聚氨酯抗雨侵蚀涂层的应用APPLICATION OF POLYURETHANE RAIN EROSION RESISTANT COATING

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5880. The airline has a copy of the Boeing Process Specifications Manual.

本主题中的数据来自波音工艺规范 BAC5880。航空公司有一本《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并不涉及所有情况或特定安装。请将此数据作为指南,帮助您编写最低标准。

C. Classification

分类

(1) Type 1 — Rain Erosion Resistant Coating

类型 1 — 抗雨水侵蚀涂层

(a) Class 1 — Black

等级 1 — 黑色

(b) Class 2 — Nonyellowing White

等级 2 –泛黄白色

(c) Class 3 — White

等级 3 — 白色

(d) Class 4 — (Reserved)

等级 4 –(保留)

(e) Class 5 — Gloss Gray Color 707

等级 5 — 灰色光泽 707

(2) Type 2 — Antistatic Rain Erosion Resistant Coating

类型 2 — 抗静电雨水侵蚀涂层

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商名称和地址清单请参见 SOPM 20-00-00。

2. MATERIALS 材料

WARNING :THESE FINISHES AND SOLVENTS ARE POISONOUS AND FLAMMABLE. DO ALL WORK IN A WELL VENTILATED AREA. OBEY ALL SAFETY AND FIRE PRECAUTIONS. DO NOT BREATHE VAPORS. IF CHEMICALS GET IN EYES, FLUSH WITH WATER FOR 15 MINUTES AND GET MEDICAL ATTENTION IMMEDIATELY. IF CHEMICALS GET ON SKIN, FLUSH WITH WATER. WIPE UP ALL SPILLS IMMEDIATELY.

警告 :这些饰面和溶剂有毒且易燃。请在通风良好的地方进行所有作业。遵守所有安全和防火措施。切勿吸入蒸汽。如果化学品进入眼睛,用水冲洗 15 分钟并立即就医。如果化学品沾到皮肤上,用水冲洗。立即擦掉所有溢出物。

NOTE: Equivalent substitutes can be used.

注: 可使用同等替代品。

A. Type 1 Coatings

1 类涂料

(1) Class 1 — Black

等级 1 – 黑色

(a) Black Caapcoat B-274 Vehicle, Curing Agent and Accelerator (V60922)

黑色 Caapcoat B-274 底料、固化剂和促进剂 (V60922)

(b) Astrocoat Base 8000 and Catalyst 8100 (V60003)

(2) Class 2 — Nonyellowing White

等级 2 –泛黄白色

(a) Nonyellowing White Caapcoat C-W4 Vehicle, Curing Agent, and Accelerator; MIL-C-83445, Class 1 (V60922)

(b) Astrocoat Base 8004 and Catalyst 8101 (V60003)

(3) Class 3 — White

等级 3 — 白色

(a) Astrocoat Base 8001 and Catalyst 8100 (V60003)

(4) Class 5 — Gray Caapcoat FP-200 Vehicle, Curing Agent and Accelerator (V60922)

等级 5– 灰色 Caapcoat FP-200 底料、固化剂和促进剂 (V60922)

B. Type 2 Coatings (Antistatic)

2 类涂料(抗静电)

(1) Astrocoat Antistatic Topcoat, Base 8003 and Catalyst 8100 (V60003)

Astrocoat 抗静电面漆、底漆 8003 和催化剂 8100(V60003)

(2) Caapcoat AS-P108 Vehicle and Catalyst; MIL-C-83231, Class A, Type 2 (V60922)

Caapcoat AS-P108 Vehicle和催化剂;MIL-C-83231,A 级,2 类 (V60922)

(3) Caapcoat AS-P108L Vehicle and Catalyst (flat black) (V60922)

Caapcoat AS-P108L Vehicle和催化剂(平黑)(V60922)

C. Primers

底漆

(1) Astrocoat Primer Base 8200 (Part A) and Accelerator 8201 (Part B) (V60003)

Astrocoat 底漆基料 8200(A 部分)和促进剂 8201(B 部分)(V60003)

(2) Chemglaze 9924 Wash Primer Base (Part A) and Catalyst (Part B) (V30676)

Chemglaze 9924 底漆清洗剂(A 部分)和催化剂(B 部分)(V30676)

(3) Urethane Compatible, Corrosion Resistant Primer, BMS 10-79, Type 2, Grade A

与聚氨酯兼容的抗腐蚀底漆,BMS 10-79,2 类,A 级

D. Thinners

稀释剂

(1) Astrocoat Thinner 8300, or Low Aromatic Thinner 8301 (V60003)

Astrocoat 稀释剂 8300 或低芳烃稀释剂 8301 (V60003)

(2) Caapcoat Polyurethane Thinner (V60922) or MIL-T-81772, Type 1.

Caapcoat 聚氨酯稀释剂(V60922)或 MIL-T-81772,类型 1。

(3) Methyl Isobutyl Ketone (MIBK), ASTM D 1153

甲基异丁基酮 (MIBK),ASTM D 1153

E. Solvents

溶剂

(1) Methyl Ethyl Ketone (MEK), TT-M-261

甲基乙基酮 (MEK),TT-M-261

(2) Toluene (Toluol), TT-T-548 or JAN-T-171 Grade A

甲苯(Toluol),TT-T-548 或 JAN-T-171 A 级

(3) Xylene, TT-X-916

二甲苯,TT-X-916

(4) Series 94 (Ref SOPM 20-30-94)

94 系列(参考 SOPM 20-30-94)

F. Miscellaneous

杂项

(1) Abrasive Pads

研磨片

(a) Scotch-Brite Finishing Type A, very fine (V76381)

A 型 Scotch-Brite Finishing,极细 (V76381)

(b) Aluminum Abrasive Nylon Pad Type F (V06565)

F 型尼龙铝研磨片 (V06565)

(2) Masking Tape, Solvent Resistant

耐溶剂遮蔽胶带

(a) No. 226 or YR-239 (V76381)

226 号或 YR-239 号(V76381)

(b) P-705 (V99742)

(3) Wipers, BMS 15-5, Class A

擦拭布,BMS 15-5,A 级

3. SURFACE PREPARATION 表面处理

A. Give protection to all areas not to be touched by solvents, cleaners, or equivalent agents.

保护所有不接触溶剂、清洁剂或类似物质的区域。

B. Remove temporary coatings per SOPM 20-44-02.

按照 SOPM 20-44-02 标准清除临时涂层。

C. Remove all organic coatings, except polyurethane rain erosion resistant coatings, as follows:

除聚氨酯抗雨侵蚀涂层外,按以下步骤清除所有有机涂层:

(1) Plastic laminates — Remove coatings down to the surfacer or the laminate by abrasive cleaning per SOPM 20-30-03. Do not expose the fibers of the laminate.

塑料层压板 — 按照 SOPM 20-30-03 标准,通过研磨清洗去除涂层直至表层或层压板。不要暴露层压板的纤维。

(2) Aluminum substrates — Remove organic coatings per SOPM 20-30-02. Solvent clean the surface per SOPM 20-30-03 until the wiper collects no visible residue.

铝基板 — 按照 SOPM 20-30-02 标准去除有机涂层。按照 SOPM 20-30-03 进行溶剂清洁表面,直至擦拭布上无可见残留物。

D. Prepare surface for coating

准备涂层表面

CAUTION :DO NOT LET SOLVENT STAY ON THE SURFACE TOO LONG A TIME, OR IT COULD CAUSE THE SURFACE TO SWELL.

注意 :不要让溶剂在表面上停留太久,否则会导致表面膨胀。

(1) Existing polyurethane rain erosion resistant coatings: Clean and reactivate with abrasive pads and water, then wipe with methyl ethyl ketone until the wiper collects no sign of coating residue.

现有的聚氨酯抗雨侵蚀涂层: 用研磨片和水进行清洁和重新激活,然后用甲乙酮擦拭,直到擦拭布收集不到涂层残留物的迹象。

(2) Fiberglass laminate: If the overhaul instructions do not give details, prepare the surface per SOPM 20-10-06 or BAC 5837. If the overhaul instructions do not give the primer, apply one coat of BMS 10-103 primer (but not wash primer) per BAC 5325 before you apply the rain erosion resistant coating.

玻璃纤维层压板: 如果大修说明中没有详细说明,则按照 SOPM 20-10-06 或 BAC 5837 对表面进行处理。如果大修说明没有给出底漆,则在涂刷抗雨侵蚀涂层之前,按照 BAC 5325 涂刷一层 BMS 10-103 底漆(但不是水洗底漆)。

(3) Clad aluminum:

包铝:

(a) Before you apply wash primer, give the clad surface a satin finish with Scotch Brite wet with solvent, then solvent clean per SOPM 20-30-03.

在应用水洗底漆之前,先用Scotch Brite沾湿溶剂对包层表面进行缎光处理,然后按照 SOPM 20-30-03 进行溶剂清洗。

(b) Before you apply BMS 10-79 primer, chemical treat per SOPM 20-43-03.

在涂 BMS 10-79 底漆前,按照 SOPM 20-43-03 进行化学处理。

(4) Anodized aluminum: Solvent clean per SOPM 20-30-03.

阳极氧化铝:按照 SOPM 20-30-03 进行溶剂清洗。

(5) Aluminum flame sprayed surfaces:

火焰喷涂铝表面:

(a) Before you apply wash primer, solvent clean per SOPM 20-30-03.

在涂刷水洗底漆之前,按照 SOPM 20-30-03 进行溶剂清洁。

(b) Before you apply BMS 10-79 primer, chemical treat per SOPM 20-43-03.

在涂 BMS 10-79 底漆之前,按照 SOPM 20-43-03 进行化学处理。

4. MIXING 混合

A. Shake or fully stir each ingredient before you mix them together. Base and vehicle components must be smoothly continuous before you add catalyst or curing agent.

将每种成分混合在一起之前,都要摇匀或充分搅拌。在添加催化剂或固化剂之前,底层和载体部件必须平滑连续。

B. Do not use more than the material amounts that are supplied in each kit.

不要超过每个套件中提供的材料用量。

C. Do not mix kit components of different vendors.

不要混合不同供应商的套件部件。

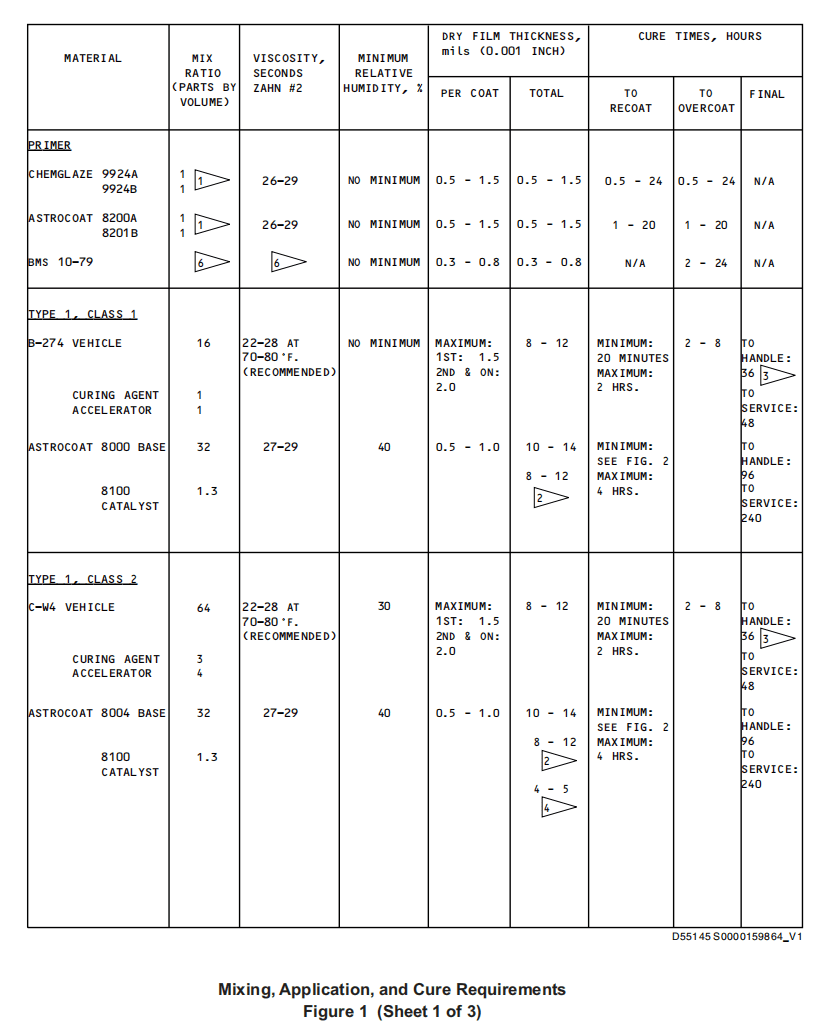

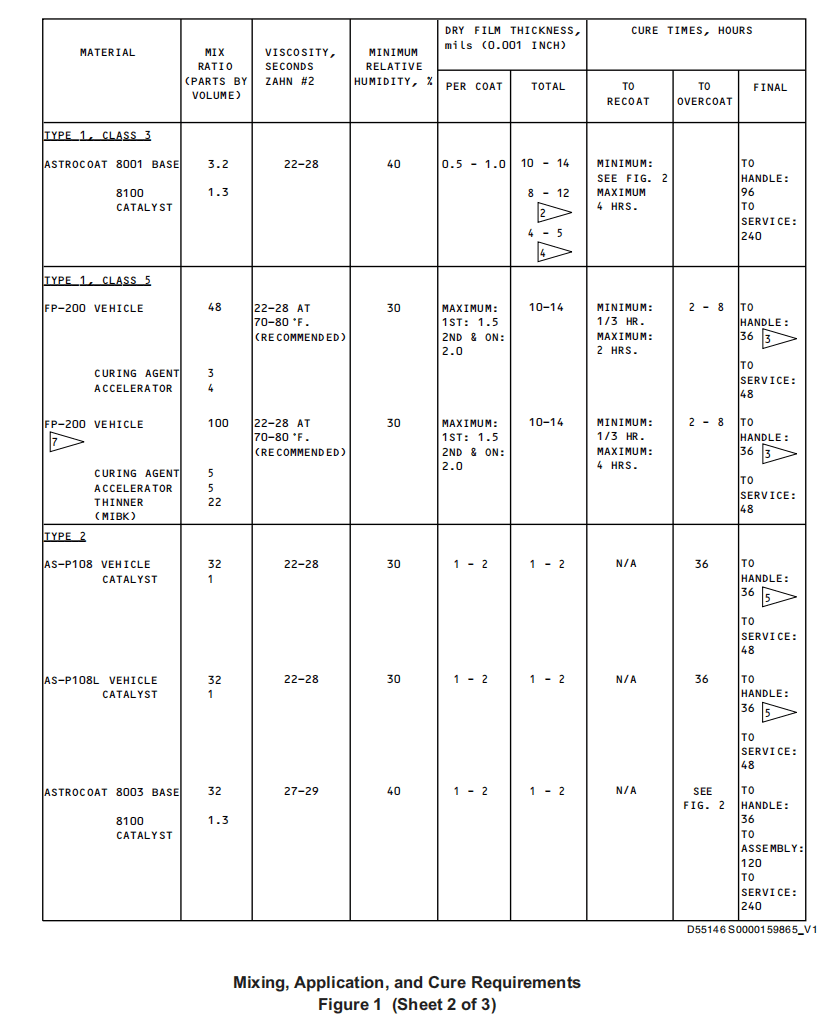

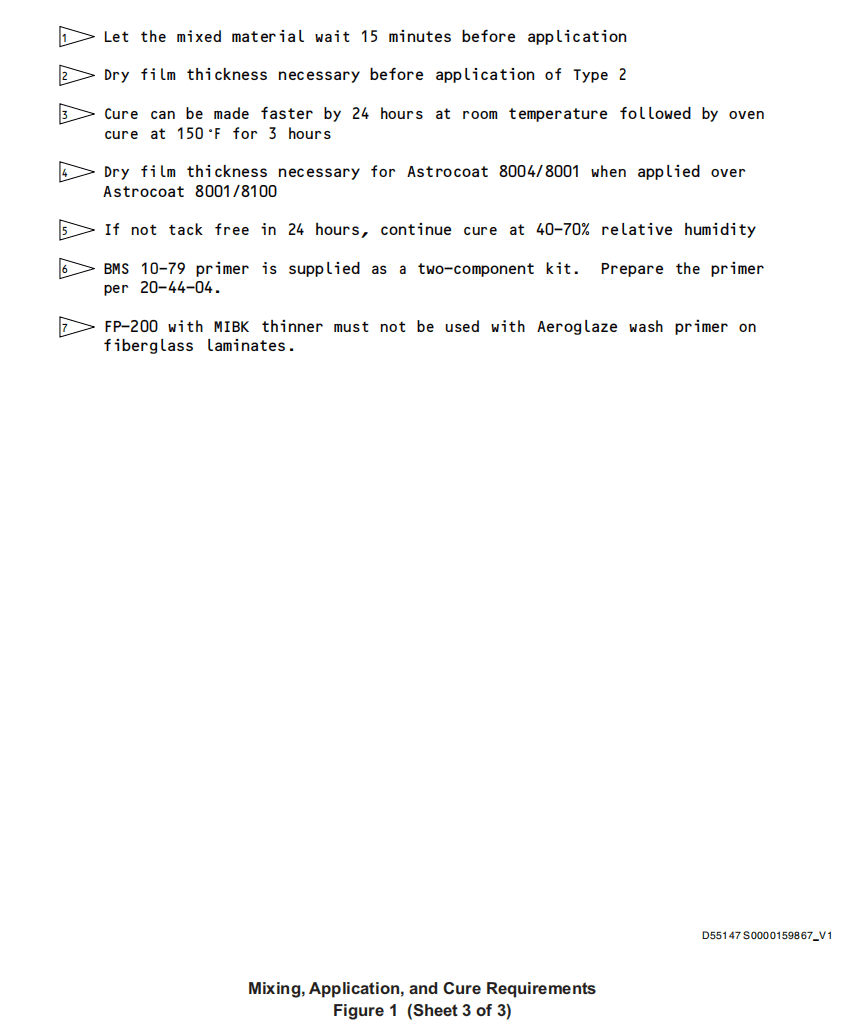

D. Mix and thin materials per Figure 1. Where thinner is used, do not use more than 1 volume part thinner to 2 volume parts mixed primer, or 1 volume part thinner to 4 volume parts mixed Type 1 or Type 2 coating material.

按照图 1 混合和稀释材料。使用稀释剂时,稀释剂与混合底漆的比例不得超过 1 体积份数与 2 体积份数的比例,或稀释剂与混合 1 型或 2 型涂料的比例不得超过 1 体积份数与 4 体积份数的比例。

E. The pot life of primers is 8 hours at or below 75°F, and 4 hours above 75°F. The pot life of Types 1 and 2 materials is 4 hours at or below 75°F and 2 hours above 75°F. Discard all mixed materials remaining after pot life.

底漆在 75°F 或以下的固化时间为 8 小时,在 75°F 以上的固化时间为 4 小时。1 类和 2 类涂料在 75°F 或以下温度下的固化时间为 4 小时,在 75°F 以上温度下的固化时间为 2 小时。报废罐装寿命后剩余的所有混合材料。

F. Unmixed primer and coating materials can be used until 24 months from date of manufacture if they were stored in accordance with standard industry practices, and if tests at 12 and 18 months from date of manufacture show that they agree with specifications. Discard materials more than 2 years old.

如果未混合的底漆和涂层材料是按照标准行业惯例储存的,并且在生产日期后 12 个月和 18 个月的测试表明其符合规格要求,则可使用至生产日期后 24 个月。报废 2 年以上的材料。

5. APPLICATION 应用

A. Apply primers and coatings by spray only, except as specified.

除规定外,底漆和涂料只能以喷涂方式施用。

B. Apply primer first, followed by a Type 1 coating, and then the topcoat, if applicable.

如适用,先涂底漆,再涂 1 类涂料,然后涂面漆。

C. Mix, thin and apply materials to get dry film thicknesses per Figure 1. If you use MIBK as a thinner, do not use more than shown in Figure 1.

按照图 1 混合、稀释和涂抹材料,以获得干膜厚度。如果使用 MIBK 作为稀释剂,用量不要超过图 1 所示。

D. If you must stop more than 4 hours during application of Astrocoat Type 1 coating, do not catalyze the last coat applied before you stop. Continue application after 8 – 18 hours at 40-50% relative humidity and 70-75°F, if the last coat is dry to the touch. Be sure to catalyze the last coat applied.

如果在涂覆 Astrocoat 1 型涂料的过程中必须停止超过 4 小时,则在停止前不要催化涂覆的最后一层涂料。在相对湿度为 40-50%、温度为 70-75°F 的条件下,如果最后一层涂层触摸感觉干燥,则在 8 – 18 小时后继续涂抹。一定要催化最后涂抹的涂层。

E. Immediately before you apply a subsequent coat, examine the last coat for signs of bubbles. If you find bubbles, decrease the thickness of the coat, wait more time between coats, or both. Small amounts of bubbles are acceptable if the next two coats applied do not show signs of bubbles.

在涂刷下一层涂料之前,应立即检查上一层涂料是否有气泡迹象。如果发现气泡,可减少涂层厚度,延长涂层之间的间隔时间,或两者兼而有之。如果接下来涂抹的两层涂料没有气泡迹象,少量气泡是可以接受的。

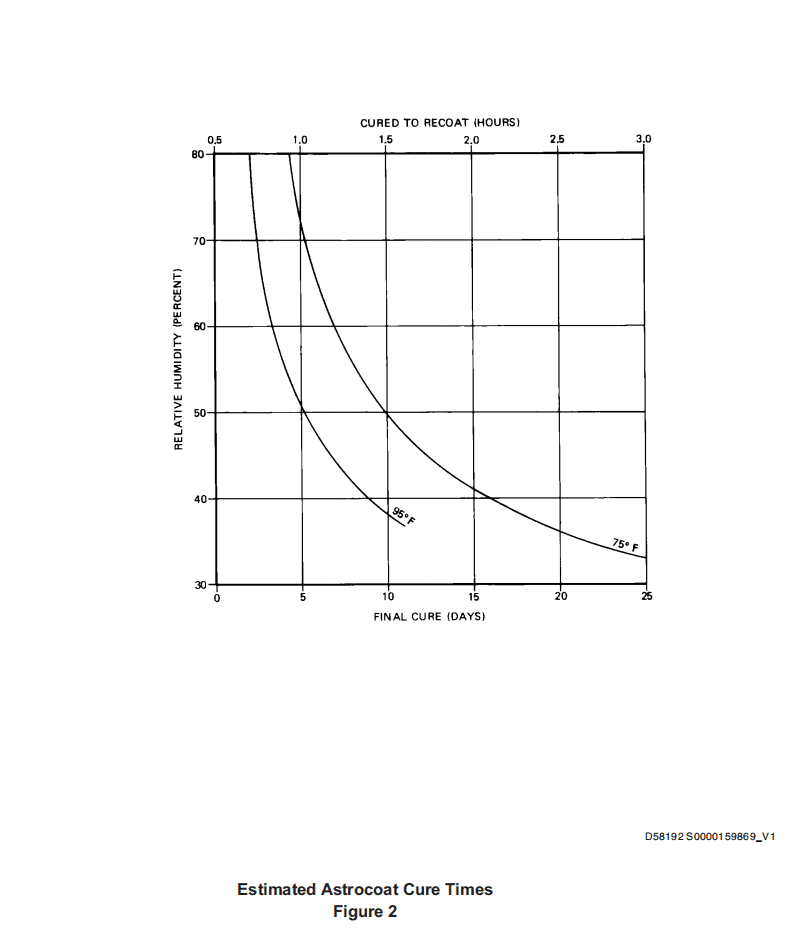

F. Cure coats per Figure 1 and Figure 2, as applicable. Note that Figure 2 uses the same curves for two different conditions, cured for recoat and final cure.

根据情况按照图 1 和图 2 固化涂层。请注意,图 2 使用了两种不同条件下的相同曲线,即重涂固化和最终固化。

6. IN-PROCESS CORRECTIVE ACTION 过程中的纠正措施

A. Primer Coat: If the film is rough, lightly sand with 180 grit or finer aluminum oxide abrasive paper or pad, before you apply the rain erosion resistant coating. Remove sanding residues with wipers lightly wet with toluene or xylene per SOPM 20-30-03.

底漆: 如果漆膜粗糙,在涂刷抗雨侵蚀涂层之前,用 180 粗细度或更细的氧化铝砂纸或砂片轻轻打磨。根据 SOPM 20-30-03,用沾有甲苯或二甲苯的擦拭布将打磨残留物擦拭干净。

B. Completed Topcoats — Minor Repair

已完成的面漆–小修

(1) No substrate exposed

无基底暴露

CAUTION :DO NOT GO THROUGH TO THE PRIMER OR FIBERGLASS SUBSTRATE. IF YOU SEE THE FIBERGLASS SUBSTRATE, APPLY PRIMER, BUT DO NOT APPLY PRIMER OVER THE OLD POLYURETHANE LAYER.

注意 :不要穿透底漆或玻璃纤维底层。如果看到玻璃纤维底层,则涂底漆,但不要在旧的聚氨酯层上涂底漆。

(a) Cut or sand off all loosened coatings. Sand smooth the area and the edges. Use 280 grit or finer abrasive. A small, high-speed disk sander is recommended.

切除或打磨掉所有松动的涂层。打磨平整该区域和边缘。使用 280 粗细度或更细的砂纸。建议使用小型高速盘式砂光机。

(b) Vacuum to fully remove the sand and dust.

用真空吸尘器彻底清除沙子和灰尘。

(c) Immediately before you start to apply the coating, wipe the sanded area with thinner. Wipe again with solvent on a clean wiper until you see no particles or discoloration on the wiper. Wipe dry with clean dry cloth.

开始涂装前,立即用稀释剂擦拭打磨过的区域。在干净的擦拭布上再用溶剂擦拭一次,直到擦拭布上看不到颗粒或变色为止。用干净的干布擦干。

(d) With a brush, apply the appropriate polyurethane coating(s) to required thicknesses. Do not overlap this coating onto unsanded areas of the old finish.

用刷子按照要求的厚度涂上适当的聚氨酯涂层。不要将涂层重叠在旧饰面的未打磨区域。

(2) Substrate Exposed

基材外露

(a) If you see small damaged areas of primer or epoxy fiberglass substrate, cut off the loosened coating. Sand to remove the remaining loosened coating, then make the area and the edges smooth with the good coating. Do not go through to the glass fabric.

如果发现底漆或环氧玻璃纤维基底有小面积损坏,应将松动的涂层切掉。用砂纸打磨掉剩余的松动涂层,然后用好的涂层使该区域和边缘平滑。切勿与玻璃纤维织物接触。

(b) Clean the repaired area with a bristle brush and a Series 94 solvent (Ref. SOPM 20-30-94) for one minute minimum. Immediately blot dry with a clean, dry cloth, then use a dry brush and vacuum to remove loose particles.

用鬃毛刷和 94 系列溶剂(参考 SOPM 20-30-94)清洁修复区域至少一分钟。立即用干净的干布擦干,然后用干刷和真空吸尘器清除松散的颗粒。

(c) With a brush, apply the primer and coatings to the specified thicknesses. Do not apply primer over the old polyurethane coating.

用刷子将底漆和涂料涂到规定的厚度。不要在旧的聚氨酯涂层上涂刷底漆。

7. QUALITY CONTROL 质量控制

A. The final finish must be smooth, continuous, and have no particles.

最终饰面必须光滑、连续、无颗粒。

B. The final dry film thickness must be within the limits of Figure 1, and the coatings must agree to the contour of the part.

最终干膜厚度必须在图 1 的限制范围内,涂层必须与零件轮廓一致。

C. Resistivity of Type 2 coatings, as measured per MIL-C-83231, must be 0.5 – 1.5 megohms for coatings that are completely cured (5 or more days).

根据 MIL-C-83231 测量,完全固化(5 天或 5 天以上)的 2 类涂层的电阻率必须为 0.5 – 1.5 兆欧。