存储(含运输)STORAGE (INCLUDING TRANSPORTATION)

1. Planning Data

计划数据

A. Reason for the Job

工作原因

(1) Use these procedures to prepare the modulating shutoff valve for storage or transportation. The function of these procedures is to make sure that the modulating shutoff valve has protection from dust, moisture, and other contamination.

使用这些程序准备调节关断活门进行储存或运输。这些程序的功能是确保调节关断活门免受灰尘、湿气和其他污染。

B. Job Setup Data

工作设置数据

(1) You can use equivalent alternatives for the special tools, fixtures, equipment, and consumable materials unless specified differently. The user must find equivalent alternatives.

特殊工具、夹具、设备和消耗材料可以使用等效替代品,除非另有规定。用户必须找到同等替代品。

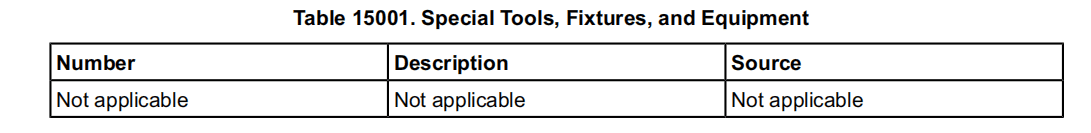

(2) Refer to Table 15001 for the specified special tools, fixtures, and equipment in this section.

有关本节中规定的特殊工具、夹具和设备,请参见表 15001。

(3) CAGE codes and manufacturers’ addresses are available at https://cag.dia.mil.

CAGD和制造商地址可在 https://cag.dia.mil 上查阅。

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参考制造商的材料安全数据表。 有些材料可能很危险。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用与霍尼韦尔指定材料未等效的材料。非等效材料可能会导致设备损坏,并使保修失效。

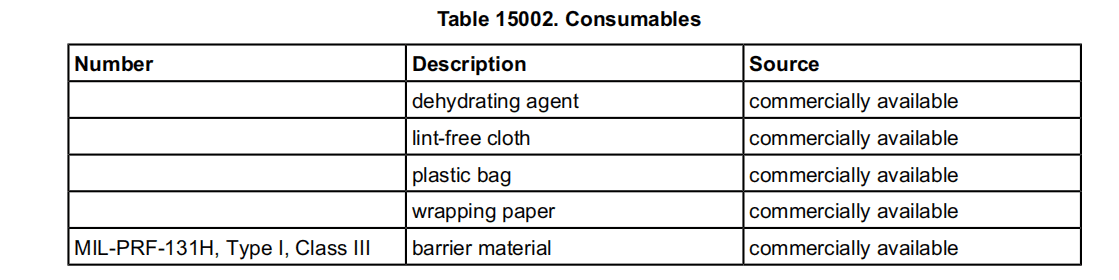

(4) Refer to Table 15002 for the specified consumable materials in this section.

本节中的指定消耗材料请参见表 15002。

(5) The list that follows identifies Honeywell publications that are related to this section:

以下清单列出了与本节相关的霍尼韦尔出版物:

• Not applicable.

– 不适用。

2. Procedure

程序

A. Job Setup

工作设置

WARNING: BEFORE YOU USE A MATERIAL, REFER TO THE MANUFACTURERS’ MATERIAL SAFETY DATA SHEETS. SOME MATERIALS CAN BE DANGEROUS.

警告:在使用材料之前,请参阅制造商的材料安全数据表。 有些材料可能很危险。

CAUTION: DO NOT USE MATERIALS THAT ARE NOT EQUIVALENT TO HONEYWELL SPECIFIED MATERIALS. MATERIALS THAT ARE NOT EQUIVALENT CAN CAUSE DAMAGE TO THE EQUIPMENT AND CAN MAKE THE WARRANTY NOT APPLICABLE.

注意:请勿使用与霍尼韦尔指定材料未等效的材料。非等效材料可能会导致设备损坏,并使保修失效。

CAUTION: DO THESE PROCEDURES IN A CLEAN ENVIRONMENT TO PREVENT DAMAGE TO MECHANICAL COMPONENTS.

注意:请在清洁的环境中执行这些程序,以防止损坏机械组件。

(1) Obey the precautions.

遵守注意事项(预防措施)。

B. Preservation

保存

(1) Age control is not necessary for assemblies, silicon rubber, fluorocarbon rubber, fuel tank synthetics, or static seals used with fasteners.

对于组件、硅橡胶、碳氟橡胶、油箱合成橡胶或与紧固件一起使用的静态密封件,无需进行时效控制。

(2) Age Controls of Age-Sensitive Elastomeric Material for Aerospace Applications is specified in SAE ARP5316. Refer to this standard for all military and commercial use. Assemblies that contain age-sensitive material in this specification are limited by failure rates, in-service use, and system life estimated by the user.

SAE ARP5316 中规定了航空航天应用中对时效敏感弹性材料的时效控制。所有军用和商业用途均参照此标准。本规范中包含对时效敏感材料的组件受失效率、在役使用和用户估计的系统寿命的限制。

(3) Bad storage conditions can cause damage to parts. Such conditions are, but not limited to:

恶劣的储存条件会导致部件损坏。这些条件包括但不限于

– Moisture

水分

– High temperature (over 125°F (52°C))

高温(超过125华氏度(52 C))

– Fuel or solvents that have expanded

已经膨胀的燃料或溶剂

– Fumes that can cause corrosion

会引起腐蚀的烟雾

– Mechanical stresses

机械应力

– Ultraviolet light.

紫外光

(4) Parts that have been in bad storage conditions must be examined for damage and replaced as necessary.

必须检查存放条件恶劣的部件是否损坏,必要时予以更换。

C. Packing

包装

(1) Clean the external surfaces with a clean, lint-free cloth.

用干净的无绒布清洁外表面。

(2) Put covers on all openings.

在所有开口处盖上盖子。

(3) Wrap the unit in wrapping paper and put in a plastic bag.

用包装纸包裹设备并装入塑料袋。

(4) Use cushions at sharp corners to prevent damage to the MIL-PRF-131H, Type I, Class III barrier material and fill containers with dehydrating agent. Use the applicable size barrier material.

在尖角处使用垫子,以防损坏 MIL-PRF-131H,I 类,III 级阻隔材料,并将脱水剂装入容器。使用适用尺寸的阻隔材料。

D. Storage

存储

(1) Keep the unit in an area away from high temperatures, dust, moisture and corrosive fumes.

将部件放在远离高温、灰尘、潮湿和腐蚀性烟雾的地方。

(2) The recommended storage temperature is less than 100°F (38°C) and must not be more than 125°F (52°C).

建议存放温度低于 38°C (100°F),不得高于 52°C (125°F)。

(3) Control the humidity to prevent moisture on the unit.

控制湿度,防止设备受潮。

E. Transportation

运输

(1) Not applicable.

不适用

F. Job Close-up

工作结束

(1) Not applicable.

不适用