固体润滑膜的应用APPLICATION OF BONDED SOLID FILM LUBRICANTS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5811 and BAC5814, and from special instructions for application of the other lubricants. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范BAC5811和BAC5814,以及其他润滑剂的特殊应用说明。可访问波音工艺规范。

B. The data is general. Use it as a guide to help you write minimum standards.

数据为通用数据。请将其作为帮助您制定最低标准的指南。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

供应商名称和地址列表请参考SOPM 20-00-00。

2. DESCRIPTION 描述

A. A bonded solid film (or dry film) lubricant starts as a mixture of a solvent and resins and solid lubricants such as molybdenum disulfite and graphite. When the liquid is applied to the substrate, the solvent evaporates and the resins, when heated, make a lubricant layer approximately 0.0005 inch thick.

粘结固体薄膜(或干膜)润滑剂由溶剂、树脂和固体润滑剂(如二硫化钼和石墨)的混合物组成。当液体涂覆到基材上时,溶剂蒸发,加热后的树脂形成约0.0005英寸厚的润滑层。

B. These lubricants are used where other lubricants (such as oils and greases) are not easy to apply to or keep on the surface, or where there could be contamination by dirt or dust. These lubricants can also decrease wear and prevents galling and seizure of metals.

这些润滑剂用于其他润滑剂(如油和润滑脂)不易涂抹或附着在表面,或可能被污垢或灰尘污染的地方。这些润滑剂还可以减少磨损,防止金属磨损和咬合。

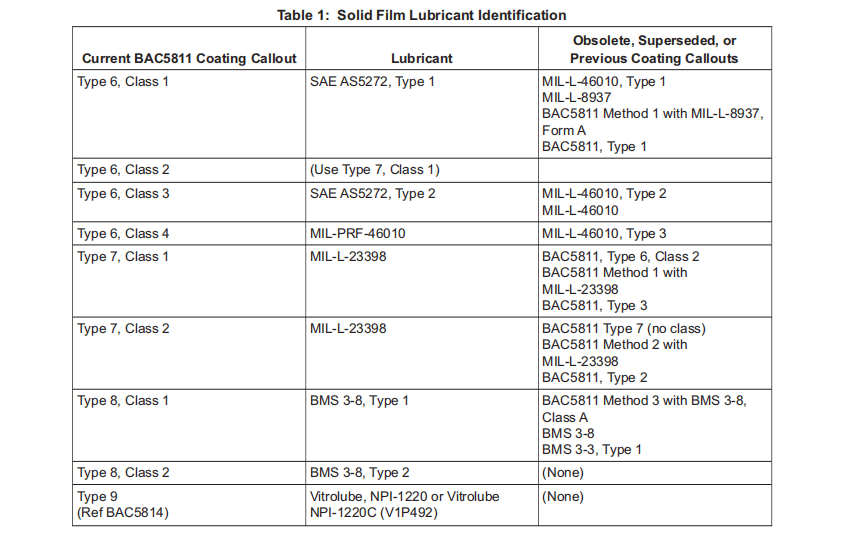

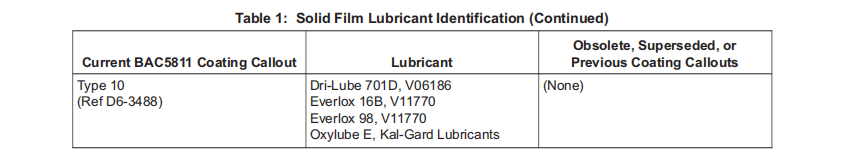

C. Table 1 compares the different solid or dry film lubricant names you could find in the overhaul instructions.

表1比较了大修说明中列出的不同固体或干膜润滑剂名称。

3. MATERIALS AND EQUIPMENT 材料和设备

NOTE: Refer to the applicable Qualified Products List, or equivalent list, of the specification listed for approved material part numbers and vendors.

注意:请参阅适用的合格产品清单或同等清单,其中列出了经批准的材料零件编号和供应商。

A. Solid film lubricant, air drying — MIL-L-23398

固体薄膜润滑剂,风干——MIL-L-23398

B. Solid film lubricant, heat cured, corrosion inhibiting — MIL-PRF-46010.

固体薄膜润滑剂,热固化,防腐蚀——MIL-PRF-46010。

C. Solid film lubricant, liquid dispersed — BMS 3-8

固体薄膜润滑剂,液体分散——BMS 3-8

D. Solid film lubricant, heat cured, corrosion inhibiting — SAE AS5272

固体润滑膜,热固化,防腐蚀——SAE AS5272

E. Other lubricants (SOPM 20-60-03)

其他润滑剂(SOPM 20-60-03)

(1) Drilube 700, V06186

NOTE: BMS 3-8 is an acceptable substitute up to 500°F.

备注:BMS 3-8是可接受的替代品,最高温度为500°F。

(2) Drilube 701D, V06186

(3) Everlox 16B, V11770

(4) Everlube 811, V11770

(5) Everlube 967, V11770

(6) Vitrolube NPI-1220 or NPI-1220C, V1P492

NOTE: This is a vendor-proprietary coating. Only the vendor (V1P492) can apply it.

注意:这是供应商专有的涂层。只有供应商(V1P492)才能使用。

F. Solvents (SOPM 20-60-01)

溶剂(SOPM 20-60-01)

(1) Aliphatic Naphtha – TT-N-95 (Replaces BMS 3-2)

脂肪烃石脑油——TT-N-95(取代BMS 3-2)

(2) P-D-680

(3) Methyl Ethyl Ketone (MEK) — ASTM D740

甲基乙基酮(MEK)——ASTM D740

(4) Ethyl Alcohol (Ethanol) — O-E-760

乙醇(酒精)——O-E-760

G. Wipers — BMS 15-5 (SOPM 20-60-04)

刷子——BMS 15-5(SOPM 20-60-04)

H. Paper towel, Kraft grade or equivalent

纸巾,Kraft级或同等产品

I. Masking tape

遮蔽胶带

J. Curing oven (preferred), or quartz or infrared lamps (optional) that can supply controlled heat to 575°F

固化烘箱(首选),或石英灯或红外灯(可选),可控制加热至575°F

4. LUBRICANT STORAGE AND SHELF LIFE 润滑油的储存和保质期

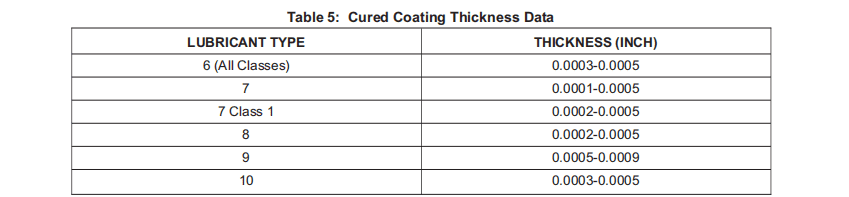

A. See Table 2 for details of storage and age requirements.

有关储存和保质期的详细信息,请参阅表2。

B. Do tests on lubricants as specified in BAC5811 or BAC5814 as necessary.

根据需要按照BAC5811或BAC5814的规定对润滑油进行测试。

C. For lubricants not shown, refer to the vendor’s instructions for storage and test requirements.

对于未列出的润滑剂,请参考供应商的说明,了解存储和测试要求。

5. GENERAL 通用

WARNING :SOME OF THESE MATERIALS ARE TOXIC, FLAMMABLE AND HAZARDOUS. OBEY THE SAFETY PRECAUTIONS. MAKE SURE THE VENTILATION IS SUFFICIENT. USE PROTECTIVE EQUIPMENT.

警告:这些材料中有一些有毒、易燃且危险。请遵守安全预防措施。确保通风良好。使用防护设备。

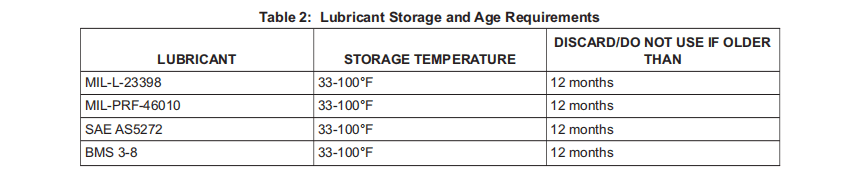

A. See Figure 1 for a general process flow for the application of dry film lubricant.

参见图1,了解干膜润滑剂应用的一般流程。

B. Do not let the surfaces become contaminated before coating. Use only clean lint free gloves or tongs to prevent fingerprint contamination.

在涂覆前,不要让表面受到污染。仅使用干净的无绒手套或钳子,以防止指纹污染。

C. After the pretreatment, give the surfaces protection from dust, handling, abrasion and liquids until you start the coating procedure.

在预处理后,在开始涂覆前,应保护表面免受灰尘、处理、磨损和液体的影响。

(1) Unless the surface is chemically treated or anodized aluminum or is passivated, BAC5811 coating must be applied as quickly as possible after surface pretreatment, and no later than 72 hours afterward.

除非表面经过化学处理或阳极氧化铝或钝化,否则必须在表面预处理后尽快涂覆 BAC5811 涂层,且不得迟于预处理后 72 小时。

(2) BAC5811 coating can be applied to chemically treated or anodized aluminum or passivated surfaces that waited more than 72 hours, if you solvent clean the surface and make sure there is no visible contamination.

BAC5811涂层可以涂覆在化学处理或阳极氧化铝或钝化表面上,但需等待72小时以上,前提是使用溶剂清洁表面并确保没有可见的污染。

(3) On all other surfaces that waited more than 72 hours, strip the surface and apply new pretreatment before you apply BAC5811 coating.

在所有其他等待超过72小时的表面上,在涂覆BAC5811涂层之前,应去除表面并涂覆新的预处理剂。

(4) Type 9 (BAC5814) coating on titanium must start within 30 minutes after the pretreatment is complete.

钛合金上的9型(BAC5814)涂层必须在预处理完成后30分钟内开始。

D. Make sure the coating material ingredients are fully and smoothly mixed before you apply the material. Shake or mix the material as necessary.

在喷涂前,确保涂层材料成分充分混合均匀。必要时摇匀或混合材料。

E. Apply BAC5811, Type 6 and 8 coatings only when the relative humidity is less than 70%.

仅在相对湿度低于70%时喷涂BAC5811、6型和8型涂层。

F. Apply Type 9 (BAC5814) coatings only to those materials that will not be damaged by short term exposure (up to 30 minutes) to temperatures of 950-1000°F. Alloys which are not corrosion resistant must be chrome or nickel plated for corrosion protection and to give a satisfactory surface for the lubricant coating. Some approved base materials are:

仅将9型(BAC5814)涂料用于短期暴露(最长30分钟)于950-1000°F高温下不会受损的材料。非耐腐蚀合金必须镀铬或镀镍,以提供防腐蚀保护,并使润滑涂层表面光滑。一些经过认证的基础材料包括:

(1) Titanium — CP; 6Al -4V

钛——CP;6Al -4V

(2) Nickel-based alloys — Alloys 625 and 718

镍基合金——625和718合金

(3) CRES (heat-treated to 170 ksi or less) — 15-5PH, 17-4PH, 17-7PH, and A286

CRES(热处理至170 ksi或更低)——15-5PH、17-4PH、17-7PH和A286

(4) Low-alloy steel — Tool steel with tempering temperature higher than 1000°F, such as H-11 (220-240 ksi) and M-50; nitrided Nitralloys N and 135M; AISI 4330M and 4340 (170 ksi or less); and BMS 7-182, Type 2 (220-240 ksi)

低合金钢——回火温度高于1000°F的工具钢,如H-11(220-240 ksi)和M-50;氮化镍基合金 N和135M;AISI 4330M和4340(170 ksi或更低);以及BMS 7-182,类型2(220-240 ksi)

(5) Platings – Chrome (electrolytic); nickel (electrolytic and electroless)

镀层——铬(电解);镍(电解和非电解)

6. SURFACE PRETREATMENT 表面处理

A. BAC5811 Processes

BAC5811 工艺

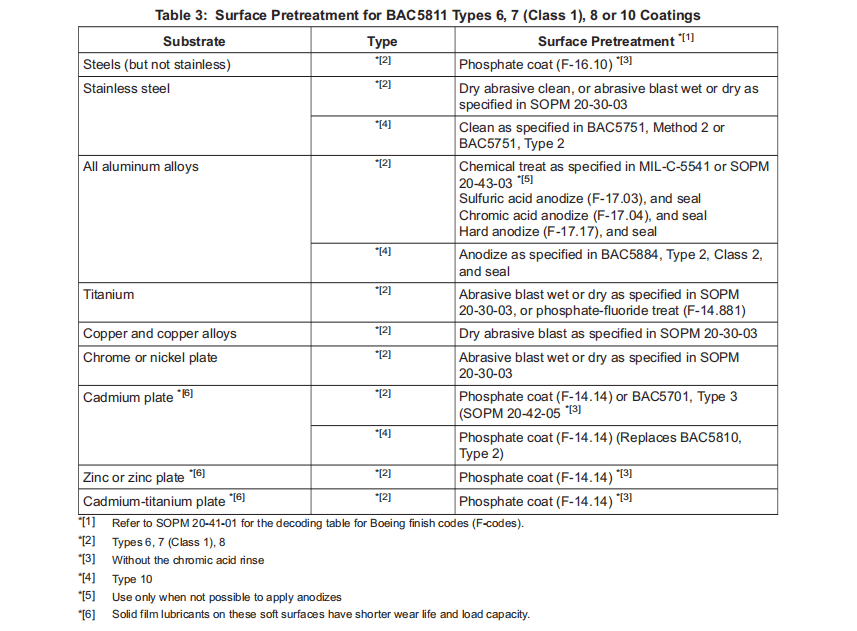

(1) Types 6, 7 (Class 1), 8, 10 — See Table 3.

类型 6、7(1 级)、8、10——见表 3。

(2) Type 7 — Solvent clean as specified in SOPM 20-30-03.

类型 7——按照 SOPM 20-30-03 中的规定进行溶剂清洁。

(3) Apply masks to surface areas that will not get the solid film lubricant, unless overspray of the lubricant is permitted by the overhaul instructions. Be careful during and after masking to prevent contamination of surfaces to be coated.

除非大修说明允许过量喷涂润滑剂,否则应在不会沾上固体薄膜润滑剂的表面区域使用遮蔽罩。在遮蔽期间和之后,应小心操作,防止待涂覆表面受到污染。

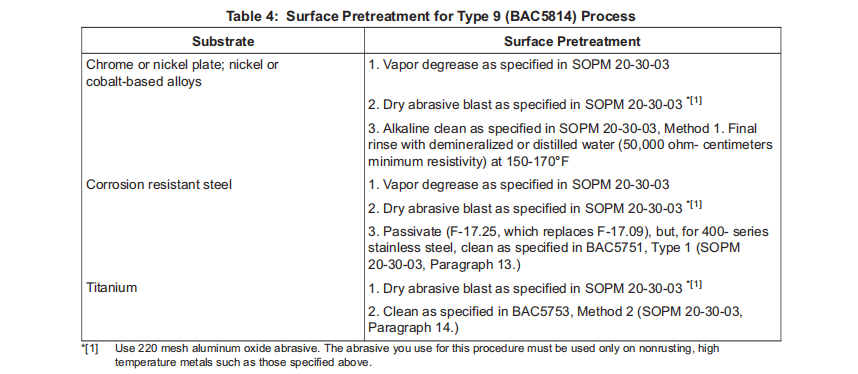

B. Type 9 (BAC5814) Process

类型 9(BAC5814)工艺

(1) The machined finish of the surface area to be coated must be 16 microinches or smoother, unless specified by the overhaul instructions.

除非大修说明另有规定,否则待涂覆表面的机械加工表面粗糙度必须达到 16 微英寸或更光滑。

(2) See Table 4 for surface pretreatment.

表面预处理请参阅表4。

7. SPRAY APPLICATION 喷涂应用

A. Use a cup-type spray gun of 1 quart or less capacity, that can continuously shake the lubricant in the cup.

使用容量为1夸脱或更小的杯型喷枪,该喷枪可连续摇动杯中的润滑剂。

B. Spray with the gun at a constant distance (6-8 inches) from the work, and move the gun at a constant speed to prevent runs and sags.

喷枪与工作区域保持恒定距离(6-8英寸)进行喷涂,并以恒定速度移动喷枪,以防止流淌和下垂。

C. Shake the spray gun after each pass to make sure the lubricant stays mixed.

每次喷涂后摇动喷枪,确保润滑剂保持混合状态。

D. Cure the complete layer as specified in Paragraph 12.

按照第12段所述固化整个涂层。

8. DIP APPLICATION 浸涂法

A. This procedure can be used if it makes a smooth layer.

如果能够形成光滑的涂层,可以使用此方法。

B. Start the dip tank agitation 15 minutes before you put in the first part.

在放入第一个零件前15分钟启动浸槽搅拌。

C. Lift the tank cover only to put in or remove parts, to minimize solvent evaporation.

仅当放入或取出零件时才打开槽盖,以减少溶剂蒸发。

D. Cure the complete layer as specified in Paragraph 12.

按第12段规定固化整个涂层。

9. DRILUBE 700 APPLICATION ON PARTS USED IN HIGH TEMPERATURE AREAS 在高温区域使用的零件上的应用DRILUBE 700

NOTE: BMS 3-8 is an acceptable substitute up to 500°F.

注意:BMS 3-8是可接受的替代品,最高温度可达500°F。

A. Make sure the surface has no dirt, grease or other unwanted material.

确保表面没有灰尘、油脂或其他不需要的材料。

B. Apply the lubricant to make a layer of the thickness specified in the overhaul instructions.

涂抹润滑剂,形成大修说明中规定的厚度。

C. Bake at 525-575°F for 1 hour.

在 525-575°F 下烘烤 1 小时。

10. EVERLUBE 811 APPLICATION ON PARTS USED IN EXTREME TEMPERATURE AND EXTREME PRESSURE AREAS (-365 to 1200°F) 在极端温度和压力区域使用的零件上涂抹 EVERLUBE 811(-365 至 1200°F)

A. Make sure the surface has no dirt, grease or other unwanted material.

确保表面没有灰尘、油脂或其他不需要的材料。

B. Apply the lubricant by the spray or dip procedures or with a brush.

通过喷涂、浸渍或刷涂的方式涂抹润滑剂。

C. Let the layer dry at room temperature. Then bake 2 hours at 150°F and 2 more hours at 400°F.

让润滑层在室温下干燥。然后在150°F下烘烤2小时,在400°F下再烘烤2小时。

11. EVERLUBE 967 APPLICATION FOR SOLID FILM LUBRICANTS & COATINGS 固体润滑膜和涂层上应用EVERLUBE 967

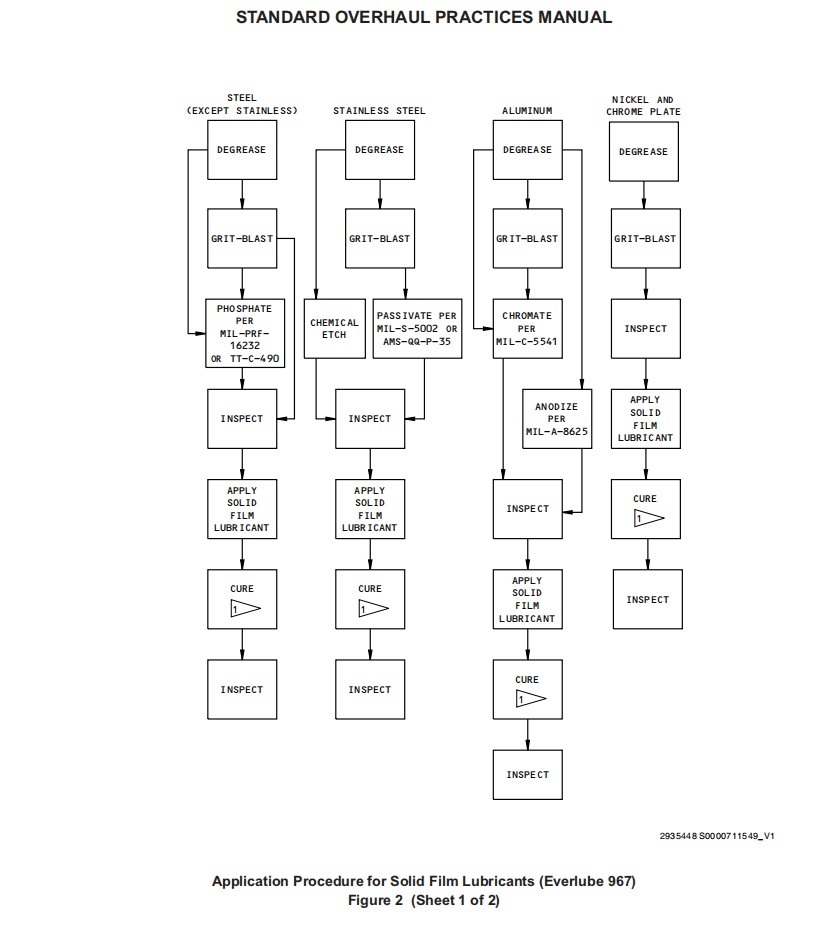

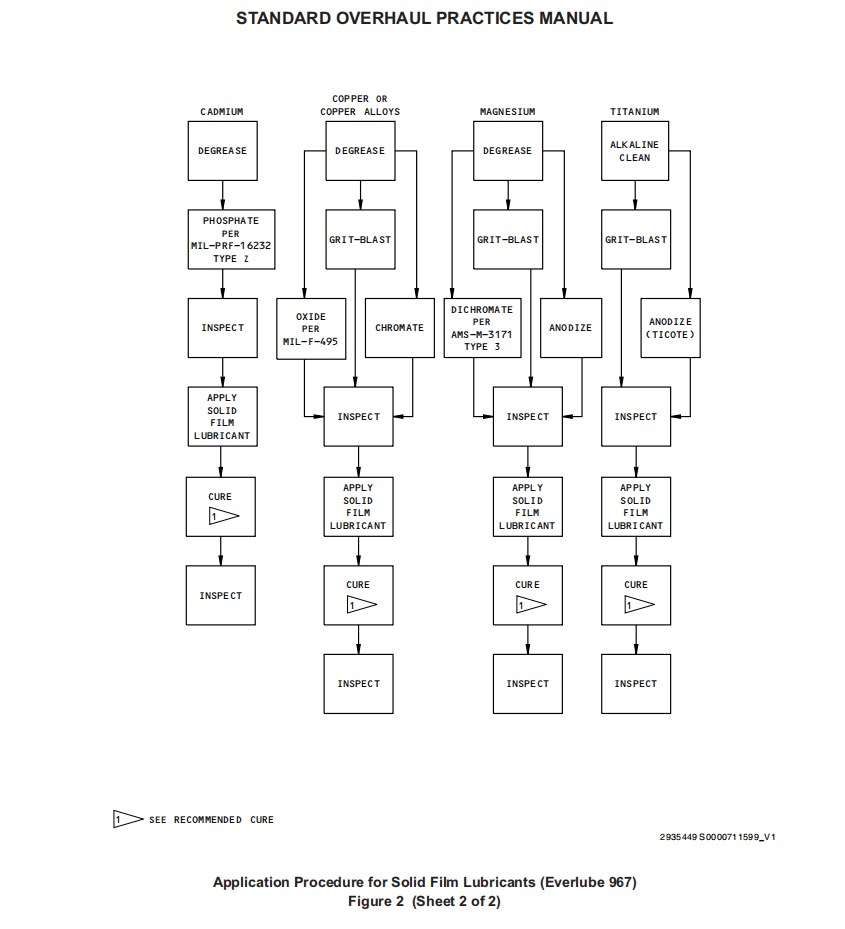

A. Before beginning application, it is important to understand that solid film lubricants and other engineered coatings should be viewed as a system, taking into account the base material, surface pretreatment, method of application and correct cure cycle. See Figure 2.

在开始应用前,请务必了解固体薄膜润滑剂和其他工程涂层应被视为一个系统,同时考虑基材、表面预处理、施工方法和正确的固化周期。见图2。

NOTE: Eighty per cent of all solid film lubricant failures are due to incorrect surface pretreatment and application. Twenty percent of solid film failures is the wrong coating was chosen.

注意:80%的固体薄膜润滑剂失效是由于不正确的表面预处理和施工。20%的固体薄膜失效是由于选择了错误的涂层。

B. Select Pretreatment according to Base Metal

根据基材选择预处理

(1) General Considerations

通用注意事项

(a) Soft metals such as aluminum, copper, and magnesium should only be grit blasted to remove oxides and impart the degree of roughness necessary for good adhesion of the coating 16 to 32 micro-inch roughness is generally ideal. Too much pressure in grit blasting could cause grit particles to imbed in the metal surface, although high pressure grit blast is acceptable on steel and titanium. Before beginning, adequately mask any areas to remain uncoated. Never touch pretreated parts with bare hands; always wear white cotton gloves.

铝、铜和镁等软金属应仅通过喷砂去除氧化物,并赋予涂层良好附着力所需的粗糙度。16至32微英寸的粗糙度通常较为理想。喷砂压力过大可能导致砂粒嵌入金属表面,但高压喷砂在钢和钛上是可以接受的。在开始之前,应充分遮盖任何不涂层的区域。切勿徒手触碰预处理过的零件;务必佩戴白色棉质手套。

(2) For Aluminum

对于铝材

(a) Vapor degrease the surfaces to be coated with perchloroethylene or other suitable solvent, depending upon local environmental restrictions. Continue with one of the following:

根据当地环境限制,用四氯乙烯或其他合适的溶剂对待涂覆表面进行蒸汽脱脂。然后进行以下操作之一:

• Anodize per MIL-A-8625.

按照MIL-A-8625进行阳极氧化。

• Grit blast and/or chromate conversion coat per MIL-C-5541.

按照MIL-C-5541进行喷砂和/或铬酸盐转化涂层。

(3) For Copper

对于铜材

(a) Vapor degrease as for aluminum. Grit blast and follow with chromate conversion coat per MIL-C-5541.

铝材的蒸汽脱脂。喷砂,然后按照MIL-C-5541进行铬酸盐转化涂层。

(4) For Magnesium

对于镁材

(a) Vapor degrease as for aluminum. Follow with one of these procedures:

与铝材一样的蒸汽脱脂。然后按照以下步骤之一进行:

• Dichromate per AMS-M-3171, Type III.

AMS-M-3171 III类型的重铬酸盐。

• Anodize per ASTM D-1732.

ASTM D-1732的阳极氧化。

• Grit blast.

喷砂。

(5) For Steel (Except Stainless)

对于钢(不锈钢除外)

(a) Degrease as for aluminum. Grit blast, or grit blast and phosphate per MIL-PRF-16232 or TT-C-490. Phosphate coating, although not mandatory, will enhance wear life and corrosion resistance and is highly recommended.

按照铝的处理方法进行除油。按照MIL-PRF-16232或TT-C-490进行喷砂或喷砂加磷化处理。虽然磷酸盐涂层不是强制性的,但它能够延长磨损寿命和提高耐腐蚀性,因此强烈建议使用。

(6) For Stainless Steel

对于不锈钢

(a) Vapor degreases as for aluminum. Grit blast and passivate per MIL-S-5002 as per AMS-QQ-P-35.

与铝材一样的蒸汽脱脂。根据AMS-QQ-P-35按照MIL-S-5002进行喷砂和钝化处理。

(7) For Titanium

对于钛材

(a) Alkaline clean surfaces to be coated. Then grit blast and titanium anodize or apply a phosphate fluoride conversion coating.

待涂层的表面进行碱性清洁。然后进行喷砂和钛阳极氧化处理,或涂覆磷酸氟化物转化涂层。

(b) Coating should be applied as soon as possible after surface preparation. If a delay of more than 8 hours is necessary, parts should be cleaned and degreased before coating.

表面处理后应尽快涂覆涂层。如果需要延迟8小时以上,则应在涂覆前清洁零件并去除油脂。

C. Prepare the Coating Mixture

准备涂层混合物

• Mix the coating thoroughly. For solvent-based coatings, we recommend an Indco air mixer with a low shear blade such as a Jiffy brand. (If you have had the coating compound in storage for some time and the solids have settled into a mass, a high shear blade may be necessary to achieve a complete suspension, although a high shear blade should never be used with coatings containing copper.) For water-based coatings, mix by stirring only agitating will cause unwanted air bubbles.

充分混合涂料。对于溶剂型涂料,我们推荐使用带有低剪切力叶片的Indco空气混合器,例如Jiffy品牌。(如果涂料混合物在储存了一段时间后,固体沉淀成块,则需要使用高剪切力叶片才能完全悬浮,但高剪切力叶片不能用于含有铜的涂料。)对于水性涂料,仅通过搅拌混合即可,否则会导致不必要的气泡。

• If you purchased your coating in the read-to-apply condition, no further preparation is necessary. For concentrate, thin using the solvent and dilution ratio recommended on the individual Technical Data Sheet. If a mixture of two different solvents is required, always pre-blend the solvents before introduction into the coating material.

如果您购买的涂料是即开即用型,则无需进一步准备。如果是浓缩型涂料,请按照单独的技术数据表上推荐的溶剂和稀释比例进行稀释。如果需要混合两种不同的溶剂,请务必在将溶剂引入涂料材料之前进行预混合。

D. Applying the Coating

喷涂

(1) You will get the best results using the spray method, although dip, brush, or automatic application are acceptable, depending upon the configuration and quantity of parts to be coated.

喷涂效果最佳,当然,根据待喷涂零件的配置和数量,也可采用浸涂、刷涂或自动喷涂。

(2) For spraying, we recommend any conventional, airatomized spray gun which utilizes a 0.040 in. (1.016 mm) – 0.070 in. (1.778 mm) fluid nozzle. An atomizing air pressure of 25- 35 pounds is suggested. A spray booth with exhaust fan is mandatory. Observe all the usual precautions for handling laquers and paints: full ventilation, organic respirator masks, and avoid skin contact, flames, and any other ignition sources.

喷涂时,我们建议使用常规的空气雾化喷枪,其喷嘴直径为0.040英寸(1.016毫米)至0.070英寸(1.778毫米)的流体喷嘴。建议雾化气压为25-35磅。必须配备带排气扇的喷漆室。遵守处理漆料和油漆的所有常规预防措施:充分通风、佩戴有机呼吸器面罩,并避免皮肤接触、火焰和任何其他火源。

(3) Pressure pot systems may be used, however we recommend the following: keep the coating under constant agitation, minimize the length of the hoses to reduce the chance of pigment settling, and always clear the lines when the equipment is not going to be used for a lengthy period of time.

可以使用压力罐系统,但我们建议:持续搅拌涂层,尽量缩短软管长度以减少颜料沉淀的可能性,在长时间不使用设备时,务必清理管道。

(4) We recommend you apply several very thin, uniform coats, allowing each to dry to the touch before applying the next.

我们建议您涂上几层非常薄且均匀的涂层,每层涂层都要等摸起来干了再涂下一层。

E. For Thermally Cured Coatings

对于热固化涂层

• Allow coated parts to air dry to the touch, approximately 30 minutes, depending upon atmospheric conditions.

让涂覆的零件自然风干,大约30分钟,具体时间取决于大气条件。

• Remove any masking materials.

清除所有遮蔽材料。

• Refer to the individual Technical Data Sheet for the correct cure time and temperature.

正确的固化时间和温度请参考单独的技术数据表。

• Cure in a pre-heated, air-circulating, vented convection oven with an accurate temperature control. Be sure the substrate of all parts is at full temperature for the entire cure cycle.

在预热的、空气循环的、通风的并且精确控制温度对流烘箱中固化。确保所有零件的基材在整个固化周期内都处于完全受热状态。

• Cool parts completely before testing.

在测试前让零件完全冷却。

F. For Air Drying Coatings

对于空气干燥涂料

(1) Follow all pretreatment and application procedures described for the heat curing products. Then follow the air drying cure cycle shown on the Technical Data Sheet for each individual coating. With most air drying products, the cure cycle can be accelerated by oven baking at a low temperature. Again, refer to the Technical Data Sheet for detailed information.

遵循热固化产品描述的所有预处理和应用程序。然后遵循每种涂料的技术数据表上显示的空气干燥固化周期。对于大多数空气干燥产品,可以通过低温烘烤来加速固化周期。同样,请参阅技术数据表以获取详细信息。

G. Inspection and Testing

检查和测试

(1) Visually check the parts for a smooth, even finish. The coating should have uniform color, smoothness and thickness, and be free of cracks, scratches, pin holes, blisters, runs, sags, foreign matter, separation of ingredients, and any other surface imperfections.

目测检查零件表面是否光滑、均匀。涂层应具有均匀的颜色、光滑度和厚度,且无裂纹、划痕、针孔、气泡、流痕、凹陷、异物、成分分离和其他表面瑕疵。

(2) For solid film lubricants, a glossy, lacquer-like appearance indicates improper mixing of the coating material. A brownish color may be an indicator that the cure temperature was too high. A grainy, rough surface is the result of too-dry spray and will result in poor adhesion and wear.

对于固体薄膜润滑剂,光泽、漆状的外观表明涂层材料混合不当。褐色可能是固化温度过高的迹象。 粗糙的颗粒状表面是喷涂太干的后果,会导致附着力差和磨损。

(3) Perform a tape test to check for adhesion. Place a strip of adhesive tape (per ASTM D-5486 or equivalent), not more than 6 months old, firmly on an area of your coated part, then remove it in one sharp pull. A uniform deposit of powdery material clinging to the tape is not cause for rejection. However, any lifting of the coating that exposes the base or pretreatment material is cause for rejection.

进行胶带测试以检查附着力。将不超过6个月的新胶带(符合ASTM D-5486或同等标准)牢固地贴在涂覆零件的某个区域,然后用力将其撕下。如果胶带上有均匀的粉末状物质附着,则不会导致不合格。但是,如果涂层被揭起,露出底材或预处理材料,则会导致不合格。

(4) We do not recommend touch up on problem areas. Rejected parts should be stripped and reworked.

我们不建议对有问题的区域进行修补。被拒收的零件应进行剥离和返工。

H. Stripping

剥离

(1) To strip the coating, use one of these methods.

要剥离涂层,请使用以下方法之一。

• Walnut shell (or equivalent) blast has a light abrasive action, which may remove the coating with minimum risk of disturbing the base of pretreatment material.

核桃壳(或类似物)喷砂具有轻微的研磨作用,可以去除涂层,且不会干扰预处理材料基底的风险极低。

• Immersion for one minute in a boiling 20% chromic acid solution. This method will also remove cadmium plating, anodizing, and some other pretreatment. Use extreme caution with this very hazardous material. DO NOT use with copper.

将工件浸入20%的铬酸溶液中一分钟。这种方法还可以去除镀镉、阳极氧化和其他一些预处理。使用这种非常危险的材料时必须格外小心。不要与铜一起使用。

• High phenolic-bodied paint strippers, designed for epoxy-type finishes, are sometimes used successfully if the immersion time is extended.

专为环氧类型表面处理设计的高酚类脱漆剂有时可以成功使用,但需要延长浸泡时间。

• Grit blasting, use with care.

喷砂,使用时需小心。

I. Engineering and Design Suggestions

工程和设计建议

(1) If it is necessary to apply a solid film lubricant to only one surface in a hard/soft bearing system, applying it to the softer material will extend the life of the system. However, the harder a substrate material, the more effectively the lubricant will perform.

如果需要在硬/软轴承系统中仅在一个表面涂覆固体薄膜润滑剂,将其涂覆在较软的材料上可以延长系统的使用寿命。然而,基材材料越硬,润滑剂的效果越好。

(2) In general, the coefficient of friction will be slightly higher if both mating surfaces are coated than if only one surface is coated. However, wear life will increase if both surfaces are coated.

一般来说,如果两个接触表面都涂有润滑剂,摩擦系数会比只涂一个表面略高。然而,如果两个表面都涂有润滑剂,磨损寿命将会增加。

(3) In either of these situations, the user should determine which is more important onger wear or more effective lubrication.

在上述两种情况下,应确定磨损或润滑哪个更重要。

(4) The recommended operating thickness of most Everlube Products solid film lubricants and most other coatings is from 0.0002 to 0.0005 inch thick. (Refer to the individual Technical Data Sheet for each product to be sure of the correct coating thickness.) Such a thin film seldom requires alteration of established clearance between moving parts, except possibly on very small, fine parts which normally operate with very little clearance. In that case, because the cured coating is relatively soft, any interference produced by the thickness of the coating will cause rapid wear (burnishing) of the film to the point where interference is eliminated. Such burnishing may also be done mechanically by using 000 or XXX steel wool or soft (white) Scotch Brite pads.

大多数Everlube产品固体薄膜润滑剂和大多数其他涂层的推荐操作厚度为0.0002至0.0005英寸。(请参阅每种产品的单独技术数据表,以确保正确的涂层厚度。)这种薄涂层通常不需要改变运动零件之间已确定的间隙,除非是非常小的精细零件,这些零件通常在很小的间隙内操作。在这种情况下,由于固化涂层相对较软,涂层厚度产生的任何干涉都会导致涂层快速磨损(烧蚀),直到消除干涉为止。这种烧蚀也可以通过使用000或XXX钢丝绒或软(白色)Scotch Brite片进行机械处理。

12. CURING OF COATINGS 涂层固化

CAUTION :DO NOT INSTALL TEMPERATURE INDICATORS ON LUBRICATED SURFACES.

注意:请勿在润滑表面安装温度指示器。

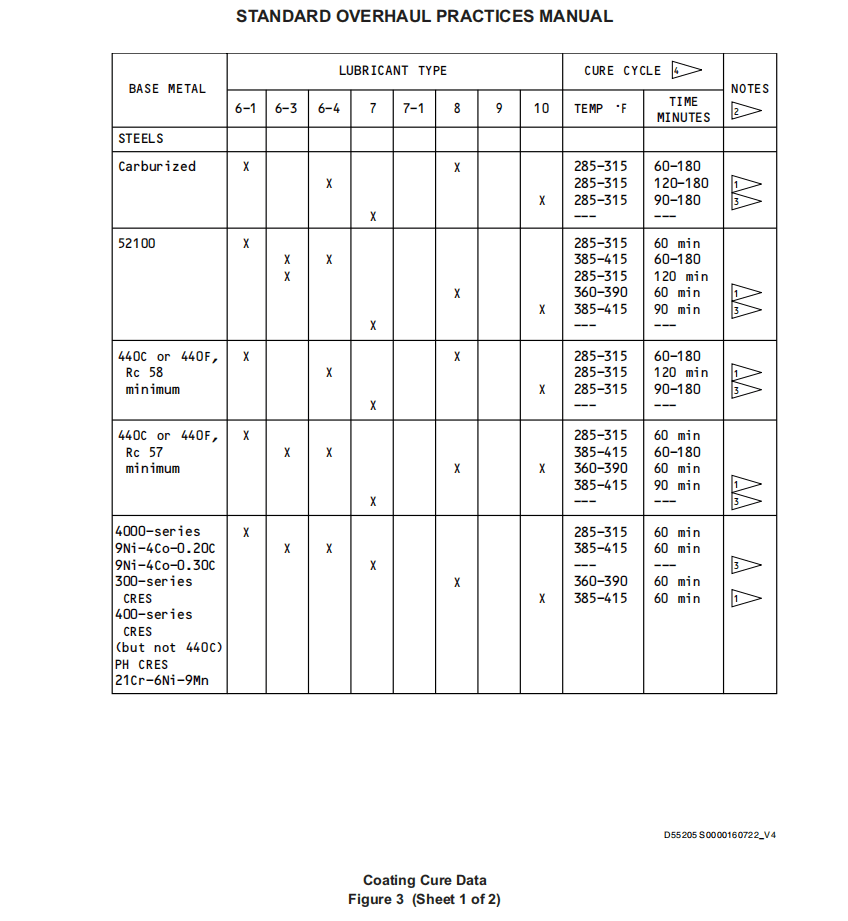

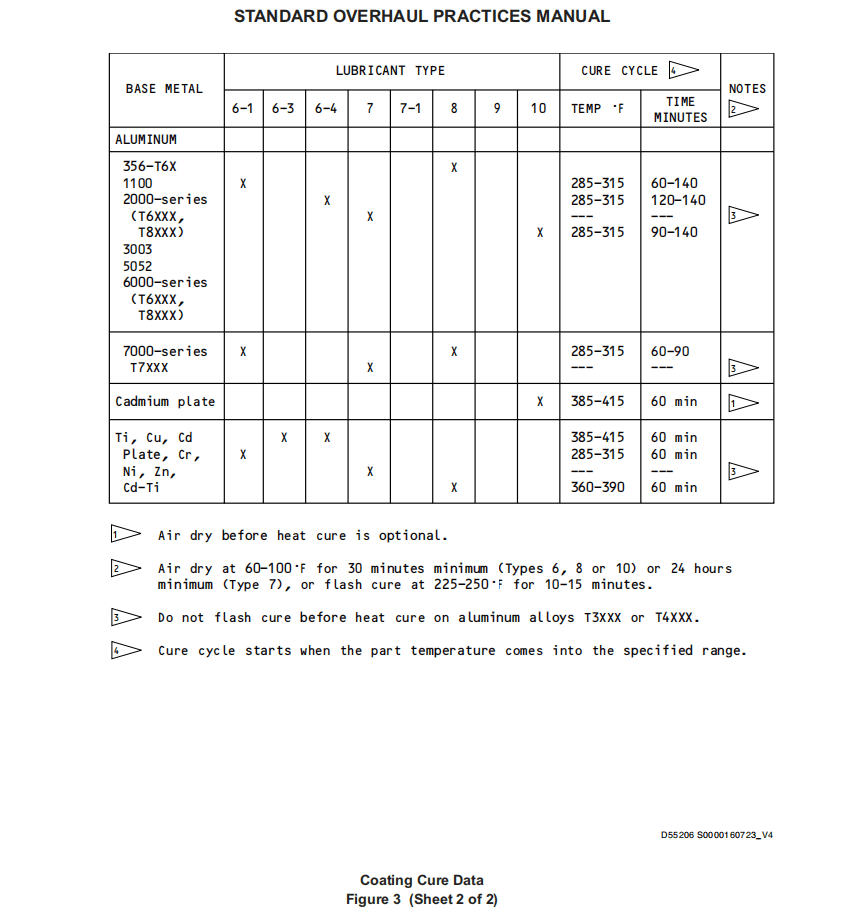

A. As applicable, give the lubricant coating an air cure at room temperature and a bake, as specified in Figure 3. Obey the limits of Paragraph 12.B.

按照图3的规定,在室温下对润滑涂层进行空气固化并烘烤。遵守第12.B段的限制。

B. Bake Limits

烘烤限制

(1) Do not give aluminum alloys more than two cure cycles.

铝合金的固化周期不得超过两次。

(2) Do not give carburized steels more than three cure cycles.

渗碳钢的固化周期不得超过三次。

(3) Bake coatings as applicable as specified in Figure 3 and the lubricant vendor’s instructions. Start to measure the cure time when the part comes into the cure temperature range.

根据图3和润滑油供应商的说明烘烤涂层。当零件达到固化温度范围时,开始测量固化时间。

(4) If parts are large but the area to be cured is small, it could be easier to locally heat the coated area with quartz or infrared lamps than to bake all of the item.

如果零件较大,但需要固化的区域较小,则用石英灯或红外线灯局部加热涂层区域比烘烤整个零件更容易。

13. QUALITY CONTROL 质量控制

A. When visually examined without magnification, the cured lubricant coating must be smooth and continuous with no sign of unwanted material such as grit, rough particles, or other contamination. Application defects such as runs, dimples, cracks, or blisters are not acceptable. A slightly rough surface is acceptable if the roughness is caused by lubricant solids that become collected into groups that make a continuous layer.

在不使用放大镜的情况下进行目视检查时,固化润滑剂涂层必须光滑且连续,没有砂砾、粗糙颗粒或其他污染物等不需要的物质。不允许出现流痕、凹坑、裂纹或气泡等涂覆缺陷。如果润滑剂固体聚集在一起形成连续的涂层,导致表面略微粗糙,则可以接受。

B. The cured lubricant layer can be examined for fluid resistance as follows:

固化润滑层可按照以下方法进行流体阻力测试:

(1) BAC5811, Type 6 (all classes)

BAC5811,类型6(所有级别)

(a) Rub an area of the layer for one minute with a wiper wet with methyl ethyl ketone. The cured layer is acceptable if there is no more than a trace of fine, powdery material on the wiper, and there is no bare surface in the rubbed area.

用蘸有甲基乙基酮的刷子在润滑层上擦拭一分钟。如果刷子上只有微量细小粉末状物质,且擦拭区域没有裸露表面,则表明固化层合格。

(b) Put the part in standard hydrocarbon test fluid TT-S-735 for one hour. Then do the dry tape test for adhesion as specified in BSS7225. Coating must not get on the adhesive tape. Fine, powdery material is acceptable, but there must be no particles larger than one square millimeter or more than two particles in each square centimeter of tape. The test must not make the surface bare.

将零件放入标准碳氢化合物测试液TT-S-735中浸泡一小时。然后按照BSS7225的规定进行干胶带测试。涂层不得粘附在胶带上。细小的粉末状物质是可以接受的,但每平方厘米的胶带中不得有大于一平方毫米或大于两个颗粒的颗粒。测试不得使表面裸露。

(2) BAC5811, Type 7 — These lubricants have no fluid resistance requirements. The test is not necessary.

BAC5811,类型7——这些润滑剂没有流体阻力要求。无需进行测试。

(3) BAC5811, Type 8:

BAC5811,类型8:

(a) Rub the cured layer with methyl ethyl ketone as specified in Paragraph 13.B.(1)(a). The visual requirements are the same. Also, with 15-power magnification, there must be no cracks, blisters, or separation when compared to the surface that did not get the test.

按第13.B.(1)(a)段所规定,用甲基乙基酮擦拭固化层。目测要求不变。此外,在15倍放大镜下,与未进行测试的表面相比,不得出现裂纹、气泡或分离。

(b) If a more complete test is necessary, do the 24-hour half-immersion-and-scratch test as specified in BAC5811.

如果需要进行更全面的测试,请按照BAC5811的规定进行24小时半浸渍和划痕测试。

(4) BAC5811, Type 9 (Ref BAC5814) — The test for fluid resistance uses test panels and includes wear life and friction coefficient tests. Refer to BAC5814 for details.

BAC5811,类型9(参考BAC5814)——流体阻力测试使用测试面板,包括磨损寿命和摩擦系数测试。详情请参考BAC5814。

(5) BAC5811, Type 10

BAC5811,类型10

(a) Rub the cured layer with a clean cotton swab soaked in water, with fingertip pressure for 7-10 strokes. One complete stroke is movement away from and then back to where you started.

用蘸水的干净棉签擦拭固化层,用指尖按压7-10次。一次完整的按压是从开始处移动到结束处,然后再返回。

(b) Hang the parts in very cold air, -85 to -115°F, for 2.5-3.5 hours.

将零件悬挂在温度为-85至-115°F的极冷空气中2.5-3.5小时。

(c) Remove the parts and let them warm back to room temperature. Then examine them for cracks or flakes.

取出零件,使其恢复到室温。然后检查是否有裂纹或剥落。

(d) Put the parts in distilled water for 23-25 hours.

将零件放入蒸馏水中浸泡23-25小时。

(e) Remove the parts from the water. Wipe them dry with a soft cloth.

从水中取出零件。用软布擦干。

(f) Make two parallel scratches in the coating, 1 inch apart, with a sharp stylus. Then do a tape test as specified in BSS7225. Ignore the lubricant coating particles made by the stylus.

用尖头笔在涂层上平行划出两条距离为1英寸的划痕。然后按照BSS7225的规定进行胶带测试。忽略尖头笔划出的润滑剂涂层颗粒。

C. The cured lubricant layer can be examined for a good bond as follows:

固化润滑剂层可通过以下方法检查是否粘结良好:

(1) BAC5811 Types 6, 7, 8 — Do the dry tape test for adhesion as specified in BSS7225. The coating must not get on the adhesive tape. Fine, powdery material is acceptable, but there must be no particles larger than 1 square millimeter or more than two particles in each square centimeter of tape. The test must not make the surface bare.

BAC5811 类型 6、7、8——按照 BSS7225 规定进行干式胶带测试。涂层不得粘附在胶带上。细小粉末状物质可以接受,但每平方厘米的胶带中不得有大于 1 平方毫米的颗粒或超过两个颗粒。测试不得使表面裸露。

(2) BAC5811, Type 9 (Ref BAC5814):

BAC5811,类型9(参考BAC5814):

(a) Rub the lubricant layer firmly with a dry paper towel to remove all loose particles. This must not make the surface bare or rub off large amounts of lubricant.

用干纸巾用力擦拭润滑层,去除所有松散的颗粒。这不得使表面裸露或擦掉大量润滑剂。

(b) Rub the lubricant layer firmly with a paper towel wet with ethyl alcohol until the material removed is decreased to only trace quantities.

用蘸有乙醇的纸巾用力擦拭润滑层,直到去除的材料减少到只有微量。

(c) Let the surface dry by evaporation at the air temperature or in an oven no warmer than 160°F.

让表面在室温下或不超过160°F的烤箱中蒸发干燥。

(d) The cured lubricant layer must stay serviceable without bare metal or other change in appearance, other than by burnishing. A small amount of coating could come off on the towel during the first rubs, but this must decrease to only a trace as the test continues. Reject the layer if this amount of removed lubricant increases as the test continues.

固化润滑层必须保持可用,除了抛光外,不得出现裸露金属或其他外观变化。在第一次擦拭时,纸巾上可能会掉下少量涂层,但随着测试的继续,涂层必须减少到只有痕迹。如果随着测试的继续,被去除的润滑剂量增加,则应拒绝该涂层。

14. REWORK OF COATINGS 涂层返工

A. Defective dry lubricant layers can be repaired only by removal and application of new coating.

有缺陷的干润滑剂层只能通过去除并涂覆新的涂层来修复。

B. If the layer is not cured, remove it with a wiper wet with the thinner recommended by the vendor.

如果涂层未固化,请使用供应商推荐的稀释剂蘸湿的刷子将其去除。

C. Remove cured BAC5811, Type 6, 7, 8 or 10 layers with chemical strippers as specified in SOPM 20-30-02 or by abrasive blast as specified in SOPM 20-30-03 if this will not damage the part.

使用SOPM 20-30-02中规定的化学剥离剂或SOPM 20-30-03中规定的喷砂法去除已固化的BAC5811、类型6、7、8或10涂层,前提是不会损坏零件。

D. Remove cured BAC5811, Type 9 (Ref BAC5814) layers by dry abrasive blast with 220-mesh aluminum oxide as specified in SOPM 20-30-03. Make sure the abrasive is used only on the metals shown in Table 4.

按照SOPM 20-30-03的规定,用220目氧化铝干磨去除固化的BAC5811,类型9(参考BAC5814)。确保磨料仅用于表4所示的金属。

E. Dry and examine to make sure all of the lubricant is removed.

干燥并检查,确保所有润滑剂都已去除。

F. Prepare the surface again as specified in Paragraph 6.

按照第6段的规定再次准备表面。

G. Apply the lubricant layer again, as necessary.

根据需要重新涂抹润滑层。

H. Do not apply more layers of lubricant on cured films to build up lubricant thickness or to try to repair defects.

不要在固化膜上涂抹更多润滑层来增加润滑剂厚度或试图修复缺陷。

I. If the applied lubricant layer is too thick to agree with the overhaul instructions, do not decrease the thickness by burnishing or other mechanical procedures unless permitted by overhaul instructions. When the thickness is too thick, remove the lubricant from the parts and apply a layer of the correct thickness.

如果涂抹的润滑层太厚,不符合大修说明的要求,除非大修说明允许,否则不要通过打磨或其他机械程序来降低厚度。如果润滑层太厚,请从零件上清除润滑剂,然后涂抹一层厚度正确的润滑剂。