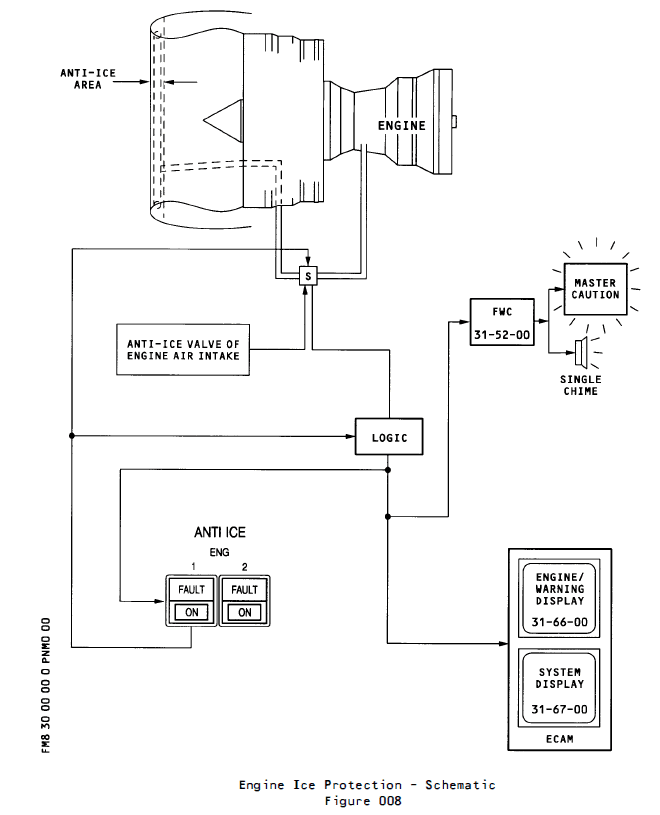

Engine Air Intake Ice Protection (Ref. 30-21-00)(Ref. Fig. 008)

发动机进气防冰

Each engine has an air-intake ice protection system that operates independently of the aircraft pneumatic system. Hot air bled from the engine HP compressor is used to heat the air-intake lip.

每台发动机都有一个独立于飞机气动系统运行的进气防冰系统。发动机 HP 压缩机的热引气用于加热进气口唇口。

An anti-ice valve controls the supply of engine bleed air to the air-intakes. If a failure of the electrical power supply to the system occurs (with the engines in operation) the anti-ice valves stay open. A related P/BSW controls each anti-ice valve.

防冰活门控制发动机引气向进气口的供应。如果系统的电力供应发生故障(发动机仍在运行),防冰活门将保持打开状态。一个相关的 P/BSW 控制着每个防冰活门。

A restrictor is installed downstream of each anti-ice valve to:

– adjust the flow of air from the engine

– control the flow of air if a failure of a distribution duct occurs.

每个防冰活门的下游都安装有一个限流器,用于:

– 调节来自发动机的空气流量

– 在分配管发生故障时控制空气流量。

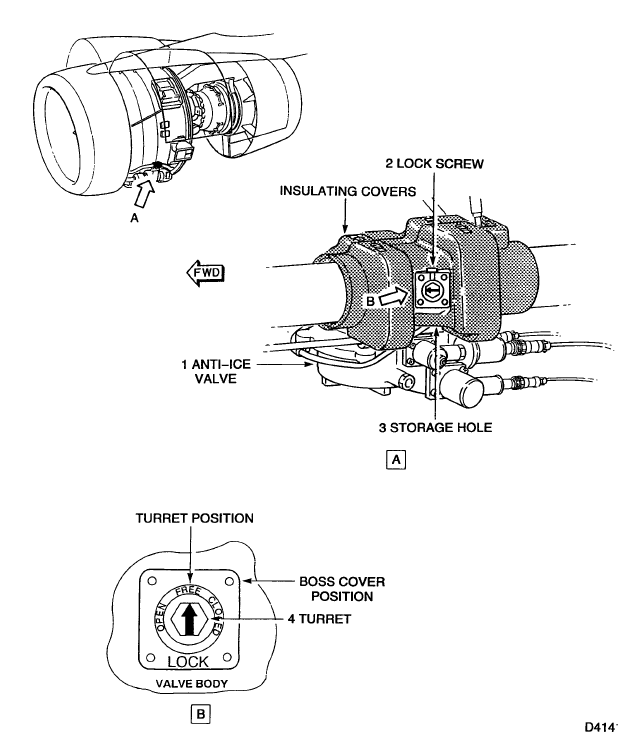

If failure of the anti-ice valve occurs on the ground before take off, the valve butterfly can be manually locked in the open or the closed position. This permits the aircraft to fly.

如果防冰活门在起飞前在地面发生故障,可手动将蝶板(活门)锁定在打开或关闭位置。这样飞机就可以飞行。

If a failure of the engine ice-protection system occurs, the ECAM system gives an audible and visual warning.

如果发动机防冰系统发生故障,ECAM 系统会发出声光警告。

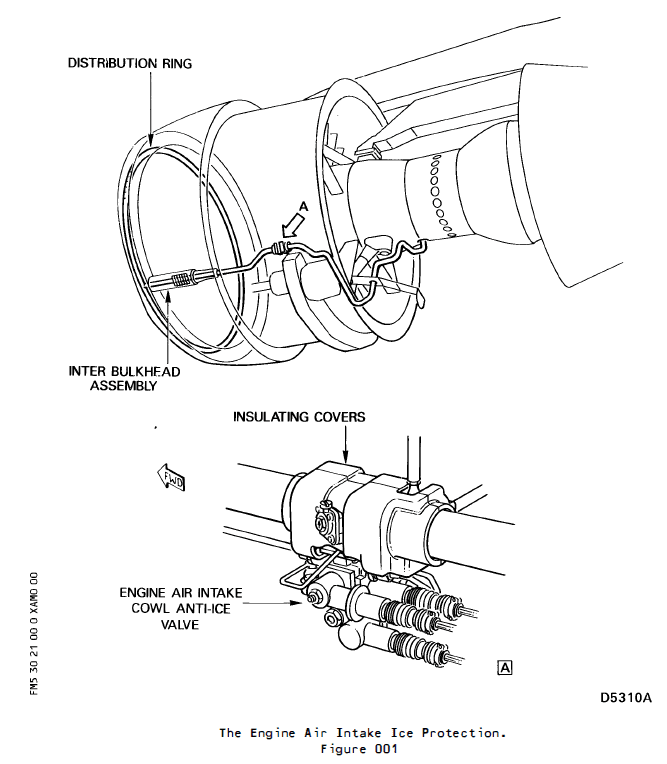

System Description

系统描述

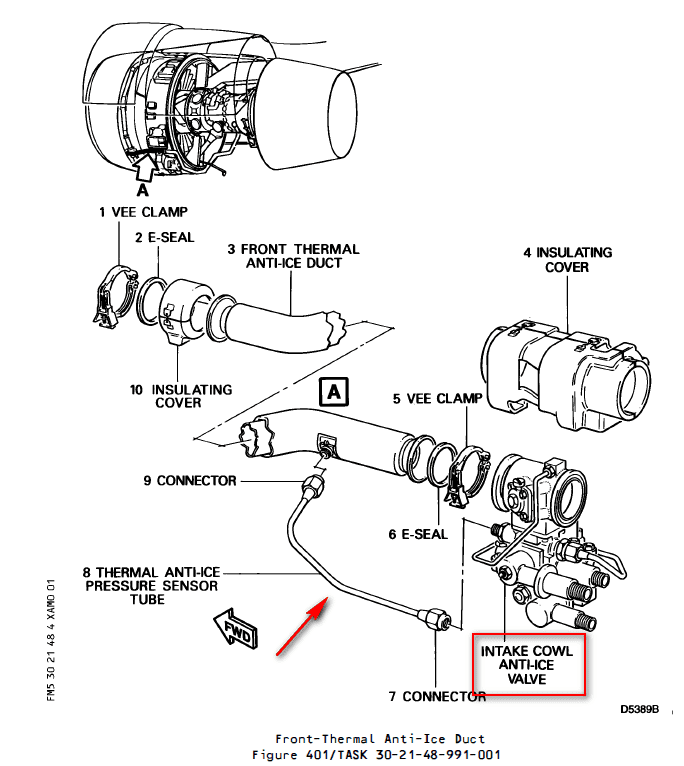

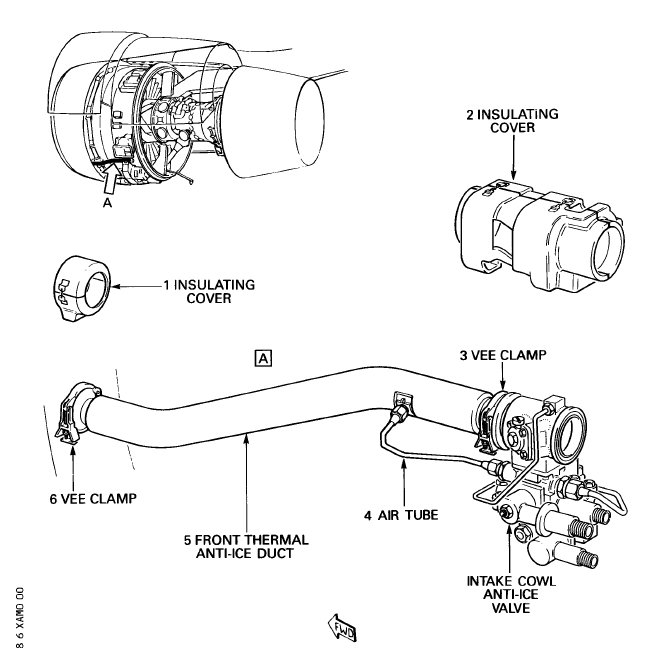

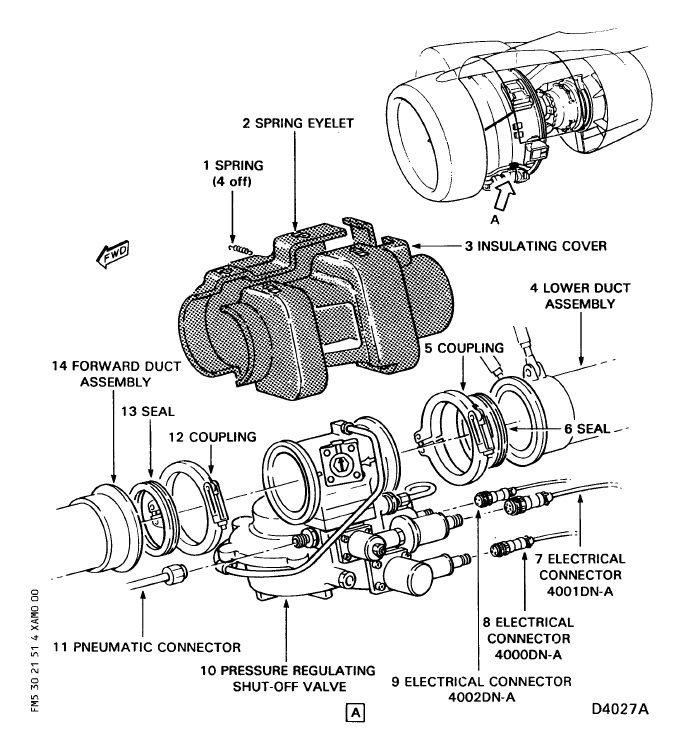

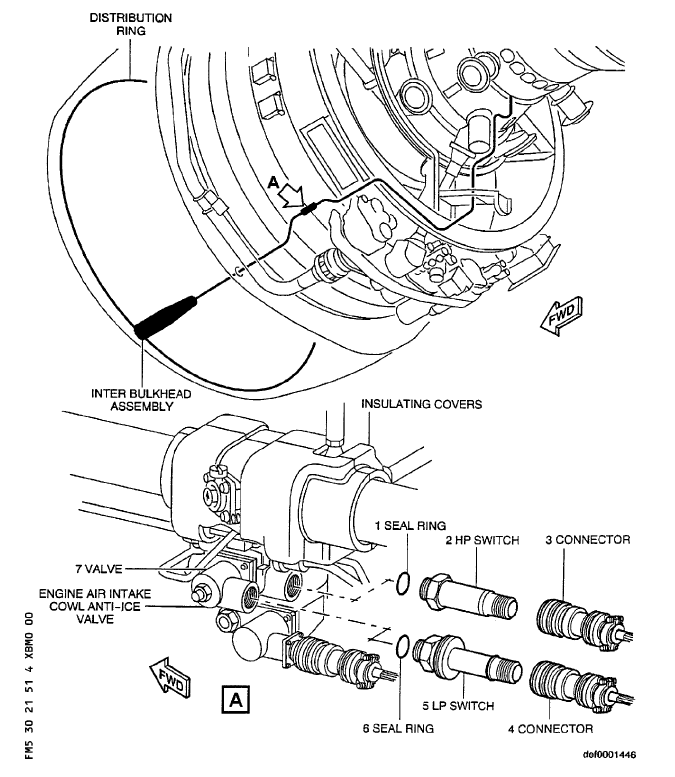

Between the core engine and the distribution ring the system has two venturis and an engine air intake cowl anti-ice valve (4000DN). Bolts attach one of the ducts to the core engine. Clamps hold the ducts together. Clamps also keep the ducts in position at the rear bulkhead of the intake cowl. A seal is installed in the joints between the ducts. There are two bleed points that are downstream of the engine air intake cowl anti-ice valve (4000DN). One bleed point goes to a high pressure switch (4069KS) on the valve. The other bleed point goes to a low pressure switch (4001DN) on the valve. In the intake cowl the system has a distribution ring and an inter-bulkhead assembly. The distribution ring is installed between the front bulkhead and the lip skin. It cannot be removed. The inter-bulkhead assembly is in two parts, the inner duct and the outer duct. Each part can be removed. Seals prevent air leakage around the ends of the two ducts.

在核心发动机和分配环之间,系统有两个通风管和一个发动机进气罩防冰活门(4000DN)。 螺栓将其中一个管道连接到核心发动机上。 夹子将管道固定在一起。 夹子还能将管道固定在进气罩后隔板上。 管道之间的接缝处安装有密封件。 发动机进气罩防冰活门 (4000DN) 下游有两个引气点。 一个引气点通向活门上的高压开关 (4069KS)。 另一个引气点通向活门上的低压开关 (4001DN)。 在进气罩内,系统有一个分配环和一个舱盖间组件。 分配环安装在前隔板和唇皮之间。 它不能拆卸。 舱盖间组件分为两部分,即内导管和外导管。 每个部分都可以拆卸。 密封件可防止两个导管末端的空气泄漏。

Interface

接口

The system has interfaces with the core engine, the aircraft electrical system and the aircraft instrument system. The low pressure switch (4001DN) gives an indication to the aircraft instrument system when; the valve has opened and there is pressure in the duct downstream of the valve. This signal is stopped when the valve is closed and the duct pressure downstream of the valve decreases.

该系统具有与核心发动机、飞机电气系统和飞机仪表系统的接口。 低压开关(4001DN)会在活门打开且活门下游管道内有压力时向飞机仪表系统发出指示。 当活门关闭,活门下游管道压力降低时,该信号停止。

The high pressure switch (4069KS) gives a signal to the aircraft instrument system when these conditions occur; there is too much pressure downstream of the valve and, if the control function of the valve does not operate correctly. The interface with the core engine gives the system continuity of airflow between the areas that follow; the HP compressor off-take and the lip skin. The engine air intake cowl anti-ice valve (4000DN) has interfaces with the aircraft electrical system and the aircraft instrument system.

当出现以下情况时,高压开关(4069KS)会向飞机仪表系统发出信号:活门下游压力过高,以及活门的控制功能无法正常工作。 与核心发动机的接口可使系统在随后的区域(HP 压缩机输出口和唇皮)之间保持气流的连续性。 发动机进气整流罩防冰活门 (4000DN) 与飞机电气系统和飞机仪表系统有接口。

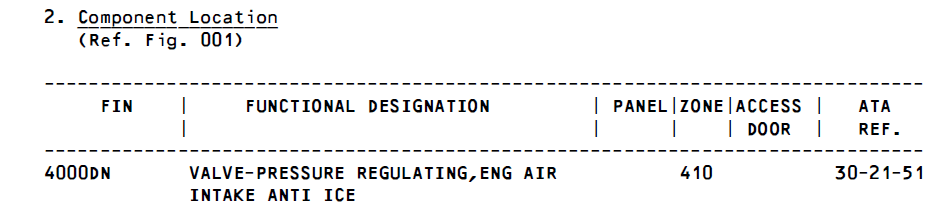

The Engine Air Intake Cowl Anti-Ice Valve (4000DN):

发动机进气口内罩防冰活门(4000DN):

The primary components of the engine air intake cowl anti-ice valve (4000DN) are:

发动机进气罩防冰活门(4000DN)的主要部件为:

– the valve body

活门壳体

– the butterfly shut-off valve

-蝶板关断阀

– the pneumatic actuator/regulator

-气动作动器/调节器

– the electrical solenoid

-电磁阀

– the HP and LP pressure switches (4069KS and 4001DN).

-高压和低压压力开关(4069KS和4001DN)。

All the components are attached to, or installed in, the valve body. A _direction of flow_ arrow on the valve body shows the correct position to install and align the valve. The spindle of the butterfly shut-off valve has a hexagon end for manual operation of the valve. The valve locking pin can be installed through the pointer handle and into a flange on the valve body. This will stop the movement of the butterfly valve.

所有组件都连接到或安装在活门壳体中。活门壳体上的气流方向箭头表示安装和对齐活门的正确位置。蝶板关断阀的主轴有一个六角端,用于手动操作活门。活门锁定销可以通过指针手柄安装到活门壳体上的一个法兰中。这将停止蝶板的运动。

The valve body has a machined flange at each end to connect the anti-icing ducts. The butterfly shut-off valve is a precision fit in the valve body. The shut-off valve can seal the airflow through the engine air intake cowl anti-ice valve (4000DN). The pneumatic actuator is attached to the valve body. It is mechanically connected to the butterfly shut-off valve and the position switch.

活门壳体两端有一个加工的法兰,以连接防冰管道。蝶板关断阀是在活门壳体中精确配合。关断阀可以通过发动机的气流进气罩防冰活门(4000DN)密封气流。气动作动器连接在活门壳体上。它是机械连接到蝶板关断阀和位置开关。

Operation/Control and Indicating

操作/控制和指示

Air from the 3rd stage of the HP compressor flows to the engine air intake cowl anti-ice valve (4000DN) through the anti-ice ducts. The first venturi assembly (which is under the left fan cowl) limits the quantity of airflow through the ducts. This makes sure that the engine keeps the necessary performance if the system gets a leak downstream of the first venturi. The first venturi does not affect the satisfactory operation of the system.

来自 HP 压缩机第三级的空气通过防冰管道流入发动机进气罩防冰活门 (4000DN)。 第一个文丘里管组件(位于左侧风扇罩下方)限制了通过管道的气流。这样可以确保在系统在第一个文丘里管下游发生泄漏时,发动机仍能保持必要的性能。 第一文丘里管不会影响系统的正常运行。

The engine air intake cowl anti-ice valve (4000DN) uses the upstream air pressure for its pneumatic operation. The electrical solenoid controls the flow of the upstream air into the pneumatic actuator. When the system is pressurized and the electrical power is removed from the electrical solenoid, the valve controls the pressure to 62 PSIg (427KPa). If the system stays pressurized, and the electrical solenoid is energized, the valve will close. With no upstream air pressure the valve stays open if the electrical solenoid is energized or has its electrical power removed.

发动机进气罩防冰活门 (4000DN) 使用上游气压进行气动操作。 电磁阀控制上游气流进入气动作动器。当系统加压且电磁阀断电时,活门将压力控制在 62 PSIg (427KPa)。 如果系统保持加压状态,且电磁阀通电,活门将关闭。 在没有上游气压的情况下,如果电磁阀通电或断电,活门将保持打开状态。

The air from the engine air intake cowl anti-ice valve (4000DN) flows through the anti-ice ducts to the inter-bulkhead assembly. The inner duct of the inter-bulkhead assembly connects the distribution ring to the anti-ice ducts.

来自发动机进气整流罩防冰活门 (4000DN) 的空气通过防冰管道流向舱盖间组件。 舱盖间组件的内部管道将分配环与防冰管道连接起来。

The air in the distribution ring flows out through small supply holes and into the space between the lip skin and the front bulkhead. The hot air increases the temperature of the lip skin and gives ice protection to the air intake.

分配环中的空气通过小供气孔流出,进入唇形蒙皮和前隔板之间的空间。 热空气可提高唇缘表皮的温度,并为进气口提供冰保护。

Used anti-ice air flows to the anti-ice outlet-grille through the outer duct of the inter-bulkhead assembly (Ref. Fig. 003). The seals on the connections of the inter-bulkhead assembly prevent the flow of anti-ice air to other areas of the air intake.

使用过的防冰空气通过舱盖间组件的外导管流向防冰出口格栅(参考图 003)。 舱盖间组件连接处的密封件可防止防冰空气流入进气口的其他区域。

With no upstream air pressure, the engine air intake cowl anti-ice valve (4000DN) can be manually operated with an applicable hand wrench. If the valve is put in the fully open position, the locking pin can be installed in the lock hole. The locking pin can also be installed in the lock hole when the valve is in the fully closed position. With the locking pin in the lock hole the pneumatic actuator (and thus the valve) is locked in position.

在没有上游气压的情况下,可使用适用的手动扳手手动操作发动机进气罩防冰活门 (4000DN)。 如果活门处于全开位置,可将锁销安装到锁孔中。 当活门处于完全关闭位置时,锁销也可安装在锁孔中。 锁销插入锁孔后,气动作动器(以及活门)将被锁定。