组装ASSEMBLY

1. Planning Data

计划数据

A. Reason for the Job

工作原因

(1) Use these procedures to assemble the modulating shutoff valve. Do only those procedures that are applicable to the disassembly done.

使用这些程序组装调节关断活门。 仅执行适用于已完成分解的程序。

B. Job Setup Data

工作设置数据

(1) You can use equivalent alternatives for the special tools, fixtures, equipment, and consumable materials unless specified differently. The user must find equivalent alternatives.

专用工具、夹具、设备和消耗材料可以使用同等替代品,除非另有规定。 用户必须找到同等替代品。

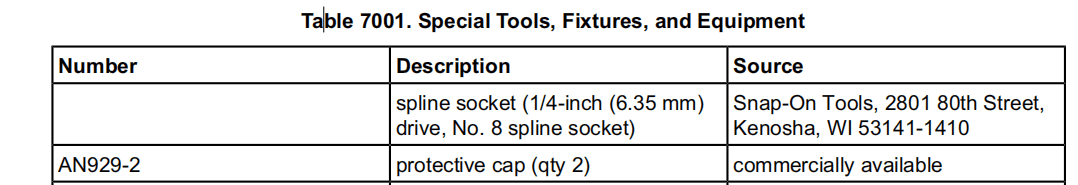

(2) Refer to Table 7001 for the specified special tools, fixtures, and equipment in this section.

有关本节中规定的专用工具、夹具和设备,请参见表7001。

(3) CAGE codes and manufacturers’ addresses are available at https://cage.dla.mil.

CAGE代码和制造商的地址可在https://cage.dla.mil上找到。

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参考制造商的材料安全数据表。 有些材料可能很危险。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用与霍尼韦尔指定材料未等效的材料。非等效材料可能会导致设备损坏,并使保修失效。

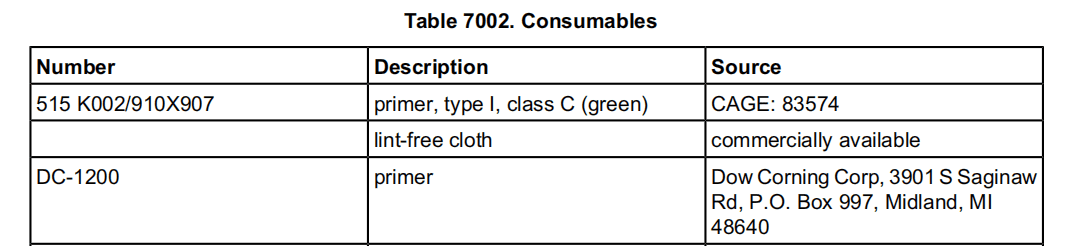

(4) Refer to Table 7002 for the specified consumable materials in this section.

本节中的指定消耗材料请参见表 7002。

(5) The list that follows identifies Honeywell publications that are related to this section:

以下清单列出了与本节相关的霍尼韦尔出版物:

• Not applicable.

– 不适用。

2. Procedure

程序

A. Job Setup

工作设置

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参阅制造商的材料安全数据表。 有些材料可能很危险。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用与霍尼韦尔指定材料未等效的材料。非等效材料可能会导致设备损坏,并使保修失效。

CAUTION: DO THESE PROCEDURES IN A CLEAN ENVIRONMENT TO PREVENT DAMAGE TO MECHANICAL COMPONENTS.

注意:请在清洁的环境中执行这些程序,以防止损坏机械组件。

(1) Obey the precautions.

遵守注意事项(预防措施)。

(2) The item numbers shown in the DPL are the same as the item numbers on the exploded view illustration(s). To find a part number, find the part on the illustration and note the item number. Find the item number in the parts list and read the correct part number. Item numbers refer to the same figure until a different figure is specified.

DPL 中显示的项目编号与爆炸视图插图上的项目编号相同。 要查找件号,请在插图上找到该零件并记下项目号。 在零件清单中查找项目编号,然后读取正确的件号。 在指定不同的图之前,项目编号指的是同一个图。

(3) If applicable, refer to the data written during disassembly for the location of the tie points and where to connect the components and wires.

如果适用,请参阅分解过程中记录的数据,了解连接点的位置以及连接部件和保险的位置。

B. General Assembly Requirements

通用组装要求

(1) Remove all corrosion preventive compound and contamination from the parts before assembly. Refer to REPAIR (PGBLK 29-20-17-6000).

组装前清除零件上的所有防腐蚀化合物和污染物。请参阅 REPAIR (PGBLK 29-20-17-6000)。

(2) All the nuts, bolts and screws must be tightened to a standard torque and tolerance unless the torque is specified in the text. Refer to SPM 20-00-02/70-00-01, for the standard torque.

所有螺母、螺栓和螺钉必须以标准扭矩和公差拧紧,除非文中规定了扭矩。标准扭矩参见 SPM 20-00-02/70-00-01。

(3) Use MIL-PRF-907 lubricating compound for the assembly of all threaded parts as follows:

使用 MIL-PRF-907 润滑剂装配所有螺纹部件,具体操作如下:

CAUTION: TOO MUCH LUBRICATING COMPOUND CAN CAUSE CLOGGED VENTS AND ORIFICES.

注意:润滑剂过多会导致通气孔和限流孔堵塞。

(a) Apply a small quantity of MIL-PRF-907 lubricating compound to the threads of all male threaded parts.

在所有外螺纹部件的螺纹上涂抹少量 MIL-PRF-907 润滑剂。

(b) Remove all of the lubricating compound that is remaining after assembly of the threaded parts.

清除螺纹部件组装后剩余的所有润滑剂。

WARNING: USE THE CORRECT PERSONAL PROTECTION. OIL CAN HAVE AN ADDITIVE CALLED TRICRESYL PHOSPHATE IN IT. THIS CHEMICAL IS AN ASPHYXIANT, IT IS POISONOUS AND CAN BE ABSORBED THROUGH THE SKIN.

警告:使用正确的个人防护用品。油中可能含有一种叫做磷酸三甲苯酯的添加剂。这种化学物质是一种窒息剂,有毒并可通过皮肤吸收。

(4) Apply Santovac 5 lubricant to packings when dry installation of packing is difficult to do or physical damage to packing could occur.

当密封难以干安装或可能对密封造成物理损坏时,在密封上涂抹 Santovac 5 润滑剂。

(5) Use MS9226-04 lockwire on all hardware (bolts, screws, plumbing, electrical connectors) with lockwire holes. The lockwire must fill a minimum of 75 percent of the lockwire hole.

在所有带有保险丝孔的硬件(螺栓、螺钉、管道、电气连接器)上使用 MS9226-04 保险丝。保险丝必须至少填满保险丝孔的 75%。

(6) When screws or bolts are too long or too short, a longer or shorter standard screw or bolt can be used if there is a minimum of one full thread more than the face of the threaded part or nut.

当螺钉或螺栓过长或过短时,如果比螺纹部分或螺母表面至少多一个完整螺纹,则可使用较长或较短的标准螺钉或螺栓。

(threaded part表示螺纹零件还是螺纹部分?)

NOTE: There are no optional screw or bolt lengths allowed for blind hole applications.

注:盲孔安装不允许选择螺钉或螺栓的长度。

(7) On rivet installation, if the shank of the rivet is too long or too short, use one size longer or one size shorter rivet as necessary.

安装铆钉时,如果铆钉柄太长或太短,可根据需要使用长一规格或短一规格的铆钉。

(8) The Check Points in this section are used by Honeywell at/or after precision build operations.

霍尼韦尔在精密制造操作过程中或之后使用本节中的检查点。

Table 7003 shows the Check Points.

表7003说明检查点

|

Check Point |

Operation |

|

10 |

After completion of the assembly procedures, make a full visual inspection of the assembled modulating shutoff valve and check for loose screws, bolts or nuts. Check for parts which are incorrectly assembled. 完成组装程序后,对组装好的调节关断活门进行全面目视检查,检查螺钉、螺栓或螺母是否松动。检查装配不正确的零件。 |