聚氨酯兼容底漆的应用APPLICATION OF URETHANE COMPATIBLE PRIMER

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5882. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5882。可查阅波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据具有通用性。并不涉及所有情况或特定安装。请将此数据作为帮助您编写最低标准的指南。

C. Classification

分类

(1) The BMS 10-79 primer comes in different types, classes, and grades.

BMS 10-79 底漆有不同类型、级别和等级。

(a) Types

类型

1) Type 1 is obsolete. Use Type 3.

类型

2) Type 2 is urethane compatible primer for high erosion areas.

类型 2 是适用于高侵蚀区域的聚氨酯兼容底漆。

3) Type 3 is urethane compatible primer for high erosion areas with less than 1% aromatic amine in the mixed components.

类型 3 是用于高侵蚀区域的聚氨酯兼容底漆,混合部件中的芳香胺含量低于 1%。

(b) Classes

级别

1) Class A is material for the usual application procedures, which include air or airless spray.

A 级是用于通常应用程序的材料,包括空气或无气喷涂。

2) Class B is material for application with electrostatic painting equipment as well as the usual application equipment.

B 级是适用于静电喷涂设备和普通喷涂设备的材料。

(c) The grade identifies the solvent content.

等级标识溶剂含量。

1) Grade A is conventional primer, usually with a volatile organic compound (VOC) content of 650 grams per liter or more in mixed components. Grade A can be used for wet installation of fasteners.

A 级为常规底漆,通常混合部件的挥发性有机化合物(VOC)含量为每升 650 克或以上。A 级可用于紧固件的湿式安装。

2) Grade B is now replaced by Grade D.

B 级现已被 D 级取代。

3) Grade C is obsolete. Use Grade A or D.

C 级已废弃。请使用 A 级或 D 级。

4) Grade D is a low VOC primer that has a VOC content of 350 grams per liter or less in mixed components. Grade D can be used for wet installation of fasteners, but when Grade D primer is used, TR-114 exempt thinner must not be used.

D 级是一种低挥发性有机化合物底漆,其混合部件中的挥发性有机化合物含量为每升 350 克或更少。D 级可用于紧固件的湿式安装,但在使用 D 级底漆时,不得使用 TR-114 豁免稀释剂。

(2) If the overhaul or refinish instructions do not specify the type, use Type 3. If the class is not specified, use Class A or B. If the grade is not specified, use Grade A or D.

如果大修或修补说明没有规定类型,则使用 3 类。如未规定等级,则使用 A 级或 B 级;如未规定等级,则使用 A 级或 D 级。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

注: 可使用同等替代品。

A. Abrasives

研磨剂

(1) Abrasive paper, silicone free

(a) 220 grit or finer

(b) 320 grit or finer

(2) Aluminum pads, very fine, maroon color, aluminum oxide, non-woven, resin bonded

(a) Scotch-Brite General Purpose Hand Pad 7447, V76381

(b) Scotch-Brite Clean and Finish, Grade A, V76381

(c) Bear-Tex 747 General Purpose, V0LBH6 or V06565

(3) Aluminum oxide impregnated nylon fiber, 180 grit or finer

B. Tack Rags

抹布

(1) C-60, V0EK96

C. Solvents

溶剂

(1) Methyl ethyl ketone (MEK), ASTM D 740

(2) VM&P naphthas, ASTM D3735, Type 3

(3) TL-52, V98502

(4) Ardrox 241K (formerly Tec 902), V44389

(5) Isopropyl alcohol, ASTM D 770

(6) Diethylene glycol monobutyl ether (butyl carbitol), V80524

D. Paint Strainer — Any medium mesh paint strainer, such as the Louis M. Gerson Co. Aqua 4000™ Cotton Mesh Strainer, medium mesh, V26895

油漆过滤网 — 任何中网油漆过滤网,如 Louis M. Gerson Co. Aqua 4000™ 中目棉网过滤器,V26895

E. Alkaline Cleaners

碱性清洁剂

(1) Ardrox 160-B, V44389

(2) Pace B-82, V44389

(3) Pace MF-30, V44389

(4) Turco 4215, V61102

(5) Ridoline 909, V61102

(6) Super Bee 300LF, V71361

F. pH Paper — Any pH paper, such as pH indicator strips, ColorpHast™, Catalog 9590, V0AL61

pH 纸 — 任何 pH 纸,如 pH 指示条,ColorpHast™,目录 9590,V0AL61

G. Primers

底漆

(1) BMS 10-79, Type 2, Class A or B

(2) BMS 10-79, Type 3, Class A or B

H. Wipers — BMS 15-5, Class A

擦拭布 — BMS 15-5,A 级 3.

3. SURFACE PREPARATION 表面处理

A. Exterior composite or plastic surfaces prepared as specified in BAC5837 (SOPM 20-10-06).

按 BAC5837(SOPM 20-10-06)规定制备的外部复合材料或塑料表面。

(1) Keep the surface clean and dry.

保持表面清洁干燥。

(2) If the surface gets contamination, reprocess it as specified in BAC5837 unless the contamination is only particulate. Remove particulate contamination with compressed air or a new tack rag.

如果表面受到污染,除非污染仅为微粒,否则应按 BAC5837 的规定重新处理。用压缩空气或新抹布清除微粒污染。

(3) Apply the primer within 72 hours after the BAC5837 process.

在 BAC5837 处理后 72 小时内涂刷底漆。

B. Exterior composite or plastic surfaces prepared as specified in BAC5837 (SOPM 20-10-06) and then coated with BMS 10-21 conductive coating (BAC5639).

按 BAC5837 (SOPM 20-10-06)规定制备,然后涂上 BMS 10-21 导静电涂层 (BAC5639) 的外部复合材料或塑料表面。

(1) Keep the surface clean and dry.

保持表面清洁干燥。

(2) If the surface gets contamination, clean it with VM&P naphthas as specified in BAC5750 SOPM 20-30-03 unless the contamination is only particulate. Remove particulate contamination with compressed air or a new tack rag.

如果表面受到污染,用 BAC5750 SOPM 20-30-03 规定的 VM&P 萘烷清洗,除非污染只是微粒。用压缩空气或新的粘性抹布清除微粒污染物。

(3) Apply the primer within 24 hours after the BMS 10-21 conductive coating was applied as specified by BAC5639.

按照 BAC5639 规定,在涂抹 BMS 10-21 导静电涂层后 24 小时内涂抹底漆。

C. Metal surfaces without paint

无涂料的金属表面

NOTE: Bare metal surfaces must have a pretreatment such as anodize or chemical conversion coating.

注:裸金属表面必须进行阳极氧化或化学转化涂层等预处理。

(1) General

通用

(a) Be careful with pretreated metal parts, because the coating is soft and easily damaged. Be sure to use gloves when you touch or move these parts.

小心操作预处理过的金属零件,因为涂层较软,容易损坏。接触或移动这些零件时一定要戴手套。

(b) When you use gloves on pretreated metal parts:

在预处理过的金属零件上使用手套时:

1) Keep the outside surfaces of the gloves clean, dry, lint-free and powder-free.

保持手套外表面清洁、干燥、无绒毛、无粉末。

2) Do not touch oily or contaminated surfaces.

不要接触油污或被污染的表面。

3) Change gloves as necessary to prevent containation of the pretreated metal parts.

必要时更换手套,以防止预处理过的金属零件受到污染。

4) Use white or light-colored gloves because dark-colored contamination is easier to see.

使用白色或浅色手套,因为深色污染更容易被看到。

5) Do not use gloves with silicone or other substances that could cause an unsatisfactory bond with the primer.

不要使用含有硅树脂或其他可能导致与底漆粘接不理想的物质的手套。

(2) If the surface is anodized aluminum without a seal (BAC5019 Class 5 chromic acid anodize as in SOPM 20-43-01, BAC5022 Class 5 sulfuric acid anodize or BAC5632 Class 5 boric acid – sulfuric acid anodize), be careful because the surface layer is porous and can easily get contamination. A dirty surface will not make a good bond with the primer.

如果表面是没有密封的阳极氧化铝(如 SOPM 20-43-01 中的 BAC5019 5 级铬酸阳极氧化、BAC5022 5 级硫酸阳极氧化或 BAC5632 5 级硼酸-硫酸阳极氧化),则要小心,因为表层是多孔的,很容易受到污染。脏污的表面无法与底漆很好地粘合。

(a) Do not touch the parts with fingers or gloves that touched oily surfaces.

不要用接触过油性表面的手指或手套接触零件。

(b) Remove light, non-oily surface contamination with compressed air or a BMS 15-5, Class A wiper soaked with water. Do not wipe the surface too much, or you could damage the less dense outer layer of the anodic coating and cause an unsatisfactory bond with the primer. After removal of the contamination, dry the surface with a dry BMS 15-5, Class A wiper.

用压缩空气或蘸水的 BMS 15-5 A 级擦拭布清除轻微的非油性表面污染物。不要过多擦拭表面,否则会损坏阳极涂层密度较低的外层,导致与底漆的结合不理想。清除污染物后,用干燥的 BMS 15-5 A 级擦拭布擦干表面。

(c) Solvent clean light oily contamination as specified in BAC5750 (SOPM 20-30-03). Or clean the parts as specified by the applicable anodize specification.

按照 BAC5750(SOPM 20-30-03)的规定,用溶剂清洁轻度油性污染物。或按照适用的阳极氧化规范的规定清洁零件。

(d) If the anodize coating must wait more than the time limit specified in the anodize specification before you can apply the primer, remove the anodize and apply a new anodize. If no time limit is specified, start to apply the primer within 16 hours of the anodize.

如果阳极氧化涂层必须等待超过阳极氧化规范规定的时限后才能涂刷底漆,则应清除阳极氧化层并涂刷新的阳极氧化层。如果没有规定时限,则在阳极氧化后 16 小时内开始涂底漆。

(3) Sealed anodized aluminum

密封的阳极氧化铝

(a) Be sure to start to apply the liquid coating within 72 hours.

确保在 72 小时内开始涂抹液体涂层。

(b) If the surface becomes contaminated, solvent clean it as specified in BAC5750 (SOPM 20-30-03). Remove particulate contamination with compressed air or a new tack rag. Do not wipe the surface too much, or you could damage the less dense outer layer of the anodic coating and cause an unsatisfactory bond with the primer.

如果表面受到污染,应按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗。用压缩空气或新的粘性抹布清除微粒污染物。不要过多擦拭表面,否则会损坏阳极涂层中密度较低的外层,导致与底漆的结合不理想。

(4) If an aluminum surface has pretreatment other than anodize without a seal, and has contamination, solvent clean it as specified in BAC5750 (SOPM 20-30-03). Be careful if the treatment is anodize with a seal, because the top layer is soft and easily damaged. This could cause an unsatisfactory bond with the primer.

如果铝表面经过阳极氧化以外的预处理而没有密封,并且有污染,则应按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗。如果处理方式是带密封的阳极氧化,则要小心,因为表层较软,容易损坏。这可能导致与底漆的粘接效果不理想。

D. Surfaces with a layer of primer

有一层底漆的表面

NOTE: No more cleaning could be necessary if you apply the subsequent layers of paint without delay and in conditions known to give protection from the risk of contamination.

注:如果在已知可避免污染风险的条件下立即涂刷后续油漆层,则无需再进行清洁。

(1) BMS 10-79 Grade D Primer less than 12 hours old

BMS 10-79 D 级底漆使用不到 12 小时

(a) If the surface gets contamination, clean it with VM&P naphthas as specified in BAC5750 (SOPM 20-30-03) unless the contamination is only particulate. Remove particulate contamination with compressed air or a new tack rag.

如果表面受到污染,用 BAC5750(SOPM 20-30-03)规定的 VM&P 萘烷清洗,除非污染只是微粒。用压缩空气或新的除尘抹布清除微粒污染。

(2) BMS 10-79 Grade D Primer more than 12 hours old

12 小时以上的 BMS 10-79 D 级底漆

(a) Solvent clean as specified by BAC5750 (SOPM 20-30-03)

按 BAC5750 (SOPM 20-30-03) 的规定进行溶剂清洗

(b) Lightly sand the surface with an abrasive material to remove gloss. Or you can lightly sand the surface with an abrasive pad to remove gloss, then sand with an abrasive material to reactivate the primer layer.

用研磨材料轻轻打磨表面以去除光泽。或用研磨片轻轻打磨表面以去除光泽,然后再用研磨材料研磨,以重新活化底漆层。

(c) Solvent clean as specified by BAC5750 (SOPM 20-30-03) to remove the sanding dust. To help, you can use compressed air or a clean tack rag.

按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗,以去除打磨粉尘。可使用压缩空气或干净的粘性抹布来帮助清除。

(3) Group X Primers

X 组底漆

NOTE: Group X primers are as follows:

注:X 组底漆如下:

BMS 10-11, Type 1, Grades A and E less than 48 hours old

BMS 10-11,类型 1,A 级和 E 级,使用不足 48 小时

BMS 10-20, Type 2, Grades A and D less than 48 hours old

BMS10-20,第 2 类,A 级和 D 级,使用不足 48 小时

BMS 10-79, Types 2 and 3, Grade A less than 48 hours old

BMS10-79,2 型和 3 型,A 级不足 48 小时

BMS 10-103, Type 1, Grades A and E less than 48 hours old

BMS 10-103,1 型,A 级和 E 级,不足 48 小时

BMS 10-11, Type 1, Grade B less than 24 hours old

BMS10-11,1 类,B 级不足 24 小时

(a) If the surface gets contamination, clean it with VM&P naphthas as specified in BAC5750 (SOPM 20-30-03) unless the contamination is only particulate. Remove particulate contamination with compressed air or a new tack rag.

如果表面受到污染,用 BAC5750(SOPM 20-30-03)规定的 VM&P 萘烷清洗,除非污染只是微粒。用压缩空气或新的除尘抹布清除微粒污染。

(4) Group Y Primers

Y 组底漆

NOTE: Group Y primers are as follows:

注:Y 组底漆如下:

BMS 10-11, Type 1, Grades A and E more than 48 hours old

BMS 10-11,1 类,A 级和 E 级,使用超过 48 小时

BMS 10-20, Type 2, Grades A and D more than 48 hours old

BMS10-20,2 类,A 级和 D 级,使用超过 48 小时

BMS 10-79, Types 2 and 3, Grade A more than 48 hours old

BMS10-79,2 类和 3 类,A 级超过 48 小时

BMS 10-103, Type 1, Grades A and E more than 48 hours old

BMS 10-103,1 类,A 级和 E 级超过 48 小时

BMS 10-11, Type 1, Grade B more than 24 hours old

BMS 10-11,1 类,B 级超过 24 小时

BMS 5-89 primer of all ages

所有时长段的 BMS 5-89 底漆

(a) Reactivate the primer layer by one of these Methods:

用以下方法之一重新活化底漆层:

1) Method 1

方法 1

a) Manually solvent clean as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定进行手工溶剂清洗。

b) Clean with abrasive material. Be careful not to go through to the substrate.

用研磨材料清洁。注意不要穿透基材。

c) Manually solvent clean as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定进行手动溶剂清洁。

2) Method 2

方法 2

a) Clean with an alkaline cleaner (Paragraph 2.E.), diluted with seven parts of water by volume as follows:

使用碱性清洁剂(第 2.E 段),按如下方法用 7 份的水(按体积)稀释:

<1> Manually clean as specified in BAC5750 (SOPM 20-30-03), or

按 BAC5750 (SOPM 20-30-03)规定手工清洗,或

<2> Pressure clean with a non-atomizing spray gun. Apply the spray to the surface a minimum of 5 seconds with a maximum stand time of 15 minutes.

使用非雾化喷枪进行压力清洗。在表面喷洒至少 5 秒钟,最长停留时间为 15 分钟。

<3> Do not let the cleaner dry on the part.

不要让清洁剂在零件上干燥。

<4> Complete removal of blue stains from leak detection paint is not necessary.

不需要完全清除泄露检测漆上的蓝色污渍。

b) Remove the cleaner with clean water.

用清水清除清洁剂。

c) Wipe and blow the surface dry with compressed air.

用压缩空气擦拭并吹干表面。

d) Solvent clean to remove dirt that you can see as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗,去除可以看到的污垢。

e) Within 48 hours of Paragraph 3.D.(4)(a)2)a), clean with Ardrox 241K by one of these two steps:

在第 3.D.(4)(a)2)a)段所述 48 小时内,用 Ardrox 241K 按以下两个步骤之一进行清洁:

<1> Manually clean as specified in BAC5750 (SOPM 20-30-03), or

按照 BAC5750(SOPM 20-30-03)的规定进行手工清洗,或

<2> Pressure clean with a non-atomizing spray gun. Apply the spray to the surface a minimum of 5 seconds with a maximum stand time of 2 minutes.

使用非雾化喷枪进行压力清洗。在表面喷洒至少 5 秒钟,最长停留时间为 2 分钟。

f) Fully rinse with water before the Ardrox 241K cleaner evaporates.

在 Ardrox 241K 清洁剂挥发之前用水充分冲洗。

g) Solvent clean with TL 52 by one of these two steps:

用 TL 52 溶剂清洗,可采用上述两个步骤之一:

<1> Manually clean as specified in BAC5750 (SOPM 20-30-03), or

按照 BAC5750(SOPM 20-30-03)的规定进行手动清洗,或

<2> Pressure clean with a non-atomizing spray gun. Apply the spray to the surface a minimum of 5 seconds.

使用非雾化喷枪进行压力清洗。在表面喷洒至少 5 秒钟。

h) Blow dry with filtered compressed air.

用过滤压缩空气吹干。

3) Method 3

方法 3

a) Solvent clean to remove dirt that you can see as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗,去除可以看到的污垢。

b) Within 48 hours, clean with Ardrox 241K by one of these two steps:

在 48 小时内,用 Ardrox 241K 按以下两个步骤之一进行清洁:

<1> Manually clean as specified in BAC5750 (SOPM 20-30-03), or

按照 BAC5750(SOPM 20-30-03)的规定进行手工清洗,或

<2> Pressure clean with a non-atomizing spray gun. Apply the spray to the surface a minimum of 5 seconds with a maximum stand time of 2 minutes.

使用非雾化喷枪进行压力清洗。在表面喷洒至少 5 秒钟,最长停留时间为 2 分钟。

c) Fully rinse with water before the Ardrox 241K cleaner evaporates.

在 Ardrox 241K 清洁剂挥发之前用水充分冲洗。

d) Solvent clean with TL 52 by one of these two steps:

用 TL 52 溶剂清洗,可采用上述两个步骤之一:

<1> Manually clean as specified in BAC5750 (SOPM 20-30-03), or

按照 BAC5750(SOPM 20-30-03)的规定进行手动清洗,或

<2> Pressure clean with a non-atomizing spray gun. Apply the spray to the surface a minimum of 5 seconds.

使用非雾化喷枪进行压力清洗。在表面喷洒至少 5 秒钟。

e) Blow dry with filtered compressed air.

用过滤压缩空气吹干。

4) Method 4

方法 4

a) Solvent clean as specified in BAC5750 (SOPM 20-30-03). Abrasive pads can be used to help remove the dirt.

按照 BAC5750(SOPM 20-30-03)的规定进行溶剂清洗。可使用研磨片帮助清除污垢。

b) Clean with abrasive pads and alkaline cleaner (Paragraph 2.E.), diluted with seven parts of water by volume (±5%) until you get a water-break-free surface.

使用研磨片和碱性清洁剂(第 2.E 段)进行清洁,用 7 份体积比的水(±5%)稀释,直到获得无断水表面。

NOTE: A water-break-free surface is a surface that keeps a continuous layer of water for approximately 30 seconds after the surface is rinsed with water. The 30 second period starts when the flow of all visible curtains of water stops.

注:无断水表面是指表面用水冲洗后,在大约 30 秒钟的时间内保持连续的水层。30 秒的时间从所有可见水帘停止流动时开始。

c) Fully rinse with clean water to remove remaining dust and cleaner. If you do not get a water-break-free surface, clean again as specified by Paragraph 3.D.(4)(a)4)b).

用清水充分冲洗,去除残留的灰尘和清洁剂。如果没有得到无断水的表面,按第 3.D.(4)(a)4)b)段的规定再次清洗。

d) Complete removal of blue stains from leak detection paint is not necessary.

无需完全清除泄漏检测漆上的蓝色污渍。

e) Be careful not to go through to the substrate.

注意不要渗透到底层。

f) If parts with BMS 10-20 primer must be touched-up with chemical treatment and primer, apply Alodine 600 as specified in BAC5719 (SOPM 20-43-03) or BAC5626 before you apply the primer.

如果涂有 BMS 10-20 底漆的零件必须用化学处理和底漆润饰,则在涂底漆之前,应按照 BAC5719 (SOPM 20-43-03) 或 BAC5626 的规定涂上 Alodine 600。

g) Fully dry the parts before you paint them.

在对零件进行涂漆之前,要充分晾干。

5) Method 5 (for BMS 10-11, Type 1 primer and BMS 5-89 primer only)

方法 5(仅适用于 BMS 10-11、1 类底漆和 BMS 5-89 底漆)

a) For BMS 5-89 primer, soak alkaline clean with Turco 4215 alkaline cleaner as specified in BAC5749 (SOPM 20-30-03).

对于 BMS 5-89 底漆,按照 BAC5749(SOPM 20-30-03)的规定,用 Turco 4215 碱性清洁剂浸泡碱性清洁。

b) For BMS 10-11, Type 1 primer:

对于 BMS 10-11,1 类底漆:

<1> Soak alkaline clean for approximately 5 minutes with Super Bee 300LF or Ridoline 909 cleaner as specified in BAC5749 (SOPM 20-30-03). Use Ridoline 909 on assemblies only if all mating surfaces are primed to prevent sandwich corrosion.

按照 BAC5749(SOPM 20-30-03)的规定,用 Super Bee 300LF 或 Ridoline 909 清洁剂浸泡碱性清洁剂约 5 分钟。只有在所有配合表面都涂有底漆的情况下,才能在组件上使用 Ridoline 909以防止夹层腐蚀。

<2> Fully rinse. If you do not get a water-break-free surface, rinse again.

充分冲洗。如果表面无断水,则再次冲洗。

NOTE: A water-break-free surface is a surface that keeps a continuous layer of water for approximately 30 seconds after the surface is rinsed with water. The 30 second period starts when the flow of all visible curtains of water stops.

注:无断水表面是指在用水冲洗表面后的大约 30 秒钟内,表面仍能保持连续的水层。当所有可见的水帘停止流动时,30 秒的时间就开始了。

<3> Fully dry the parts before you paint them.

在对零件进行喷漆之前,要将其完全晾干。

6) Method 6 (For BMS 10-20 primer only)

方法 6(仅适用于 BMS 10-20 底漆)

a) Alkaline emulsion clean with this mixture and procedure:

使用此混合物和程序进行碱性乳液清洁:

<1> Emulsion cleaner mixture (tolerance ±5% by volume):

乳剂清洁剂混合物(容许误差 ±5% (按体积)):

<a> MEK: 1 part by volume

甲基汞:1 份(按体积计)

<b> Isopropyl alcohol: 1 part by volume

异丙醇:1 份(按体积计)

<c> Pace B-82: 1 part by volume

Pace B-82:1 份(按体积计)

<d> Water: 1 part by volume

水:1 份(按体积计)

<2> Procedure

程序

<a> Fully mix the emulsion cleaner mixture components.

充分混合乳液清洁剂混合物部件。

<b> Apply the emulsion cleaner mixture on the surface to be cleaned.

将乳液清洁剂混合物涂抹在要清洁的表面上。

<c> Scrub with abrasive pads to remove the contamination.

用研磨片擦洗,清除污染物。

<d> Do not dip the abrasive pads into the cleaner.

不要将研磨片浸入清洁剂中。

<e> Do not let the cleaner dry on the surface.

不要让清洁剂在表面上变干。

b) Complete removal of blue stains from leak detection paint is not necessary.

不必完全清除泄漏检测漆上的蓝色污渍。

c) Fully rinse with clean water.

用清水充分冲洗。

d) Manually clean as specified in BAC5744 (SOPM 20-30-03) with this mixture and procedure:

按照 BAC5744(SOPM 20-30-03)中的规定,用这种混合物和程序进行手动清洁:

<1> Emulsion cleaner mixture (tolerance ±5% by volume):

乳剂清洁剂混合物(容许误差 ±5% (按体积计)):

<a> Pace B-82: 1 part by volume

Pace B-82:1 份(按体积计)

<b> Water: 3 parts by volume

水:3 份(按体积计)

<2> Procedure:

程序:

<a> Fully mix the emulsion cleaner mixture components.

充分混合乳液清洁剂混合物部件。

<b> Apply the emulsion cleaner mixture on the surface to be cleaned.

将乳液清洁剂混合物涂抹在要清洁的表面上。

<c> Scrub with abrasive pads to remove the contamination.

用研磨片擦洗,去除污染物。

<d> Fully rinse. If you do not get a water-break-free surface, do Paragraph 3.D.(4)(a)6)d)<2><b> thru Paragraph 3.D.(4)(a)6)d)<2><d> again.

充分冲洗。如果表面无断水,请再次执行第 3.D.(4)(a)6)d)<2><b>至第 3.D.(4)(a)6)d)<2><d>段。

NOTE: A water-break-free surface is a surface that keeps a continuous layer of water for approximately 30 seconds after the surface is rinsed with water. The 30 second period starts when the flow of all visible curtains of water stops.

注:无断水表面是指在用水冲洗表面后,能在大约 30 秒钟内保持连续水层的表面。当所有可见的水帘停止流动时,30 秒时间开始计算。

<e> Do not let the cleaner dry on the surface.

不要让清洁剂在表面上干燥。

e) Fully rinse with clean water to remove remaining dust and cleaner. If you do not get a water-break-free surface, clean again as specified by Paragraph 3.D.(4)(a)6)d).

用清水充分冲洗,去除残留的灰尘和清洁剂。如果表面无断水,则按照第 3.D.(4)(a)6)d)段的规定再次清洗。

f) Use pH paper to make a check for complete removal of the alkaline cleaner. The pH of the rinse water on the surface must be the same as the pH of the supplied tap water. If not, continue to rinse until the pH values of the two waters is the same.

用 pH 纸检查碱性清洁剂是否完全清除。表面冲洗水的 pH 值必须与所供自来水的 pH 值相同。如果不一致,则继续冲洗,直到两种水的 pH 值相同。

g) If there are areas of bare metal, apply applicable surface treatments as specified by the applicable specifications.

如果有裸露的金属区域,则按照相关规范的规定进行相应的表面处理。

h) Fully dry the parts before you paint them.

在对零件进行喷漆之前,应将其完全晾干。

7) Method 7 (Alkaline Emulsion Cleaning)

方法 7(碱性乳液清洗)

a) Manually alkaline emulsion clean with Cleaner A or Cleaner B and the procedure that follows:

使用清洁剂 A 或清洁剂 B 和以下程序手动进行碱性乳液清洁:

<1> Cleaner A

清洁剂 A

<a> Diethylene glycol monobutyl ether: 30-33% by volume

二乙二醇单丁醚: 30-33% (体积百分比)

<b> Pace B-82: 30-36% by volume

Pace B-82: 30-36%(体积百分比)

<c> Water to make up the remaining volume

水补足剩余体积

NOTE: Pace MF-30 has the same composition as this blend.

注: Pace MF-30 的成分与此混合物相同。

<2> Cleaner B

清洁剂 B

<a> MEK: 13-17% by weight

MEK:13-17%(重量百分比)

<b> Diethylene glycol monobutyl ether: 18-22% by weight

二乙二醇单丁醚: 18-22% (重量百分比)

<c> Pace B-82: 8-12% by weight

Pace B-82:8-12%(重量百分比)

<d> Water: 53-57% by weight

水: 53-57% (重量百分比)

<3> Procedure

程序

<a> Fully mix Cleaner A or B.

充分混合清洁剂 A 或 B。

<b> Apply the cleaner on the surface.

将清洁剂涂抹在表面上。

<c> Let the cleaner soak for a minimum of 2 minutes.

让清洁剂浸泡至少 2 分钟。

<d> Scrub with abrasive pads or aluminum oxide impregnated nylon fibers as necessary.

必要时用研磨片或浸渍氧化铝的尼龙纤维擦洗。

<e> Do not sand through to the substrate.

不要打磨到基底。

<f> Do not let the cleaner dry on the surface.

不要让清洁剂在表面上变干。

<g> Scrub as necessary, and apply more cleaner if the dirt is not fully removed.

根据需要进行擦洗,如果污垢未完全去除,可使用更多清洁剂。

<h> Rinse fully with clean water to remove dust and cleaner.

用清水充分冲洗,去除灰尘和清洁剂。

b) Do the checks that follow to see if the surface is clean. If these checks show that the surface is clean, then the procedure in Paragraph 3.D.(4)(a)7)c) and the check in Paragraph 3.D.(4)(a)7)d) are optional.

检查表面是否清洁。如果这些检查显示表面清洁,则第 3.D.(4)(a)7)c)段中的程序和第 3.D.(4)(a)7)d)段中的检查是可选的。

<1> The surface must be water-break-free, or

表面必须无断水,或

NOTE: A water-break-free surface is a surface that keeps a continuous layer of water for approximately 30 seconds after the surface is rinsed with water. The 30 second period starts when the flow of all visible curtains of water stops.

注:无断水表面是指表面用水冲洗后,在大约 30 秒钟内保持连续的水层。30 秒时间从所有可见水帘停止流动时开始计算。

<2> If the part surface is too complicated to be sure the surface is waterbreak-free, then there must be no visual contamination.

如果零件表面过于复杂,无法确定表面无水痕,则必须没有视觉污染。

<3> Complete removal of blue stains from leak detection paint is not necessary.

无需完全清除泄漏检测漆上的蓝色污渍。

c) Procedure X

程序 X

<1> Clean with abrasive or aluminum oxide impregnated nylon fiber and alkaline cleaner diluted with seven parts of water by volume.

使用研磨剂或浸渍氧化铝的尼龙纤维和按体积用 7 份水稀释的碱性清洁剂进行清洁。

<2> Do not let the cleaner dry on the surface.

不要让清洁剂在表面上干燥。

<3> Rinse fully with water to remove dust and cleaner.

用清水充分冲洗,除去灰尘和清洁剂。

<4> Use pH paper to make a check for complete removal of the alkaline cleaner. The pH of the rinse water on the surface must be the same as the pH of the supplied tap water. If not, continue to rinse until the pH values of the two waters is the same.

使用 pH 纸检查碱性清洁剂是否完全去除。表面冲洗水的 pH 值必须与提供的自来水的 pH 值相同。否则,继续冲洗,直到两种水的 pH 值相同。

d) Do a check to see if the surface is clean as specified in Paragraph 3.D.(4)(a)7)b). If the surface is not clean, start again at Paragraph 3.D.(4)(a)7)a).

按照第 3.D.(4)(a)7)b)段的规定,检查表面是否清洁。如果表面不清洁,则从第 3.D.(4)(a)7)a)段再次开始。

e) If there are bare areas on aluminum surfaces, repair them as specified in Paragraph 7.C.

如果铝表面有裸露区域,应按照第 7.C 段的规定进行修理。

f) Make sure the surfaces are fully dry before you paint them.

涂漆前要确保表面完全干燥。

E. After you clean the surfaces, give the parts protection as necessary. Use clean lint-free gloves to prevent contamination. The surfaces must be clean and dry when the BMS 10-79 primer is applied.

清洁表面后,对零件进行必要的保护。使用干净的无绒毛手套以防污染。喷涂 BMS 10-79 底漆时,表面必须清洁干燥。

4. MIXING 搅拌

A. Shake or fully mix the base material until all solids are sufficiently mixed before you mix the base material with the curing solution.

在将基础材料与固化溶液混合之前,先摇动或充分混合基础材料,直到所有固体充分混合。

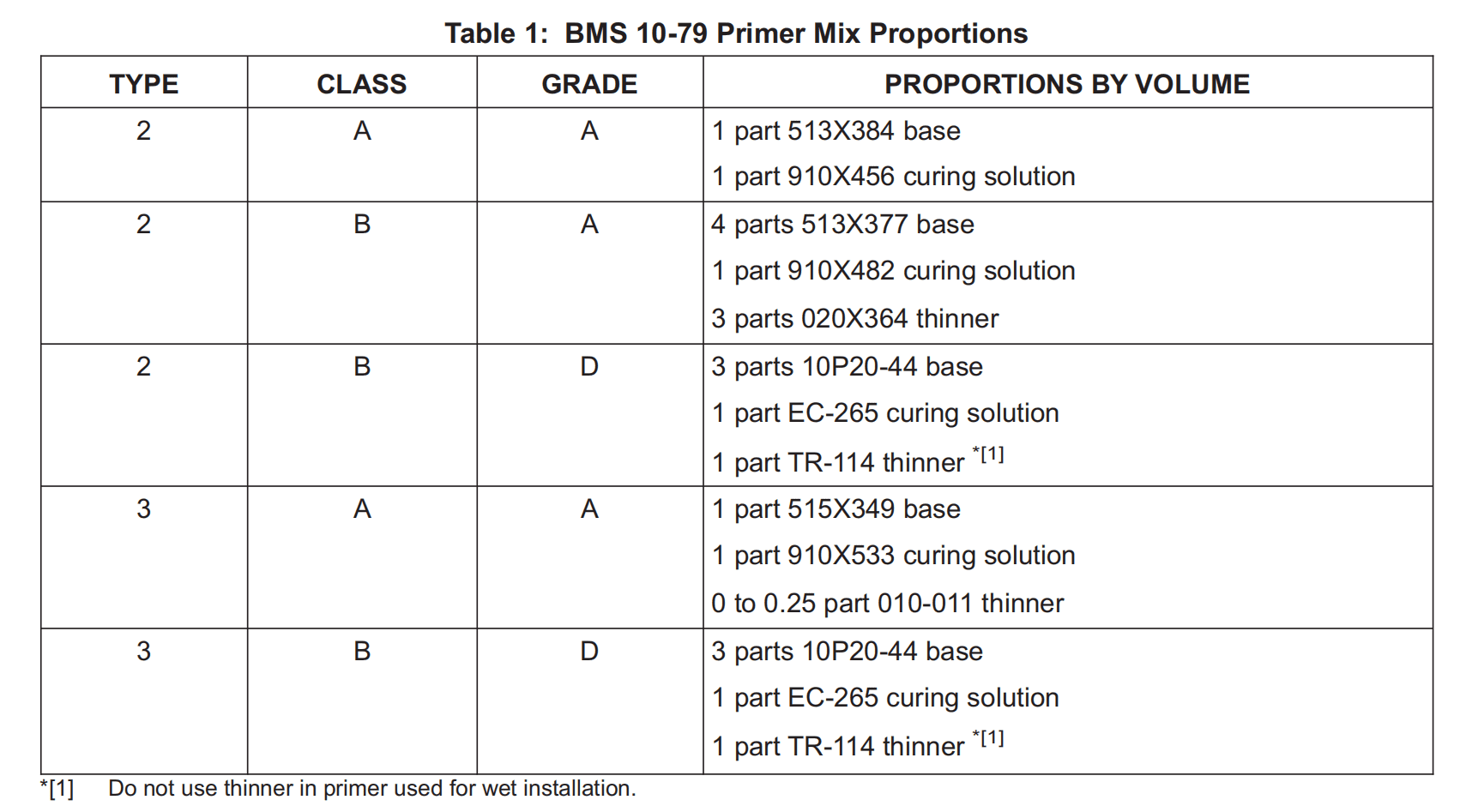

B. Mix and thin materials as specified in Table 1.

按表 1 规定混合和稀释材料。

(1) Put the specified proportion of base material into a clean solvent-resistant container. Metal, polyethylene and polypropylene containers are preferred. Containers such as coated and uncoated paper cups are not recommended because these could put contamination in the primer or change its properties.

将规定比例的基料放入干净的耐溶剂容器中。最好使用金属、聚乙烯和聚丙烯容器。不建议使用有涂层和无涂层的纸杯等容器,因为这些容器可能会污染底漆或改变其性能。

(2) While you continuously mix the base material, add the specified proportion of curing solution.

在连续混合基料的同时,加入规定比例的固化溶液。

(3) If thinner is applicable, while you continuously mix the base and curing solution mixture, add the specified proportion of thinner. Do not use thinner for Grade D primer used for wet installation.

如果使用稀释剂,在连续混合基料和固化溶液混合物的同时,加入规定比例的稀释剂。用于湿式安装的 D 级底涂不得使用稀释剂。

(4) Let the Grade A mixture wait 30 minutes before you apply it.

将 A 级混合料等待 30 分钟后再涂抹。

(5) Put the mixture through a paint strainer before you apply it.

使用前将混合物放入油漆过滤网。

(6) Apply the BMS 10-79 primer within the pot life as follows:

BMS 10-79 底漆的罐装寿命如下:

(a) Pot life at 100°F (38°C) or below. Discard all mixed materials remaining after pot life.

100°F (38°C) 或以下的罐装寿命。报废罐装寿命后剩余的所有混合材料。

1) Grade A: 8 hours

A 级:8 小时

2) Grade D:

D 级:

a) Mixed and thinned: 4 hours

混合并稀释: 4 小时

b) For wet installation (no thinner): 1 hour

湿法安装(无稀释剂): 1 小时

C. Unmixed Grade A or D primer components can be used until 12 months from the date of manufacture if they were stored by standard industry practices. After that, only Grade A components can be used within 12 more months if tests show that they agree with specifications. Grade D components must be discarded if they are older than 12 months from the date of manufacture.

未混合的 A 级或 D 级底漆部件,如果按标准行业惯例存放,可在生产日期起 12 个月内使用。此后,如果测试表明 A 级部件符合规范要求,则只能在 12 个月内使用。D 级部件如果从生产日期算起已超过 12 个月,则必须报废。

5. APPLICATION 应用

A. Brush or Spray

刷涂或喷涂

(1) You can apply the primer by spray or brush (spray is preferred).

喷涂或刷涂底漆均可 (首选喷涂)。

(2) Apply the primer at 40-100°F (4-38°C) air temperature; 50-90°F (10-32°C) is preferred.

在 40-100°F (4-38°C)的温度下应用底漆;最好在 50-90°F (10-32°C)的温度下应用。

(3) Apply the mixed and thinned (as applicable) materials to get a dry film thickness as follows:

按照以下步骤涂抹混合和稀释(如适用)的材料,以获得干膜厚度:

(a) Metal parts:

金属零件:

1) 1 layer: 0.5-1.0 mil

1 层: 0.5-1.0 密耳

2) 2 layers: 1.1-2.1 mil

2 层:1.1-2.1 密耳

(b) Composite or plastic parts:

复合材料或塑料零件:

1) 1 layer: 0.3-0.8 mil

1 层 0.3-0.8 密耳

2) 2 layers: 0.7-1.7 mils

2 层:0.7-1.7 密耳

(4) Let the completed layer wait 30 minutes, to let the solvents evaporate, before you force dry the parts.

让完成的底层等待 30 分钟,让溶剂挥发,然后再强力干燥零件。

(5) Cure the primer as specified in Paragraph 6.

按照第 6 段的规定固化底漆。

B. Wipe-on Primer for Plated Parts

电镀零件的擦拭式底漆

(1) Wipe the surface with solvent as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定用溶剂擦拭表面。

(2) Apply BMS 10-79, Type 3 primer on all of the specified surface with wipers soaked with primer. The primer can run onto adjacent surfaces, but you must remove that primer before it dries, as specified in Paragraph 5.B.(3).

用蘸有底漆的擦拭布在所有规定表面涂上 BMS 10-79,3 类底漆。底漆可以流到相邻表面上,但必须按照第 5.B.(3)段的规定,在底漆干燥前将其清除。

(3) Before the primer dries, gently remove unwanted wet primer with clean wipers. Do not use a solvent.

在底漆干之前,用干净的擦拭布轻轻擦拭掉不需要的湿底漆。不要使用溶剂。

(4) Cure the primer as specified in Paragraph 6.

按照第 6 段的规定固化底漆。

6. DRYING/CURING 干燥/固化

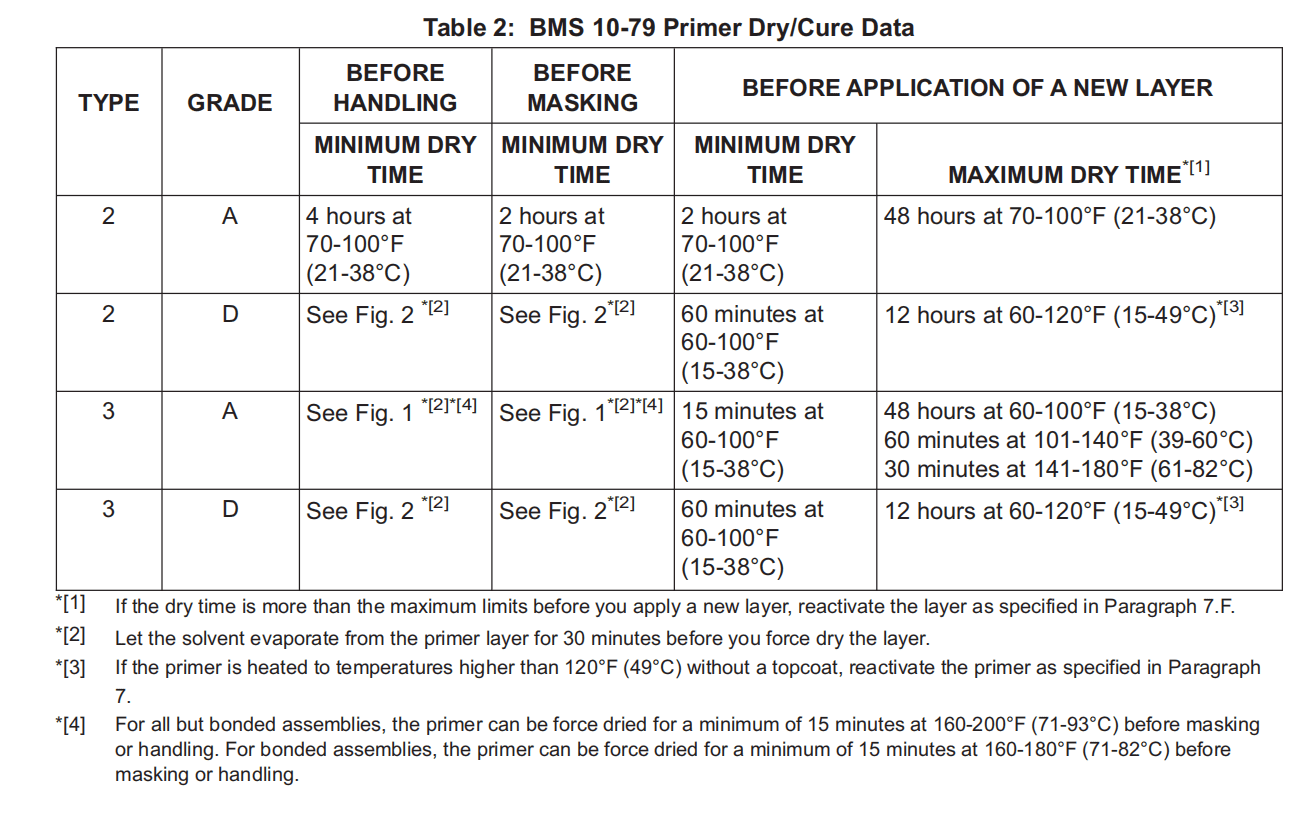

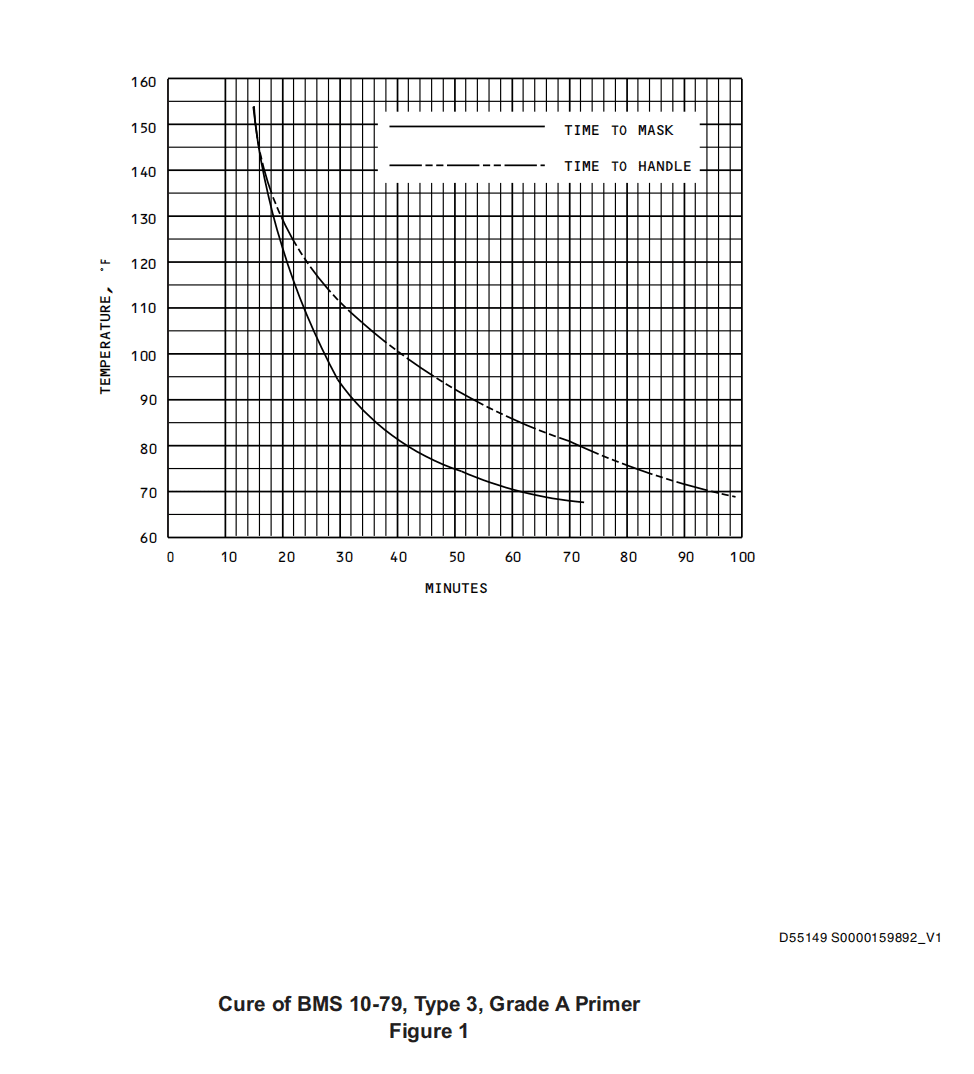

A. Dry/cure the layers as specified in Table 2 and Figure 1 or Figure 2, as applicable. Grade A primers can be baked a minimum of 15 minutes at 160-180°F (bonded assemblies) or 160-200°F (all other parts) before you touch or mask the parts.

按表 2 和图 1 或图 2(如适用)的规定干燥/固化各层。A 级底漆可在 160-180°F (粘接组件)或 160-200°F (所有其他零件)温度下烘烤至少 15 分钟,然后再接触或遮盖零件。

7. REWORK 返修

A. Use these procedures when the primer layer becomes scratched or damaged.

当底漆层出现划痕或损坏时,使用这些程序。

B. Rework when the base material has no bare spots

当底层材料无裸露点时进行返修

(1) Solvent clean the damaged area, and the area adjacent to the damaged area as necessary, as specified in BAC5750 (SOPM 20-30-03).

按 BAC5750 (SOPM 20-30-03)的规定,必要时用溶剂清洗受损区域及受损区域的邻近区域。

(2) Lightly sand the damaged area, and the area adjacent to the damaged area as necessary, with abrasive material or abrasive pads. Be careful not to sand the primer down to the base material.

根据需要,用研磨材料或研磨片轻轻打磨受损区域和受损区域附近的区域。注意不要将底漆打磨到基底材料。

(3) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03. You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,用溶剂清洗返修区域以除去灰尘。可以使用压缩空气或新的除尘抹布帮助除尘。

(4) Apply a new layer of primer that was prepared as specified in Paragraph 4. to the damaged area, and the area adjacent to the damaged area as necessary, as specified in Paragraph 5.

按照第 5 段的规定,在受损区域以及必要时在受损区域的邻近区域涂上一层按第 4 段规定制备的新底漆。

(5) Dry/cure the primer as specified in Paragraph 6.

按第 6 段规定干燥/固化底漆。

C. Rework when the base material has small bare spots

当基材有小的裸露点时进行返修

(1) Composite or plastic parts and assemblies

复合或塑料零件及组件

(a) Solvent clean the damaged area, and the area adjacent to the damaged area as necessary, as specified in BAC5750 (SOPM 20-30-03).

按 BAC5750 (SOPM 20-30-03)的规定,必要时用溶剂清洗受损部位及与受损部位相邻的区域。

(b) Sand the area with abrasive material or abrasive pads.

用研磨材料或研磨片打磨该区域。

(c) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03. You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,对返修区域进行溶剂清洁以除去灰尘。可使用压缩空气或新的除尘抹布帮助除尘。

(d) Apply a new layer of primer to the damaged area, and the adjacent areas as necessary, as specified in Paragraph 5.

按照第 5 段的规定,在受损区域以及必要的邻近区域涂上一层新的底漆。

(e) Dry/cure the primerl as specified in Paragraph 6.

按第 6 段的规定干燥/固化底漆。

(2) Metal parts and assemblies

金属零件和组件

(a) Damaged areas of titanium or CRES parts with pretreatment, or aluminum with a chemical conversion coating pretreatment (but not the anodize pretreatment) can be reworked as follows:

经过预处理的钛或 CRES 零件,或经过化学转换涂层预处理(但未经过阳极氧化预处理)的铝的受损部位可按以下方法返修:

1) Solvent clean the damaged area, and the area adjacent to the damaged area as necessary, as specified in BAC5750 (SOPM 20-30-03).

根据 BAC5750(SOPM 20-30-03)的规定,必要时对受损区域以及受损区域的邻近区域进行溶剂清洗。

2) Sand the bare area, and the area adjacent to the damaged area as necessary, with abrasive material or abrasive pads, to remove remaining coatings.

根据需要用研磨材料或研磨片打磨裸露区域和受损区域的邻近区域,以去除剩余涂层。

3) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03). You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,对返修区域进行溶剂清洗,清除灰尘。可以使用压缩空气或新的除尘抹布帮助除尘。

4) Apply a sol-gel conversion coating to titanium and CRES parts and assemblies as specified in BAC5665. Prepare aluminum parts as specified in BAC5719, Type 2, Class A (SOPM 20-43-03).

按照 BAC5665 的规定,为钛和 CRES 零件和组件涂上溶胶-凝胶转换涂层。按照 BAC5719 中 2 类 A 级(SOPM 20-43-03)的规定准备铝零件。

5) Immediately before you apply the primer, wipe the surfaces with a new tack rag or blow the surfaces with compressed air to remove particulate contamination.

在涂刷底漆之前,立即用一块新的除尘抹布擦拭表面,或用压缩空气吹表面以去除微粒污染。

6) Apply a new layer of primer that was prepared as specified in Paragraph 4. to the damaged area, and the adjacent area as necessary, as specified in Paragraph 5.

按照第 5 段的规定,在受损区域以及必要时在相邻区域涂上一层按第 4 段规定制备的新底漆。

7) Dry/cure the primer as specified in Paragraph 6.

按第 6 段的规定干燥/固化底漆。

(b) Aluminum with an anodize pretreatment, with defects on less than 5% of the surface, can be reworked one time by this procedure:

阳极氧化预处理的铝材,如果表面缺陷少于 5%,可按此程序返修一次:

1) Solvent clean the damaged area, and the area adjacent to the damaged area as necessary, as specified in BAC5750 (SOPM 20-30-03).

按照 BAC5750(SOPM 20-30-03)的规定,必要时对受损区域以及受损区域的邻近区域进行溶剂清洗。

2) Remove local defective coating areas as specified in BAC5725 (SOPM 20-30-02) or lightly sand with abrasive material or abrasive pads to remove the remaining coatings.

按照 BAC5725(SOPM 20-30-02)的规定清除局部有缺陷的涂层区域,或用研磨材料或研磨片轻轻打磨,以清除剩余涂层。

3) Sand the bare areas and the adjacent areas with abrasive to make them rough. Smooth and blend the edges of the good coating with abrasive.

用研磨剂打磨裸露区域和邻近区域,使其变得粗糙。用磨料将良好涂层的边缘打磨平整。

4) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03). You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,用溶剂清洗返修区域以去除灰尘。可以使用压缩空气或新的除尘抹布帮助除尘。

5) Apply Alodine 600 to the bare areas as specified in BAC5719, Type 2 (SOPM 20-43-03).

按照 BAC5719 类型 2(SOPM 20-43-03)的规定,在裸露区域涂抹 Alodine 600。

6) Immediately before you apply the primer, wipe the surfaces with a new tack rag or blow the surfaces with compressed air to remove particulate contamination.

在涂刷底漆之前,立即用一块新的除尘抹布擦拭表面,或用压缩空气吹表面,以清除微粒污染。

7) Apply a new layer of primer that was prepared as specified in Paragraph 4., to the damaged area, and the adjacent area as necessary, as specified in Paragraph 5.

按照第 5 段的规定,在受损区域以及必要时在邻近区域涂上一层按第 4 段规定制备的新底漆。

8) Dry/cure the primer as specified in Paragraph 6.

按照第 6 段的规定干燥/固化底漆。

D. Rework when removal of primer from large areas is necessary

需去除大面积底漆时的返修

(1) Composite or plastic parts and assemblies

复合或塑料零件及组件

(a) Sand off the primer with an abrasive material or abrasive pads.

用研磨材料或研磨片打磨掉底漆。

(b) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03). You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,用溶剂清洗返修区域以除去灰尘。可使用压缩空气或新的除尘抹布帮助除尘。

(c) If applicable, prepare the plastic surfaces for paint as specified in BAC5837, or apply anti-static coating as specified in BAC5639.

如果适用,按照 BAC5837 的规定准备塑料表面的油漆,或按照 BAC5639 的规定涂上防静电涂层。

(d) Immediately before you apply the primer, wipe the surfaces with a new tack rag or blow the surfaces with compressed air to remove particulate contamination.

在涂刷底漆之前,立即用一块新的除尘抹布擦拭表面,或用压缩空气吹表面,以去除微粒污染。

(e) Apply a new layer of primer that was prepared as specified in Paragraph 4., as specified in Paragraph 5.

按照第 5 段的规定,涂上一层按第 4 段规定制备的新底漆。

(f) Dry/cure the primer as specified in Paragraph 6.

按第 6 段规定干燥/固化底漆。

(2) Metal parts and assemblies

金属零件和组件

(a) Sand off the primer with an abrasive material or abrasive pads.

用研磨材料或研磨片打磨掉底漆。

(b) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03). You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750(SOPM 20-30-03)的规定,用溶剂清洗返修区域以除去灰尘。可使用压缩空气或新的除尘抹布帮助除尘。

(c) As an alternative to Paragraph 7.D.(2)(a) and Paragraph 7.D.(2)(b), chemically remove the layer as specified in BAC5725 (SOPM 20-30-02).

作为第 7.D.(2)(a)段和第 7.D.(2)(b)段的替代方法,按照 BAC5725(SOPM 20-30-02)的规定,用化学方法去除涂层。

(d) Apply the pretreatment (such as plating) specified by the overhaul instructions.

进行大修说明规定的预处理(如电镀)。

(e) Immediately before you apply the primer, wipe the surfaces with a new tack rag or blow the surfaces with compressed air to remove particulate contamination.

在涂刷底漆之前,立即用一块新的除尘抹布擦拭表面,或用压缩空气吹表面以清除微粒污染。

(f) Apply a new layer of primer that was prepared as specified in Paragraph 4., to the damaged area and the adjacent area as necessary, as specified in Paragraph 5.

按照第 5 段的规定,必要时在受损区域和邻近区域涂上一层按第 4 段规定制备的新底漆。

(g) Dry/cure the primer as specified in Paragraph 6.

按第 6 段规定干燥/固化底漆。

E. Rework if the dry film layer is too thick

干膜层太厚时的返修

(1) Sand the areas with abrasive material or abrasive pads until the layer is within the specified thickness limits.

用研磨材料或研磨片打磨有关区域,直至干膜层在规定的厚度范围内。

(2) Solvent clean the reworked area to remove the dust as specified in BAC5750 (SOPM 20-30-03). You can use compressed air or new tack rags to help remove the dust.

按照 BAC5750 (SOPM 20-30-03)的规定,用溶剂清洗返修区域以除去灰尘。可使用压缩空气或新的除尘抹布帮助清除灰尘。

F. Rework if the dry time is more than the maximum limits specified for application of a new topcoat

如果干燥时间超过规定的涂刷新面漆的最大限度,则应返修

(1) BMS 10-79, Type 2

BMS 10-79,类型 2

(a) Grade A: Reactivate as specified in Paragraph 3.D.(4).

A 级:按第 3.D.(4)段的规定重新活化(重涂)。

(b) Grade D: Reactivate as specified in Paragraph 3.D.(2).

D 级:按第 3.D.(2)段的规定重新活化(重涂)。。

(c) Apply a new layer of BMS 10-79, Type 2 primer as specified in Paragraph 5.

按第 5 段规定涂上一层新的 BMS 10-79 2 型底漆。

(2) BMS 10-79, Type 3

BMS 10-79,类型3

(a) Grade A: Reactivate as specified in Paragraph 3.D.(4).

A 级:按第 3.D.(4)段规定重新活化。

(b) Grade D: Reactivate as specified in Paragraph 3.D.(2).

D 级:按第 3.D.(2)段规定重新活化。

(c) Apply a new layer of BMS 10-79, Type 3 primer as specified in Paragraph 5.

按第 5 段规定涂上一层新的 BMS 10-79 3 型底漆。

8. QUALITY CONTROL 质量控制

A. Sprayed or brushed-on primer

喷涂或刷涂底漆

(1) Metal parts

金属零件

(a) The measured dry film thickness for one layer of primer must be 0.5-1.0 mil (0.0005-0.0010 inch) thick (after the minimum dry to tape time). In local areas of rework, overlap and overspray, the primer can be a maximum of 2.0 mils (0.0020 inch) thick.

一层底漆的测量干膜厚度必须为 0.5-1.0 密耳(0.0005-0.0010 英寸)厚(经过最短干燥至胶带时间)。在局部返修、重叠和过喷区域,底漆厚度最多可达 2.0 密耳(0.0020 英寸)。

(b) The measured dry film thickness of the primer for two layers must be 1.1-2.1 mils (0.0011-0.0021 inch) thick (after the minimum dry to tape time). In local areas of rework, overlap and overspray, the primer can be a maximum of 3.0 mils (0.0030 inch) thick.

两层底漆的测量干膜厚度必须为 1.1-2.1 密耳(0.0011-0.0021 英寸)厚(经过最短干燥至胶带时间)。在局部返修、重叠和过喷区域,底漆的厚度最多可达 3.0 密耳(0.0030 英寸)。

(c) Refer to BSS7413 for measurement procedures.

有关测量程序,请参阅 BSS7413。

(d) Round off the measured thickness values to the nearest tenth of a mil (0.0001 inch).

将测得的厚度值四舍五入到最接近的十分之一密耳(0.0001 英寸)。

(2) Plastic parts

塑料零件

(a) The measured dry film thickness of the primer for one layer must be 0.3-0.8 mil (0.0003-0.0008 inch) thick (after the minimum dry to tape time). For best coating performance, a thickness of 0.3 mil (0.0003 inch) is recommended.

一层底漆的测量干膜厚度必须为 0.3-0.8 密耳(0.0003-0.0008 英寸)厚(经过最短干燥至胶带时间)。为获得最佳涂层性能,建议厚度为 0.3 密耳(0.0003 英寸)。

(b) The measured dry film thickness of the primer for two layers must be 0.7-1.7 mils (0.0007-0.0017 inch) thick (after the minimum dry to tape time).

测量两层底漆的干膜厚度必须为 0.7-1.7 密耳(0.0007-0.0017 英寸)厚(经过最短干燥至胶带时间)。

(c) To measure the thickness, use one of these BAC5882 Methods:

测量厚度时,请使用 BAC5882 方法中的一种:

1) Method 1

方法 1

a) Put metallic panels adjacent to the parts to get the coating. Put the panels in a position to get the same thickness as that to be applied to the parts.

将金属板放在要获得涂层的零件旁边。将金属板放在与要涂在零件上的厚度相同的位置。

b) Apply the coating to the plastic part and the metallic panel at the same time.

同时在塑料零件和金属板上涂抹涂层。

c) Measure the coating thickness on the metallic panel as specified in BSS7413.

按照 BSS7413 的规定测量金属面板上的涂层厚度。

d) Use this value as the thickness value of the coating on the plastic part.

将此值作为塑料零件上涂层的厚度值。

2) Method 2

方法 2

a) If the parts have fastener hardware or other metal inserts to be coated at the same time as the plastic surface, measure the dry film thickness on the metal inserts as specified in BSS7413.

如果零件上有紧固件硬件或其他金属嵌件要与塑料表面同时涂覆,则按照 BSS7413 中的规定测量金属嵌件上的干膜厚度。

b) Use this value as the thickness value of the coating on the plastic part

将此值作为塑料零件上涂层的厚度值;

(d) Round off the measured thickness values to the nearest tenth of a mil (0.0001 inch).

将测得的厚度值四舍五入到最接近的十分之一密耳(0.0001 英寸)。

B. Wiped-on Primer

擦拭底漆

(1) Film thickness, adhesion and solvent resistance requirements are not applicable to wiped-on primer on plated surfaces.

薄膜厚度、附着力和耐溶剂性要求不适用于电镀表面的擦拭式底漆。

(2) Some sign of primer on the plated surfaces is acceptable.

电镀表面上有一些底漆的痕迹是可以接受的。

(3) Chrome plate can be polished after the primer dries, to keep primer only in the porosity of the chrome plate.

可在底漆干燥后对电镀铬板进行抛光,使底漆仅留在电镀铬板的孔隙中。