清洁CLEANING

1.Planning Data

计划数据

A.Reason for the Job

工作原因

(1) Use these procedures to remove dust, dirt, and unwanted oil and grease. Be careful not to cause damage to the parts when you do these procedures.

使用这些程序清除灰尘、污垢和不需要的油脂。执行这些程序时要小心,不要对零件造成损坏。

B. Job Setup Data

工作设置数据

(1)You can use equivalent alternatives for the special tools, fixtures, equipment, and consumable materials unless specified differently. The user must find equivalent alternatives.

除非另有规定,您可以使用等效替代品来替代专用工具、夹具、设备和消耗材料。必须找到等效替代品。

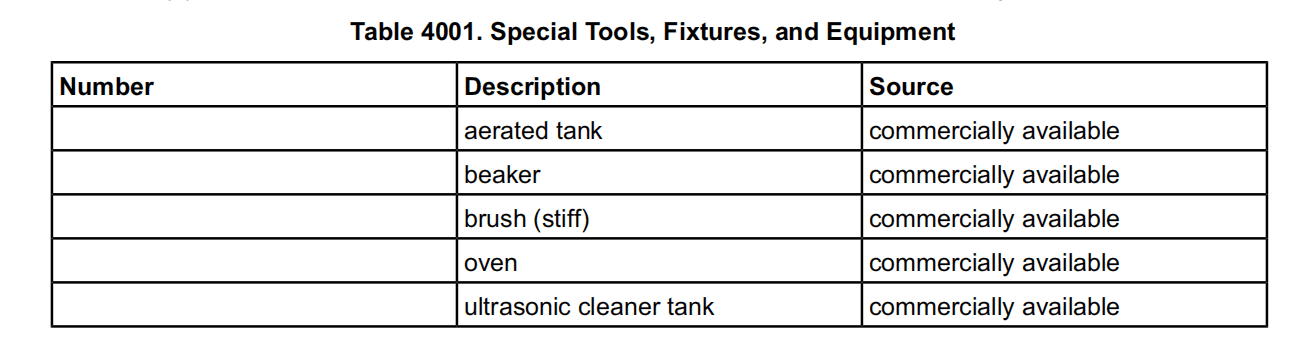

(2) Refer to Table 4001 for the specified special tools, fixtures, and equipment in this section.

本节规定的专用工具、夹具和设备请参见表 4001。

(3) CAGE codes and manufacturers’ addresses are available at https://cage.dla.mil.

CAGE代码和制造商地址见 https://cage.dla.mil。

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参考制造商的材料安全数据表。一些材料可能具有危险性。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用没有与HONEYWELL规定材料等效的材料。非等效材料可能会导致设备损坏,并使索赔不适用(保修失效)。

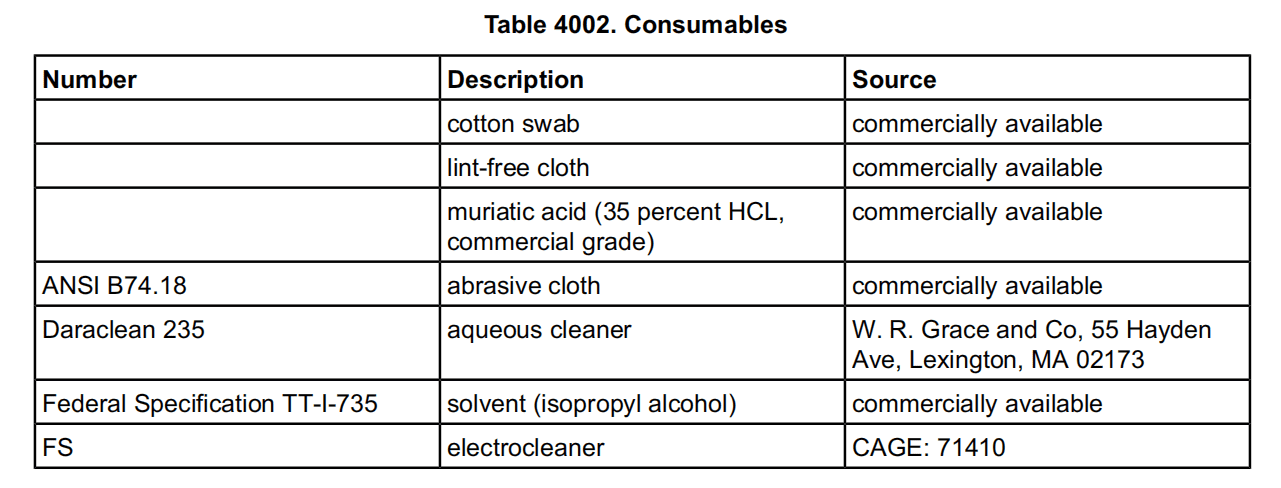

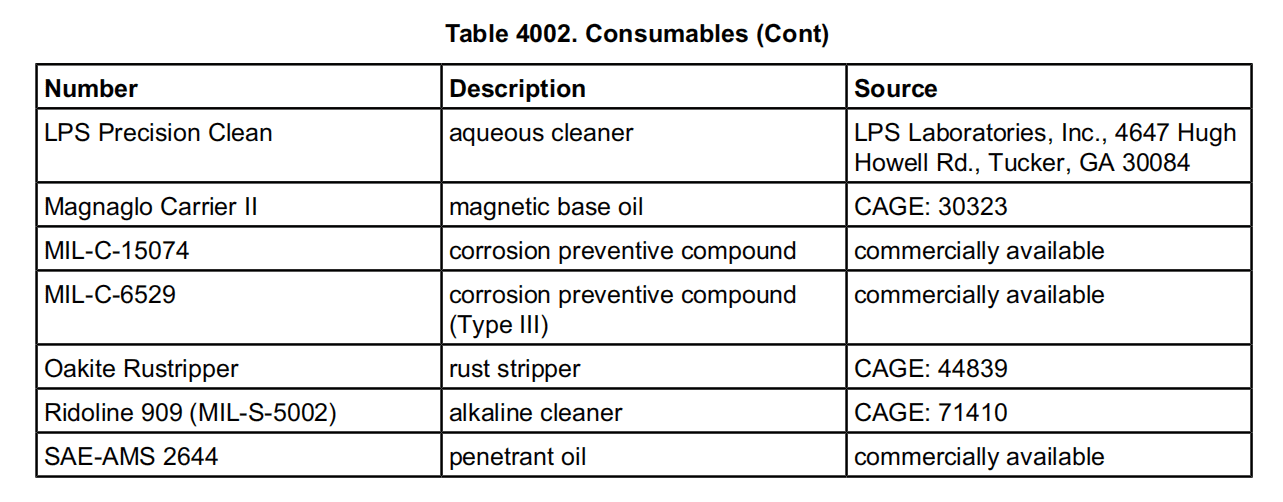

(4)Refer to Table 4002 for the specified consumable materials in this section.

有关本节中规定的消耗材料,请参见表 4002。

(5) The list that follows identifies Honeywell publications that are related to this section:

• Not applicable.

以下清单列出了与本节相关的Honeywell出版物:

– 不适用。

2. Procedure

程序

A. Job Setup

工作设置

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

CAUTION: DO THESE PROCEDURES IN A CLEAN ENVIRONMENT TO PREVENT DAMAGE TO MECHANICAL COMPONENTS.

(1) Obey the precautions.

(2) Do the procedures in a clean location.

(3) When you use pressurized air to clean assemblies and parts, do not use more air pressure than is necessary.

(4) After you clean the assemblies and parts, supply protection from moisture, dust, and other contamination until you do a visual check and assemble the component.

警告:在使用材料之前,请参考制造商的材料安全数据表。一些材料可能具有危险性。

注意:请勿使用没有与HONEYWELL规定材料等效的材料。非等效材料可能会导致设备损坏,并使索赔不适用(保修失效)。

警告:请在清洁的环境中执行这些程序,以防止损坏机械部件。

(1) 遵守预防措施。

(2) 在清洁的场所执行程序。

(3) 使用加压空气清洁组件和零件时,不要使用超过必要的气压。

(4) 清洁组件和零件后,在进行目视检查和组装组件之前,应防止潮湿、灰尘和其他污染。

B. General Cleaning Practices

通用清洗方法

(1) Each part must be cleaned with the procedures referred to in this section or the equivalent procedures used by an approved overhaul facility. Solutions specified must be made with the instructions in this manual or to the instructions supplied by the product manufacturer.

(2) These procedures agree with good shop procedures as used by the Honeywell overhaul facility. Clean parts are important to satisfactory overhaul and operation.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIRFLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(3) Use clean, dry, filtered, compressed air at a maximum of 20 PSIG (138 kPa) to dry parts.

(1) 每个零件必须按照本节所述程序或经批准的大修设备使用的等效程序进行清洗。规定的溶液必须按照本手册的说明或产品制造商提供的说明配制。

(2) 这些程序与Honeywell大修设备使用的良好车间程序一致。清洁的零件对于令人满意的大修和运行非常重要。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(3) 使用清洁、干燥、过滤、最大压力为 20 PSIG (138 kPa) 的压缩空气干燥零件。

C. General Cleaning Procedures

通用清洁程序

WARNING: CLEAN PARTS IN AN AREA OPEN TO THE AIR, THAT HAS GOOD LIGHT AND SUFFICIENT SAFETY AND FIRE PREVENTION EQUIPMENT.

(1) Clean all metal parts to remove oil, grease, rust, and dirt. Clean the flange areas and sealing surfaces to remove old gaskets and compounds.

(2) Clean painted parts but do not remove old paint if it is still serviceable.

(3) Remove carbon and combustion contamination.

(4) Heat discoloration of metal surfaces (not to include too much heat caused by malfunction) is permitted. Remove scale that can come loose and damage the unit.

(5) Remove all light surface corrosion from parts and treat base metal to prevent corrosion. Refer parts with heavier corrosion to inspection personnel for analysis.

(6) Cap, plug or seal all ports and orifices of cleaned parts. Make sure the parts have protection while in storage.

NOTE: Use only approved caps, plugs and barrier materials for part storage after cleaning.

(7) Steel and 400 series stainless steel parts require the application of MIL-C-6529 corrosion preventive compound after cleaning to prevent rust and corrosion.

警告:在光线充足、安全和防火设备齐全的露天场所清洗零件。

(1) 清洁所有金属零件,去除油、油脂、锈和污垢。清洁法兰区域和密封表面,去除旧垫圈和化合物。

(2) 清洁油漆零件,但如果仍可使用,则不要清除旧油漆。

(3) 清除积碳和燃烧污染。

(4) 允许金属表面受热变色(不包括因故障导致的过热)。清除可能松动和损坏设备的污垢。

(5) 清除零件表面的所有轻度锈蚀,并对基体金属进行防锈处理。将锈蚀较重的零件交给检验人员进行分析。

(6) 盖上、堵上或密封已清洁零件的所有端口和孔口。确保零件在存放期间受到保护。

注:清洗后的零件存放只能使用经批准的盖子、塞子和隔离材料。

(7) 钢和 400 系列不锈钢零件需要在清洗后涂抹 MIL-C-6529 防腐化合物,以防止生锈和腐蚀。

D. Cleaning of Assemblies Made of Different Types of Materials

清洁不同类型材料制成的组件

CAUTION: AN ASSEMBLY MUST NOT BE CLEANED IN A SOLUTION THAT CAN CAUSE DAMAGE TO ONE OF THE PARTS IN THE ASSEMBLY.

(1) Clean parts made of different base materials one at a time.

(2) Clean the assemblies that contain brass, bronze, steel, or cadmium with the procedures that are applicable to the base material.

(3) Carefully clean synthetic or natural materials with a cleaning procedure that will not damage the material.

警告:不得用可能导致组件中某个零件损坏的溶液清洗组件。

(1) 逐个清洗由不同基础材料制成的零件。

(2) 使用适用于基础材料的程序清洗含有黄铜、青铜、钢或镉的组件。

(3) 使用不会损坏材料的清洁程序仔细清洁合成或天然材料。

E. Aqueous Cleaner Solution Preparation

水基清洁剂制备(中性清洗剂)

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. THE DANGER AND PRECAUTIONS FOR EACH CHEMICAL IS DIFFERENT.

(1) Use manufacturer’s instructions to mix Daraclean 235 aqueous cleaner or LPS Precision Clean aqueous cleaner.

(2) Keep solution at 140 to 150°F (60 to 66°C) in an aerated tank.

警告:使用正确的个人防护用品。该化学品/溶液可对皮肤、眼睛和肺部造成伤害。每种化学品的危险性和预防措施各不相同。

(1) 按照制造商的说明混合 Daraclean 235 水基清洁剂或 LPS Precision Clean 水基清洁剂。

(2) 将溶液置于通气槽中,温度保持在 140 至 150°F (60 至 66°C)。

F. Alkaline Cleaner Solution Preparation

碱性清洁剂溶液制备

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE, AND LUNG DAMAGE. THE DANGER AND PRECAUTIONS FOR EACH CHEMICAL IS DIFFERENT.

(1) Mix 4 to 6 oz (113 to 170 g) of Ridoline 909 (MIL-S-5002) alkaline cleaner in each gallon (3.8 L) of water.

(2) Keep the solution at 130 to 180°F (54 to 82°C) in an aerated tank.

警告:使用正确的个人防护用品。该化学物质/溶液可对皮肤、眼睛和肺部造成伤害。每种化学品的危险性和预防措施都不同。

(1) 在每加仑(3.8 升)水中混合 4 至 6 盎司 (113 至 170 克)的 Ridoline 909 (MIL-S-5002) 碱性清洁剂。

(2) 将溶液置于通气槽中,温度保持在 130 至 180°F (54 至 82°C)。

G. Rust Stripper Solution Preparation

除锈剂溶液制备

WARNING: USE THE CORRECT PERSONAL PROTECTION. RUST STRIPPER SOLUTION FUMES CAN BE DANGEROUS. MIX WATER AND ADD RUST STRIPPER SO SOLUTION DOES NOT BECOME TOO HOT.

(1) Mix 3 to 5 pounds (1.4 to 2.3 kg) of Oakite Rustripper rust stripper in each gallon (3.8 L) of water.

(2) Keep the solution at 160 to 200°F (71 to 93°C) in an aerated tank.

警告:使用正确的个人防护用品。除锈剂溶液的烟雾可能很危险。混合水并加入除锈剂,以免溶液过热。

(1) 在每加仑(3.8 升)水中混合 3 至 5 磅(1.4 至 2.3 千克)的 Oakite Rustripper 除锈剂。

(2) 将溶液置于通气槽中,温度保持在 160 至 200°F (71 至 93°C)。

H. Electrocleaner Solution Preparation

电解清洁剂溶液制备

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER INSTRUCTION FOR EACH CHEMICAL.

(1) Mix 9 oz (255 g) of FS electrocleaner in each gallon (3.8 L) of water.

(2) Keep the solution at 160 to 200°F (72 to 93°C) in an aerated tank.

警告:使用正确的个人防护用品。该化学物质/溶液可对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(1) 在每加仑(3.8 升)水中混合 9 盎司(255 克)FS 电解清洁剂。

(2) 将溶液置于通气槽中,温度保持在 160 – 200°F (72 – 93°C)。

I. Heavy Oil and Grease Removal (Procedure 1)

清除严重的油和油脂(程序 1)

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/ SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER INSTRUCTION FOR EACH CHEMICAL.

(1) Use Daraclean 235 aqueous cleaner or LPS Precision Clean aqueous cleaner in an aerated tank.

(2) Soak the parts for 20 to 30 minutes.

(3) Remove the heavy grease or soft carbon with the use of a brush.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIR FLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(4) Dry the parts with compressed air.

(5) If necessary, do Steps (2) through (4) again.

警告:使用正确的个人防护用品。该化学品/溶液可对皮肤、眼睛和肺部造成伤害。请遵守每种化学品的制造商说明。

(1) 在通气槽中使用 Daraclean 235 水基清洁剂或 LPS Precision Clean 水基清洁剂。

(2) 将零件浸泡 20 至 30 分钟。

(3) 用刷子清除重油脂或软碳。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(4) 用压缩空气擦干零件。

(5) 如有必要,再次执行步骤 (2) 至 (4)。

J. Soft Carbon and Dirt Removal (Procedure 2)

清除软碳和污垢(程序 2)

(1) Use Paragraph 2.I. (Subtask 29-20-17-110-005-A01) to remove heavy oil and grease from the surfaces.

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/ SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER INSTRUCTION FOR EACH CHEMICAL.

(2) Put the parts in the alkaline cleaner solution for a maximum of 30 minutes.

(a) Clean the surfaces with a brush until clean.

(b) Carefully remove the old gaskets and compounds with a blade and scrape the surfaces clean.

(c) Do the soak and clean procedure again or until the part is clean.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIR FLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(3) Flush the parts with water and dry with compressed air.

(4) Use an ANSI B74.18 abrasive cloth with SAE-AMS 2644 penetrant oil to remove light surface corrosion.

(5) Flush the parts with water at 80 to 110°F (27 to 43°C).

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIR FLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(6) Dry the parts with compressed air.

WARNING: USE THE CORRECT PERSONAL PROTECTION. THE HEATED PARTS WILL CAUSE BURNS.

(7) Dry all metal parts that have different metal inserts, crevices or deep blind holes in an oven at 225 to 275°F (107 to 135°C) for a minimum of 1 hour. Make sure the parts are completely dry.

(8) Keep the parts in a dry location away from gases that can cause corrosion.

(1) 使用第 2.I 段(子任务 29-20-17-110-005-A01)清除表面的严重的油和油脂。

警告:使用正确的个人防护用品。该化学品/溶液可对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(2) 将零件放入碱性清洁剂溶液中最多 30 分钟。

(a) 用刷子清洁表面直至干净。

(b) 用刀片小心去除旧垫圈和化合物,并将表面刮干净。

(c) 再次执行浸泡和清洁程序或直到零件清洁为止。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(3) 用清水冲洗零件并用压缩空气吹干。

(4) 使用带有 SAE-AMS 2644 渗透油的 ANSI B74.18 砂布清除轻微的表面腐蚀。

(5) 用温度为 27 至 43°C (80 至 110°F) 的水冲洗零件。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(6) 用压缩空气干燥零件。

警告:使用正确的个人防护措施。加热的零件会导致烧伤。

(7) 将有不同金属钢丝螺套、缝隙或深盲孔的所有金属零件放入烘箱中,在 225 – 275°F (107 – 135°C) 温度下烘干至少 1 小时。确保零件完全干燥。

(8) 将零件放在干燥的地方,远离可能导致腐蚀的气体。

K. Light Surface Corrosion Removal (Procedure 3)

轻度表面腐蚀清除(程序 3)

(1) Use Paragraph 2.I. (Subtask 29-20-17-110-005-A01) and Paragraph 2.J. (Subtask 29-20-17-110-006-A01), to clean the surfaces.

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/ SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. THE DANGER AND PRECAUTIONS FOR EACH CHEMICAL IS DIFFERENT.

CAUTION: MORE DAMAGE CAN OCCUR TO NON-STEEL PARTS IF CLEANED WITH RUST STRIPPER SOLUTION.

(2) Put the parts in a rust stripper solution for 10 to 20 minutes.

CAUTION: DO NOT DAMAGE THE HIGHLY FINISHED SURFACES. USE ONLY A BRUSH ON SUCH AREAS.

(3) Remove the parts from the rust stripper solution. Flush the part with water and clean with a brush. Remove heavy corrosion, hard carbon or scale by abrasive blasting the surfaces. Refer to REPAIR (PGBLK 29-20-17-6000).

(4) Remove light surface corrosion on steel alloy parts without paint.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIR FLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(5) Flush the parts in water at 80 to 110°F (27 to 43°C) and dry with compressed air.

(6) Parts that must have a magnetic particle or a fluorescent penetrant inspection in 8 hours can be left dry until examined. Put the parts in a clean container.

(7) Parts that must have a magnetic particle inspection and will be kept for more than 8 hours or up to 48 hours, must have a layer of Magnaglo Carrier II magnetic base oil applied. Put the parts in a clean container.

(8) Put the steel parts that do not get a magnetic particle inspection in a dip tank of oil. Remove and let drain, then put them in a clean container and keep them away from moist conditions and gases that can cause corrosion.

(9) Stainless steel and some corrosion-resistant steel parts that are usually used where there is no oil, must have protection from moist conditions that can cause corrosion.

(10) Steel parts to be kept for more than six months or kept in humid conditions must have protection with the use of MIL-C-15074 corrosion preventive compound.

(1) 使用第 2.I 段(子任务 29-20-17-110-005-A01)和第 2.J 段(子任务 29-20-17-110-006-A01)清洁表面。

警告:使用正确的个人防护用品。该化学品/溶液可对皮肤、眼睛和肺部造成伤害。每种化学品的危险性和预防措施都不同。

警告:如果使用除锈溶液清洗,可能会对非钢零件造成更大的损坏。

(2) 将零件放入除锈溶液中 10 至 20 分钟。

注意:不要损坏高度精加工的表面。在这些区域只能使用刷子。

(3) 将零件从除锈溶液中取出。用水冲洗零件并用刷子清洗。通过吹砂表面来清除严重锈蚀、硬碳或水垢。参见修理 (PGBLK 29-20-17-6000)。

(4) 清除钢合金零件未喷漆表面的轻度腐蚀。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(5) 将零件放入温度为 27 至 43°C (80 至 110°F) 的水中冲洗,然后用压缩空气吹干。

(6) 必须在 8 小时内进行磁粉或荧光渗透检查的零件可保持干燥,直至检查完毕。将零件放入干净的容器中。

(7) 必须进行磁粉检查并将存放超过 8 小时或最多 48 小时的零件,必须涂上一层 Magnaglo Carrier II 磁性基油。将零件放入干净的容器中。

(8) 将未进行磁粉检查的钢制零件放入浸油槽中。取出并沥干,然后放入一个干净的容器中,远离潮湿环境和可能导致腐蚀的气体。

(9) 通常在没有油的地方使用的不锈钢和一些耐腐蚀的钢制零件,必须有保护措施,使其远离可能引起腐蚀的潮湿环境。

(10) 存放时间超过 6 个月或存放在潮湿环境中的钢制零件必须使用 MIL-C-15074 防腐化合物进行保护。

L. Plumbing Component Cleaning (Procedure 4)

管道部件清洗(程序 4)

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER’S INSTRUCTIONS FOR EACH CHEMICAL.

(1) Use Paragraph 2.I. (Subtask 29-20-17-110-005-A01) and Paragraph 2.J. (Subtask 29-20-17-110-006-A01), to clean the tubes and fittings externally and internally.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIRFLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(2) Use low pressure air at 20 PSIG (138 kPa) maximum to dry part.

(3) Make sure there is no blockage in the tubes.

CAUTION: USE APPROVED CAPS, PLUGS AND BARRIER MATERIALS FOR PROTECTION OF PARTS AFTER CLEANING.

(4) Install plugs or caps at the ends of the tubes or fittings for protection against contamination and thread damage.

警告:使用正确的个人防护用品。该化学品/溶液可对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(1) 使用第 2.I 段(子任务 29-20-17-110-005-A01)和第 2.J 段(子任务 29-20-17-110-006-A01)清洗管道和接头的外部和内部。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(2) 使用最大压力为 20 PSIG (138 kPa) 的低压空气干燥零件。

(3) 确保管道没有堵塞。

注意:清洗后使用经批准的盖子、塞子和隔离材料保护零件。

(4) 在管道或接头的末端安装塞子或盖子,以防止污染和螺纹损坏。

M. Synthetic or Natural Materials Cleaning (Procedure 5)

合成或天然材料清洁(程序 5)

(1) Clean the parts in a weak cleaner with a brush.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIRSTREAM CAN CAUSE CUTS; DO NOT POINT IT AT YOUR SKIN.

(2) Flush the parts with water at 80 to 110°F (27 to 43°C) and dry with compressed air.

(1) 用刷子在弱清洁剂中清洁零件。

警告:使用正确的个人防护用品。压缩空气会导致能进入眼睛里的松散颗粒。气流可能导致割伤。切勿对准皮肤。

(2) 用温度为 27 至 43°C (80 至 110°F) 的水冲洗零件,然后用压缩空气吹干。

N. Electrical Component Cleaning (Procedure 6)

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER’S INSTRUCTIONS FOR EACH CHEMICAL.

(1) Rub parts with a clean, lint-free cloth moist with Federal Specification TT-I-735 solvent.

(2) Clean the electrical connectors with Federal Specification TT-I-735 solvent. Remove oily type soil with a cotton swab moist with Federal Specification TT-I-735 solvent.

电气部件清洁(程序 6)

警告:使用正确的个人防护用品。该化学物质/溶液会对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(1) 用干净的无绒布沾联邦规格 TT-I-735 溶剂擦拭零件。

(2) 用联邦规格 TT-I-735 溶剂清洗电气连接器。用沾有联邦规格 TT-I-735 溶剂的棉签清除油性污垢。

O. Metallic Filter Element Cleaning (Procedure 7)

金属滤芯清洁(程序 7)

(1) Use Paragraph 2.I. (Subtask 29-20-17-110-005-A01) and Paragraph 2.J. (Subtask 29-20-17-110-006-A01), to remove the grease from the filter element.

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL/SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. FOLLOW THE MANUFACTURER’S INSTRUCTIONS FOR EACH CHEMICAL.

(2) Put the filter element in electrocleaner solution for 4 to 6 minutes. During this time, make the filter element an anode for 1 to 2 minutes at 4 to 7 VDC.

(3) Flush the filter element in water.

(4) Put the filter element in a solution of equal parts muriatic acid and water, by volume, at room temperature for 1/2 to 1 minute.

(5) Flush the filter element with water.

(6) Put the filter element in electrocleaner solution for 4 to 6 minutes.

(7) Flush the filter element internally and externally with clean water at a high pressure.

(8) Put the filter element in a beaker with the open end of the filter down and fill the beaker with an electrocleaner solution.

(9) Put the beaker, with the filter element, in an ultrasonic cleaner tank. Fill the tank with water until the water level is 3/8 inch (9.53 mm) from the top of the beaker.

(10) Operate the ultrasonic cleaner tank for 5 minutes. Remove the filter element and discard the dirty electrocleaner solution. Flush the filter element and the beaker with clean electrocleaner solution with the use of a plastic squeeze bottle.

(11) Put the filter element in a beaker and put it in an ultrasonic cleaner tank. Fill the beaker with electrocleaner solution and operate the ultrasonic cleaner tank for 5 minutes more.

(12) Do the steps that follow until the electrocleaner solution stays clean after 5 minutes of operation.

(a) Operate the ultrasonic cleaner tank for 5 minutes. Remove the filter element and discard the dirty electrocleaner solution. Flush the filter element and the beaker with clean electrocleaner solution with the use of a plastic squeeze bottle.

(b) Put the filter element in a beaker and put it in an ultrasonic cleaner tank. Fill the beaker with electrocleaner solution and operate the ultrasonic cleaner tank for 5 minutes more.

(13) Remove the filter element from the beaker and flush internally and externally with clean water at a high pressure.

WARNING: USE THE CORRECT PERSONAL PROTECTION. COMPRESSED AIR WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES. THE AIR FLOW CAN CAUSE CUTS. DO NOT POINT IT AT YOUR SKIN.

(14) Dry the filter element with compressed air.

(15) Do a test on the cleaned filter element for pressure decrease. Refer to INSPECTION/CHECK (PGBLK 29-20-17-5000).

(1) 使用第 2.I 段(子任务 29-20-17-110-005-A01)和第 2.J 段(子任务 29-20-17-110-006-A01)清除滤芯上的油脂。

警告:使用正确的个人防护用品。该化学物质/溶液会对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(2) 将滤芯放入电解清洁剂溶液中 4 – 6 分钟。在此期间,在 4 – 7 伏直流电压下使滤芯成为阳极 1 – 2 分钟。

(3) 用清水冲洗滤芯。

(4) 在室温下,将滤芯放入等体积的氢氰酸和水溶液中 1/2 – 1 分钟。

(5) 用清水冲洗滤芯。

(6) 将滤芯放入电解清洁剂溶液中 4 – 6 分钟。

(7) 用高压清水冲洗滤芯内部和外部。

(8) 将滤芯放入烧杯中,滤芯开口向下,并在烧杯中注入电解清洁剂溶液。

(9) 将装有滤芯的烧杯放入超声波清洗槽中。向槽中注水,直至水位距烧杯顶部 3/8 英寸 (9.53 毫米)。

(10) 操作超声波清洗槽 5 分钟。取下滤芯并报废脏的电解清洁器溶液。用塑料挤压瓶冲洗滤芯和烧杯中的清洁电解质溶液。

(11) 将滤芯放入烧杯中,然后放入超声波清洗槽中。向烧杯中注入电解质溶液,再操作超声波清洗槽 5 分钟。

(12) 执行以下步骤,直到运行 5 分钟后电解清洁剂溶液保持清洁。

(a) 运行超声波清洗槽 5 分钟。取下滤芯,报废脏的电解清洗液。用塑料挤压瓶冲洗滤芯和烧杯中的清洁电解质溶液。

(b) 将滤芯放入烧杯中,然后放入超声波清洗槽中。向烧杯中注入电解质溶液,再操作超声波清洗槽 5 分钟。

(13) 从烧杯中取出滤芯,用高压清水冲洗内部和外部。

警告:使用正确的个人防护用品。该化学物质/溶液会对皮肤、眼睛和肺部造成伤害。请遵守制造商对每种化学品的说明。

(14) 用压缩空气干燥滤芯。

(15) 对清洁后的滤芯进行压力下降测试。请参阅 INSPECTION/CHECK。