检查INSPECTION/CHECK

1. Planning Data

计划数据

A. Reason for the Job

工作原因

(1) Use these procedures to find damage or worn parts and parts that show signs of near failure.

使用这些程序来查找损坏或磨损的零件以及出现故障迹象的零件。

B. Job Setup Data

工作设置数据

(1) You can use equivalent alternatives for the special tools, fixtures, equipment, and consumable materials unless specified differently. The user must find equivalent alternatives.

除非另有规定,您可以使用等效替代品来替代专用工具、夹具、设备和消耗材料。必须找到等效替代品。

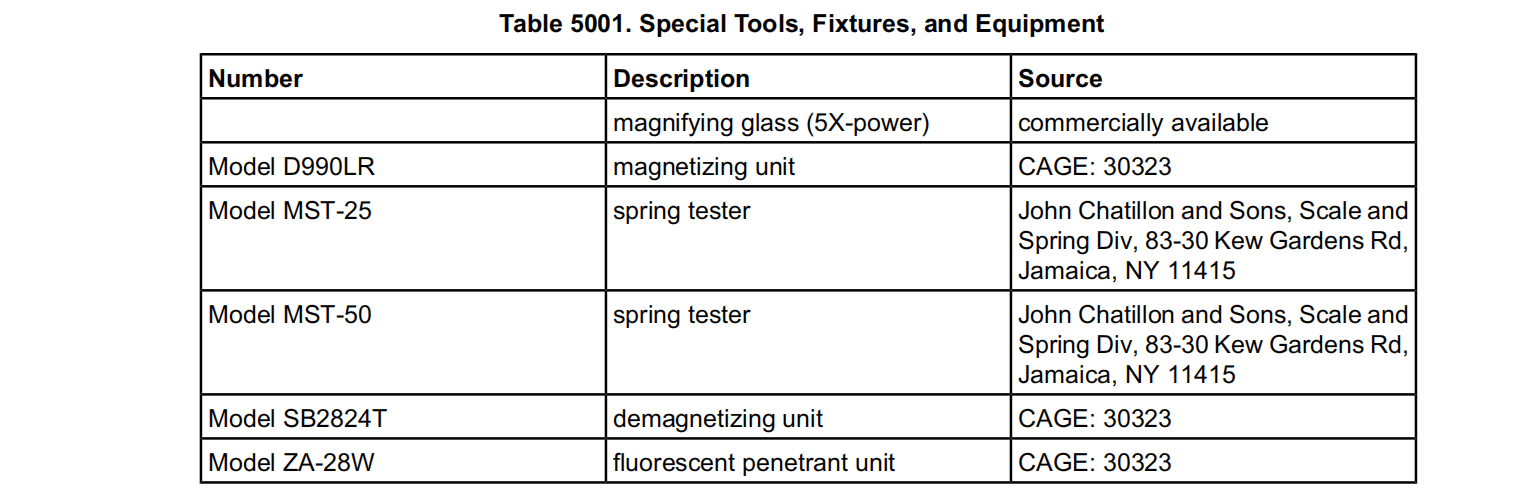

(2) Refer to Table 5001 for the specified special tools, fixtures, and equipment in this section.

本节规定的专用工具、夹具和设备请参见表 5001。

(3) CAGE codes and manufacturers’ addresses are available at https://cage.dla.mil.

CAGE代码和制造商地址见 https://cage.dla.mil。

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参考制造商的材料安全数据表。一些材料可能具有危险性。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用没有与HONEYWELL规定材料等效的材料。非等效材料可能会导致设备损坏,并使索赔不适用(保修失效)。

(4) Refer to Table 5002 for the specified consumable materials in this section.

有关本节中规定的消耗材料,请参见表 5002。

(5) The list that follows identifies Honeywell publications that are related to this section:

• Not applicable.

以下清单列出了与本节相关的Honeywell出版物:

• 不适用。

2. Procedure

程序

A. Job Setup

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

CAUTION: DO THESE PROCEDURES IN A CLEAN ENVIRONMENT TO PREVENT DAMAGE TO MECHANICAL COMPONENTS.

(1) Obey the precautions.

(2) Replace all damaged or worn parts. This prevents possible failures of the equipment.

工作设置

警告:在使用材料之前,请参考制造商的材料安全数据表。一些材料可能具有危险性。

注意:请勿使用没有与HONEYWELL规定材料等效的材料。非等效材料可能会导致设备损坏,并使索赔不适用(保修失效)。

警告:请在清洁的环境中执行这些程序,以防止损坏机械部件。

(1) 遵守预防措施。

(2) 更换所有损坏或磨损的零件。这样可以防止设备出现故障。

B. General Inspection/Check Procedure of the modulating shutoff valve

(1) Use a magnifying glass to examine the parts.

(2) Refer to the detailed check procedures, if a part shows a condition that could have caused wear.

(3) Dimensional inspections are given for parts that wear. If a visual check shows no damage or wear, but damage is suspected, specific check instructions are given.

(4) Examine the parts that are usually replaced at each scheduled inspection cycle. Damage to these parts can show a malfunction of other components.

(5) Examine threaded parts.

(a) Examine all threaded parts for crossed, stripped or broken threads. Discard the part if threads are damaged.

(b) Examine for loose threaded inserts and the condition of the threads. Refer to REPAIR (PGBLK 29-20-17-6000) if the inserts are loose or damaged.

(6) Examine seal surfaces.

(a) Examine all seal surfaces for minor surface defects. Refer to REPAIR (PGBLK 29-20-17-6000) if the seal surfaces are damaged.

(b) Examine all flanges for minor surface defects. Refer to REPAIR (PGBLK 29-20-17-6000) if the flanges are damaged.

调节关断活门的通用检查/检测程序

(1) 使用放大镜检查零件。

(2) 如果零件出现可能导致磨损的状况,请参考详细的检查程序。

(3) 对磨损的零件进行尺寸检查。如果目视检查未发现损坏或磨损,但怀疑存在损坏,则给出具体的检查说明。

(4) 检查每个定期检查周期通常更换的零件。这些零件损坏可能表明其他组件出现故障。

(5) 检查螺纹零件。

(a) 检查所有螺纹零件,查看螺纹是否交叉、磨损或断裂。如果螺纹损坏,则应丢弃该零件。

(b) 检查螺纹钢丝螺套是否松动以及螺纹的状况。如果钢丝螺套松动或损坏,请参阅修理(PGBLK 29-20-17-6000)。

(6) 检查密封表面。

(a) 检查所有密封表面是否有轻微的表面缺陷。如果密封表面损坏,请参阅修理(PGBLK 29-20-17-6000)。

(b) 检查所有法兰是否有轻微的表面缺陷。如果法兰损坏,请参阅修理(PGBLK 29-20-17-6000)。

C. Fluorescent Penetrant Inspection

NOTE: It is not necessary to do the fluorescent penetrant inspection on anodized, plated or painted surfaces, unless wear or physical damage is found.

(1) Do a fluorescent penetrant inspection. Refer to ASTM E1417.

(2) Remove anodize or paint from the surface. Refer to CLEANING (PGBLK 29-20-17-4000).

(3) Remove all rust, scale, burrs, dirt, grease, and other contaminations. Make sure the part is dry. Refer to CLEANING (PGBLK 29-20-17-4000).

(4) Refer to the manufacturer’s instructions to use Model ZA-28W fluorescent penetrant unit and SAE-AMS 2644 penetrant oil.

(5) When completed, remove all penetrant oil. Refer to CLEANING (PGBLK 29-20-17-4000).

(6) Apply anodize or paint if necessary. Refer to REPAIR (PGBLK 29-20-17-6000).

荧光渗透检测

注意:除非发现磨损或物理损坏,否则无需对阳极氧化、电镀或喷漆表面进行荧光渗透检测。

(1) 进行荧光渗透检测。请参考 ASTM E1417。

(2) 去除表面的阳极氧化层或油漆。请参考清洁(PGBLK 29-20-17-4000)。

(3) 清除所有锈迹、氧化皮、毛刺、脏污、油脂和其他污染物。确保零件干燥。请参阅清洁(PGBLK 29-20-17-4000)。

(4) 请参考制造商的说明,使用型号为ZA-28W的荧光渗透剂和SAE-AMS 2644渗透剂。

(5) 完成后,请清除所有渗透剂。请参考清洁(PGBLK 29-20-17-4000)。

(6) 如有必要,涂上阳极氧化层或油漆。请参阅修理(PGBLK 29-20-17-6000)。

D. Magnetic Particle Inspection

NOTE: It is not necessary to do the magnetic particle inspection on anodized, plated, or painted surfaces, unless wear or physical damage is found.

(1) Do a magnetic particle inspection. Refer to ASTM E1444 and use the wet continuous direct current method.

(2) Remove paint from the surface. Refer to CLEANING (PGBLK 29-20-17-4000).

(3) Remove all rust, scale, burrs, dirt, grease, and other contaminations from the part. Make sure that the part is dry. Refer to CLEANING (PGBLK 29-20-17-4000).

(4) Refer to the manufacturer’s instructions to use the Model D990LR magnetizing unit, Magnaglo Carrier II magnetic base oil and Magnaglo Dry Concentrate No. 14A magnetic particles compound.

(5) Magnetize the part in the longitudinal direction, do the inspection, then magnetize in the circumferential direction and do the inspection again.

(6) When completed, use the Model SB2824T demagnetizing unit to demagnetize the part to a maximum of 3 gauss.

(7) After the part is demagnetized, remove all the magnetic base oil. Refer to CLEANING (PGBLK 29-20-17-4000).

(8) Paint the part if necessary. Refer to REPAIR (PGBLK 29-20-17-6000).

磁粉检测

注意:除非发现磨损或物理损坏,否则无需对阳极氧化、电镀或喷漆表面进行磁粉检测。

(1) 进行磁粉检测。请参考 ASTM E1444,并使用湿式连续直流法。

(2) 去除表面的油漆。请参考清洁(PGBLK 29-20-17-4000)。

(3) 清除零件上的所有锈迹、氧化皮、毛刺、污垢、油脂和其他污染物。确保零件干燥。请参阅清洁(PGBLK 29-20-17-4000)。

(4) 请参考制造商的说明,使用D990LR型磁化装置、Magnaglo Carrier II磁性基础油和Magnaglo Dry Concentrate No. 14A磁性颗粒化合物。

(5) 沿零件的纵向进行磁化,然后进行检查,再沿圆周方向进行磁化,再次进行检查。

(6) 完成后,使用型号为 SB2824T 的消磁装置将零件消磁至最大 3 高斯。

(7) 零件消磁后,清除所有磁性基础油。请参阅清洁(PGBLK 29-20-17-4000)。

(8) 如有必要,给零件上漆。参考修理(PGBLK 29-20-17-6000)。