镀硬铬HARD CHROME PLATING

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5709. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5709。可访问波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum standards.

数据为通用数据。并不涉及所有情况或特定安装。使用此数据可帮助您编写最低标准。

C. Hard chrome plating done by this subject will agree with AMS 2460 Class 2 (which supersedes AMS-QQ-C-320, Class 2) for steel parts heat treated below 220 ksi and MIL-STD-1501 for steel parts heat treated to 220 ksi and above. Other procedures which give the same results can be used as equivalents.

对于热处理温度低于 220 ksi 的钢制零件,通过本主题完成的硬铬电镀将与 AMS 2460 2 级(取代 AMS-QQ-C-320 2 级)一致;对于热处理温度达到 220 ksi 及以上的钢制零件,将与 MIL-STD-1501 一致。其它可得出相同结果的程序可等同使用。

D. BAC5709 puts chrome plating into 4 classes. Class 1 is decorative chrome plating. Class 2 is hard chrome plating (or plating and grinding) to specified dimensions. Class 3 is the same as Class 2, but with a special pretreatment for a better bond of the plating. Class 4 is a special thin, hard plating with a minimum hardness of Rockwell C 67. If the overhaul instructions do not give the class, use Class 2 or Class 3. If the overhaul instructions refer to BMS 10-70, Type 1 or Type 2, use Class 4.

BAC5709 将镀铬分为四个等级。第 1 级为装饰性镀铬。第 2 级为硬镀铬(或镀铬和打磨),达到规定的尺寸。第 3 级与第 2 级相同,但需进行特殊预处理,以提高镀层的结合力。4 级是一种特殊的薄硬镀层,硬度最低为洛氏硬度 C 67。如果大修说明中没有给出等级,则使用 2 级或 3 级。如果大修说明中提到 BMS 10-70、1 类或 2 类,则使用 4 类。

E. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商名称和地址的清单请参见 SOPM 20-00-00。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

注: 可使用等效替代品。

A. Plating Compound — Unichrome CR-110, V27201

电镀化合物 — Unichrome CR-110、V27201

B. Plating Compound — Unichrome CR-204, V27201

电镀化合物 — Unichrome CR-204,V27201

C. Plating Compound — Econochrome S, V71361

电镀化合物 — Econochrome S,V71361

D. Plating Compound — Econochrome 40, V71361

电镀化合物 — Econochrome 40,V71361

E. Plating Compound — Econochrome 66, V71361

电镀化合物–Econochrome 66,V71361

F. Sulfuric Acid — 66 degree Baume’, Water White, 2.5 ppm Maximum Arsenic

硫酸 — 66 度 Baume’,水白色,最大砷含量 2.5 ppm

G. Hydrochloric Acid — 20 degree Baume’, Technical

盐酸 — 20 度 Baume’,工业级

H. Chromic Acid (Chromium Trioxide), Technical

铬酸(三氧化二铬),工业级

I. Abrasives for Scouring

擦洗用磨料

(1) Wyandotte F-1013 pumice detergent, V83339

Wyandotte F-1013 浮石洗涤剂,V83339

(2) Pumice

浮石

(3) Abrasive paper, silicon carbide

碳化硅研磨纸

(4) Tripoli powder

Tripoli粉

(5) Scotch-Brite pads, No. 7448, silicon carbide, V76381

Scotch-Brite 研磨盘,编号 7448,碳化硅,V76381

J. Anodes

阳极

(1) Lead, 4 to 7 percent tin

铅,4-7% 锡

(2) Lead, 4 to 7 percent antimony

铅,4%-7%的锑

(3) Chemical Lead

化学铅

(4) Nickel, 99% pure: rolled, depolarized, electrolytic grade or carbon-nickel cast and rolled. Optional: sulfur depolarized (SD) nickel chips

镍,纯度 99%:轧制、去极化、电解级或碳镍铸造和轧制。可选项:硫磺去极化(SD)镍片

(5) Carbon

碳

(6) Platinum wire, lead or lead-tin plated steel wire

铂丝、铅丝或镀铅锡钢丝

K. Sodium Cyanide — 97% NaCN minimum, Plating Grade

氰化钠 — 最低含量为 97%的 NaCN,电镀级

L. Sodium Hydroxide — Flake or Granulated, Technical

氢氧化钠 — 片状或颗粒状,工业级

M. Hydrofluoric acid, Technical

工业氢氟酸

N. Nickel Chloride Hexahydrate, Technical

六水氯化镍(Nickel Chloride Hexahydrate),工业级

O. Ammonium bifluoride, Technical

氟化氢铵,工业级

P. Copper Sulfate (CuSO4 .5H2O), Technical

硫酸铜(CuSO4 .5H2O),工业级

Q. Barium Carbonate (BaCO3), Technical

碳酸钡(BaCO3),工业级

3. PREPARATION OF SOLUTION 配制溶液

NOTE: The dilute standard, concentrated standard, and self-regulated high speed chromium plating solutions are alternates for each other.

注:稀释标准溶液、浓缩标准溶液和自调高速镀铬溶液可相互替代。

A. Use distilled or deionized water if the regular water supply is more than the following maximums:

如果常规供水超过以下最大值,则使用蒸馏水或去离子水:

(1) 450 ppm maximum dissolved solids.

450 ppm 最大溶解固体。

(2) 50 ppm maximum dissolved chlorides.

50 ppm 最大溶解氯化物。

B. Chromium Plating Solution, Dilute Standard Bath

镀铬溶液,稀释标准槽

(1) Clean the tank. Then add two-thirds total amount of water.

清洗槽。然后加入总水量的三分之二。

(2) Add 200 pounds chromic acid for each 100 gallons of final solution.

每 100 加仑最终溶液加入 200 磅铬酸。

(3) Fill tank with water to the operating level and mix fully.

向槽中加水至操作水平并充分混合。

(4) Operate the solution at a temperature of 110-140°F (Class 1 plating), 120-140°F (Class 2 plating; 130-140°F is best), 130-140°F (Class 3 plating), or 120-130°F (Class 4 plating).

溶液的操作温度为 110-140°F(1 级电镀)、120-140°F(2 级电镀;130-140°F 最佳)、130-140°F(3 级电镀)或 120-130°F(4 级电镀)。

(5) Control the solution at 30-35 oz/gal chromic acid, CrO3 /SO4 ratio of 80-115 to 1 (Class 1, 2, or 4) or 80-100 to 1 (Class 3), maximum of 0.53 oz/gal trivalent chromium, and maximum of 1.0 oz/gal iron.

将溶液控制在 30-35 盎司/加仑铬酸、CrO3 /SO4 比率为 80-115 比 1(1、2 或 4 级)或 80-100 比 1(3 级)、最多 0.53 盎司/加仑三价铬和最多 1.0 盎司/加仑铁。

NOTE: Do not add sulfuric acid on makeup. After the chromic acid is dissolved and diluted to the correct volume, analyze for sulfates and add sulfuric acid as necessary to adjust the chromate/sulfate ratio. For Class 1, 2, or 4 plating, to make the plating bond better and decrease chicken wire cracks, keep this ratio in the 95-100 to 1 range. For Class 3 plating, keep the ratio in the 90-95 to 1 range.

注意:不要在制备时添加硫酸。铬酸溶解并稀释到正确的体积后,分析硫酸盐并根据需要添加硫酸,以调整铬酸/硫酸的比例。对于 1 级、2 级或 4 级电镀,为了使电镀层更好地结合并减少鸡丝裂纹,应将此比率保持在 95-100 比 1 的范围内。对于 3 级电镀,该比率应保持在 90-95 比 1 的范围内。

(6) Use anodes as necessary. Dummy plate to keep the anodes active, as indicated by a brown-black layer of lead peroxide. A bright yellow surface layer is a sign of lead chromate, which is passive and will decrease plating efficiency. Use auxiliary anodes as necessary to get a continuous plating thickness in recesses and corners. Remove and clean the anodes if the plating bath will not be used for a long time. Keep the anodes in a clean dry place until you use them again.

根据需要使用阳极。通过过氧化铅的棕黑色镀层来显示阳极的活性。亮黄色表层是铬酸铅的迹象,它是被动的,会降低电镀效率。必要时使用辅助阳极,以便在凹槽和拐角处获得连续的镀层厚度。如果电镀槽长时间不使用,应将阳极取出并清洗干净。将阳极放在干净干燥的地方,直到再次使用。

NOTE: A very dark colored bath is usually a sign of too high a chromate concentration, and frequently will occur with passive yellow anodes. This will cause unserviceable plating. To correct the bath you must dummy plate in it a long time, sometimes for days. Do not let organic materials such as solvents, greases, or dirty oily surfaces get into the bath because these break down the chromic acid into chromate ions.

注意:镀液颜色过深通常是铬酸盐浓度过高的表现,被动黄色阳极也会经常出现这种情况。这将导致镀层无法使用。要纠正这种情况,必须在镀液中进行长时间的假镀,有时甚至需要数天。不要让溶剂、油脂或肮脏的油性表面等有机物进入镀液,因为这些物质会将铬酸分解成铬酸根离子。

(7) For Class 1, 2, or 4 plating plate at 1-4 ASI (ferrous alloys) or 1-5 ASI (aluminum and copper alloys). For Class 3, plate at 2-3 ASI.

对于 1、2 或 4 级电镀,镀层为 1-4 ASI(铁合金)或 1-5 ASI(铝和铜合金)。对于第 3 级,镀层为 2-3 ASI。

C. Chromium Plating Solution, Concentrated Standard Bath

镀铬液,浓缩标准槽

(1) Clean the tank. Then add two-thirds total amount of water.

清洗槽。然后加入三分之二的水。

(2) Add 330 pounds chromic acid for each 100 gallons of final solution.

每 100 加仑最终溶液加入 330 磅铬酸。

(3) Fill the tank with water to the operating level and mix fully.

将水注入槽中至操作水平并充分混合。

(4) Operate the solution at a temperature of 120-140°F (Class 1 plating), 110-140°F (Class 2 plating; 130-140°F is best), 130-140°F (Class 3 plating), or 120-130°F (Class 4 plating).

溶液的操作温度为 120-140°F(1 级电镀)、110-140°F(2 级电镀;130-140°F 最佳)、130-140°F(3 级电镀)或 120-130°F(4 级电镀)。

(5) Control the solution at 50-55 oz/gal chromic acid, the same CrO3 /SO4 ratio as for the dilute bath above, maximum of 0.53 oz/gal trivalent chromium, and maximum of 1.0 oz/gal iron.

将溶液控制在 50-55 盎司/加仑铬酸、与上述稀浴相同的 CrO3 /SO4 比率、最多 0.53 盎司/加仑三价铬和最多 1.0 盎司/加仑铁。

NOTE: Do not add sulfuric acid on makeup. After the chromic acid is dissolved and diluted to proper volume, analyze for chromates and add sulfuric acid as necessary to adjust the chromate/sulfate ratio. For Class 1, 2, or 4 plating, to make the plating bond better and decrease chicken wire cracks, keep this ratio in the 95-100 to 1 range. For Class 3 plating, keep the ratio in the 90-95 to 1 range.

注:不要在制备时添加硫酸。在铬酸溶解并稀释到适当体积后,分析铬酸盐并根据需要添加硫酸以调整铬酸盐/硫酸盐比率。对于 1 级、2 级或 4 级电镀,为了使电镀层更好地结合并减少鸡丝裂纹,应将该比率保持在 95-100 比 1 的范围内。对于 3 级电镀,该比率应保持在 90-95 比 1 的范围内。

(6) Use anodes as necessary.

必要时使用阳极。

(7) Plate at the same current densities as for the dilute bath above.

在与上述稀浴相同的电流密度下进行电镀。

D. Self Regulating High Speed Unichrome CR-110 Bath

自调节式高速 Unichrome CR-110 喷浴槽

(1) Clean the tank. Then add two-thirds total amount of water. Adjust temperature to 120°F.

清洗水槽。然后加入总水量的三分之二。将温度调至 120°F。

(2) Add 230 pounds of Unichrome CR-110 for each 100 gallons of final solution. Mix into solution for 2-3 hours.

每 100 加仑最终溶液加入 230 磅 Unichrome CR-110。与溶液混合 2-3 小时。

(3) Fill the tank with water to operating level and mix fully.

将水箱注满水至操作水平并充分混合。

(4) Operate the solution at 120-140°F (Class 1, 2, or 4 plating) or 130-140°F (Class 3 plating).

将溶液的温度控制在 120-140°F(1、2 或 4 级电镀)或 130-140°F(3 级电镀)。

(5) Control the solution at 33.6-40.0 ounces of Unichrome CR-110 per gallon of water. Adjust with CR-204 or CR-110 added by the manufacturer’s instructions. Mix the solution for 2-3 hours after makeup or additions.

将溶液控制在每加仑水含 33.6-40.0 盎司 Unichrome CR-110。根据制造商的说明添加 CR-204 或 CR-110 进行调整。制备或添加后,将溶液混合 2-3 小时。

NOTE: If you must remove a small amount of CR-204 or CR-110 from a large container, be sure to mix the contents of the container first to make sure the catalyst concentration is constant in all of the material.

注: 如果必须从一个大容器中取出少量 CR-204 或 CR-110,一定要先混合容器中的物质,以确保所有物质中的催化剂浓度恒定。

(6) Use anodes as necessary.

必要时使用阳极。

(7) For Class 1, 2, or 4 plating, plate at 1-4 ASI (ferrous alloys) or 1-5 ASI (aluminum and copper alloys). For Class 3 plating, plate at 2-3 ASI.

对于 1、2 或 4 级电镀,在 1-4 ASI(铁合金)或 1-5 ASI(铝和铜合金)下进行电镀。对于 3 级电镀,以 2-3 ASI 进行电镀。

E. Econochrome S Bath

Econochrome S 电镀槽

(1) Clean the tank. Then add two-thirds total amount of water. Adjust temperature to 125°F.

清洗槽。然后加入三分之二的水。将温度调至 125°F。

(2) Add 125 pounds of Econochrome S for each 100 gallons of final solution. Mix until fully dissolved.

每 100 加仑最终溶液加入 125 磅 Econochrome S。搅拌至完全溶解。

(3) Fill the tank with water to the operating level and mix fully.

将水槽注满水至操作水位并充分混合。

(4) Operate the solution at 115-150°F (Class 1 plating), 120-140°F (Class 2 plating; 130-140°F is best), 130-140°F (Class 3) or 120-130°F (Class 4).

溶液的操作温度为 115-150°F(1 级电镀)、120-140°F(2 级电镀;130-140°F 最佳)、130-140°F(3 级)或 120-130°F(4 级)。

(5) Control the solution at 18-21 oz Econochrome S per gallon with a CrO3/66 ratio of 5.0-6.7 and a CrO3 /SO4 ratio of 105-200 to 1 (125-155 to 1 is best) for Class 1, 2, or 4, or 85-105 to 1 for Class 3.

将溶液控制在每加仑 18-21 盎司 Econochrome S,CrO3/66 比率为 5.0-6.7,CrO3/SO4 比率为 105-200 比 1(125-155 比 1 最佳)(1、2 或 4 级),或 85-105 比 1(3 级)。

NOTE: The CrO3 /66 ratio is ounces per gallon of chromates to units per gallon of Econochrome 66, where 1 unit is 1.28 fluid ounce of Econochrome 66. For Class 1, 2, or 4 plating, to make the plating bond better and decrease chicken wire cracks, keep this ratio in the 95-100 to 1 range. For Class 3 plating, keep the ratio in the 90-95 to 1 range.

注: CrO3 /66 比率是指每加仑铬酸盐的盎司数与每加仑 Econochrome 66 的单位数之比,其中 1 单位为 1.28 液量盎司的 Econochrome 66。对于 1 级、2 级或 4 级电镀,为了使电镀层更好地结合并减少鸡丝裂纹,应将这一比率保持在 95-100 比 1 的范围内。对于 3 级电镀,该比例应保持在 90-95 比 1 的范围内。

(6) Add sulfuric acid to bring sulfate within limits.

加入硫酸,将硫酸盐含量控制在一定范围内。

(7) For Class 1, 2, or 4 plating, plate at 1.0-4.5 ASI. For Class 3 plating, plate at 2-3 ASI.

对于 1、2 或 4 级电镀,在 1.0-4.5 ASI 下进行电镀。对于 3 级电镀,在 2-3 ASI 下进行电镀。

F. Econochrome 40 Bath

Econochrome 40 染色槽

(1) Clean the tank Then add two-thirds total amount of water.

清洗槽,然后加入三分之二的水。

(2) Add 205 pounds of Econochrome 40 for each 100 gallons of final solution, and mix until fully dissolved.

每 100 加仑最终溶液加入 205 磅 Econochrome 40,搅拌至完全溶解。

(3) Fill the tank with water to the operating level.

将水槽注满水至操作水位。

(4) Operate the solution at 115-150°F (Class 1 plating), 120-140°F (Class 2 plating; 130-140°F is best), 130-140°F (Class 3 plating) or 120-140°F (Class 4 plating).

将溶液的温度控制在 115-150°F(1 级电镀)、120-140°F(2 级电镀;130-140°F 最佳)、130-140°F(3 级电镀)或 120-140°F(4 级电镀)。

(5) Control the solution at 18-40 ounces Econochrome 40 per gallon (28-32 oz/gal is best) with a CrO3 /66 ratio of 25-50 to 1 and a CrO33/SO4 ratio of 75-200 to 1 (75-125 is best), for Classes 1, 2, or 4, or 85-105 to 1 for class 3.

将溶液控制在每加仑 18-40 盎司 Econochrome 40(28-32 盎司/加仑最佳),CrO3 /66 比率为 25-50 比 1,CrO33/SO4 比率为 75-200 比 1(75-125 比 1 最佳),适用于 1、2 或 4 级,或 85-105 比 1 适用于 3 级。

NOTE: The CrO3 /66 ratio is ounces per gallon of chromates to units per gallon of Econochrome 66, where 1 unit is 1.28 fluid ounce of Econochrome 66. For Class 1, 2, or 4 plating, to make the plating bond better and decrease chicken wire cracks, keep this ratio in the 95-100 to 1 range. For Class 3 plating, keep the ratio in the 90-95 to 1 range.

注:CrO3 /66 比率是指每加仑铬酸盐的盎司数与每加仑 Econochrome 66 的单位数之比,其中 1 单位为 1.28 液量盎司的 Econochrome 66。对于 1 级、2 级或 4 级电镀,为了使电镀层更好地结合并减少鸡丝裂纹,应将这一比率保持在 95-100 比 1 的范围内。对于 3 级电镀,该比例应保持在 90-95 比 1 的范围内。

(6) Add sulfuric acid to adjust the sulfate within limits.

加入硫酸,将硫酸盐调整到一定范围内。

(7) For Class 1, 2, or 4 plating, plate at 1.0-4.5 ASI. For Class 3 plating, plate at 2-3 ASI.

对于 1、2 或 4 级电镀,在 1.0-4.5 ASI 下进行电镀。对于 3 级电镀,在 2-3 ASI 下进行电镀。

G. Sulfuric Acid Etch Solution

硫酸蚀刻液

(1) Clean the tank. Then mix 10 gallons sulfuric acid and 90 gallons water for each 100 gallons final solution.

清洗槽。然后为每 100 加仑最终溶液混合 10 加仑硫酸和 90 加仑水。

(2) Operate the solution at a temperature of 86°F maximum.

溶液的最高温度为 86°F。

(3) Control the solution at 20.0-24.0 oz/gal sulfuric acid.

将溶液控制在 20.0-24.0 盎司/加仑硫酸。

H. Chromic Acid Etch Solution

铬酸蚀刻溶液

(1) Clean the tank. Then mix a solution of 30-50 ounces chromic acid for each gallon of final solution.

清洗槽。然后为每加仑最终溶液混合 30-50 盎司铬酸溶液。

(2) Operate the solution at room temperature.

在室温下操作溶液。

I. Cyanide Holding Solution

氰化物保持溶液

(1) Clean the tank. Then add one-half total amount of water.

清洗槽。然后加入总量二分之一的水。

(2) Add 31.0 pounds sodium cyanide for each 100 gallons of final solution. Stir until dissolved.

每 100 加仑最终溶液加入 31.0 磅氰化钠。搅拌直至溶解。

(3) Add 10.0 pounds sodium hydroxide for each 100 gallons of final solution. Add chemical slowly, or the solution will get too hot. Stir until dissolved.

每 100 加仑最终溶液加入 10.0 磅氢氧化钠。缓慢加入化学品,否则溶液会过热。搅拌直至溶解。

(4) Fill the tank with water to the operating level.

将水注入槽内至操作水位。

(5) Operate the solution at room temperature.

在室温下操作溶液。

(6) Control the solution at 4.0-5.0 oz/gal sodium cyanide and 1.0-2.0 oz/gal sodium hydroxide.

将溶液控制在 4.0-5.0 盎司/加仑氰化钠和 1.0-2.0 盎司/加仑氢氧化钠。

J. Sulfuric Acid – Hydrofluoric Acid Etch Bath

硫酸-氢氟酸蚀刻槽

(1) Clean the tank. Then mix 25 gallons sulfuric acid, 4 gallons of 70% hydrofluoric acid, or 6.5 gallons of 45% hydrofluoric acid, or 46 pounds ammonium bifluoride, and 71 gallons of water for each 100 gallons of final solution.

清洗槽。然后混合 25 加仑硫酸、4 加仑 70% 氢氟酸或 6.5 加仑 45% 氢氟酸或 46 磅氟化氢铵,以及 71 加仑水(每 100 加仑最终溶液)。

NOTE: You can use other concentrations of hydrofluoric acid if you adjust the quantity of acid.

注:如果调整酸的数量,可以使用其他浓度的氢氟酸。

(2) Operate the solution at 60-100°F.

将溶液的温度控制在 60-100°F。

(3) Control the solution at 50-70 oz/gal sulfuric acid, 3-6 oz/gal fluoride, 1.5 oz/gal maximum dissolved iron.

将溶液控制在 50-70 盎司/加仑硫酸、3-6 盎司/加仑氟化物、1.5 盎司/加仑最大溶解铁。

K. Nickel Strike Bath

镍击槽

(1) Clean the tank. Then fill to three-quarter level with water.

清洗槽。然后加水至四分之三水位。

(2) Add 200 pounds nickel chloride for each 100 gallons of final solution and stir until fully dissolved.

每 100 加仑最终溶液加入 200 磅氯化镍,搅拌至完全溶解。

(3) Add 8.6 gallons hydrochloric acid for each 100 gallons of final solution and stir.

每 100 加仑最终溶液加入 8.6 加仑盐酸并搅拌。

(4) Fill tank with water to operating level and stir.

在槽中加水至操作水位并搅拌。

(5) Operate the solution at 60-100°F.

将溶液的温度控制在 60-100°F。

(6) Control the solution at 30-35 oz/gal nickel chloride hexahydrate, 3.7-4.3 oz/gal HCl, and 1 oz/gal maximum dissolved iron. Make up a new bath when the maximum iron level is reached. Use nickel or carbon anodes, or both, as required to control the nickel concentration. Remove the nickel anodes if the bath will not be used for a long time.

将溶液控制在 30-35 盎司/加仑六水氯化镍、3.7-4.3 盎司/加仑盐酸和 1 盎司/加仑最大溶解铁。达到最大铁含量时,重新配制新的溶液。根据需要使用镍阳极或碳阳极,或两者兼用,以控制镍浓度。如果水浴长时间不使用,请移除镍阳极。

L. Procedure to Decrease Sulfates in Chrome Plating Bath

减少镀铬液中硫酸盐的程序

(1) Use this procedure only when the usual controls do not decrease the sulfates.

只有在通常的控制方法不能降低硫酸盐时,才使用此步骤。

(2) Before you add the barium carbonate powder, mix up the plating bath for a minimum of 1 minute.

加入碳酸钡粉之前,先将镀液搅拌至少 1 分钟。

(3) Slowly add barium carbonate over the surface of the bath. Continue to mix the bath for a minimum of 30 minutes. Do not use too much barium carbonate. One weight part of barium carbonate will remove 0.3 weight parts of sulfate ion.

在镀液表面缓慢加入碳酸钡。继续搅拌镀液至少 30 分钟。不要使用过多的碳酸钡。1 重量份的碳酸钡可去除 0.3 重量份的硫酸根离子。

(4) Turn off the agitation. Let the barium sulfate settle for a minimum of 4 hours.

关闭搅拌。让硫酸钡沉淀至少 4 小时。

(5) Carefully pump the liquid layer of the bath into a clean tank, but do not include the bottom layer of precipitates. Discard the layer of precipitate and clean the tank.

小心地将槽液层泵入干净的槽中,但不包括底层沉淀。丢弃沉淀层并清洗槽。

(6) Send the removed chrome plating solution through a filter and back into the cleaned tank.

将取出的镀铬液通过过滤器送回清洁槽。

(7) Make an analysis of the plating solution and adjust the concentrations as necessary.

对镀液进行分析,必要时调整浓度。

4. PLATING SOLUTION SLUDGE REMOVAL 去除镀液沉淀物

A. Remove sludge from the self-regulating high speed chromium plating solution (Paragraph 3.D.) as follows:

按以下步骤清除自动调节式高速镀铬溶液(第 3.D 段)中的沉淀物:

(1) Heat the solution to 150°F.

将溶液加热至 150°F。

(2) Stir the solution to put the sludge back into the solution.

搅拌溶液,将沉淀物回到溶液中。

(3) Let the bath settle for at least 30 minutes.

让镀液沉淀至少 30 分钟。

(4) Siphon off all but a few inches of the solution into a clean tank, heated if possible.

用虹吸管将除几英寸以外的所有溶液吸入一个干净的槽中,如有可能,应加热该槽。

(5) Manually remove the sludge and the remaining solution from the plating tank.

手动清除镀槽中的沉淀物和剩余溶液。

(6) Fully clean the plating tank.

全面清洗电镀槽。

(7) Put the siphoned-off solution back in the plating tank.

将虹吸出的溶液放回镀槽。

(8) Adjust the solution to the correct concentration with Unochrome CR-110 plating compound added as specified in Paragraph 3.D.(5).

按照第 3.D.(5)段的规定加入 Unochrome CR-110 电镀剂,将溶液调整到正确的浓度。

(9) Heat solution to a temperature of 135-145°F.

将溶液加热至 135-145°F。

(10) Add 5 pounds Unichrome CR-204 plating compound for each 100 gallons of solution, as you stir, until no more plating compound will dissolve. Too much of this plating compound is not a problem for the bath.

每 100 加仑溶液加入 5 磅 Unichrome CR-204 电镀剂,边搅拌边加入,直到不再有电镀剂溶解为止。电镀液过多不会有问题。

(11) Adjust solution temperature to 120-140°F.

将溶液温度调至 120-140°F。

B. Remove sludge from the other plating solutions with a filter and an acid proof filter pump, or siphon off the liquid into a clean holding tank and remove the sludge manually from the plating tank.

用过滤器和防酸过滤泵清除其他镀液中的沉淀物,或用虹吸管将镀液吸入干净的保温槽中,然后用手将沉淀物从镀槽中清除。

C. Use a 5-micron filter to remove fine particulate matter when you siphon off the solution and when you put it back in the plating bath.

在虹吸溶液和将溶液放回电镀槽时,使用 5 微米过滤器去除微粒物质。

5. PREPARATION OF PARTS 零件的准备

A. General

通用

(1) Unless specified by the overhaul instructions, surfaces to be Class 2 or 3 plated must have a 63 microinch finish or smoother.

除非大修说明有规定,否则 2 级或 3 级电镀表面必须达到 63 微英寸或更光滑。

(2) Unless specified by overhaul instructions, the surfaces to be Class 4 plated must be smooth, without defects that will not let the part be serviceable. All important surfaces to be Class 4 plated must have a 32-microinch finish or smoother.

除非大修说明有规定,否则 4 级电镀的表面必须光滑,没有使零件不能使用的缺陷。所有要镀 4 级的重要表面必须有 32 微英寸或更光滑。

(3) Unless specified, do not chrome plate until all base-metal heat treatment and mechanical operations (machining, brazing, welding, forming, perforating, etc.) have been completed.

除非另有规定,在完成所有基体金属热处理和机械操作(机加工、钎焊、焊接、成型、穿孔等)之前,不得进行镀铬。

(4) Some ferrous alloy parts heat treated 160 ksi and above must be stress relieved before plating. Refer to Paragraph 5.B. for details.

某些经热处理 160 ksi 及以上的铁合金部件必须在电镀前消除应力。详见第 5.B 段。

B. Before you plate, stress relieve low alloy and corrosion-resistant steel parts as specified in the overhaul instructions. Where no stress relief details are given, stress relieve as specified in SOPM 20-10-02.

在电镀前,应按照大修说明中的规定对低合金钢和耐腐蚀钢部件进行应力消除。如无消除应力的详细说明,则按 SOPM 20-10-02 的规定消除应力。

6. PLATING PROCESSES 电镀工艺

A. General

通用

(1) Unless specified by the overhaul instructions, the plating thickness must be 0.003 inch minimum for Class 2 and 3, and 0.0003-0.0005 inch for Class 4. The maximum plating thickness is 0.015 inch. The minimum and maximum thickness limits apply after all specified metal finishing operations are completed.

除非大修说明另有规定,镀层厚度对于 2 级和 3 级必须至少为 0.003 英寸,对于 4 级必须为 0.0003-0.0005 英寸。最大镀层厚度为 0.015 英寸。最小和最大厚度限制适用于所有规定的金属表面处理操作完成后。

(2) See Table 1 to help you make estimates of time necessary for a specified plating thickness. Actual plating rates could be smaller or larger by 50% or more from these values because of anodes or plating solutions.

请参见表 1,以帮助您估算达到指定镀层厚度所需的时间。由于阳极或电镀溶液的原因,实际电镀率可能比这些数值小或大50%或更多。

(3) Surfaces must be water-break-free after they were in a processing solution or rinse, unless after vapor degreasing, solvent cleaning, or emulsion cleaning. A water-break-free surface is a surface which keeps a continuous water film for at least 30 seconds after they were sprayed or put into clean water cooler than 100°F. Clean parts again if they get water breaks.

除非经过蒸气脱脂、溶剂清洗或乳液清洗,否则表面在加工溶液或冲洗后必须无断水裂痕。无断水表面是指在喷洒或放入温度低于 100 华氏度的清水中至少 30 秒钟后,表面仍能保持一层连续的水膜。如果出现断水,请再次清洗零件。

(4) You can temporarily stop the current during plating to measure dimensions with Procedure 1 or 2, as follows:

您可以在电镀过程中暂时停止电流,用程序 1 或程序 2 测量尺寸,方法如下:

(a) Procedure 1

程序 1

1) Decrease the current to zero amperes.

将电流降至零安培。

2) Remove the part and measure the dimensions. Keep the part wet with the chrome plating solution while the part out is of the bath.

取出零件并测量尺寸。在零件离开镀槽时,保持镀铬溶液浸湿零件。

3) Put the part back in the bath in 5 minutes or less.

在 5 分钟或更短时间内将零件放回电镀槽。

4) Let the part get back to solution temperature with the current off for 10 minutes.

让零件恢复到溶液温度,关闭电流 10 分钟。

5) Anodic etch in plating bath at 1-2 ASI for 30 seconds to 1 minute.

在 1-2 ASI 的电镀槽中阳极蚀刻 30 秒至 1 分钟。

6) Apply cathodic current at 5-60 asf (0.03-0.42 ASI) for 10 minutes.

以 5-60 ASF(0.03-0.42 ASI)的电流施加阴极电流 10 分钟。

7) Slowly increase the current to the specified plating density and continue plating.

缓慢增加电流至指定的电镀密度,然后继续电镀。

(b) Procedure 2

程序 2

1) Decrease the current to zero amps but do not turn the power off.

将电流降至零安培,但不要关闭电源。

2) Remove the part from the bath and measure the dimensions. If the part is touched or rinsed, keep it wet with water or the chrome plating solution. If the part is not touched or rinsed, you can let the solution dry on the part.

将零件从镀槽中取出并测量尺寸。如果接触或冲洗过零件,则用水或镀铬液保持其湿润。如果没有接触或冲洗过零件,可以让溶液在零件上干透。

3) Put the part back in the bath at zero amps in 5 minutes or less.

在 5 分钟或更短时间内将零件放回零安培的镀槽中。

4) Let the parts soak for 2-5 minutes at zero amps with the power on.

接通电源,让零件在零安培下浸泡 2-5 分钟。

5) Increase the current to the specified current density in the next 5-10 minutes and continue plating.

在接下来的 5-10 分钟内将电流增加到规定的电流密度,然后继续电镀。

(5) If you must temporarily stop the current, use one of these procedures to reactivate and continue plating:

如果必须暂时停止电流,可使用以下程序之一重新启动并继续电镀:

(a) Procedure 1 (preferred)

程序 1(首选)

1) Vapor degrease, alkaline clean, solvent clean, or emulsion clean (SOPM 20-30-03).

蒸汽脱脂、碱性清洗、溶剂清洗或乳液清洗(SOPM 20-30-03)。

2) Continue with Paragraph 6.A.(4)(a)4) or Paragraph 6.A.(4)(b)5) above.

继续执行上文第 6.A.(4)(a)4)段或第 6.A.(4)(b)5)段。

(b) Procedure 2 (optional)

程序 2(可选)

1) Vapor degrease, alkaline clean, solvent clean, or emulsion clean (SOPM 20-30-03).

蒸汽脱脂、碱性清洗、溶剂清洗或乳液清洗 (SOPM 20-30-03)。

2) Electrolytically clean with Endox 214 (BAC5625 Solution 21)

使用 Endox 214 进行电解清洗(BAC5625 溶液 21)

a) Put the parts in the Endox 214 solution. Set the voltage at 4-6 volts DC and periodic reverse clean, 15 seconds anodic and 5 seconds cathodic, for 3 minutes. End with an anodic cycle for 10-20 seconds.

将零件放入 Endox 214 溶液中。将电压设置为 4-6 伏直流,进行周期性反向清洁,阳极 15 秒,阴极 5 秒,持续 3 分钟。最后进行 10-20 秒的阳极循环。

b) Remove the parts and visually examine the surface. Remove visible contamination with fine silicon carbide abrasive paper or a gray Scotch-Brite pad wet with the Endox 214 solution.

取出零件并目视检查表面。用细碳化硅研磨纸或沾有 Endox 214 溶液的灰色 Scotch-Brite 垫清除可见污染物。

3) Do Paragraph 6.A.(5)(b)2)a) again.

再次执行第 6.A.(5)(b)2)a)段。

4) Water rinse for 5-7 minutes. Do not let the parts dry.

水冲洗 5-7 分钟。不要让零件干燥。

5) Make electrical connections. Set the rectifier at zero volts and put the parts into the chrome plate solution. Let the parts soak 5-7 minutes.

进行电气连接。将整流器设置为零伏,然后将零件放入铬板溶液中。让零件浸泡 5-7 分钟。

6) Increase the current to the specified current density in the next 5-10 minutes and continue to plate.

在接下来的 5-10 分钟内将电流增加到规定的电流密度,然后继续镀铬。

(6) The bare part surface or the chrome plated surface can be polished, buffed, lapped, honed, or ground to get the specified surface finish and dimensions. Obey these precautions:

可对裸零件表面或镀铬表面进行抛光、磨光、研磨或磨削,以获得规定的表面光洁度和尺寸。请遵守以下注意事项

(a) Polish or buff only with soft polishing or buffing wheels, 50-grit or finer abrasive, and light pressure on the surface. Do not let local areas of Class 2 or 3 plated parts become hotter than the stress relief temperature. Do not let Class 4-plated parts get too hot to hold with bare hands.

只能使用柔软的抛光轮或磨光轮、50 级或更细的磨料进行抛光或磨光,并在表面上轻压。不要让 2 级或 3 级电镀零件的局部区域温度超过应力消除温度。不要让 4 级镀层零件温度过高而无法用手握住。

(b) Grind the chrome plate as specified in SOPM 20-10-04, but do not grind the Class 4 chrome plate. This is a special thin dense chrome plate which is applied to get the specified dimensions directly, without subsequent mechanical procedures.

按照 SOPM 20-10-04 的规定磨削镀铬板,但不要磨削 4 级镀铬板。这是一种特殊的薄致密镀铬板,可直接获得规定尺寸,无需后续机械程序。

B. Ferrous Alloys

铁合金

(1) Stress relieve as specified in Paragraph 5.B., if necessary.

如有必要,按第 5.B 段的规定消除应力。

(2) Shot peen as specified in SOPM 20-10-03, if necessary.

如有必要,按 SOPM 20-10-03 的规定进行喷丸处理。

(3) Vapor degrease, solvent clean, or emulsion clean as specified in SOPM 20-30-03.

按 SOPM 20-30-03 规定进行蒸汽脱脂、溶剂清洗或乳剂清洗。

(4) For parts to be Class 1, 2, or 4 plated:

对于 1 级、2 级或 4 级电镀的零件:

(a) As an option for steels heat treated below 180 ksi, alkaline clean as specified in SOPM 20-30-03 and rinse, then clean with specified abrasives, or dry abrasive blast as specified in SOPM 20-30-03.

对于热处理温度低于 180 ksi 的钢材,可选用 SOPM 20-30-03 中规定的碱性清洁和冲洗,然后用规定的磨料清洁,或 SOPM 20-30-03 中规定的干式喷砂。

(b) If rust or scale is present

如果存在铁锈或垢

1) Parts below 180 ksi: Clean and descale as specified in SOPM 20-30-03.

低于 180 ksi 的零件: 按照 SOPM 20-30-03 的规定进行清洁和除垢。

2) Parts above 180 ksi: Abrasive clean as specified in SOPM 20-30-03, grind or polish if required. If you grind the parts, stress relieve them again.

高于 180 ksi 的零件: 按照 SOPM 20-30-03 的规定进行研磨清洁,必要时进行研磨或抛光。如果对零件进行研磨,则应再次进行应力消除。

(5) For steels to be Class 3 plated, dry abrasive blast, with 80-120 grit aluminum only, as specified in SOPM 20-30-03. As an option for Class 3 plating less than 0.0007 inch thick on surfaces 32-microinch finish or smoother, lightly sand the surfaces, or polish them. If more masking is necessary, after you apply the masks, manually solvent clean the unmasked areas with MEK, acetone, or BMS 11-7 solvent as specified in SOPM 20-30-03.

对于要进行 3 级电镀的钢材,按照 SOPM 20-30-03 的规定,仅使用 80-120 粗细度的铝材进行干式喷砂。对于厚度小于 0.0007 英寸的 3 级电镀,表面光洁度为 32 微英寸或更光滑,可选择对表面进行轻度打磨或抛光。如果需要更多的遮蔽物,在涂抹遮蔽物后,按照 SOPM 20-30-03 的规定,用 MEK、丙酮或 BMS 11-7 溶剂手动清洗未遮蔽的区域。

(6) If plating must wait more than 10 minutes for wet parts:

如果电镀必须等待潮湿零件超过 10 分钟,则应:

(a) Put parts in cyanide holding solution for a maximum of 4 hours.

将零件放入氰化物保持溶液中最多 4 小时。

(b) Cold water rinse. If a water-break-free surface does not occur, do Paragraph 6.B.(4) or Paragraph 6.B.(5) again.

冷水冲洗。如表面未出现无水裂纹,则再次执行第 6.B.(4)段或第 6.B.(5)段。

(7) If plating must wait more than two hours for abrasive cleaned parts or more than 16 hours for polished parts, make sure there are no signs of corrosion, dirt, or discoloration after you use one of these two procedures:

如果磨料清洗过的零件电镀必须等待两小时以上,或抛光过的零件电镀必须等待 16 小时以上,则在使用这两种程序之一后,应确保没有腐蚀、污垢或变色的迹象:

(a) Hold the parts at ambient conditions for a maximum of six hours in a clean area with protection from dust and fumes.

将零件放在防止灰尘和烟雾的清洁区域内,在环境条件下放置最多 6 小时。

(b) Put the parts in cyanide holding solution (Solution 11 of BAC5625 or BAC5751) for a maximum of four hours.

将零件放入氰化物保存溶液(BAC5625 或 BAC5751 的溶液 11)中最多四小时。

(8) For Class 1, 2, or 4 plating on corrosion resistant steel, nickel and cobalt based alloys, and other heat resistant alloys, do Paragraph 6.B.(8)(a), Paragraph 6.B.(8)(b), or Paragraph 6.B.(8)(c); then do Paragraph 6.B.(8)(d).

在耐腐蚀钢、镍基和钴基合金以及其他耐热合金上进行第 1、2 或 4 级电镀时,应执行第 6.B.(8)(a)、6.B.(8)(b)或 6.B.(8)(c)段;然后执行第 6.B.(8)(d)段。

(a) Nickel strike anodically in nickel strike bath for up to 2 minutes at 30-35 asf. Follow immediately with cathodic current for 3-4 minutes at 10-15 asf.

在镍镀槽中以 30-35 asf 阳极电击 2 分钟。然后立即以 10-15 asf 的电压进行 3-4 分钟的阴极电流。

(b) Anodic etch in plating bath at 1-2 ASI for 30 seconds to 5 minutes.

在电镀槽中以 1-2 ASI 阳极蚀刻 30 秒至 5 分钟。

(c) Cathodically treat in sulfuric acid bath at 5-6 volts for 2-3 minutes at room temperature.

在室温下,在 5-6 伏特的硫酸槽中阴极处理 2-3 分钟。

(d) Cold water rinse (100°F maximum).

冷水冲洗(最高 100°F)。

(9) For Class 3 plating (and optionally for Class 2 plating) on PH or low alloy steels or parts with areas of nickel plating:

在 PH 或低合金钢或有镀镍区域的零件上进行第 3 级电镀(可选择进行第 2 级电镀):

(a) Put the part in sulfuric-hydrofluoric acid etch solution with current off.

电流关闭时将零件放入硫酸-氢氟酸蚀刻溶液中。

(b) Activate anodically at 3-4 ASI (3-6 ASI for PH steels) for 60-70 seconds.

在 3-4 ASI(PH 钢为 3-6 ASI)下阳极活化 60-70 秒。

(c) Cold water rinse.

冷水冲洗。

(d) Examine the surfaces. A uniform brown to black smut will be on the low alloy steel, but no change in appearance will occur on nickel plated surfaces or PH steels. The smut on low alloy steel is necessary for a good bond of the chrome plating.

检查表面。低合金钢上会出现均匀的棕色至黑色污点,但镀镍表面或 PH 钢的外观不会发生变化。低合金钢上的污点是镀铬层良好结合所必需的。

(e) Keep the surfaces wet and move the parts to the plating bath within 7 minutes.

保持表面湿润,并在 7 分钟内将零件移入镀槽。

(10) For Class 3 plating (and optionally for Class 2 plating) on nickel-based alloys:

在镍基合金上进行第 3 级电镀(可选择进行第 2 级电镀):

(a) Procedure 1 (preferred)

程序 1(首选)

1) Air-water-pumice blast (BAC5748 Type 2, Class 2), then

空气-水-浮石喷射(BAC5748 第 2 类,第 2 级),然后

2) Periodic reverse treat in Enprep 214 (BAC5625 Solution 16D) at 4-7 volts. Start anodic for 15-20 seconds. The anodic cycle time must be longer than the cathodic cycle time. Always end on the anodic cycle. Continue to periodic reverse treat for 2-10 minutes or until the surfaces are water-break-free.

在 4-7 伏的 Enprep 214(BAC5625 溶液 16D)中进行周期性反向处理。开始阳极处理 15-20 秒。阳极循环时间必须长于阴极循环时间。始终在阳极周期结束。继续周期性反向处理 2-10 分钟,或直到表面无水渍。

3) Cold water rinse for a minimum of 2 minutes.

冷水冲洗至少 2 分钟。

(b) Procedure 2 (optional)

步骤 2(可选)

1) Put the part in sulfuric-hydrofluoric acid etch solution with the current off.

将零件放入硫酸-氢氟酸蚀刻溶液中,电流关闭。

2) Activate anodically at 0.5-1.0 ASI for 45-60 seconds.

在 0.5-1.0 ASI 下阳极活化 45-60 秒。

3) Cold water rinse.

冷水冲洗。

4) Keep the surfaces wet and move the parts to the plating bath within 7 minutes.

保持表面湿润,并在 7 分钟内将零件移至电镀槽中。

(11) For Class 3 plating of nickel alloys, set the voltage at 1.5-2.5 volts. Then put the parts in the plating bath for 1-5 minutes as necessary to heat the parts to the solution temperature. For all parts other than Class 3 plating of nickel alloys, put the parts in the plating bath, with the current off, for 1-10 minutes as necessary to heat the parts to the temperature of the solution. As an option, strike at 3-5 ASI for 30-90 seconds, then decrease the plating current to the correct range and plate to get the specified thickness, as follows:

对于镍合金的 3 级电镀,将电压设定在 1.5-2.5 伏。然后根据需要将零件放入电镀槽 1-5 分钟,使零件加热到溶液温度。对于镍合金 3 级电镀以外的所有零件,根据需要将零件放入电镀槽 1-10 分钟,关闭电流,将零件加热到溶液温度。也可选择在 3-5 ASI 下电镀 30-90 秒,然后将电镀电流减小到正确的范围,再进行电镀,以获得规定的厚度,如下所示:

(a) For Class 2, plate at the current density specified for the solution you use. Adjust the current density to make allowance for the solution temperature. A lower solution temperature requires a lower current density.

对于 2 级,以所用溶液规定的电流密度进行电镀。根据溶液温度调整电流密度。溶液温度越低,电流密度越低。

(b) For Class 3 plating, decrease the current to 2-3 ASI and plate to the specified thickness.

对于 3 级电镀,将电流减小到 2-3 ASI,并按规定厚度进行电镀。

(c) For Class 4 plating, plate at the current density and temperature that gives the necessary hardness, usually at higher current densities and lower temperatures. Plating that is too thick will have decreased bond strength and an increased risk of chicken wire cracks.

对于 4 级电镀,电镀时的电流密度和温度应达到所需的硬度,通常电流密度越大,温度越低。镀层太厚会降低结合强度,增加鸡丝裂纹的风险。

(12) Cold water rinse (100°F maximum), followed by hot water rinse (above 130°F), if necessary to help dry the parts.

冷水冲洗(最高 100°F),必要时再用热水冲洗(130°F 以上),以帮助干燥零件。

(13) Remove maskants and dry with clean, moisture-free compressed air.

去除掩蔽剂,用清洁、无湿气的压缩空气吹干。

(14) Bake parts within 10 hours as specified in Paragraph 7.

按照第 7 段的规定,在 10 小时内烘烤零件。

C. Aluminum and Aluminum Alloys

铝及铝合金

(1) Prepare parts for plating as specified in SOPM 20-42-04. Do not let the part dry after the last rinse of the preparation procedure.

按照 SOPM 20-42-04 的规定准备零件进行电镀。在准备程序的最后一次冲洗后,不要让零件干燥。

(2) Put the parts in the plating bath, with power off, for 1-10 minutes as necessary to heat the parts to the temperature of the solution. Then strike at 3-5 ASI for 30-90 seconds. Then plate at the same current density as given above for steels, to get the specified plating thickness. Adjust the current density to make allowance for the solution temperature. A lower temperature goes with a lower current density.

将零件放入电镀槽中,必要时关闭电源 1-10 分钟,将零件加热至溶液温度。然后在 3-5 ASI 下电镀 30-90 秒。然后以与上述钢材相同的电流密度进行电镀,以获得规定的镀层厚度。根据溶液温度调整电流密度。温度越低,电流密度越低。

(3) Cold water rinse (100°F maximum), followed by hot water rinse (above 130°F), if necessary to help dry the parts.

冷水冲洗(最高 100°F),必要时再用热水冲洗(130 华氏度以上),以帮助干燥零件。

(4) Dry parts and remove maskants.

擦干零件并去除掩蔽剂。

(5) Bake parts within 10 hours as specified in Paragraph 7.

按照第 7 段的规定,在 10 小时内烘烤零件。

D. Copper and Copper Alloys

铜及铜合金

(1) Prepare the surface as specified in Cleaning of Copper and Copper Alloys in SOPM 20-30-03.

按照 SOPM 20-30-03 中铜和铜合金的清洗规定准备表面。

(2) Put the parts in the plating bath, with power off, for 1-10 minutes as necessary to heat the parts to the temperature of the solution. Then strike at 3-5 ASI for 30-90 seconds. Then plate at the same current density as given above for steels, to get the specified plating thickness.

将零件放入电镀槽中,必要时关闭电源 1-10 分钟,使零件加热至溶液温度。然后以 3-5 ASI 的电流密度电镀 30-90 秒。然后以与上述钢材相同的电流密度进行电镀,以获得规定的镀层厚度。

(3) Rinse. Hot water (above 130°F) can be used to help dry the parts.

冲洗。可使用热水(130°F 以上)帮助擦干零件。

(4) Dry with clean, moisture free compressed air and remove maskants.

使用清洁、无湿气的压缩空气进行干燥,并去除掩蔽剂。

(5) Bake beryllium-copper alloy parts within 10 hours as specified in Paragraph 7.

按照第 7 段的规定,在 10 小时内烘烤铍铜合金零件。

7. POST-PLATE BAKING 镀后烘烤

A. Within 10 hours after the plating, or within 24 hours after you first apply plating current to the part, whichever is shortest, bake applicable parts as specified in Table 2, unless specified differently by the overhaul instructions. One bake can be used for more than one chrome plating operation on the part, if the bake starts within 24 hours after you first apply plating current to the part.

在电镀后 10 小时内,或在首次对零件施加电镀电流后 24 小时内(以时间最短者为准),按表 2 的规定烘烤适用零件,除非大修说明另有规定。如果在首次对零件施加电镀电流后 24 小时内开始烘烤,则一次烘烤可用于对零件进行一次以上的镀铬操作。

B. If the part must be chrome plated longer than 24 hours, you must remove the part from the bath in time to start the bake by the 24-hour time limit. After this bake, reactivate the part (Paragraph 6.A.(4) or (5) above), and then continue the plating process. A new set of 10-hour and 24-hour time limits starts when you again apply the plating current. If the part must be plated longer, be sure to remove it from the bath to start another bake by the new 24-hour time limit. Continue as necessary until the plating is completed, then bake the part within the final 10-hour or 24-hour limit.

如果零件的镀铬时间必须超过 24 小时,则必须在 24 小时时限内及时将零件从镀槽中取出,以便开始烘烤。烘烤后,重新激活零件(上文第 6.A.(4)或(5)段),然后继续电镀过程。再次施加电镀电流时,一组新的 10 小时和 24 小时时限开始。如果必须延长零件的电镀时间,一定要在新的 24 小时时限前将其从电镀槽中取出,开始另一次烘烤。根据需要继续进行,直到电镀完成,然后在 10 小时或 24 小时的最后时限内烘烤零件。

C. When the part will be later cadmium or cadmium titanium plated, the bake can be:

当零件稍后将进行镀镉或镀镉钛时,可进行烘烤:

(1) stopped after 6 hours to let you grind and do more plating. A minimum 6 hour bake between each plating cycle is necessary. After the last plating cycle, bake as necessary for the requirements of the last plating deposited, or to complete the minimum bake requirement for chrome plating, whichever is longer.

6 小时后停止烘烤,以便打磨和进行更多电镀。每个电镀周期之间至少需要进行 6 小时的烘烤。在最后一个电镀周期后,根据最后一个电镀的要求进行必要的烘烤,或完成镀铬的最低烘烤要求,以时间较长者为准。

(2) not done until after the cadmium or cadmium titanium plating operation, if you are sure to start the bake within 24 hours after you first applied the chrome plating current to the part. The bake and application of post chromate treatment and primer (if applicable) must be completed before you start to grind.

在镉或镉钛电镀操作之后才做,如果确定在首次向零件施加镀铬电流后 24 小时内开始烘烤。烘烤和铬酸盐后处理及底漆(如适用)的应用必须在开始打磨之前完成。

8. CHROME PLATE RUNOUT 镀铬跳动

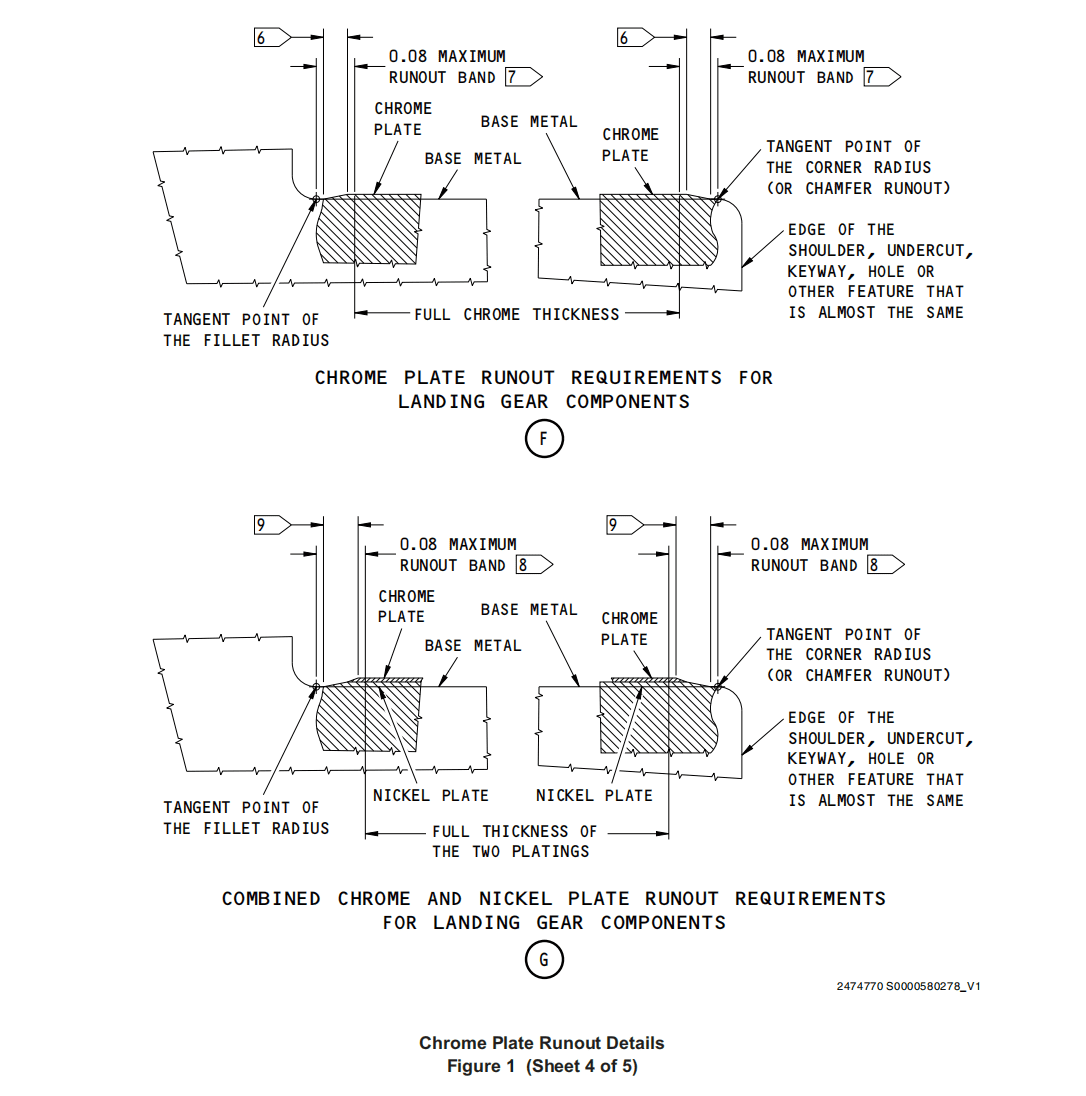

A. The chrome plate runout area is that area of the chrome plated surfaces where the chrome plating thickness changes from the required thickness to zero. The specified runout is necessary to be sure the plating area is correct and to give clearance for grinding (when applicable) and masking materials.

镀铬跳动区域是镀铬表面上镀铬厚度从所需厚度变为零的区域。规定的跳动是必要的,以确保电镀区域正确,并为打磨(如适用)和遮蔽材料留出间隙。

B. Make the runout during the plating operation with special electrodes, a current robbing procedure, or metal tape and shields, to get a gradual runout without a bead or a square edge.

在电镀操作过程中,使用特殊电极、抢电流程序或金属带和屏蔽罩来制作跳动,以获得没有胎圈或方形边缘的渐变跳动。

C. Unless specified differently by the overhaul instructions, make the chrome plating run out within a 0.080 inch wide band at the edges of the plated area (see Figure 1).

除非大修说明有不同的规定,否则应在镀铬区域边缘 0.080 英寸宽的范围内进行镀铬跳动(见图 1)。

D. If the overhaul instructions specify the 160T1000 procedure for refinish thicknesses of chrome plate, see Figure 2 for instructions. Do not use this procedure for repair thicknesses of chrome plate.

如果大修说明规定的 160T1000 程序适用于镀铬板的修补厚度,请参见图 2 进行说明。不要将此程序用于修理镀铬板厚度。

9. QUALITY CONTROL 质量控制

A. The plating must be smooth, fine grained, bonded tightly to the base metal, and have no blisters, pits, nodules, porosity, excessive edge buildup, or signs of burns. No signs of cracks which can be seen by the unaided eye are permitted. This includes chicken wire cracks. Small color changes because of the bakes or rinses are acceptable.

电镀层必须光滑、纹理清晰、与基体金属紧密结合、无起泡、凹坑、结节、气孔、边缘过度堆积或烧伤痕迹。不允许出现肉眼可见的裂纹。这包括鸡丝裂缝。因烘烤或冲洗而产生的细微颜色变化是可以接受的。

B. To be sure your plating procedure makes plating bonded tightly to the base metal, do a chisel test or a bend test on a sample. Use the chisel test on class 3 plating. Use the chisel test or the bend test on class 2 plating. Refer to BAC5709 for details.

为确保电镀程序能使电镀层与基体金属紧密结合,请对样品进行凿击测试或弯曲测试。对 3 级电镀使用凿击试验。对 2 级电镀使用凿击测试或弯曲测试。详情请参阅 BAC5709。

C. Hardness of class 2 and 3 plating must be Rc 55 or more. Hardness of class 4 must be Rc 67 or more. Refer to BAC5709 for test details.

2 级和 3 级电镀的硬度必须达到 Rc 55 或以上。4 级镀层的硬度必须达到 Rc 67 或以上。测试详情请参阅 BAC5709。

D. For class 3 plating, analyze the bath for chromic acid and sulfate concentrations a minimum of one time per week while the bath is in operation.

对于 3 级电镀,在电镀槽运行期间,每周至少分析一次电镀槽的铬酸和硫酸盐浓度。

E. Do tests on samples at regular intervals to be sure of the plating quality. If the interval is not specified by this procedure or in BAC5709, use an interval that agrees with standard industry practices, your experience with the procedure, and to make sure you can find parts that could have bad plating. If BAC5709 gives a formula to calculate the interval, use it for your basic quality control plan.

定期对样品进行测试,以确保电镀质量。如果本程序或 BAC5709 没有规定间隔时间,则应使用符合标准行业惯例、您的程序经验的间隔时间,并确保您能找到可能存在不良电镀的零件。如果 BAC5709 提供了计算间隔时间的公式,请将其用于基本质量控制计划。

F. Do tests for hydrogen embrittlement on the chrome plating you made

对您制作的电镀层进行氢脆测试

(1) When you make a new chrome plating bath

制作新的电镀液时

(2) When you replace more than 30% of a chrome plating bath

更换镀铬液 30% 以上时

(3) When you add barium carbonate to the chrome plating bath to remove sulfates. Refer to BAC5709 for details.

在电镀液中加入碳酸钡以去除硫酸盐时。详情请参阅BAC5709。