分解DISASSEMBLY

1. Planning Data 计划数据

A. Reason for the Job

工作原因

(1) Use these procedures to remove parts from the modulating shutoff valve to do the cleaning, checks, and repair. Do only those procedures of disassembly that are necessary to remove the defective parts.

使用这些程序拆卸调节关断活门上的零件,以进行清洁、检查和维修。只做拆卸故障零件所需的拆卸步骤。

B. Job Setup Data

工作设置数据

(1) You can use equivalent alternatives for the special tools, fixtures, equipment, and consumable materials unless specified differently. The user must find equivalent alternatives.

专用工具、夹具、设备和消耗材料可以使用同等替代品,除非另有规定。用户必须找到同等替代品。

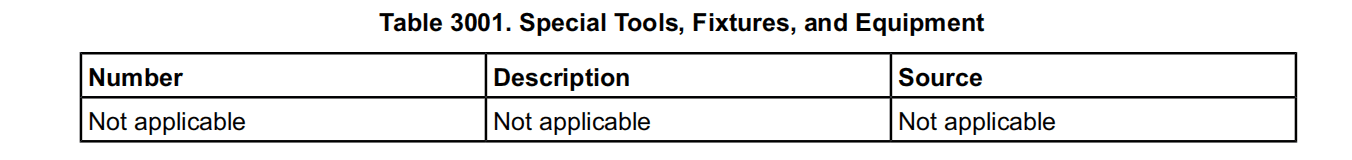

(2) Refer to Table 3001 for the specified special tools, fixtures, and equipment in this section.

本章节中指定的专用工具、夹具和设备请参见表 3001。

(3) CAGE codes and manufacturers’ addresses are available at https://cage.dla.mil.

CAGE码和制造商地址见 https://cage.dla.mil。

WARNING:BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参阅制造商的材料安全数据表。某些材料可能具有危险性。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:不要使用与霍尼韦尔规定材料未等效的材料。非等效材料可能导致设备损坏,并使保修失效。

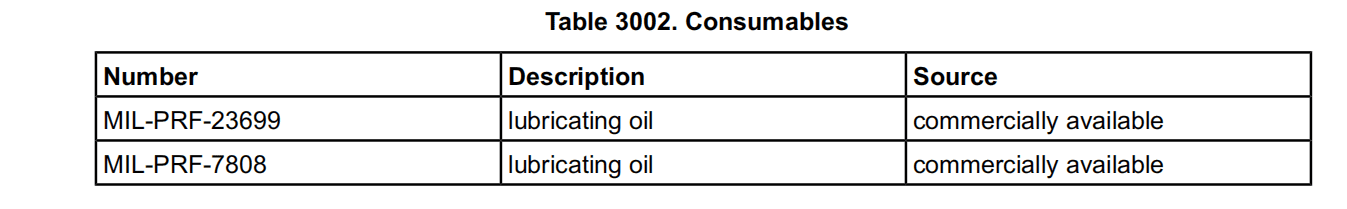

(4) Refer to Table 3002 for the specified consumable materials in this section.

有关本章节中规定的消耗材料,请参见表 3002。

(5) The list that follows identifies Honeywell publications that are related to this section:

以下清单列出了与本章节相关的霍尼韦尔出版物:

• Not applicable.

不适用。

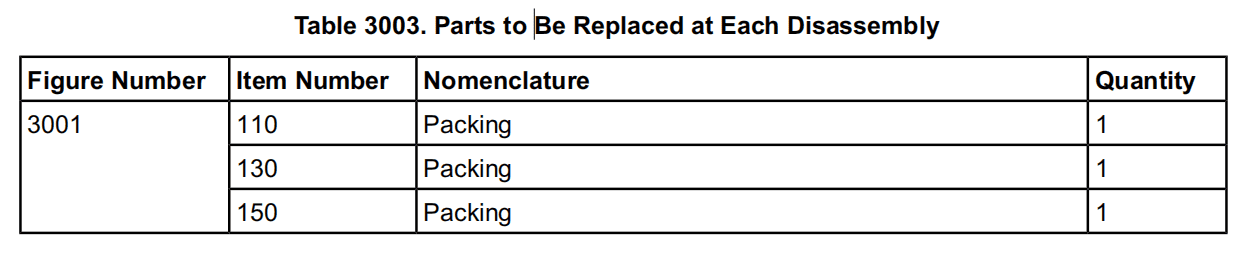

(6) Refer to Table 3003 for the recommended parts to be replaced at each disassembly.

每次分解时建议更换的零件参见表 3003。

NOTE: In-service experience can be used for actual replacement of parts.

注:实际更换零件时可参考在用经验。

(7) Honeywell recommends during an overhaul, as a minimum, all bearings, packings and seals be replaced.

霍尼韦尔建议在大修期间至少更换所有轴承、橡胶密封和密封件。

2. Procedure程序

A. Job Setup

工作设置

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参阅制造商的材料安全数据表。某些材料可能具有危险性。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:不要使用与霍尼韦尔规定材料未等效的材料。非等效材料可能导致设备损坏,并使保修失效。

CAUTION: DO THESE PROCEDURES IN A CLEAN ENVIRONMENT TO PREVENT DAMAGE TO MECHANICAL COMPONENTS.

注意:请在清洁的环境中执行这些程序,以防止损坏机械部件。

(1) Obey the precautions.

遵守预防措施。

(2) The item numbers shown in the DPL are the same as the item numbers on the exploded view illustration(s). To find a part number, find the part on the illustration and note the item number. Find the item number in the parts list and read the correct part number. Item numbers refer to the same figure until a different figure is specified.

DPL 中显示的项目编号与爆炸视图插图上的项目编号相同。要查找件号,请在插图上找到该零件并记下项目编号。在零件清单中找到项目编号并读出正确的件号。在规定不同的数字之前,项目编号指的是同一数字。

(3) Before disassembly, use TESTING AND FAULT ISOLATION to examine the condition of the unit or to find the malfunction. Do this to prevent disassembly that is not necessary.

在拆卸之前,使用测试和故障隔离检查部件的状态或查找故障。这样做是为了防止不必要的分解。

(4) If applicable, as an aid for assembly, tag the items that are disconnected to show where the connections were made.

如适用,作为组装的辅助工具,在断开连接的组件上贴上标签,以显示连接的位置。

B. General Disassembly Procedures

通用分解程序

(1) Disassemble in a dry, bright, clean room.

在干燥、明亮、洁净的室内进行分解。

(2) Be careful to prevent damage to parts that can be used again.

小心防止损坏可再次使用的零件。

WARNING: USE THE CORRECT PERSONAL PROTECTION. OIL CAN HAVE AN ADDITIVE CALLED TRICRESYL PHOSPHATE IN IT. THIS CHEMICAL IS AN ASPHYXIANT, IT IS POISONOUS AND CAN BE ABSORBED THROUGH THE SKIN.

警告:使用正确的个人防护用品。油中可能含有一种名为磷酸三甲苯酯的添加剂。这种化学物质是一种窒息剂(引起窒息的),有毒并可通过皮肤吸收。

(3) If necessary, apply MIL-PRF-23699 lubricating oil to parts and put them in a clean container to prevent corrosion until the parts can be cleaned and examined.

如有必要,可在零件上涂抹 MIL-PRF-23699 润滑油,并将其放在干净的容器中以防止腐蚀,直到可以对零件进行清洗和检查。

(4) Do not disassemble any staked, welded, riveted, soldered, swaged, or press fit assemblies. Do not remove plates, passage hole plugs, or threaded inserts unless replacement is necessary.

切勿分解任何桩固定、焊接、铆接、电气焊接、压接或压装组件。除非有必要更换,否则不拆除标牌、孔塞或钢丝螺套。

(5) Examine all bearings for roughness, brinelling, and damaged races or retainers. These conditions can be an indication of possible damage.

检查所有轴承是否粗糙、硬化、滚道或保持架损坏。这些情况可能是可能损坏的迹象。

(6) Remove all protective caps, plugs, and closures before disassembly of the unit.

在分解部件之前,取下所有保护帽、塞子和封闭装置。

(7) Make a record of the quantities and thickness of the shims and washers. This will help when you assemble the unit.

记录垫片和垫圈的数量和厚度。这将有助于组装部件。