保护层的剥离

STRIPPING OF PROTECTIVE FINISHES

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5725 and BAC5771 for stripping organic and inorganic finishes. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5725 和 BAC5771,用于有机和无机面漆的剥离。可查阅波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并非针对所有情况或特定安装。请将此数据作为指南,帮助您制定最低标准。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

注: 可使用等效替代品。

A. Strippers for Organic Finishes

有机面漆剥离剂

(1) Immersion Strippers with Water Seal

水封浸入式剥离器

(a) Cee Bee A-215 (concentrate solution), V71361

(b) Turco 5351-Thin, V61102

(2) Immersion Stripper with Oil Seal: Turco 6776-Thin (with Turco 5668 No. 1 additive), V61102

带油封的浸入式剥离器:Turco 6776-Thin (with Turco 5668 No. 1 additive), V61102

(3) Immersion Strippers, Alkali

碱浸入式剥离器

(a) Isoprep 177, V6Z384

(b) Turco 4338, V61102

(4) Immersion Strippers, Acid

酸性浸入式剥离器

(a) Cee Bee A-805, V71361

(b) Fosrinse C.P., V86460

(5) Spray or Brush-On Strippers

喷雾式或刷涂式剥离剂

(a) Ardrox 2871, V44389

(b) Cee Bee A-202, V71361

(c) Cee Bee A-228D, V71361

(d) Cee Bee A-306B, V71361

(e) Cee Bee R-256A, V71363

(f) DeKote, V1PYM1

(g) ES-1 Stripper, V26348

(h) Plane Naked 5765, V1PYM1

(i) PR-5044, V55208

(j) RemovAll 1012, Freeworld Coatings, Australia

(k) Socostrip A-0103N, Magchem, Inc., Quebec, Canada

(l) Turco EA 6930, V61102

(m) Turco 5351-Thick, V61102

(n) Turco 5469, V61102

(o) Turco 5873, V61102

(p) Turco 6776 LO, V61102

(q) Turco 6840S, V61102

(6) Abrasive Stripper Blasting Media

磨料剥离器喷砂介质

(a) Soft abrasive grain media: A-A-1722, Types I or II

(b) Plastic abrasive media: MIL-P-85891, Type V, Grade A, acrylic blasting media, 20/30 mesh, specific gravity 1.10-1.20

(c) Wheat starch: Envirostrip, 12/30 mesh or finer, 99.98% minimum purity, V35367

(d) Magic 1 Nanocomposite abrasive media, 30/60 mesh, U.S. Technologies

(e) Magic 2 Nanocomposite abrasive media, 30/60 mesh, U.S. Technologies

(f) Magic 3 Nanocomposite abrasive media, 10/60 mesh, U.S. Technologies

(7) Miscellaneous materials

杂项材料

(a) Abrasive pads, nonmetallic

(b) Abrasive paper, aluminum oxide, 150 and 240 grit or finer

(c) Aluminum Metal Polish: A-A-59318

(d) Chromium trioxide (chromic acid), Technical: O-C-303

(e) Nitric acid, Technical: O-N-350 or 40-42° Baumé

(f) Paint brushes, natural fiber

(g) Phosphoric acid, Technical : O-O-670

(h) Potassium hydroxide, Technical: O-P-566

(i) Potassium permaganate, Technical: MIL-P-11970

(j) Scotch-Brite pads, Type A, V76381

(k) Scrapers, wood or plastic

(l) Scrub brushes, fiber-bristle long handled

(m) Squirt bottles, polyethylene

(n) Wipers: BMS 15-5 Class B (Class A optional)

B. Strippers for Inorganic Finishes: Refer to Paragraph 4.

无机饰面的剥离剂: 参见第 4 段。

3. ORGANIC FINISHES 有机面漆

WARNING :MANY OF THE STRIPPING SOLUTIONS ARE FLAMMABLE, POISONOUS OR CAN CAUSE CORROSION. DO NOT BREATHE SOLVENT AND STRIPPING SOLUTION VAPORS. THESE MATERIALS MUST NOT BE USED IN CONFINED SPACES WITHOUT SUFFICIENT VENTILATION. EXHAUST VENTILATION MUST BE SUPPLIED OVER OPEN SOLUTION TANKS. KEEP STRIPPING SOLUTIONS AWAY FROM SKIN. WEAR CHEMICAL-RESISTANT GLOVES. IF STRIPPING CHEMICALS COULD SPLASH, WEAR GOGGLES OR PROTECTIVE FACE SHIELD AND CHEMICAL-RESISTANT CLOTHING. IMMEDIATELY WASH OFF SOLUTION THAT GETS ON YOUR SKIN. FLUSH OUT WITH WATER ANY SOLUTION THAT IS SPLASHED INTO YOUR EYES, AND GET MEDICAL AID.

警告 :许多剥离溶液易燃、有毒或可导致腐蚀。切勿吸入溶剂和剥离液蒸汽。在没有充分通风的密闭空间内不得使用这些材料。必须在敞开的溶液罐上进行排气通风。让剥离溶液远离皮肤。戴上防化学腐蚀手套。如果剥离化学品可能飞溅,请戴上护目镜或防护面罩,并穿上防化服。立即清洗沾到皮肤上的溶液。用水冲洗溅入眼内的溶液,并寻求医疗救助。

CAUTION :DO NOT LET CHEMICAL STRIPPERS GET ON SEALS, SEALANT, OR FILLET SEALS, OR FLOW INTO FAYING SURFACES OF BONDED OR SEALED JOINTS.

注意 :不要让化学剥离剂沾到密封件、密封胶或圆角密封件上,也不要让其流入已粘合或密封接缝的接合面。

A. Organic finishes include paints, enamels, varnishes, lacquers and some elastomeric and polymerized resin finishes.

有机饰面包括涂料、瓷漆、清漆、油漆和某些弹性体及聚合树脂饰面。

B. Stripping Methods

剥离方法

(1) Immersion stripping is preferred for detail parts. Do not use on assemblies. A stripping solution with a water seal (aqueous seal) contains two layers. Stripping takes place in the lower (inner) layer, and the upper (outer) layer prevents escape of active stripper material.

细节零件宜采用浸泡剥离法。不得用于组件。带水密封(水密封)的剥离液包含两层。剥离在下层(内层)进行,而上层(外层)可防止活性剥离材料溢出。

(2) Spray or brush-on stripping can be used on unsealed assemblies and detail parts too large to fit in an immersion tank, and for areas not loosened during immersion stripping. These strippers contain thickening agents that slow down evaporation. These strippers can be applied to vertical or horizontal surfaces.

喷涂或刷涂剥离剂可用于未密封的组件和细节零件,这些零件太大,无法放入浸泡槽,也可用于浸泡剥离过程中未松动的区域。这些剥离剂含有增稠剂,可减缓蒸发。这些剥离剂可用于垂直或水平表面。

(3) Chemical wipe or squirt-on stripping is used to remove wax-type materials that can be dissolved in solvent and then wiped off. Examples are crayon marks, temporary coatings and overspray.

化学擦拭或喷涂剥离用于去除可溶解在溶剂中然后擦掉的蜡型材料。例如蜡笔痕迹、临时涂层和过喷。

(4) Dry abrasive stripping

干磨剥离

(a) Conventional abrasive blasting or dry sanding can be used for ferrous alloys, titanium, nickel, and magnesium. Use soft abrasive grains on metal surfaces. Use dry sanding on composite surfaces.

对于铁合金、钛、镍和镁,可使用传统的喷砂或干磨。在金属表面使用软磨粒。在复合材料表面使用干砂。

(b) Plastic media blasting can be usead (bare) aluminum 0.125 inch or thicker, ferrous alloys, titanium, parts plated with cadmium-titanium, cadmium, nickel, zinc-nickel, chrome, and copper, and chemically treated or anodized magnesium. Do not strip to bare magnesium. Plastic media blasting damages plating and surface treatments such as chemical conversion and anodized coatings. All plating (other than chrome plate) and surface treatments must be removed by the procedures for inorganic find on non-clishes specified in Paragraph 塑料介质喷丸可用于 0.125 英寸或更厚的无包层(裸)铝、铁合金、钛、镀有镉钛、镉、镍、锌镍、铬和铜的零件,以及经过化学处理或阳极氧化处理的镁。切勿将镁剥至裸露。塑料介质喷丸会损坏电镀和表面处理,如化学转化和阳极氧化涂层。所有镀层(铬板除外)和表面处理必须按照第 4 段规定的无机表面处理程序进行清除。

(c) Wheat starch blasting can be used for clad and non-clad aluminum 0.032 inch or thicker, bonded aluminum honeycomb sandwich parts with face sheets 0.012 inch or thicker, all other metals, including plated surfaces, and composites such as Kevlar, graphite and fiberglass. Complete removal of organic materials by wheat starch media damages surface treatments on the base metal such as chemical conversion and anodized coatings, and can remove plating. After removal of the organic finishes, remove the remaining surface treatments by the procedure for inorganic finishes specified in Paragraph 4.

小麦淀粉喷砂可用于 0.032 英寸或更厚的包层铝和非包层铝、面片厚度为 0.012 英寸或更厚的粘合铝蜂窝夹层零件、所有其他金属(包括电镀表面)以及Kevlar、石墨和玻璃纤维等复合材料。用小麦淀粉介质完全去除有机物会破坏基体金属的表面处理,如化学转化和阳极氧化涂层,并可能去除电镀层。去除有机饰面后,按第 4 段规定的无机饰面程序去除剩余的表面处理。

(d) Nanocomposite blasting can be used for aluminum 0.040 inch or thicker, and bonded aluminum honeycomb sandwich parts with aluminum face sheets 0.012 inch or thicker, ferrous alloys, titanium alloys, parts plated with cadmium-titanium, cadmium, nickel, zinc-nickel, chrome and copper, and chemically treated or anodized magnesium. There are three Magic types of nanocomposite abrasive media. Magic 1 is for general-purpose stripping. Magic 2 gives a faster removal rate. Magic 3 is used to remove cured sealant.

纳米复合喷砂可用于 0.040 英寸或更厚的铝,以及铝面片厚度为 0.012 英寸或更厚的粘合铝蜂窝夹层零件、铁合金、钛合金、镀有镉-钛、镉、镍、锌-镍、铬和铜的零件,以及经化学处理或阳极氧化处理的镁。纳米复合研磨介质有三种 Magic 类型。Magic 1 适用于通用剥离。Magic 2 的剥离速度更快。Magic 3 用于清除固化密封胶。

C. General

通用

(1) Do not do the stripping operation in rain or hot sun.

切勿在雨天或烈日下进行剥离操作。

(2) Do not mix strippers of different vendors although the products are in the same group.

不要混合使用不同供应商的剥离剂,尽管这些产品属于同一类。

(3) When you immersion strip titanium parts, be sure to use only hardware and process fixtures that are made of titanium or titanium alloy.

在对钛零件进行浸泡剥离时,确保只使用钛或钛合金制成的硬件和加工夹具。

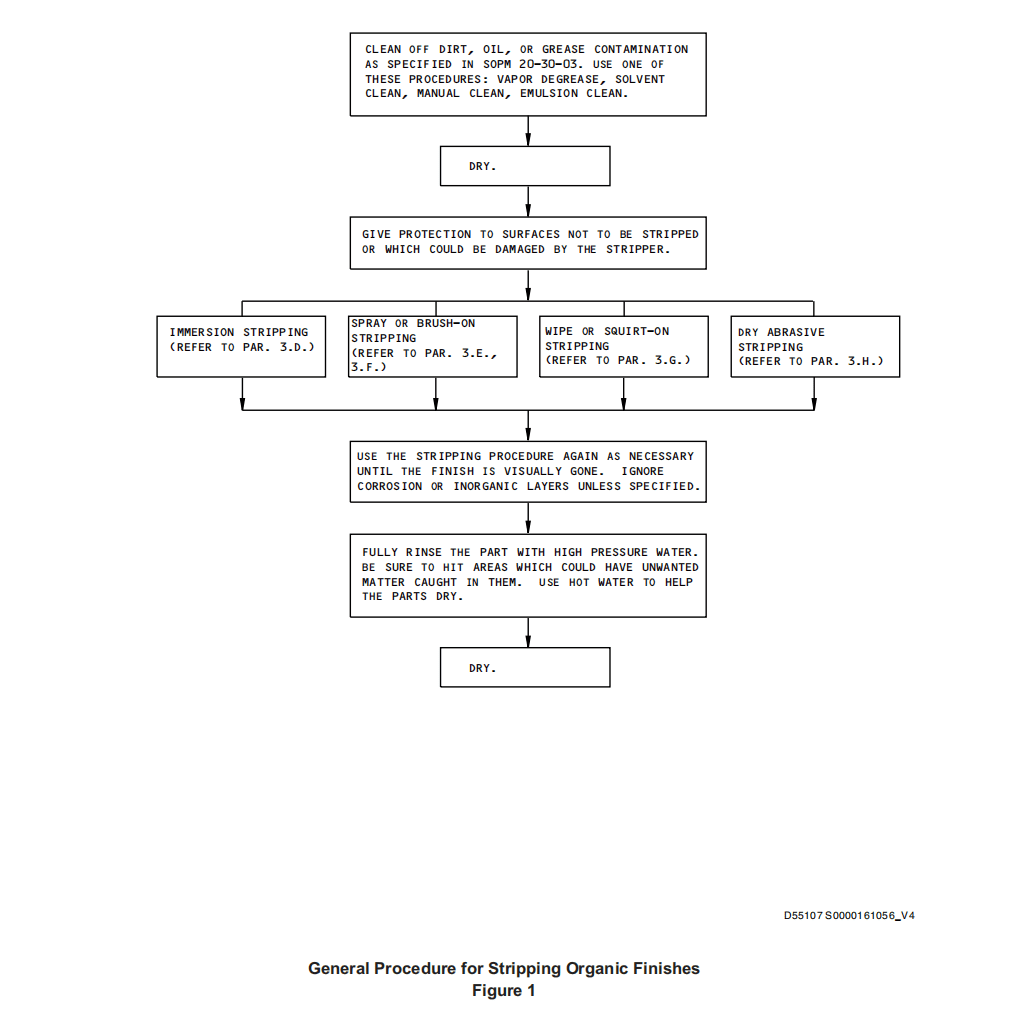

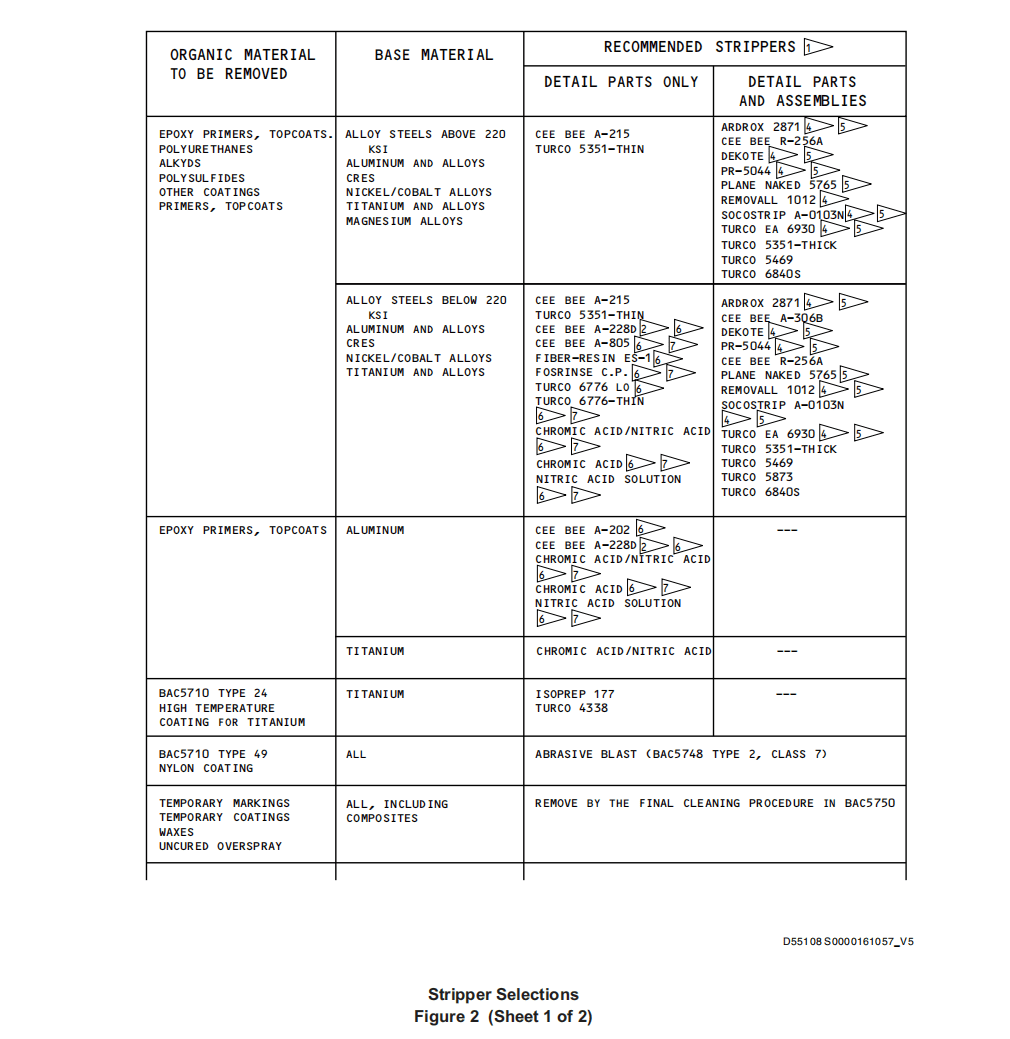

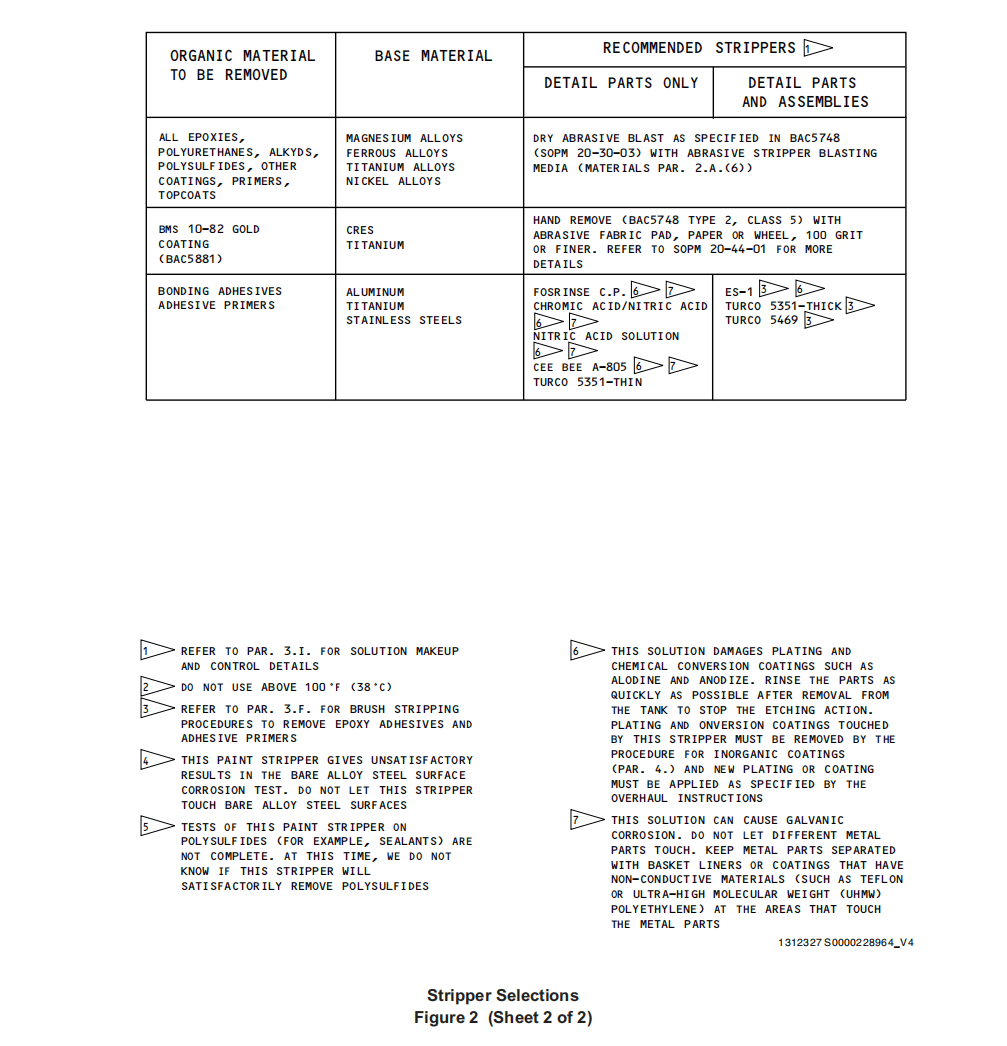

(4) The general sequence is shown in Figure 1. Make the selection of the best stripping procedure and agents as specified in Figure 2.

通用顺序如图 1 所示。按照图 2 的规定选择最佳的剥离程序和溶剂。

(5) If necessary to get full removal of coatings, you can use more than one of these stripping procedures unless not permitted by the material or configuration of the part.

如果需要完全去除涂层,可以使用多个剥离程序,除非零件的材料或构造不允许。

D. Immersion Stripping

浸入式剥离

(1) Put the parts in racks, but keep to a minimum the area touched by the rack, to let the solution get to all of the coatings to be stripped.

将零件放在架子上,但尽量减少架子接触的面积,让溶液接触到所有要剥离的涂层。

(2) Put the parts in the stripper. If the stripper has a seal, make sure all of the parts are below the seal.

将零件放入剥离器中。如果剥离器有密封圈,确保所有零件都在密封圈下方。

(3) Shake the parts in the stripper to get the stripper to touch all surfaces to be stripped.

摇晃剥离剂中的零件,让剥离剂接触到所有要剥离的表面。

(4) Keep the parts in the stripper no longer than the time specified for the stripper solution (Paragraph 3.I.). If a time limit is not specified, use 15-20 minutes as a guide. If the coating is not loosened after this time, more time in the stripper is permitted, if the total time is not more than the limit specified for the stripper. If the coating is not loosened by then, make tests of the stripper. If necessary, discard the solution and replace it with new solution.

零件在剥离剂中停留的时间不得超过剥离剂溶液规定的时间(第 3.I.段)。如果没有规定的时限,则以 15-20 分钟为宜。如果在此时间后涂层仍未松动,则允许在剥离液中停留更长时间,但总时间不得超过剥离液规定的时限。如果此时涂层仍未松动,则对剥离剂进行测试。必要时,丢弃溶液并更换新溶液。

(5) When the coating is loosened, move the parts immediately to a spray tank and complete the coating removal with an air-water blast or a water blast.

涂层松动后,立即将零件移至喷淋槽,用空气-水喷淋或水喷淋完成涂层清除。

E. Brush-on or Spray Stripping

刷涂或喷涂剥离

(1) Strip only the area that can be worked on at one time.

仅对可同时施工的区域进行剥离。

(2) Apply the stripper with a natural bristle brush or nonatomizing spray. Keep the area wet. Add more layers of stripper as necessary. Let the stripper soften and wrinkle the coating.

使用天然鬃毛刷或非雾化喷雾器涂抹剥离剂。保持区域湿润。必要时再添加几层剥离剂。让剥离剂软化并使涂层起皱。

(3) Use Fiber-Resin ES-1 at 50-80°F (10-27°C). Use PR-5044 at 60-100°F (16-38°C), but the best range is 75-85°F (24-29°C). All of the other spray or brush-on stripper can be used at 50-100°F (10-38°C), but the optimum range is 65-85°F (18-29°C).

在 10-27°C (50-80°F) 温度下使用 Fiber-Resin ES-1。在 16-38°C (60-100°F) 温度下使用 PR-5044,但最佳温度范围为 24-29°C (75-85°F)。所有其他喷涂或刷涂剥离剂都可在 10-38°C (50-100°F) 温度下使用,但最佳温度范围为 18-29°C (65-85°F)。

(4) Remove the loosened coating with a non-metallic bristle brush, a non-metallic abrasive pad, or an approved tool from BAC5000 Sealant Removal Tools (SOPM 20-50-19). Then wash the area with water, sprayed or wiped on, to remove the coating and stripper. Then dry the area.

用非金属毛刷、非金属研磨盘或 BAC5000 密封胶清除工具(SOPM 20-50-19)中认可的工具清除松动的涂层。然后用水喷洒或擦拭该区域,以去除涂层和剥离剂。然后擦干该区域。

WARNING :PR-5044 STRIPPER MAKES WATER AND OXYGEN DURING THE STRIPPING PROCEDURE. THIS ACTION WILL CONTINUE IN THE WASTE MIXTURE OF STRIPPER AND REMOVED COATING. DO NOT COLLECT THE WASTE MATERIAL IN RUSTY DRUMS, OR MIX WASTE WITH CONVERSION COATING RINSE WATER, OR THROW RAGS, GLOVES, OR OTHER FABRICS INTO THE WASTE, OR THE MIXTURE COULD START TO BURN. TO PREVENT PRESSURE BUILDUP IN CLOSED WASTE CONTAINERS, DO NOT SEAL THE CONTAINERS FOR 24 HOURS AFTER YOU PUT THE WASTE IN THEM.

警告:PR-5044 剥离剂在剥离程序中会产生水和氧气。这种作用会在剥离剂和被剥离涂层的废混合物中持续存在。切勿将废料收集在生锈的桶中,或将废料与转换涂层冲洗水混合,或将抹布、手套或其他织物扔进废料中,否则混合物可能开始燃烧。为防止密闭废物容器内压力升高,在装入废物后的 24 小时内不要密封容器。

(5) When you use PR-5044, Turco EA 6930, Socostrip A-0103N, Plane Naked, DeKote, RemovAll 1012 or Ardrox 2871 peroxide-based stripper, be sure to wash off the stripper from the removed coating and paint chips. Use a fine spray of soap or rinse the paint chips with water. Put the waste in vented containers. Apply the stripper from plastic or stainless steel equipment.

使用 PR-5044、Turco EA 6930、Socostrip A-0103N、Plane Naked、DeKote、RemovAll 1012 或 Ardrox 2871 过氧化物脱漆剂时,一定要将脱漆剂从脱下的涂层和漆片上洗掉。使用细肥皂喷雾或用水冲洗漆片。将废物放入通风容器中。使用塑料或不锈钢设备涂抹脱漆剂。

F. Stripping Epoxy Adhesives and Adhesive Primers

剥离环氧树脂粘合剂和粘合底漆

CAUTION :DO NOT LET STRIPPER STAY ON THE PARTS FOR MORE THAN A TOTAL OF 2 HOURS.

注意 :不要让剥离剂在零件上停留超过 2 小时。

(1) Brush small quantities of mixed stripper on the adhesive or primer. Keep the stripper only on the area to be stripped. Do not let the stripper splash or run.

在粘合剂或底漆上刷少量混合的剥离剂。仅将剥离剂涂在要剥离的部位。不要让剥离剂飞溅或流出。

(2) Let the stripper stay on the surface a maximum of 30 minutes.

让剥离剂在表面上最多停留 30 分钟。

(3) Remove the stripper and the loosened adhesive or primer with nonabrasive dry cloths that do not visually damage the base material surface, or an approved tool from BAC5000 Sealant Removal Tools (SOPM 20-50-19).

用不损伤基材表面的非研磨性干布或 BAC5000 密封胶清除工具 (SOPM 20-50-19)中认可的工具清除清除剂和松动的胶粘剂或底漆。

(4) Apply more stripper as necessary. Then do Paragraph 3.F.(2) and Paragraph 3.F.(3) again. Do not let stripper be on the part for more than a total of 2 hours.

根据需要涂抹更多的剥离剂。然后再次执行第 3.F.(2)段和第 3.F.(3)段。不要让剥离剂在零件上停留超过 2 小时。

(5) Sponge rinse with water and wipe dry, or solvent clean as specified in SOPM 20-30-03.

用海绵水洗并擦干,或按照 SOPM 20-30-03 规定的溶剂清洗。

(6) Remove remaining spots of adhesive with stripper applied only to the spots.

只用剥离剂清除残留的粘合剂点。

(7) Rinse and wipe dry.

冲洗并擦干。

G. Wipe or Squirt-on/Wipe-off Stripping

擦拭或喷上/擦掉剥离

(1) Apply the stripper with a squirt bottle, or wipers wet with stripper, to the coating to be removed. Keep the surface wet.

用喷壶或沾有剥离剂的抹布将剥离剂涂在要剥离的涂层上。保持表面湿润。

(2) Keep the stripper on the surface for the time recommended for the stripper. If a time is not specified, use the minimum time necessary to loosen the coating. Wrinkles in the coating are a sign that the coating is loose.

按照剥离剂建议的时间在表面上涂抹剥离剂。如果没有规定的时间,则使用使涂层松动所需的最短时间。涂层出现皱纹是涂层松动的迹象。

(3) Peel or scrape off the stripper and the loosened coating before the surface dries. Use an approved tool from BAC5000 Sealant Removal Tools (SOPM 20-50-19).

在表面干燥之前,剥离或刮掉剥离剂和松动的涂层。使用 BAC5000 密封胶清除工具(SOPM 20-50-19)中认可的工具。

(4) Rub the surface with wipers wet with stripper if necessary. Remove unwanted material that could become caught in tight areas of the parts.

如有必要,用沾有剥离剂的抹布擦拭表面。清除可能卡在零件狭小区域的不需要的材料。

H. Abrasive Stripping

研磨剥离

CAUTION :ABRASIVE STRIPPING OF ORGANIC FINISHES DAMAGES CONVERSION COATINGS AND PLATING. ANODIZE OR CHEMICAL TREATMENT ON ALUMINUM PARTS, AND CADMIUM OR CADMIUM-TITANIUM PLATING ON STEEL PARTS MUST BE COMPLETELY STRIPPED AND REAPPLIED BY THE APPLICABLE SOPM SUBJECT BEFORE THE SPECIFIED ORGANIC FINISHES ARE APPLIED. ADJACENT CHROME PLATING MUST BE EXAMINED FOR THICKNESS, SMOOTHNESS AND QUALITY TO SEE IF THE CHROME PLATING MUST BE REPLACED.

注意 :有机饰面的研磨剥离会损坏转换涂层和电镀层。铝质零件上的阳极氧化或化学处理,以及钢质零件上的镉或镉-钛镀层,必须在使用规定的有机表面处理之前,完全剥离并由适用的 SOPM 主体重新涂抹。必须检查邻近镀铬层的厚度、平滑度和质量,以确定是否必须更换镀铬层。

(1) Dry abrasive blasting

干喷砂

(a) Metal surfaces

金属表面

1) If you use soft grain media, use the Abrasive Cleaning procedure in SOPM 20-30-03.

如果使用软颗粒介质,请使用 SOPM 20-30-03 中的磨料清洁程序。

2) Use a nozzle-to-part distance of approximately 6 inches and a pressure of 90-100 psi.

喷嘴到零件的距离约为 6 英寸,压力为 90-100 psi。

(b) Composite surfaces — See Paragraph 3.H.(5) below.

复合材料表面 — 见下文第 3.H.(5)段。

(2) Plastic Media Blasting

塑料介质喷丸

(a) Plastic media blasting can be used on these surfaces:

塑料介质喷丸可用于以下表面:

1) Bare unclad aluminum alloys of gage thickness 0.125 inch or thicker. This includes chemical conversion coated and anodized surfaces.

测量厚度为 0.125 英寸或更厚的裸露无包层铝合金。包括化学转化涂层和阳极氧化表面。

2) Ferrous alloys

铁合金

3) Titanium and its alloys

钛及其合金

4) Parts plated with cadmium-titanium, cadmium, nickel, zinc-nickel, chrome, or copper plating.

镀有镉-钛、镉、镍、锌-镍、铬或铜的零件。

5) Chemically treated or anodized magnesium, but these must not be stripped to bare magnesium.

经过化学处理或阳极氧化处理的镁,但不得将其剥离为裸镁。

(b) Make sure the parts are clean, dry, and have no metal shavings.

确保零件清洁、干燥、无金属屑。

(c) Use only equipment that is limited to plastic media blasting. Be sure the equipment is clean. See Paragraph 3.H.(2)(h) below.

只能使用仅限于塑料介质喷砂的设备。确保设备清洁。参见下文第 3.H.(2)(h)段。

(d) Use a nozzle-to-part distance of 6 inches or more, and an air pressure of 20-40 psi.

喷嘴到零件的距离应为 6 英寸或以上,气压应为 20-40 psi。

(e) Adjust the nozzle-to-part angle as necessary to remove the coating. A 45-degree angle is a good general angle to use.

根据需要调整喷嘴与零件的角度,以去除涂层。45 度角是一个很好的通用角度。

(f) Put the plastic media through a screen before and while you use the media, to remove undersize media and contamination such as paint flakes, metallic particles, heavy particles, and damaged media particles. Replace or add more media as necessary.

在使用介质之前和使用过程中,将塑料介质放入筛网中,以去除尺寸过小的介质和污染物,如漆片、金属颗粒、重型颗粒和损坏的介质颗粒。必要时更换或添加更多的介质。

(g) The media in the supply hopper must contain less than 0.5 weight percent particles with specific gravity more than the limit in the media specification.

供料斗中的介质必须含有小于 0.5 重量百分比的颗粒,其比重必须大于介质规格中的限值。

(h) Be sure all blasting and media recovery components are fully cleaned before you first put the media in or change the media.

在首次放入介质或更换介质之前,应确保所有喷砂和介质回收组件已完全清洁。

(3) Wheat starch blasting

小麦淀粉喷丸

(a) Wheat starch blasting can be used on these surfaces.

小麦淀粉喷丸可用于以下表面。

1) Aluminum alloys 0.032 inch and thicker. They can be clad, chemical conversion coated, or anodized.

0.032 英寸及更厚的铝合金。可对其进行包覆、化学转化涂层或阳极氧化处理。

2) Bonded aluminum honeycomb sandwich with face sheets 0.012 inch or more thick.

厚度为 0.012 英寸或更厚的铝蜂窝夹层。

3) All other metals, plated or not.

所有其他金属,无论是否电镀。

4) Composite parts if the procedure of D6-56993 is used.

复合材料零件,如果使用 D6-56993 的程序。

(b) Make sure the parts are clean, dry, and have no metal shavings.

确保零件清洁、干燥、无金属屑。

(c) Use only equipment that is limited to wheat starch blasting.

只能使用仅限于小麦淀粉喷丸的设备。

(d) Use a nozzle-to-part distance of 6 inches or more, an air pressure of 30-50 psi, and a nozzle-to-part angle of 20-60 degrees. The lower angles are necessary to selectively strip organic finishes, such as topcoat from primer.

喷嘴到零件的距离为 6 英寸或以上,气压为 30-50 psi,喷嘴到零件的角度为 20-60 度。要选择性地剥离有机饰面(如底漆中的面漆),必须使用较小的角度。

(e) Selective stripping of the different finish layers, such as topcoat down to the primer, is acceptable if the remaining layer is serviceable and agrees with overhaul instructions.

如果剩余层可使用并符合大修说明,则可接受选择性地剥离不同的饰面层,如面漆直至底漆。

(4) Nanocomposite blasting

纳米复合喷丸

(a) Nanocomposite blasting can be used on these surfaces.

纳米复合喷丸可用于以下表面。

1) Aluminum alloys 0.040 inch and thicker. They can be clad, chemical conversion coated, or anodized.

0.040 英寸及更厚的铝合金。可对其进行包覆、化学转化涂层或阳极氧化处理。

2) Bonded aluminum honeycomb sandwich with face sheets 0.012 inch or more thick.

面层厚度为 0.012 英寸或更厚的粘合铝蜂窝夹层。

3) Ferrous alloys

铁合金

4) Titanium and its alloys

钛及其合金

5) Parts plated with cadmium-titanium, cadmium, nickel, zinc-nickel, chrome, or copper plating.

电镀镉-钛、镉、镍、锌-镍、铬或铜的零件。

6) Chemically treated or anodized magnesium, but these must not be stripped to bare magnesium.

经过化学处理或阳极氧化处理的镁,但不得将其剥离为裸镁。

(b) Make sure the parts are clean, dry, and have no metal shavings.

确保零件清洁、干燥、无金属屑。

(c) Use only equipment that is limited to nanocomposite blasting.

只能使用仅限于纳米复合材料喷砂的设备。

(d) Use a nozzle-to-part distance of 6 inches or more, an air pressure of 32 psi maximum, and a nozzle-to-part angle of 40-60 degrees. The lower angles are necessary to selectively strip organic finishes, such as topcoat from primer.

喷嘴到零件的距离为 6 英寸或以上,气压最大为 32 psi,喷嘴到零件的角度为 40-60 度。要选择性地剥离有机饰面(如底漆中的面漆),必须使用较小的角度。

(e) Selective stripping of the different finish layers, such as topcoat down to the primer, is acceptable if the remaining layer is serviceable and agrees with overhaul instructions.

如果剩余层可以使用并符合大修说明,则可以接受选择性剥离不同的饰面层,如面漆直至底漆。

(5) Composite Surfaces

复合材料表面

(a) Use 150-grit or finer sandpaper to remove the enamel or topcoat layer. Sand the topcoat smoothly down to the primer layer. Removal of the primer layer is not necessary to apply new layers of primer, enamel or topcoat.

用 150 号或更细的砂纸去除瓷釉或面漆层。将面漆平滑打磨至底漆层。在涂刷新的底漆、瓷漆或面漆层时,无需去除底漆层。

(b) Sand and blend out the primer and enamel layers with 240 grit or finer sandpaper. Do not damage the fiber of the composite substrate.

用 240 号或更细的砂纸打磨底漆层和瓷漆层并将其混合。不要损坏复合底材的纤维。

(c) If the substrate has a conductive coating, sand off all of this coating in the area to be painted, to get equal conductivity after replacement of the coating.

如果基材上有导电涂层,则应打磨掉要涂漆区域内的所有导电涂层,以便在更换涂层后获得相同的导电性。

I. Solution Makeup and Control

溶液配制和控制

(1) Fully mix vendor solutions before you put them in the tank.

将供应商的溶液充分混合后再放入槽中。

(2) For stripper solutions made from chemicals, fill the tank 3/4 with water, add and dissolve the chemicals, then add water to the operating level. Make analyses and adjustments as necessary.

对于用化学品配制的脱漆剂溶液,先在罐中注入 3/4 的水,加入并溶解化学品,然后加水至操作液位。必要时进行分析和调整。

(3) Unless the solution is a diphase process solution, mix the stripper solution after long waits, after you add stripper materials, or immediately before you start to use the solution.

除非溶液是二相工艺溶液,否则应在长时间等待后、添加脱脂剂材料后或开始使用溶液前立即混合脱脂剂溶液。

(4) To make a solution with a water seal, add stripper to the tank to the tank volume or depth specified. Then carefully add tap water over the stripper to the tank volume or level specified. The seal will dissolve the stripper to change the pH to the specified range. If the pH of the seal is not sufficiently high, add some potassium hydroxide.

要配制带水封的溶液,可将剥离剂加入水槽至规定的水槽容积或深度。然后小心地将自来水加在脱脂剂上,达到规定的水槽容积或水位。水封会溶解剥离剂,使 pH 值变为规定的范围。如果密封件的 pH 值不够高,可添加一些氢氧化钾。

(5) Cee Bee A-215 Solution (with water seal)

Cee Bee A-215 溶液(带水封)

(a) Control the A-215 at 75-80% tank volume.

将 A-215 控制在料槽容积的 75-80%。

(b) Control the seal at 20-25% tank volume (6-inch minimum) and pH of 10.5-11.5.

将水封控制在水槽容积的 20-25%(最小 6 英寸),pH 值为 10.5-11.5。

(c) Do not let the water seal be more than 25% tank volume.

不要让水封超过 25%的水槽容积。

(d) Use this solution at room temperature.

在室温下使用该溶液。

(6) Turco 5351-Thin Solution (with water seal)

Turco 5351-稀溶液(带水封)

(a) Control the Turco 5351 at 88-92% tank volume and specific gravity of 1.15-1.19.

将 Turco 5351 控制在水槽容积的 88-92%,比重 1.15-1.19。

(b) Control the seal at 8-12% tank volume (4-inch minimum), specific gravity 1.10 maximum and a pH of 8.0-10.3.

将密封控制在水槽容积 8-12%(最小 4 英寸),比重最大 1.10,pH 值 8.0-10.3。

(c) Use this solution at room temperature.

在室温下使用该溶液。

(7) Turco 4338

CAUTION :THIS STRIPPER CAN BE USED ONLY ON TITANIUM.

注意 :这种剥离剂只能用于钛。

(a) Mix 2.25 pounds of Turco 4338 for each gallon of water. Control at 32-40 ounces per gallon. Control potassium permanganate at 6-8 ounces per gallon. Control the temperature at 190-210°F (88-99°C).

每加仑水混合 2.25 磅 Turco 4338。控制在每加仑 32-40 盎司。高锰酸钾控制在每加仑 6-8 盎司。温度控制在 190-210°F (88-99°C)。

(b) Put the parts in the stripper for 30-40 minutes. Then remove the parts and rinse them. Then rinse them with pressure spray until all unwanted matter is removed.

将零件放入脱脂剂中 30-40 分钟。然后取出零件并冲洗。然后用压力喷雾器冲洗,直至去除所有不需要的物质。

(8) Cee Bee A-805

(a) Use this stripper at full strength. Add water to the tank as necessary to adjust for evaporation.

使用该剥离剂时,应使用全浓度。必要时向罐中加水,以适应蒸发。

(b) Control chromic acid at 40-70 ounces per gallon, phosphoric acid at 50-84 ounces per gallon, and the ratio of chromic acid to phosphoric acid at 0.90-1.10. Add one acid or the other as necessary to adjust.

铬酸控制在每加仑 40-70 盎司,磷酸控制在每加仑 50-84 盎司,铬酸和磷酸的比例控制在 0.90-1.10。必要时添加一种酸或另一种酸进行调节。

(c) Control the temperature at 170-190°F (76-88°C).

将温度控制在 170-190 °F(76-88°C)。

(d) Maximum time that parts can be in the solution: 20 minutes. Discard the solution when stripping time becomes more than 20 minutes.

零件在溶液中最长停留时间:20 分钟。当剥离时间超过 20 分钟时,应丢弃溶液。

(e) This solution damages plating and conversion coatings (such as Alodine and anodize). Rinse the parts as quickly as possible after removal from the tank to stop the etching action. Plating and conversion coatings touched by this stripper must be removed by the procedures for inorganic coatings (See Paragraph 4.) and new plating or coating must be applied as specified by the overhaul instructions.

该溶液会损坏电镀层和转换涂层(如镀铝层和阳极氧化层)。从槽中取出零件后应尽快冲洗,以停止蚀刻作用。必须按照无机涂层的程序(见第 4.段)清除该剥离剂接触到的电镀层和转换涂层,并按照大修说明规定的方法涂上新的电镀层或涂层。

(f) This solution can cause galvanic corrosion. Do not let different metal parts touch while in the solution. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。在溶液中不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料 (如Teflon或超高分子量 (UHMW) 聚乙烯)。

(9) Fosrinse C.P.

漂洗C.P.

(a) Use this stripper at full strength. Add water to the tank as necessary to adjust for evaporation.

使用该剥离剂时,应使用全浓度。必要时向罐中加水,以适应蒸发。

(b) Control chromates at 32-60 ounces per gallon. Add chromic acid to adjust.

将铬酸盐控制在每加仑 32-60 盎司。添加铬酸进行调节。

(c) Control phosphoric acid at 53-96 ounces per gallon. Add more phosphoric acid to adjust.

将磷酸控制在每加仑 53-96 盎司。添加更多磷酸进行调节。

(d) Control the ratio of chromic acid to phosphoric acid at 0.90-1.10. Add one acid or the other to adjust.

将铬酸与磷酸的比例控制在 0.90-1.10 之间。添加一种酸或另一种酸进行调节。

(e) Control the temperature at 170-190°F (76-88°C).

将温度控制在 170-190°F (76-88°C)。

(f) Maximum time that parts can be in the solution: 20 minutes.

零件在溶液中最长停留时间:20 分钟。

(g) This solution damages plating and conversion coatings (such as Alodine and anodize). Rinse the parts as quickly as possible after removal from the tank to stop the etching action. Plating and conversion coatings touched by this stripper must be removed by the procedure for inorganic coatings (See Paragraph 4.) and new plating or coating must be applied as specified by the overhaul instructions.

该溶液会损坏电镀层和转换涂层(如 Alodine 和阳极氧化)。从溶液槽中取出零件后应尽快冲洗,以停止蚀刻作用。必须按照无机涂层的程序(见第 4.段)清除该剥离剂接触到的电镀层和转换涂层,并按照大修说明规定的方法涂上新的电镀层或涂层。

(h) This solution can cause galvanic corrosion. Do not let different metal parts touch while in the solution. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。在溶液中不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料 (如Teflon或超高分子量 (UHMW) 聚乙烯)。

(10) Chromic Acid/Nitric Acid

铬酸/硝酸

(a) Mix 3.5 pounds of chromic acid for each gallon of water. Add nitric acid to become 5% of the final tank volume.

每加仑水混合 3.5 磅铬酸。加入硝酸的量为最终水箱容积的 5%。

(b) Control the chromic acid at 48-64 ounces per gallon. Add nitric acid as necessary to keep the stripping rate.

将铬酸控制在每加仑 48-64 盎司。必要时添加硝酸以保持剥离率。

(c) Control the temperature at 155-175°F (68-80°C).

将温度控制在 68-80°C (155-175°F)。

(d) Maximum time that parts can be in the solution: 15 minutes.

零件在溶液中的最长停留时间: 15 分钟。

(e) This solution damages plating and conversion coatings (such as Alodine and anodize). Rinse the parts as quickly as possible after removal from the tank to stop the etching action. Plating and conversion coatings touched by this stripper must be removed by the procedures for inorganic coatings (See Paragraph 4.) and new plating or coating must be applied as specified by the overhaul instructions.

该溶液会损坏电镀层和转换涂层(如镀铝层和阳极氧化层)。从溶液槽中取出零件后应尽快冲洗,以停止蚀刻作用。必须按照无机涂层的程序(见第 4.段)清除该剥离剂接触到的电镀层和转换涂层,并按照大修说明规定的方法涂上新的电镀层或涂层。

(f) This solution can cause galvanic corrosion. Do not let different metal parts touch. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料(如聚四氟乙烯或超高分子量 (UHMW) 聚乙烯)。

(11) Chromic Acid

铬酸

(a) Mix 3.5 pounds of chromic acid for each gallon of water. Control the chromic acid at 48-64 ounces per gallon.

每加仑水混合 3.5 磅铬酸。将铬酸控制在每加仑 48-64 盎司。

(b) Control the temperature at 155-175°F (68-80°C).

温度控制在 68-80°C (155-175°F)。

(c) Maximum time that parts can be in the solution: 15 minutes. Discard the solution when more than 15 minutes in it is necessary to remove coatings.

零件在溶液中停留的最长时间: 15 分钟。如果需要在溶液中浸泡 15 分钟以上才能去除涂层,则应丢弃溶液。

(d) This solution will remove conversion coatings (such as Alodine and anodize). Rinse parts as quickly as possible after removal from the tank to stop the etching action. Conversion coatings touched by this stripper must be removed by the procedure for inorganic coatings (SeeParagraph 4.) and new coating must be applied as specified by the overhaul instructions.

该溶液可去除转化涂层(如 Alodine 和阳极氧化)。从槽中取出后应尽快冲洗零件,以停止蚀刻作用。必须按照无机涂层的程序 (见第 4 段)清除该剥离剂接触到的转换涂层,并按照大修说明规定的方法涂上新涂层。

(e) This solution can cause galvanic corrosion. Do not let different metal parts touch. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料 (如Teflon或超高分子量 (UHMW) 聚乙烯)。

(12) Nitric Acid Solution

硝酸溶液

(a) Fill the tank with nitric acid. Control the nitric acid at 50-78% by weight.

将硝酸注入槽中。将硝酸控制在 50-78% (重量百分比)。

(b) Control the temperature at 100-120°F (37-49°C).

温度控制在 37-49°C (100-120°F)。

(c) Maximum time that parts can be in the solution: 20 minutes.

零件在溶液中最长停留时间:20 分钟。

(d) This solution damages plating and conversion coatings (such as Alodine and anodize). Rinse the parts as quickly as possible after removal from the tank to stop the etching action. Plating and conversion coatings touched by this stripper must be removed by the procedure for inorganic coatings (See Paragraph 4.) and new plating or coating must be applied as specified by the overhaul instructions.

该溶液会损坏电镀和转换涂层(如镀铝和阳极氧化)。从溶液槽中取出零件后应尽快冲洗,以停止蚀刻作用。必须按照无机涂层的程序(见第 4.段)清除该剥离剂接触到的电镀层和转换涂层,并按照大修说明规定的方法涂上新的电镀层或涂层。

(e) This solution can cause galvanic corrosion. Do not let different metal parts touch. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料 (如 Teflon或超高分子量 (UHMW) 聚乙烯)。

(13) Isoprep 177

(a) Mix 0.40 pounds (6.4 ounces) of Isoprep 177 for each gallon of water. Control this at 6-12 ounces per gallon.

每加仑水混合 0.40 磅(6.4 盎司)Isoprep 177。控制在每加仑 6-12 盎司。

(b) Control the temperature at 180-190°F (82-87°C).

温度控制在 82-87°C (180-190°F)。

(c) Discard the stripper when more than 20 minutes in it is necessary to remove coatings.

当需要使用脱漆剂 20 分钟以上才能去除涂层时,应丢弃脱漆剂。

(14) Turco 6776-Thin (with oil seal)

Turco 6776-Thin(带油封)

(a) Use this stripper at full strength.

全浓使用该剥离剂。

(b) Control:

控制:

1) Operating temperature: 70-130°F (21-54°C). Best temperature range: 120-130°F (49-54°C).

操作温度:华氏 70-130 度(摄氏 21-54 度)。最佳温度范围: 120-130°F(49-54°C)。

2) Seal depth: 12-15% of the total depth of the solution (the maximum seal depth is 8 inches). Use Turco 5668 No. 1 seal additive when you refill the seal level.

密封深度:溶液总深度的 12-15%(最大密封深度为 8 英寸)。加注密封液时,请使用 Turco 5668 1 号密封添加剂。

3) Analyze the solution and adjust it as necessary by the vendor’s instructions.

分析溶液,根据供应商的说明进行必要的调整。

4) To adjust for loss by evaporation, add more solution.

为弥补蒸发损失,可添加更多溶液。

(c) Maximum time that parts can be in the solution: 12 hours.

零件在溶液中的最长时间: 12 小时。

(d) After stripping:

剥离后:

1) Rinse as quickly as possible

尽快冲洗

2) Clean by one or more of these procedures to remove the oil seal (SOPM 20-30-03):

通过以下一种或多种程序进行清洗,以去除油封(SOPM 20-30-03):

a) Manual cleaning (BAC5744)

人工清洗 (BAC5744)

b) Alkaline cleaning (BAC5749)

碱性清洗 (BAC5749)

c) Solvent cleaning (BAC5750)

溶剂清洗 (BAC5750)

d) Emulsion cleaning and aqueous degreasing (BAC5763)

乳化液清洗和水性脱脂 (BAC5763)

(e) This solution damages plating and conversion coatings (such as Alodine and anodize). Rinse the parts as quickly as possible after removal from the tank to stop the etching action. Plating and conversion coatings touched by this stripper must be removed by the procedure for inorganic coatings (See Paragraph 4.) and new plating or coating must be applied as specified by the overhaul instructions.

该溶液会损坏电镀层和转换涂层(如 Alodine 和阳极氧化)。从槽中取出零件后应尽快冲洗,以停止蚀刻作用。必须按照无机涂层的程序(见第 4.段)清除该剥离剂接触到的电镀层和转换涂层,并按照大修说明规定的方法涂上新的电镀层或涂层。

(f) This solution can cause galvanic corrosion. Do not let different metal parts touch. Keep metal parts separated with basket liners or coatings on holding fixtures that have non-conductive materials (such as Teflon or ultra-high molecular weight (UHMW) polyethylene) at the areas that touch the metal parts.

该溶液可导致电偶腐蚀。不要让不同的金属零件接触。用篮子衬垫或夹具上的涂层将金属零件隔开,夹具上与金属零件接触的部位应使用非导电材料(如Teflon或超高分子量 (UHMW) 聚乙烯)。

4. INORGANIC FINISHES 无机表面处理

WARNING :MANY OF THESE STRIPPING SOLUTIONS ARE POISONOUS OR CAN CAUSE CORROSION. DO NOT BREATHE STRIPPING SOLUTION VAPORS. THESE MATERIALS MUST NOT BE USED IN CONFINED SPACES WITHOUT SUFFICIENT VENTILATION. IF THE STRIPPING SOLUTION GETS ON YOUR SKIN, WASH IT OFF IMMEDIATELY WITH WATER. IF THESE CHEMICALS GET IN YOUR EYES, FLUSH IT OUT QUICKLY WITH WATER. IMMEDIATELY GET MEDICAL AID. IMMEDIATELY WASH OFF SOLUTION THAT GETS ON YOUR SKIN. FLUSH OUT WITH WATER ANY SOLUTION THAT IS SPLASHED INTO YOUR EYES AND GET MEDICAL AID.

警告 :许多剥离溶液都有毒或会造成腐蚀。切勿吸入剥离液蒸汽。在没有充分通风的密闭空间内不得使用这些材料。如果剥离溶液沾到皮肤上,请立即用清水冲洗干净。如果这些化学品进入眼睛,应立即用水冲洗。立即就医。立即用清水冲洗掉沾在皮肤上的溶液。用清水冲洗溅入眼内的溶液,并立即就医。

CAUTION :DO NOT LET CHEMICAL STRIPPERS GET ON SEALS, SEALANT, OR FILLET SEALS, OR FLOW INTO FAYING SURFACES OF BONDED OR SEALED JOINTS.

注意 :不要让化学剥离剂沾到密封件、密封胶或圆角密封件上,或流入已粘合或密封接头的接合面。

A. Solution Selections

溶液选择

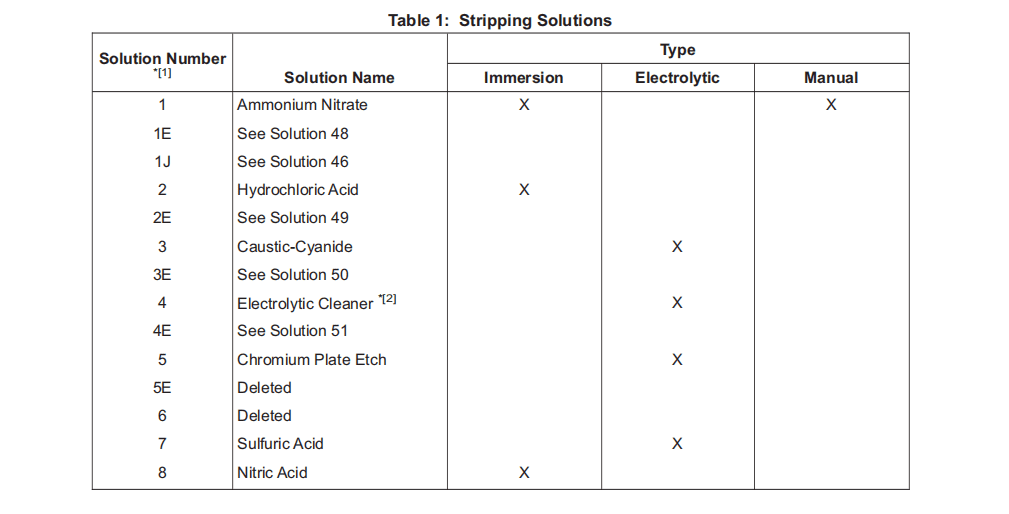

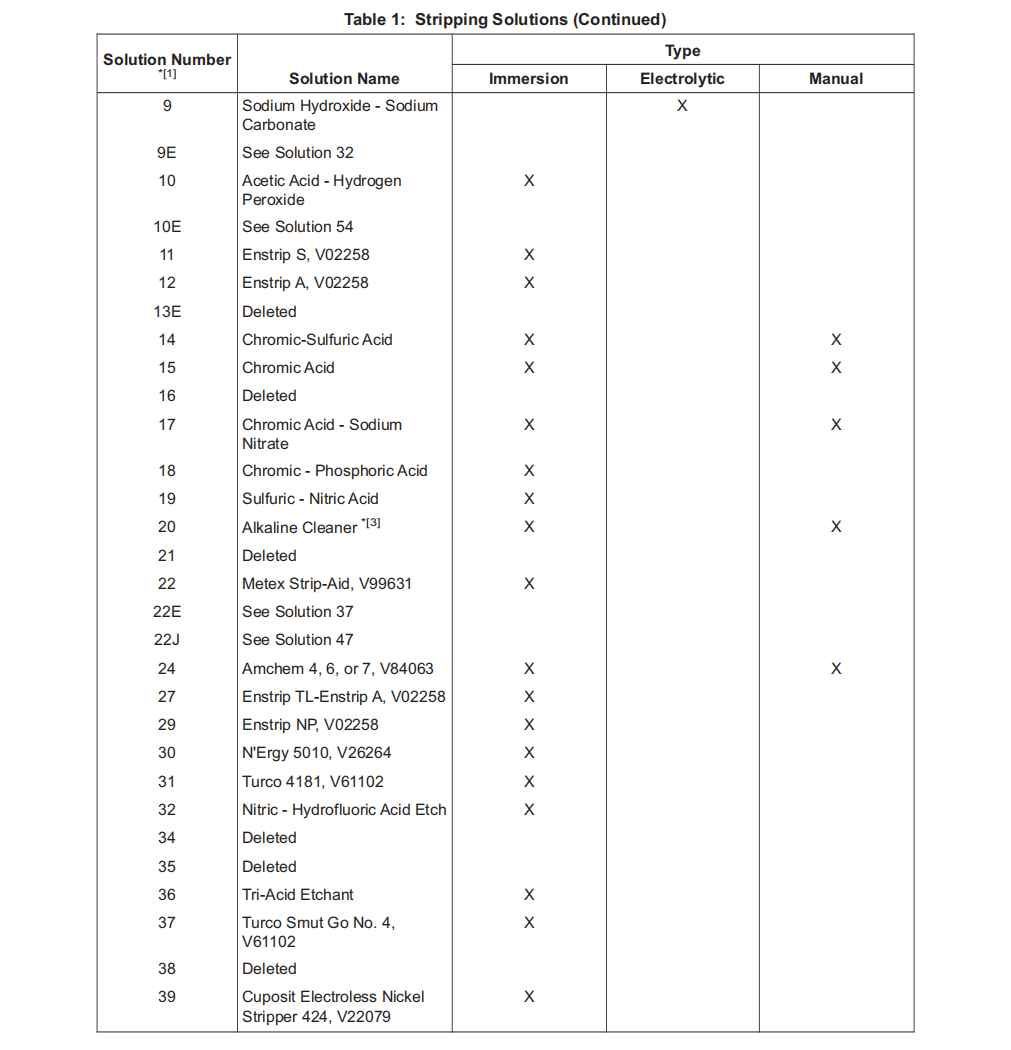

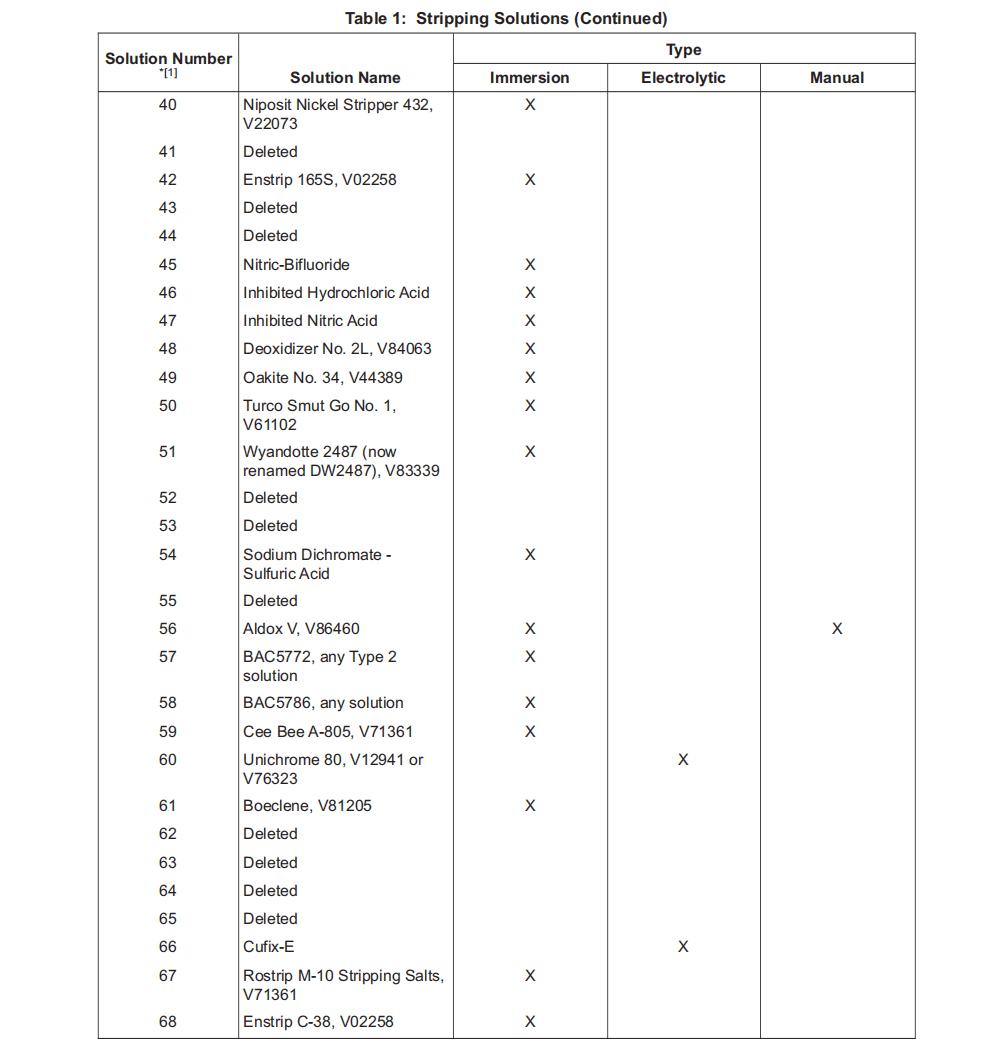

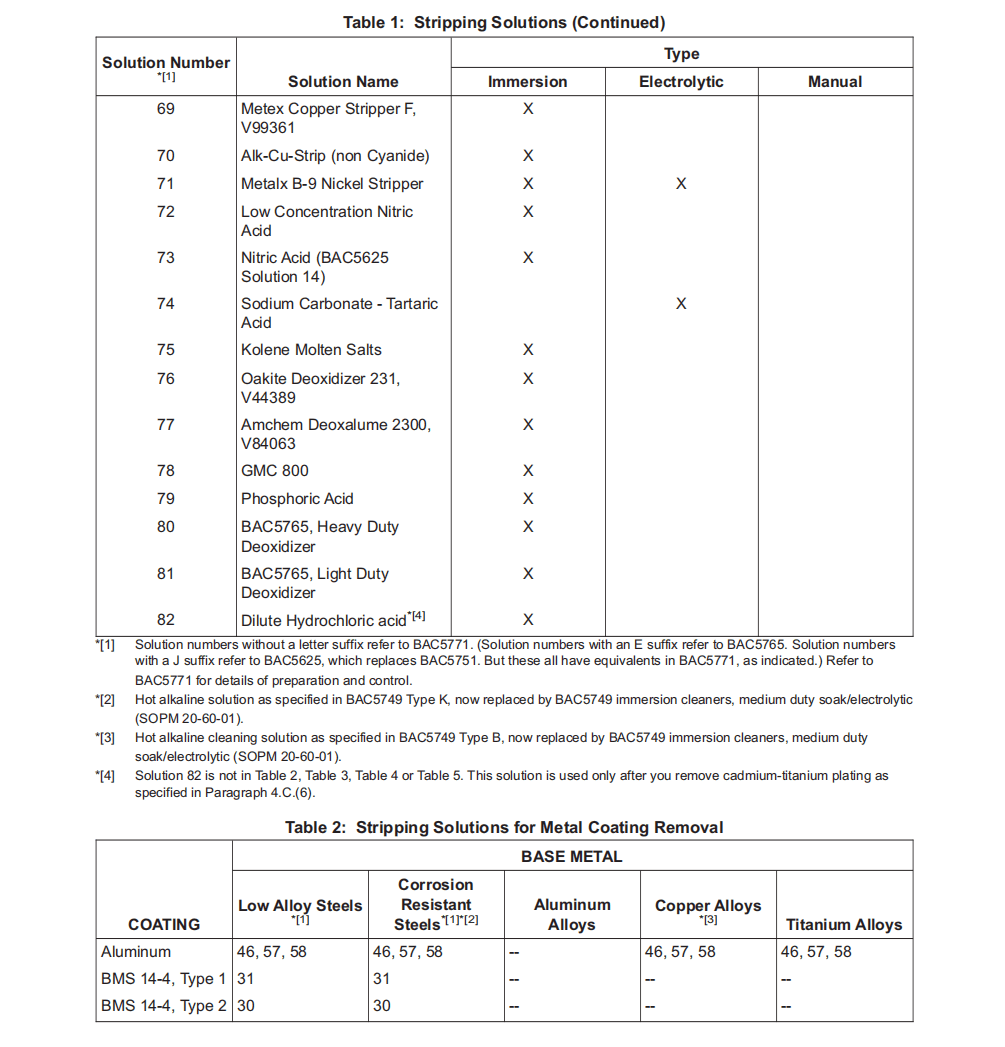

(1) For a list of the approved stripping solutions and types, see Table 1. Refer to BAC5771 for details about solution preparation and control.

批准的剥离溶液和类型清单见表 1。有关溶液制备和控制的详情,请参阅 BAC5771。

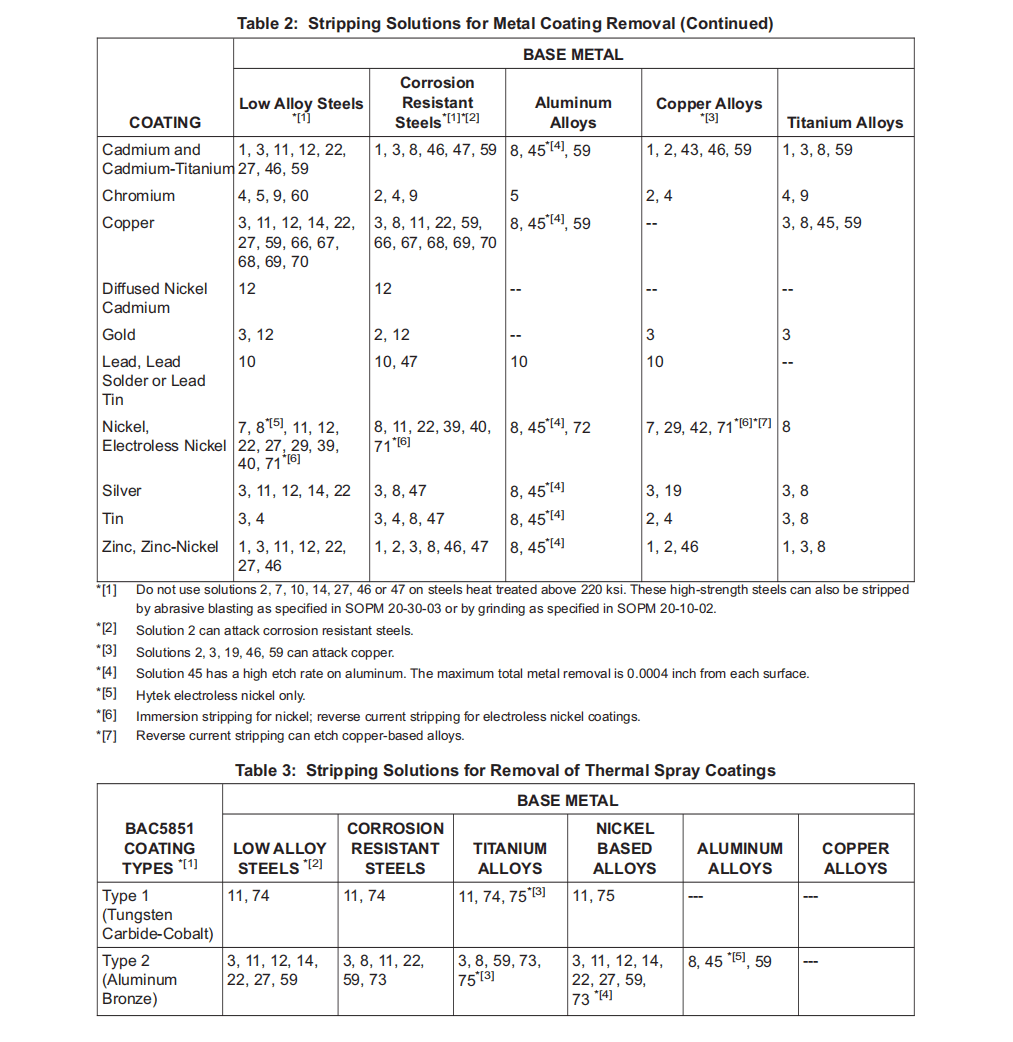

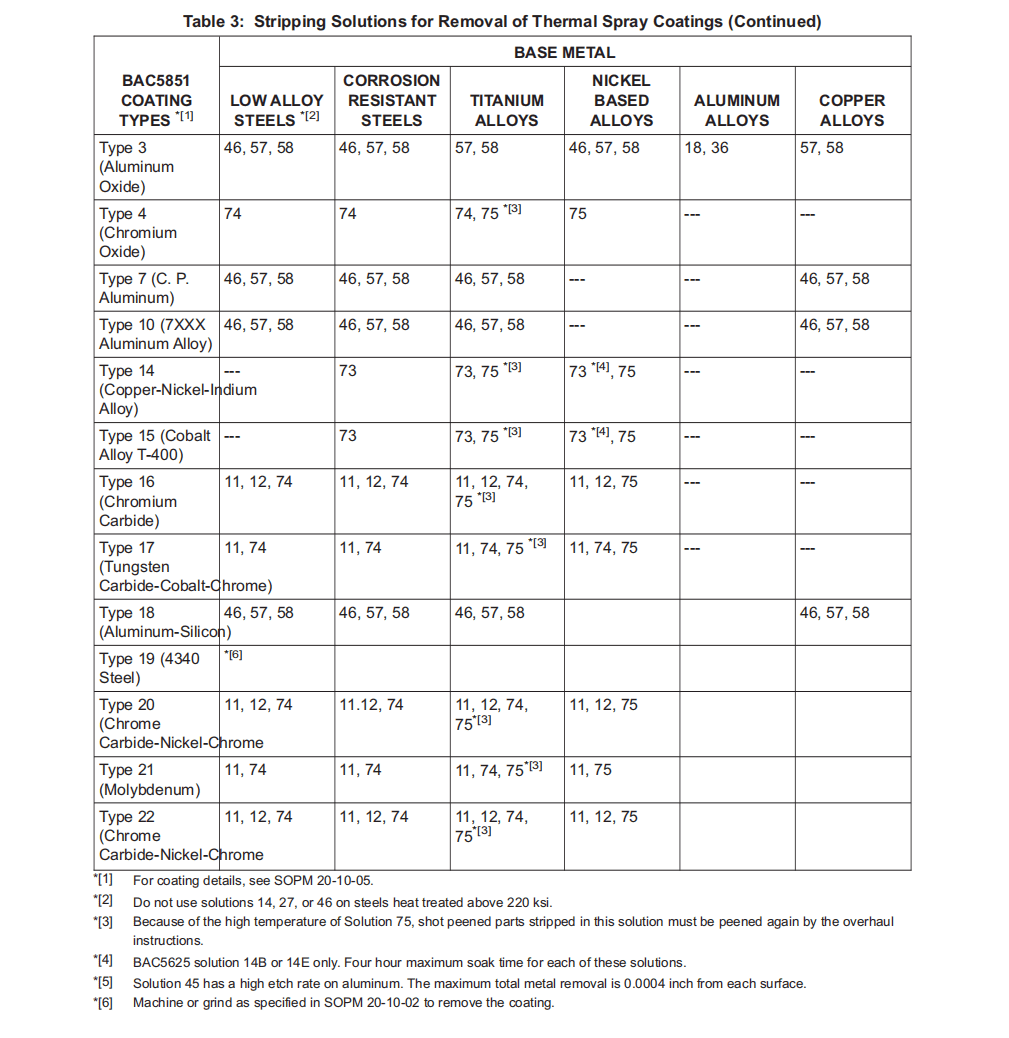

(2) For solutions to remove metal coatings, see Table 2. If the metal coatings are thermal sprayed, see Table 3.

有关去除金属涂层的溶液,请参见表 2。如果金属涂层是热喷涂的,请参见表 3。

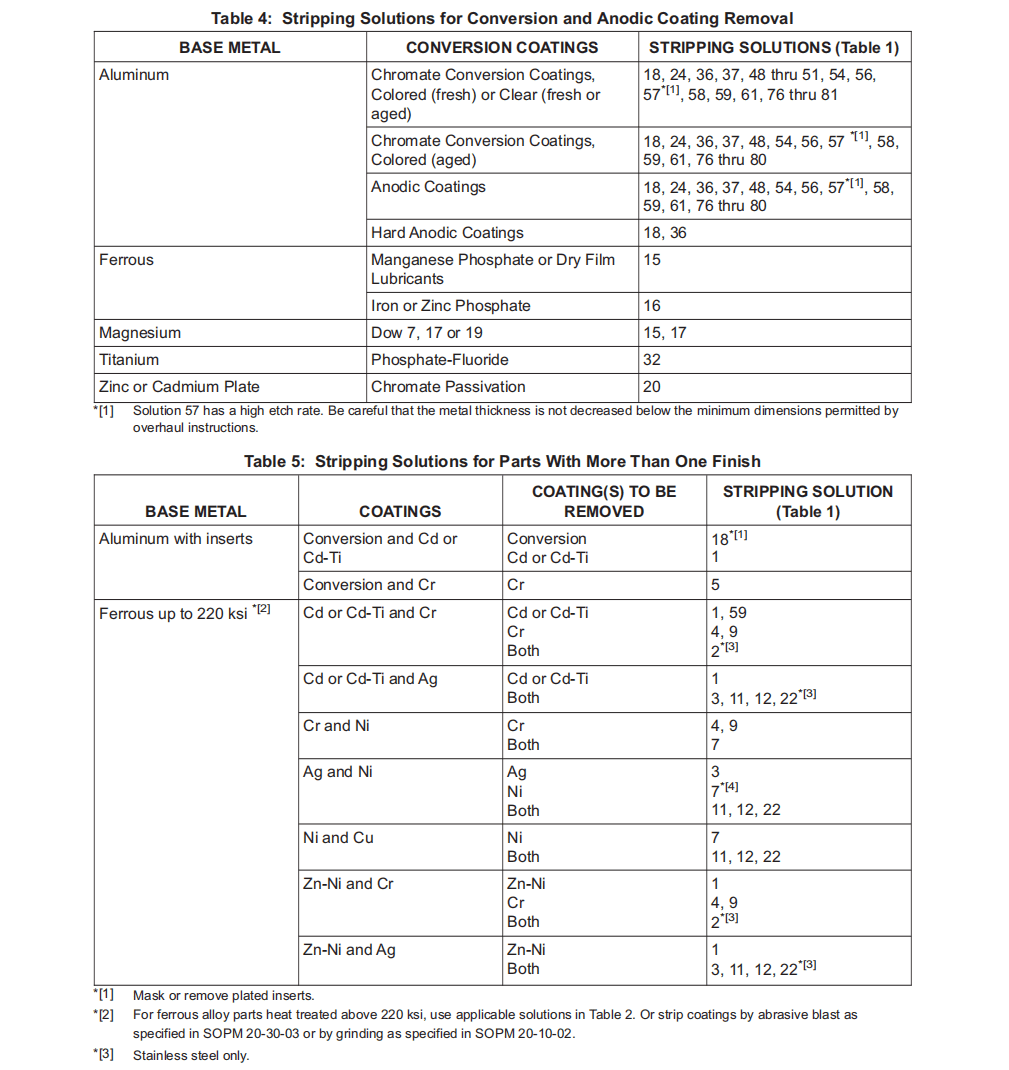

(3) For solutions to remove conversion and anodic coatings, see Table 4.

去除转换涂层和阳极涂层的溶液,请参见表 4。

(4) For solutions to remove one type of coating but let a different type stay, or to remove different coatings at the same time, see Table 5.

去除一种涂层但保留另一种涂层,或同时去除不同涂层的溶液,见表 5。

*[1] Mask or remove plated inserts.

屏蔽或去除电镀嵌入件。

*[2] For ferrous alloy parts heat treated above 220 ksi, use applicable solutions in Table 2. Or strip coatings by abrasive blast as specified in SOPM 20-30-03 or by grinding as specified in SOPM 20-10-02.

对于热处理超过 220 ksi 的铁合金零件,使用表 2 中的适用溶液。或采用 SOPM 20-30-03 规定的喷砂法或 SOPM 20-10-02 规定的打磨法剥离涂层。

*[3] Stainless steel only.

仅适用于不锈钢。

*[4] Mask silver.

罩银。

B. General

通用

(1) Unless specified below, all steel parts heat treated above 180 ksi (externally-threaded parts above 160 ksi) must be stress relieved as specified in SOPM 20-10-02 before you strip them. Stress relief is not necessary for:

除非有以下规定,所有热处理温度超过 180 ksi 的钢零件(外螺纹零件温度超过 160 ksi)在剥皮前必须按照 SOPM 20-10-02 规定的方法消除应力。以下情况不需要消除应力:

(a) Parts to be stripped in Solutions 1, 9, 22, 68 or 74.

在溶液 1、9、22、68 或 74 中剥离的零件。

(b) Parts to be stripped by abrasive blasting as specified in SOPM 20-30-03.

按 SOPM 20-30-03 规定的喷砂方法剥除的零件。

(c) Unless specified by overhaul instructions, 300-series CRES, A286 steel, 15-5PH, 17-4PH, 17-7PH or other PH steels below 180 ksi and without external threads, 17-7PH steel (CH-900 condition), nickel alloys.

除非大修说明规定的,300 系列 CRES、A286 钢、15-5PH、17-4PH、17-7PH 或其他 PH 值低于 180 ksi 且无外螺纹的钢、17-7PH 钢(CH-900 状态)、镍合金。

(2) Put the parts fully into the processing solutions to prevent local effects, such as waterline attack.

将零件完全放入加工溶液中,以防止局部效应,如水纹侵蚀。

(3) Use a simple immersion procedure, not the electrolytic process, to strip hollow or recessed parts.

使用简单的浸泡程序,而不是电解程序来剥离空心或凹陷的零件。

(4) Refer to Paragraph 4.C. for the immersion procedure. Refer to Paragraph 4.D. for special procedures applicable to some immersion strippers. Refer to Paragraph 4.E. for the local stripping procedure to be used when the immersion procedure cannot be used.

有关浸泡程序,请参见第 4.C 段。有关适用于某些浸入式剥离器的特殊程序,请参见第 4.D 段。当无法使用浸泡程序时,请参阅第 4.E 段,了解应使用的局部剥离程序。

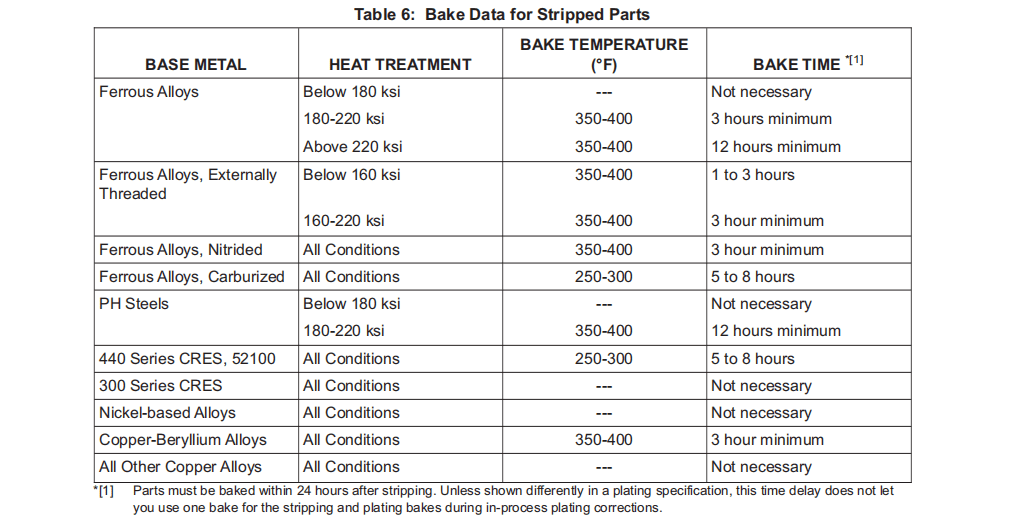

(5) Hydrogen embrittlement relief bake steel parts (but not those in Paragraph 4.B.(1) above) as specified in Table 6 after you strip them, and before you plate them. Start the bake as quickly as possible and within 25 hours after you stripped the parts. This bake is not necessary for parts stripped with Solutions 1, 9, 22, 68 or 74, or by abrasive blast.

消除氢脆钢制零件(但不包括上文第 4.B.(1)段所述的零件)在剥离后和镀层前,按表 6 规定的方法进行烘烤。在剥离零件后 25 小时内尽快开始烘烤。使用溶液 1、9、22、68 或 74 或喷砂法剥离的零件无需进行烘烤。

(6) When a stripping solution is not available, such as if the task is too small to prepare the solution, or if there are processing restrictions, you can strip the parts by one of these alternatives:

如果没有剥离溶液,例如任务量太小而无法准备溶液,或者存在加工限制,可以通过以下一种替代方法剥离零件:

(a) Local stripping as specified in Paragraph 4.E.

第 4.E 段规定的局部剥离。

(b) Machining or grinding as specified in SOPM 20-10-02.

SOPM 20-10-02 规定的机加工或打磨。

(c) Abrasive cleaning as specified in SOPM 20-30-03. MIL-P-6888 aluminum metal polish can be used to strip local areas on aluminum.

SOPM 20-30-03 规定的研磨清洗。MIL-P-6888 铝金属抛光剂可用于剥离铝的局部区域。

C. Immersion Stripping

浸入式剥离

(1) Remove all organic coatings as specified in Paragraph 3.

按第 3 段规定的方法去除所有有机涂层。

(2) Remove oil or grease by any of these procedures (SOPM 20-30-03):

以下列任何程序去除油或油脂(SOPM 20-30-03):

(a) Vapor degrease

蒸汽脱脂

(b) Emulsion clean

乳化清洗

(c) Manual alkaline clean

手工碱性清洗

(d) Solvent clean

溶剂清洗

(3) Alkaline clean as specified in SOPM 20-30-03. This is optional when the inorganic finish: is:

SOPM 20-30-03 规定的碱性清洗。当无机饰面为以下情况时,可选择此步骤:

(a) Cadmium plate

镉板

(b) Chrome plate

铬板

(c) Zinc-nickel plate

锌镍镀层

(d) Anodic or conversion coatings from aluminum

铝的阳极涂层或转换涂层

(4) Mask off or remove inserts of a metal different than of the base part, if necessary

如有必要,遮盖或拆除与基本零件不同的金属嵌入件

(5) Put the parts in the stripping solution. Use the shortest possible time necessary to fully remove the inorganic coating. Refer to Paragraph 4.D. for special procedures applicable to the stripping solution that you use.

将零件放入剥离液中。尽可能缩短完全去除无机涂层所需的时间。有关适用于所用剥离液的特殊程序,请参见第 4.D 段。

(6) After you remove cadmium-titanium plating:

去除镉钛镀层后:

(a) Put the parts in Solution 82 (a solution of 3-6% hydrochloric acid) for 30 seconds maximum, unless the parts will be cadmium-titanium plated again

将零件放入溶液 82(3-6% 的盐酸溶液)中最多 30 秒,除非零件将再次镀镉钛

(b) Rinse fully.

充分冲洗。

(c) Bake steel parts (Table 6) if necessary.

必要时烘烤钢制零件(表 6)。

(7) Rinse the parts in cold water. If necessary, remove unwanted matter with an air-water blast.

用冷水冲洗零件。如有必要,用水气喷射去除不需要的物质。

(8) If applicable, remove masks from the parts.

如适用,去除零件上的遮盖物。

(9) (Optional for low alloy steel parts stripped in an alkaline solution or to be immediately put into a plating bath) Put low alloy steel parts in a cyanide holding tank as specified in BAC5625 or in an alkaline cleaner as specified in BAC5749 (SOPM 20-30-03).

(可选用于在碱性溶液中剥离或立即放入电镀槽的低合金钢零件)将低合金钢零件放入 BAC5625 规定的氰化物保持槽或 BAC5749 规定的碱性清洗剂中(SOPM 20-30-03)。

(10) Rinse the parts. Hot water can be used to help dry the parts.

冲洗零件。可用热水帮助擦干零件。

(11) Dry all parts unless subsequent steps in your procedure will keep the parts wet.

擦干所有零件,除非程序中的后续步骤会使零件保持潮湿。

(12) Bake parts for hydrogen embrittlement relief as specified in Table 6, if applicable. This bake is not necessary if parts were stripped in Solutions 1, 9, 22, 29B (20% volume concentrated), 67 or 74, or with an abrasive blast.

如果适用,按照表 6 规定的方法对零件进行氢脆消除烘烤。如果零件在溶液 1、9、22、29B(体积浓度为 20%)、67 或 74 中进行了剥离,或使用了喷砂,则无需进行烘烤。

(13) Keep the parts clean. Apply the specified finish as quickly as possible.

保持零件清洁。尽快进行规定的表面处理。

D. Special Procures for Some Immersion Strippers

某些浸入剥离剂的特殊采购

(1) Solution 3 (Caustic-Cyanide) — Make the parts anodic at 2 volts maximum.

溶液 3(腐蚀性氰化物) — 使零件阳极电压最大为 2 伏。

(2) Solution 4 (Electrolytic Cleaner) — Make the parts anodic at 40-60 amperes per square foot (asf).

溶液 4(电解清洁剂) — 使零件在 40-60 安培/平方英尺 (asf) 下阳极化。

(3) Solution 5 (Chromium Plate Etch) — Make the parts anodic at 50-150 asf.

溶液 5(铬板蚀刻) — 使零件在 50-150 安培/平方英尺(asf)下阳极化。

(4) Solution 6 — Deleted

溶液 6 — 删除

(5) Solution 7 (Sulfuric Acid) — Make the parts anodic at 2 volts until no current flows.

溶液 7(硫酸) — 使零件在 2 伏电压下阳极化,直到没有电流。

(6) Solution 8 — Total time in the solution must not be more than 60 minutes.

溶液 8 — 在溶液中的总时间不得超过 60 分钟。

(7) Solution 9 (Sodium Hydroxide – Sodium Carbonate) — Make the parts anodic at 4-6 volts. Or, when nickel or nickel alloy base metal is masked with a nonconductive material for local stripping, make the part anodic at 4-5 volts and examine the part frequently.

溶液 9(氢氧化钠-碳酸钠) — 在 4-6 伏电压下使零件阳极化。或者,当镍或镍合金基体金属用不导电材料遮蔽以进行局部剥离时,使零件在 4-5 伏电压下呈阳极状态,并经常检查零件。

(8) Solution 21 — Deleted

溶液 21 — 删除

(9) Solution 24 (Amchem 4, 6, or 7)

溶液 24(Amchem 4、6 或 7)

(a) Put the parts in the solution for 5-30 minutes. Then rinse.

将零件放入溶液中 5-30 分钟。然后冲洗。

(b) As necessary, scrub off loosened coating with a fiber brush, air-water blast, or a Scotch-Brite pad or disk wet with water.

必要时,用纤维刷、水气喷射或用水浸湿的 Scotch-Brite 盘擦洗掉松动的涂层。

(c) Put the parts back in the solution again if necessary to remove remaining coating. Examine them at intervals no longer than every 10-15 minutes. Do not keep the parts in longer than a total of 120 minutes.

如有必要,将零件放回溶液中去除残余涂层。每隔 10-15 分钟检查一次。不要让零件在溶液中停留超过 120 分钟。

NOTE: A scrub is usually necessary to help removal of cured colored conversion coatings, and is better than to try to remove the coating by one long soak.

注意:通常需要进行擦洗,以帮助去除固化的彩色转换涂层,这比长时间浸泡去除涂层要好。

(10) Solution 32 (Nitric Acid-Hydrofluoric Acid Etch) — Soak the parts for 30 seconds maximum. Rinse fully. Do not dry. Continue immediately with subsequent procedures. Do not let the parts dry.

溶液 32(硝酸-氢氟酸蚀刻)– 最多浸泡零件 30 秒。充分冲洗。不要擦干。立即继续执行后续程序。不要让零件干燥。

(11) Solution 36 (Tri-Acid Etchant) — Use the same procedure as for Solution 24, but do not let the parts stay in the solution longer than a total of 60 minutes.

溶液 36(三酸蚀刻液) — 使用与溶液 24 相同的程序,但不要让零件在溶液中停留超过 60 分钟。

(12) Solution 37 (Smut-Go No. 4) — Use the same procedure as for Solution 24.

溶液 37(4 号 Smut-Go) — 使用与溶液 24 相同的程序。

(13) Solution 48 (Deoxidizer No. 2L) — Use the same procedure as for Solution 24.

溶液 48(脱氧剂 2L 号) — 使用与溶液 24 相同的程序。

(14) Solution 56 (Aldox V) — Use the same procedure as for Solution 24, but use a soak time of only 5-10 minutes and a maximum total time of 40 minutes (cold solution) or 30 minutes (hot solution).

溶液 56(Aldox V) — 使用与溶液 24 相同的程序,但浸泡时间仅为 5-10 分钟,总时间最长为 40 分钟(冷溶液)或 30 分钟(热溶液)。

(15) Solution 58 (Solutions as specified in BAC5786) — Refer to BAC5786 for details.

溶液 58 (BAC5786 中规定的溶液) — 详情请参阅 BAC5786。

(16) Solution 60 (Unichrome 80) — To strip chrome, make the parts anodic at 9-12 volts (2-4 amps/square inch).

溶液 60(Unichrome 80)– 要剥铬,使零件在 9-12 伏(2-4 安培/平方英寸)下呈阳极状态。

(17) Solution 66 (Cufix-E) — Make the parts anodic at 25-35 asf (25 asf is best).

溶液 66(Cufix-E) — 使零件在 25-35 安培下阳极化(25 安培最佳)。

(18) Solution 68 (Enstrip C-38)

溶液 68(Enstrip C-38)

(a) We recommend that you mechanically shake the solution.

我们建议您机械地摇动溶液。

(b) If you use baskets, they must be made of titanium.

如果使用篮子,篮子必须由钛制成。

(19) Solution 69 (Metex Copper Stripper F)

溶液 69(Metex 铜剥离剂 F)

(a) We recommend that you mechanically shake the solution or the parts. Do not shake with air.

建议用机械方法摇动溶液或零件。不要用空气摇动。

(b) If you use baskets, they must be made of titanium.

如果使用篮子,篮子必须由钛制成。

(20) Solution 70 (Al-Cu-Strip)

溶液 70(铝铜带)

(a) Do not keep the parts in the initial rinse tank for more than five minutes unless you increase the solution pH above 9.0 with 10% by volume of Alk-Cu-Strip Part A. Or, as an alternative, after the five minutes in the initial rinse tank, remove the parts and put them in an approved alkaline cleaner as specified in BAC5749 (SOPM 20-30-03). Then rinse the parts as specified in BAC5771 par. 9.2.

除非用体积分数为 10%的 Alk-Cu-Strip A 部分将溶液 pH 值提高到 9.0 以上, 否则不要让零件在初始清洗槽中停留超过五分钟。然后按照 BAC5771 第 9.2 段规定的方法冲洗零件。

(b) A hot final rinse can be used to help dry the parts.

最后可使用热冲洗帮助干燥零件。

(21) Solution 71 (Metalx B-9 Nickel stripper) — Make the parts anodic at 3-4 volts.

溶液 71(Metalx B-9 镍剥离剂)– 在 3-4 伏电压下对零件进行阳极处理。

(22) Solution 72 (Low Concentration Nitric Acid) — Total time in the solution must not be more than 60 minutes.

溶液 72(低浓度硝酸) — 在溶液中的总时间不得超过 60 分钟。

(23) Solution 74 (Sodium Carbonate-Tartaric Acid) — Make the parts anodic at 4-6 volts.

溶液 74(碳酸钠-酒石酸) — 使零件在 4-6 伏电压下呈阳极状态。

(24) Solution 75 (Kolene Molten Salts)

溶液 75(Kolene 熔盐)

(a) Abrasive clean as specified in BAC5748 Type 2, Class 1 or 2.

按照 BAC5748 Type 2, Class 1 或 Class 2 的规定进行研磨清洁。

(b) Dry the parts before you put them in the molten salt bath, or the wet parts could splash the molten salt.

在将零件放入熔盐槽之前将其擦干,否则潮湿的零件可能会溅出熔盐。

(c) Put the parts in the molten salt bath, but for no longer than a total of 12 hours.

将零件放入熔盐浴中,但总时间不得超过 12 小时。

(d) Quench and rinse the parts in clean, cold running water for a minimum of 10 minutes.

将零件在干净的流动冷水中急剧冷却和冲洗至少 10 分钟。

(e) Abrasive clean, as necessary, as specified in BAC5748 Type 2, Class 1 or 2 to remove remaining surface contamination.

必要时,按照 BAC5748 Type 2, Class 1 或 Class 2 的规定进行研磨清洗,以去除剩余的表面污染物。

(25) Solution 76 (Oakite Deoxidizer 231) — Use the same procedure as for Solution 24, but use a soak time of only 5-10 minutes and a maximum total time of 30 minutes.

溶液 76(Oakite 脱氧剂 231) — 使用与溶液 24 相同的程序,但浸泡时间仅为 5-10 分钟,总时间最长为 30 分钟。

(26) Solution 77 (Amchem Deoxalume 2300) — Use the same procedure as for Solution 24, but use a soak time of only 5-10 minutes and a maximum total time of 30 minutes.

溶液 77(Amchem Deoxalume 2300) — 使用与溶液 24 相同的程序,但浸泡时间仅为 5-10 分钟,总时间最长为 30 分钟。

(27) Solution 78 (GMC 800) 溶液 78(GMC 800)

(a) Soak the parts for 20-30 minutes, then rinse.

浸泡零件 20-30 分钟,然后冲洗。

(b) Abrasive clean, as necessary, as specified in BAC5748, Type 2, Class 2 or Class 5 to remove the loosened coating.

必要时按照 BAC5748 规定的 2 类 2 级或 5 级进行研磨清洗,以去除松动的涂层。

(c) Do Paragraph 4.D.(27)(a) and Paragraph 4.D.(27)(b) until the remaining coating is removed. The total soak time must be less than 120 minutes.

执行第 4.D.(27)(a)段和第 4.D.(27)(b)段,直至去除剩余涂层。总浸泡时间必须少于 120 分钟。

(28) Solution 79 (Phosphoric Acid) — Put the parts in the solution for 5-10 minutes or until stripped. When you strip anodize coatings from clad aluminum surfaces, make a check of the parts very 5 minutes. Pitting will occur if the parts stay in the solution too long.

溶液 79(磷酸) — 将零件放入溶液中 5-10 分钟,直至剥离。从铝包层表面剥离阳极氧化涂层时,应在 5 分钟后检查零件。如果零件在溶液中停留时间过长,会产生点蚀。

(29) Solution 80 (BAC5765 Heavy Duty Oxidizer) — Use the same procedure as for Type 24.

80 号溶液(BAC5765 重型氧化剂) — 使用与 24 型相同的程序。

(30) Solution 81 (BAC5765 Light Duty Oxidizer) — Use the same procedure as for Type 24.

溶液 81 (BAC5765 轻型氧化剂) — 使用与 24 型相同的程序。

E. Local Stripping

局部剥离

CAUTION :DO NOT USE THIS LOCAL STRIPPING PROCEDURE IF SOLUTIONS COULD BECOME CAUGHT INSIDE THE PARTS.

警告 :如果溶液可能进入零件内部,请勿使用此局部剥离程序。

(1) Use this procedure when it is not recommended to put the parts into the solution to soak them.

当不建议将零件放入溶液中浸泡时,使用此程序。

(2) Remove all organic coatings as specified in Paragraph 3.

按第 3 段规定的方法清除所有有机涂层。

(3) Vapor degrease, solvent clean or manually alkaline clean as specified in SOPM 20-30-03.

按 SOPM 20-30-03 规定的方法进行蒸汽脱脂、溶剂清洗或手工碱洗。

(4) Mask off the areas that will not be stripped.

遮盖不进行剥离的区域。

(5) Apply the stripping solution by spray, brush, swab. Or put the parts into the solution momentarily. For local stripping, these agents are satisfactory: immersion strippers that can be used at room temperature, and manual stripping solutions. Keep the solution on the surfaces the minimum possible time necessary to remove the coating.

用喷雾、刷子或棉签涂抹剥离液。或将零件瞬间放入溶液中。对于局部剥离,这些溶剂是令人满意的:可在室温下使用的浸泡剥离剂和手动剥离溶液。尽量缩短溶液在表面的停留时间,以去除涂层。

(6) Fully rinse with a good flow of water.

用流动的水充分冲洗。

(7) Remove masks. Rinse again.

取下遮盖物。再次冲洗。

(8) Dry all parts unless subsequent procedures will keep the parts wet.

擦干所有零件,除非后续程序会使零件保持潮湿。

(9) Bake the parts as specified in Table 6, if necessary.

如有必要,按表 6 规定的方法烘烤零件。

(10) Keep the parts clean. Apply the specified finish as quickly as possible.

保持零件清洁。尽快涂上规定的饰面。

F. Alternative Stripping Procedures

替代的剥离程序

(1) Use this procedure when a stripping solution is not available because of the small volume of work, or because of process restrictions.

当因工作量小或因程序限制而无法使用剥离液时,使用此程序。

(2) Strip such parts by:

通过以下方法剥除此类零件:

(a) Local stripping as specified by Paragraph 4.E.

按第 4.E 段规定的局部剥离。

(b) Machining or grinding as specified in SOPM 20-10-02.

SOPM 20-10-02 规定的机加工或打磨。

(c) Abrasive cleaning as specified in BAC5748 (SOPM 20-30-03). Aluminum metal polish A-A-59318 can be used to strip local areas on aluminum.

BAC5748(SOPM 20-30-03)规定的研磨清洗。铝金属抛光剂 A-A-59318 可用来剥离铝的局部区域。