螺栓和螺母的安装BOLT AND NUT INSTALLATION

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5009. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5009。可查阅波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据具有通用性。并不涉及所有情况或特定安装。请将此数据作为帮助您编写最低标准的指南。

C. The instructions in this subject are for bolts, screws and nuts which are not fluid tight and which are installed in metal structure. For fluid-tight fasteners, refer to BAC5047. For fasteners installed in composite structure, refer to BAC5063 (SOPM 20-50-18). For hydraulic fittings such as unions, reducers, valves, restrictors, plugs, tube and pipe fittings and clamps, refer to BAC5001-series (SOPM 20-50-00).

本主题中的说明适用于安装在金属结构中的非液密螺栓、螺钉和螺母。对于液密紧固件,请参考 BAC5047。对于安装在复合结构中的紧固件,请参考 BAC5063 (SOPM 20-50-18)。关于液压接头,如联合接头、变径接头、活门、节流孔、堵盖、管道和管接头以及夹具,请参阅 BAC5001-系列(SOPM 20-50-00)。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商名称和地址清单请参见 SOPM 20-00-00。

2. DEFINITIONS 定义

A. Breakaway torque — The torque necessary to start to turn the fastener from a stopped position during a removal cycle with no load on the base of the fastener.

松动扭矩 — 在紧固件无负载的情况下,在拆卸过程中从静止位置开始转动紧固件所需的扭矩。

B. Clamp up — The force inside (between) the installed bolt and nut. The force that holds the assembled parts together.

夹紧力 — 安装好的螺栓和螺母内部(之间)的力。将组装好的零件固定在一起的力。

C. Drive (or driving) torque — The torque necessary to keep the fastener in motion as it is turned but before it comes against the mating surface. When overhaul instructions tell you to tighten to a numerical value “above drive torque”, add the drive torque value to the specified numerical value to get the value to be read from the torque wrench as the fastener is tightened.

驱动(或传动)扭矩 — 当紧固件转动时,在其与配合表面接触之前,使其保持运动所需的扭矩。当大修说明告诉您要拧紧到 “高于驱动扭矩 ”的数值时,请将驱动扭矩值加上规定的数值,这个数值是拧紧紧固件时从扭矩扳手读取的数值。

D. Dry torque — The torque applied if the fastener (bolt, screw or stud) threads are not lubricated, compared to lube torque.

干扭矩 — 紧固件(螺栓、螺钉或螺柱)螺纹未润滑时的扭矩,与润滑扭矩相比。

E. Installation torque — The torque applied to the fastener at final assembly.

安装扭矩 — 紧固件最终装配时的扭矩。

F. Locking torque — Self-locking torque.

锁定扭矩 — 自锁扭矩。

G. Lube torque — The torque applied if the fastener (bolt, screw or stud) threads are lubricated with BMS3-33, BMS3-38, MIL-PRF-23827, MIL-PRF-46010, Bostic Never Seez Pure Nickel Special, Cetyl Alcohol, Dry Film Lubricant or Solid Film Lubricant or other material specified in the overhaul instructions. The lubricant on the threads of the fastener (bolt, screw or stud) can be applied at the manufacturer (prelubricated), or specified on the Engineering drawing or overhaul instructions to be added to the fastener hole or threads.

润滑扭矩 — 紧固件(螺栓、螺钉或螺柱)螺纹使用 BMS3-33、BMS3-38、MIL-PRF-23827、MIL-PRF-46010、Bostic Never Seez 纯镍特种润滑剂、鲸蜡醇、干膜润滑剂或固膜润滑剂或大修说明中规定的其他材料进行润滑时的扭矩。紧固件(螺栓、螺钉或螺柱)螺纹上的润滑剂可在制造商处涂抹(预润滑),或在工程图或大修说明中规定添加到紧固件孔或螺纹上。

H. Maximum or minimum torque — The upper or lower limit of the specified torque range.

最大或最小扭矩 — 规定扭矩范围的上限或下限。

I. Prevailing torque — Self-locking torque.

一般扭矩 — 自锁扭矩。

J. Run down torque — 1. Drive torque. 2. Self-locking torque.

静止扭矩 — 1. 驱动扭矩。2. 自锁扭矩。

K. Running torque — 1. Drive torque. 2. Self-locking torque.

运行扭矩 — 1. 驱动扭矩。2. 自锁扭矩。

L. Run-on torque –1. Drive torque. 2. Self-locking torque.

连贯扭矩 –1. 驱动扭矩 2. 自锁扭矩。

M. Run-up torque –1. Drive torque. 2. Self-locking torque.

预紧扭矩 –1. 驱动扭矩。2. 自锁扭矩。

N. Seating torque — The torque necessary to bring the mating faces into a final position. The torque is measured only in the tightening direction.

就位扭矩 — 将配合面最终就位所需的扭矩。该扭矩仅在拧紧方向测量。(就是拧到贴合位置即可)

O. Self-locking torque — The torque necessary to turn a fastener with a self-locking feature on its mating threaded part when 100 percent of the locking feature is engaged, and the fastener is not down against the mating surface.

自锁扭矩 — 紧固件的配合螺纹零件上具有自锁功能,当100%的锁定功能啮合时,紧固件没有向下顶住配合面,转动该紧固件所需的扭矩。

P. Snug up — To tighten a nut or fastener to overcome the self-locking torque and close all gaps under the nut or fastener, washers, and between joint components without inducing significant tension in the fastener. Reference hand tightened fasteners such as knurled knobs, wing nuts, tray hold-down knobs, etc.

拧紧 — 拧紧螺母或紧固件,以克服自锁扭矩,并闭合螺母或紧固件、垫圈下方以及连接部件之间的所有间隙,同时不对紧固件造成明显拉力。参考用手拧紧的紧固件,如滚花旋钮、翼形螺母、托盘固定旋钮等。

Q. Target value — Unless shown differently, the value midway between the lower and upper limits of the specified torque range.

目标值 — 除非另有说明,为规定扭矩范围下限和上限的中间值。

3. GENERAL 通用

A. All threads of the nut must be completely engaged and all of the chamfer at the end of the bolt must be above the outer surface of the nut. If the fastener has no chamfer, its end must extend a minimum of 1.5 threads out from the nut.

螺母的所有螺纹必须完全啮合,螺栓末端的所有倒角必须高于螺母外表面。如果紧固件没有倒角,其末端必须伸出螺母至少 1.5 个螺纹。

B. Nuts must not engage the first incomplete thread next to the shank of the bolt.

螺母不得啮合螺栓柄旁边的第一个不完整螺纹。

C. Do not degrease or lubricate bolts and nuts unless specified by the overhaul instructions.

除非大修说明书有规定,否则不得对螺栓和螺母进行脱脂或润滑。

D. Unless the fastener is fully threaded, no threads in bearing are permitted when installed in material 0.093 inch or less in thickness. In thicknesses more than 0.093 inch, a maximum of two threads in bearing is permitted. No more than 25 percent of the minimum thickness of a hole in a metal part can have threads in bearing. Grip length can be adjusted as specified in Paragraph 4.

除非紧固件为全螺纹,否则安装在厚度为 0.093 英寸或以下的材料中时,轴承中不允许有螺纹。在厚度大于 0.093 英寸的材料中,轴承内最多允许有两个螺纹。在金属零件上,轴承中的螺纹不能超过孔最小厚度的 25%。握持长度可按第 4 段规定调整。

E. Before assembly, remove burrs, sharp edges, cured sealant, dirt, grease or unwanted material from the threads of the nuts or bolts. But sealant removal from the threads is not necessary, after you install the bolt into structure through a wet sealed area, if you tighten the nut during the sealant squeeze-out time as specified in BAC5000 (SOPM 20-50-19).

组装前,清除螺母或螺栓螺纹上的毛刺、尖锐边缘、固化密封剂、污垢、油脂或不需要的材料。但如果在 BAC5000(SOPM 20-50-19)规定的密封剂挤出时间内拧紧螺母,则在通过潮湿的密封区域将螺栓安装到结构中后,无需清除螺纹上的密封剂。

F. Install the fasteners with the heads up or forward, unless specified differently by the overhaul instructions.

除非大修说明书另有规定,否则安装紧固件时应将头部朝上或朝前。

G. If applicable, install the mechanical locking safety devices by the instructions in SOPM 20-50-02.

如适用,按照 SOPM 20-50-02 的说明安装保险丝。

H. Do not apply an installation finish (such as primer or sealant) to holes or countersinks before you install fasteners, unless specified by the overhaul instructions.

除非大修说明书有规定,否则在安装紧固件之前,不要在孔或沉孔上涂抹安装饰面(如底漆或密封胶)。

I. Bolts in close-toleranced clearance or interference fit holes must not be turned with a wrench on the head, unless specified by the overhaul instructions.

除非大修说明书有规定,否则不得用扳手转动紧密公差间隙或过盈配合孔中的螺栓。

4. ADJUSTMENT OF GRIP LENGTH 握持长度的调整

A. Unless one of the conditions that follow occurs (or as specified by BAC5009), a bolt one or two grip lengths longer or shorter than that specified by the overhaul instructions can be used to obey the instructions of Paragraph 3.D. Fully threaded bolts can be adjusted to be longer or shorter by one or two length dash numbers to obey other instructions. If the overhaul instructions do not give the length, use a bolt of a length that, when installed, extends by no less than the chamfer and no more than 3 threads out from the nut (6 threads on clamps).

除非出现下列情况之一(或按 BAC5009 规定),可使用比大修说明规定长或短一个或两个握持长度的螺栓来遵守第 3.D 段的说明。全螺纹螺栓可调整长或短一个或两个长度,以遵守其他说明。如果大修说明没有给出长度,则使用安装时伸出倒角不小于螺母外 3 个螺纹(夹具上为 6 个螺纹)的螺栓长度。

(1) If one length of bolt is specified in an attach pattern of bolts, as in doors, accessories, removable panels and equipment items, the bolt grip lengths must not be changed unless specified by the overhaul instructions.

如在门,附件,可拆卸面板和设备项目的螺栓连接模式中规定了一种长度的螺栓,除非大修说明规定,否则不得改变螺栓握持的长度。

(2) If only one length of fasteners is specified by overhaul instructions, such as “No substitution of bolt grip length is permitted,” the bolt grip lengths must not be changed.

如大修说明只规定一种紧固件长度,如 “不允许替换螺栓握持长度”,则不得改变螺栓握持长度。

B. If the bolt grip length specified by the overhaul instructions does not let the end of the bolt extend through the nut as specified in Paragraph 3.A., you can adjust the grip length as necessary.

如果大修说明规定的螺栓握持长度不能让螺栓末端按照第 3.A. 段的规定穿过螺母,可以根据需要调整握持长度。

C. Grip length adjustment will be necessary when the specified grip length bolt is not available. Longer grip length bolts can be used with washers as necessary.

当没有规定握持长度的螺栓时,有必要调整握持长度。必要时可使用带垫圈的较长握持螺栓。

D. Grip length adjustment could be necessary when washers are specified for fillet relief or protection of the part surface. When washers are necessary for this adjustment, you can adjust the grip length as necessary.

当规定垫圈用于圆角消除或保护零件表面时,可能需要调整握持长度。当需要使用垫圈进行调整时,可根据需要调整握持长度。

5. USE OF WASHERS 垫圈的使用

A. Washers can be used to adjust the bolt grip length to meet the requirements of Paragraph 3.D.

垫圈可用于调整螺栓握持长度,以满足第 3.D 段的要求。

B. Washers are specified by the overhaul instructions to give protection to the surface from damage while you turn the nut or bolthead against it. As applicable, put the washer between the bolthead or the nut and the structure.

大修说明规定使用垫圈是为了在转动螺母或螺栓头时保护表面不受损坏。必要时,在螺栓头或螺母与结构之间放置垫圈。

C. One washer (with a countersunk bore) can be used below the bolthead to make space for the fillet radius between the shank and the face of the bolthead, if the hole does not have a chamfer to make this space. Grip length adjustment will be necessary when the specified grip length bolt is not available. Longer grip length bolts can be used with washers as necessary.

如果螺栓孔没有倒角,可在螺栓头下方使用一个垫圈(带沉孔),以便在螺栓柄和螺栓头表面之间留出圆角半径空间。当没有规定的握持长度螺栓时,需要调整握持长度。必要时可使用带垫圈的较长握持螺栓。

D. A total of three washers are permitted on each bolt (four are permitted if one washer is used to make space for the fillet radius between the shank and the face of the bolthead), but not more than two in one location (at the nut or at the bolthead).

每个螺栓上总共允许使用三个垫圈(如果使用一个垫圈在螺栓柄和螺栓头表面之间留出圆角半径空间,则允许使用四个垫圈),但在一个位置(螺母处或螺栓头处)不得使用超过两个垫圈。

E. If you use washers that are not specified by the overhaul instructions, be sure to use washers of a material which will be safe against the material which the washer will touch. For example, use aluminum (AN960D or NAS1149D) washers against aluminum, cadmium plated steel (AN960 or NAS1149F) washers against cadmium plated steel, and corrosion resistant steel (AN960C, NAS1149C or NAS1149E) washers against stainless steel, titanium, or magnesium.

如果使用大修说明未规定的垫圈,请务必使用与垫圈接触的材料安全的垫圈。例如,使用铝垫圈(AN960D 或 NAS1149D)防铝,使用镀镉钢垫圈(AN960 或 NAS1149F)防镀镉钢,使用耐腐蚀钢垫圈(AN960C、NAS1149C 或 NAS1149E)防不锈钢、钛或镁。

6. TIGHTENING SEQUENCE 拧紧顺序

A. If the overhaul instructions specify a multiple-bolt installation, do not tighten adjacent bolts or nuts in sequence, one after the other. A multiple-bolt installation is a row (5 or more bolts in a line), a pattern such as a circle, or multiple rows.

如果大修说明规定采用多螺栓安装,则不要一个接一个地依次拧紧相邻的螺栓或螺母。多螺栓安装是指一排(5 个或更多螺栓在一条线上)、一个图案(如圆圈)或多排。

B. In a closed pattern such as a circle, first turn opposite pairs of fasteners all around until they are tight. Then tighten opposite pairs of fasteners all around to the specified torque.

在圆形等封闭图案中,首先将相对的几对紧固件旋转一圈,直到拧紧为止。然后按规定扭矩拧紧相对的几对紧固件。

7. TORQUE REQUIREMENTS 扭矩要求

A. Use the torque values shown in the tables of BAC5009 unless:

使用 BAC5009 表中所示的扭矩值,除非

(1) The overhaul instructions give the torque value.

大修说明给出了扭矩值。

(2) Preload indicating (PLI) washers are used. Refer to BAC5009 par. 8.1.5.4 for instructions about PLI washers.

使用预紧指示(PLI)垫圈。参见 BAC5009 第 8.1.5.4 段。8.1.5.4 有关 PLI 垫圈的说明。

(3) The fasteners are number 8 (0.1640 inch diameter) or smaller and are used in electrical or electronic items. Tighten these fasteners to make the joint tight. A specified torque value is not necessary unless given by the overhaul instructions.

紧固件为 8 号(直径 0.1640 英寸)或更小,用于电气或电子设备。拧紧这些紧固件,使接头拧紧。除非大修说明有规定,否则无需规定扭矩值。

(4) The fasteners are hex-drive, radius lead-in or tapered shank bolt and nut combinations, or are installed in composite structure.

紧固件为六角、半径或锥柄螺栓和螺母组合,或安装在复合结构中。

(a) For hex-drive bolts installed in metallic structure, use the torque values shown in BAC5004-2.

对于安装在金属结构中的六角驱动螺栓,使用 BAC5004-2 中的扭矩值。

(b) For radius lead-in fasteners in aluminum, refer to BAC5060.

对于铝制半径导入紧固件,请参考 BAC5060。

(c) For tapered shank fasteners, refer to BAC5063-7.

对于锥柄紧固件,请参考 BAC5063-7。

(d) For non-metallic components in the fastener stackup, refer to BAC5063.

紧固件堆叠中的非金属部件,请参考 BAC5063。

(e) For non-metallic fasteners or structure, refer to BAC5063.

对于非金属紧固件或结构,请参阅 BAC5063。

B. Unless specified by the overhaul instructions, do not tighten the fastener more than the torque values shown in BAC5009 when you align the castellated nut with the hole for a cotter pin or other safety device.

除非大修说明书有规定,当您将柱形螺母与开口销或其他安全装置的孔对准时,紧固件的紧固力不要超过 BAC5009 中所示的扭矩值。

C. Use only certified and approved torque wrenches to apply the specified torque to the nuts and bolts. Refer to BAC5009 for details.

只能使用经认证和批准的扭矩扳手对螺母和螺栓施加规定的扭矩。详情请参阅 BAC5009。

D. Where fastener installation on the Engineering Drawing specifies snug or snug up, the definition and requirements of snug up will be used in place of the torque requirements defined in 737-678 SRM 51-40-04.

如工程图纸上的紧固件安装规定为紧固或向上紧固,将使用向上紧固的定义和要求代替 737-678 SRM 51-40-04 中规定的扭矩要求。

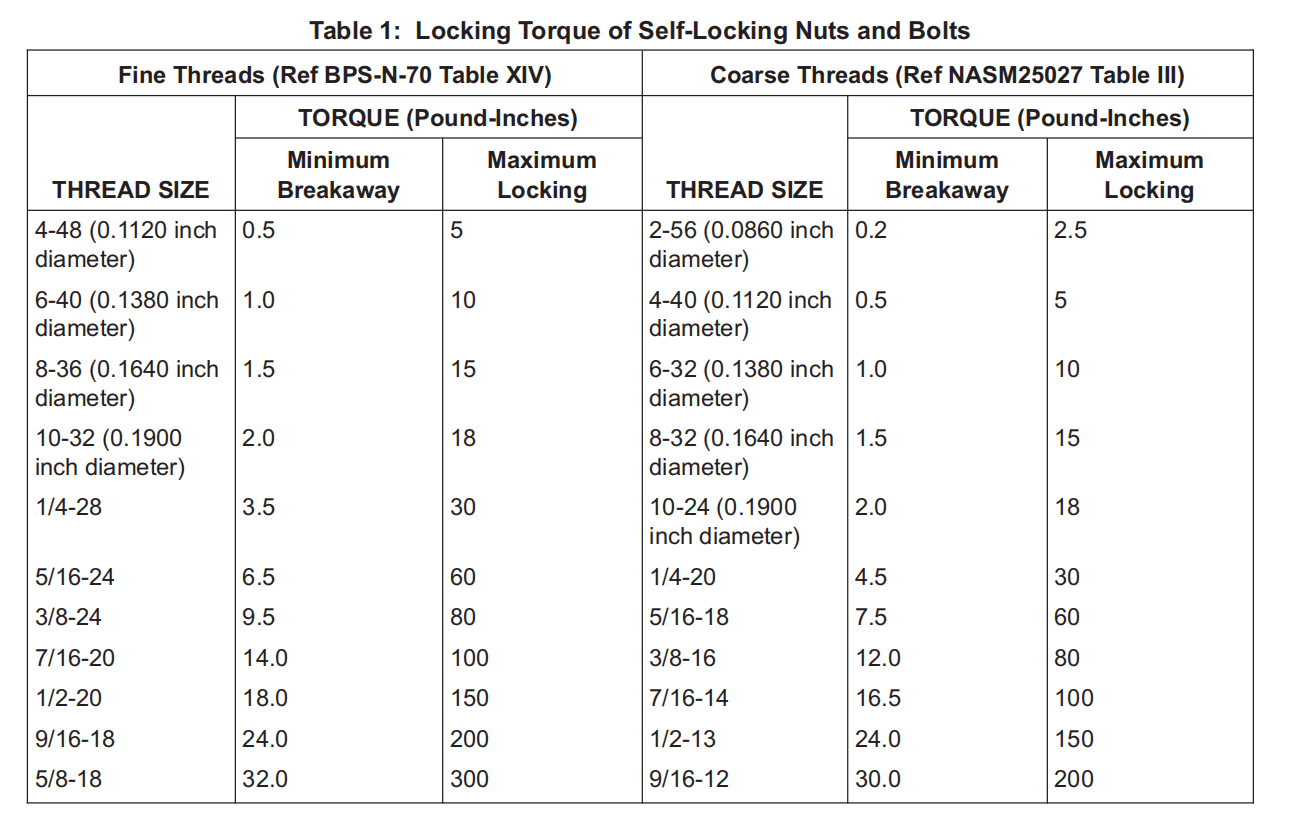

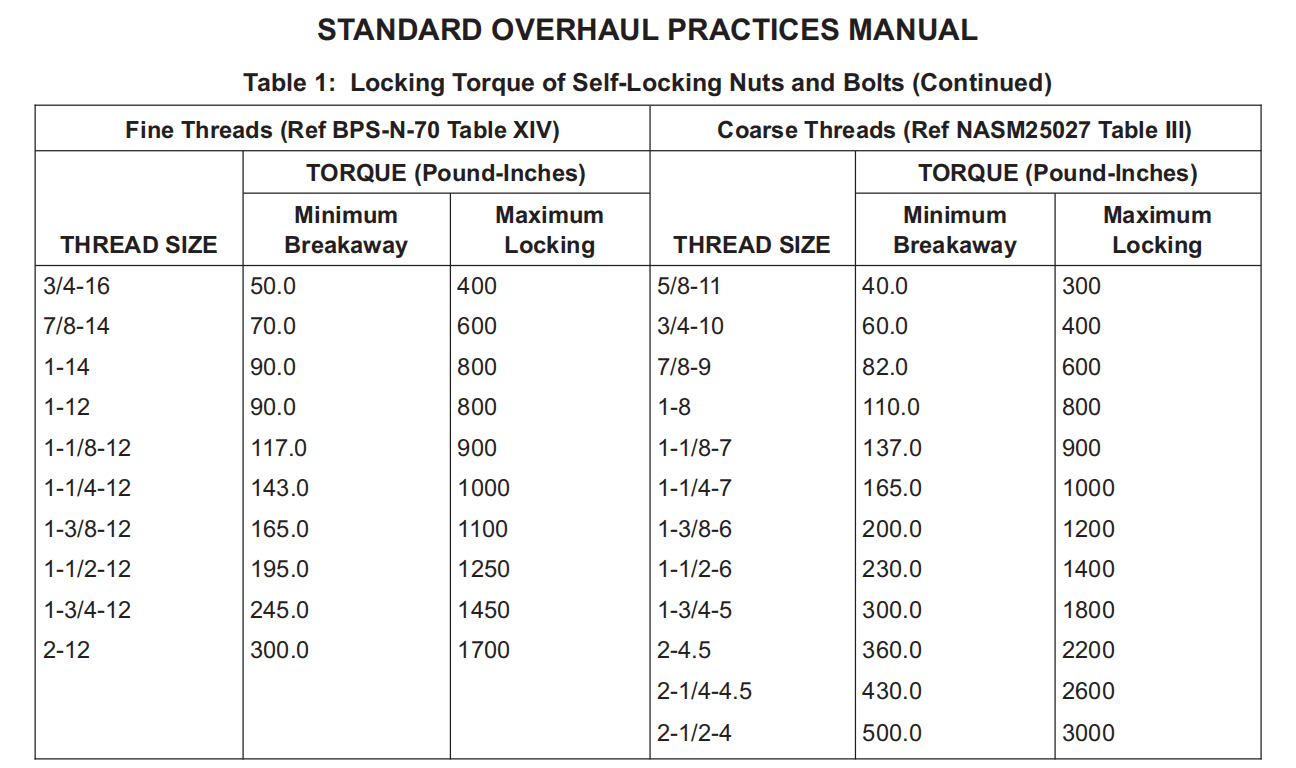

8. LOCKING TORQUE FOR SELF-LOCKING NUTS AND BOLTS 自锁螺母和螺栓的锁紧扭矩

CAUTION :IF A BACN10JC SELF-LOCKING NUT IS USED ON A BOLT THAT HAS A HOLE FOR A COTTER PIN, WE RECOMMEND THAT THE NUT NOT BE USED AGAIN AFTER REMOVAL. THE EDGES OF THE HOLE WILL MAKE THE SELF-LOCKING FEATURE UNSERVICEABLE.

注意 :如果在有开口销孔的螺栓上使用 BACN10JC 自锁螺母,我们建议在拆下螺母后不要再使用。因为孔的边缘会使自锁功能失效。

A. Use the locking torque range shown in Table 1 to help you make the decision that a self-locking nut and bolt combination is serviceable, or will be serviceable after removal.

使用表 1 所示的锁定扭矩范围来帮助您确定自锁螺母和螺栓组合是否可以使用,或拆卸后是否可以使用。

B. If you think the nut turns too easily or the torque is too much when you install the nut on the bolt, remove the nut and bolt and compare the torque with the values shown in Table 1.

如果您认为在螺栓上安装螺母时螺母太容易转动或扭矩太大,请卸下螺母和螺栓并将扭矩与表 1 中的数值进行比较。

C. A nut is installed when a minimum of one thread and the chamfer of the male thread are above the top of the nut.

安装螺母时,至少有一个螺纹和外螺纹的倒角在螺母顶部以上。

D. The removal cycle is complete when the locking device is disengaged.

当锁紧装置脱开时,拆卸周期已完成。

9. BAC5009 Torque Tables BAC5009力矩表

A. Refer to BAC5009 for its complete set of fastener torque tables.

参考BAC5009的整套紧固件扭矩表。