高强度钢零件的修理和表面处理REPAIR AND REFINISH OF HIGH STRENGTH STEEL PARTS

1. INTRODUCTION 介绍

A.The procedures in this subject are applicable to high strength, low-alloy steel parts heat-treated above 180 ksi.

本主题中的程序适用于热处理在180 ksi以上的高强度低合金钢零件。

B.These procedures are recommended to help prevent problems which could decrease the service life of the component.

建议采用这些程序,以防止出现可能缩短部件使用寿命的问题。

C.Be very careful when you repair high-strength steel parts. The strength is easily decreased by such incorrect repair practices as grinding too hot, machining with tools that are not sharp, incorrect feed settings, not sufficient cooling, defective plating, or damage during shop operations.

修理高强度钢零件时要非常小心。这些不正确的维修方法很容易降低强度,如磨削过热、使用不锋利的工具进行机加工、进给设置不正确、冷却不足、镀层缺陷或车间操作过程中的损坏。

2. REPAIR INSTRUCTIONS修理程序

A.To remove finish or plating, refer to SOPM 20-30-02.

去除表面处理或镀层,请参阅SOPM 20-30-02。

B.Machining and Grinding

机械加工和研磨

CAUTION:REFER TO SOPM 20-10-04 FOR GRINDING OF CHROME PLATING.

注意:镀铬层研磨参见SOPM 20-10-04。

(1)Refer to SOPM 20-10-02 for applicable tools, feeds, speeds, and procedures for turning, milling, boring, drilling, reaming, broaching, and honing.

有关车削、铣削、镗孔、钻孔、铰孔、拉削和珩磨的适用工具、进给量、速度和程序,请参阅SOPM 20-10-02。

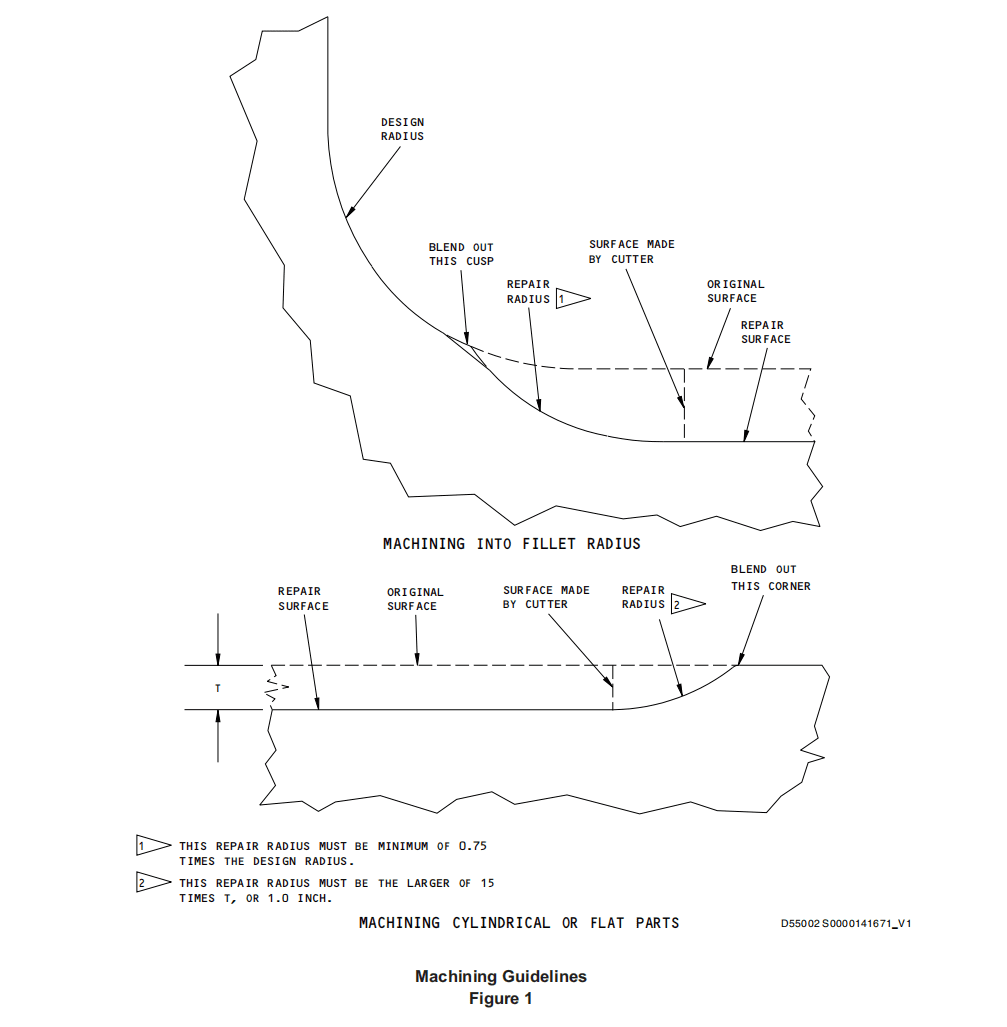

(2)Sudden changes in section size or surface direction on high strength steel parts usually are areas with sudden increases in stress level. Make all fillet or cutter runout radii as specified in the applicable overhaul instructions. When no radius is specified, use the data shown in Figure 1.

高强度钢零件截面尺寸或表面方向的突然变化通常是应力水平突然增加的区域。按照适用的大修说明中的规定,制作所有圆角或刀具跳动半径。如果没有指定半径,请使用图1中所示的数据。

(3)Visual and surface temper etch examinations will help find damage caused during machining or grinding. Refer to SOPM 20-10-02 for requirements and procedures.

目视和表面回火蚀刻检查将有助于发现机加工或研磨过程中造成的损坏。有关要求和程序,请参阅SOPM 20-10-02。

(4)Stress relief is a conservative practice that will decrease residual surface stresses that came into the metal during some metal removal operations. (But operations with unpowered hand tools, such as files or emery cloth, do not cause sufficient residual stresses to make stress relief necessary.) Stress relieve after the removal of all paint and metallic coatings. Refer to SOPM 20-10-02 for recommended times and temperatures for the different metals.

应力消除是一种保守的做法,可以减少在某些金属去除操作过程中进入金属的残余表面应力。(但是,使用锉刀或金刚砂布等无动力手动工具进行操作时,不会产生足够的残余应力来进行必要的应力消除。)去除所有油漆和金属涂层后,应力消除即可。有关不同金属的推荐时间和温度,请参阅SOPM 20-10-02。

(5)Baking (or embrittlement relief baking) at 350-400° F is necessary after processes that could introduce hydrogen. A partial stress relief at 350-400° F is also necessary before stripping of some inorganic finishes, such as plating, per SOPM 20-30-02.

在可能引入氢气的工艺之后,必须在350-400°F下进行烘烤(或脆化消除烘烤)。根据SOPM 20-30-02,在剥离某些无机饰面(如镀层)之前,也需要在350-400°F下进行部分应力消除。

(6)Unless shown differently, magnetic particle examine per SOPM 20-20-01 to make sure there are no cracks or corrosion pits. When magnetic particle inspection is not recommended, as for in-field repairs or the repair of small areas on parts with installed bushings or bearings, you can fluorescent dye penetrant examine per SOPM 20-20-02.

除非另有说明,否则应按照SOPM 20-20-01进行磁粉检测,以确保没有裂纹或腐蚀坑。当不建议进行磁粉检测时,如现场维修或已安装衬套或轴承的零件上的小区域维修,可以根据SOPM 20-20-02进行荧光染料渗透检测。

C.Shot Peening

喷丸

(1)After etch examination, stress relief and magnetic particle examination, shot peen per SOPM20-10-03:

在蚀刻检查、应力消除和磁粉检查后,根据SOPM20-10-03进行喷丸处理:

a)All repaired surfaces before you build them up with plating back to the design dimensions.

在用镀层将所有修复表面恢复到设计尺寸之前,对所有修复表面进行喷丸处理。

b)All surfaces originally shot peened, if the part was stress relieved above 400°F after machining.

如果零件在机加工后在400°F以上消除应力,则所有表面最初都经过喷丸处理。

c)All surfaces from which more than 0.002 inch material was removed from a shot peened part by any kind of machining.

通过任何类型的机械加工从喷丸零件上去除超过0.002英寸材料的所有表面。

(2)Give protection to threads and other close tolerance surfaces not to be shot peened.

保护螺纹和其他不需要喷丸处理的精密公差表面。

(3)Make sure the new shot peened surfaces run out smoothly into adjacent original shot peened surfaces, because fatigue can start at locations with sudden changes in shot peen coverage.

确保新的喷丸表面平滑地延伸到相邻的原始喷丸表面,因为疲劳可能始于喷丸覆盖范围突然变化的位置。

(4)To make the shot peened surfaces smoother, you can hone or lap them to a maximum depth of 0.002 inch.

为了使喷丸表面更光滑,可以将其珩磨或研磨至最大深度0.002英寸。

(5)Shot peening is not necessary if the surfaces will be repaired only by honing to a maximum depth of 0.002 inch, or if the surfaces will be only refinished.

如果仅通过珩磨将表面修复至最大深度0.002英寸,或者仅对表面进行表面修整,则不需要喷丸处理。

D.Polishing

抛光

CAUTION:IF THIS OPERATION MAKES SPARKS, IT IS THE SAME AS GRINDING. THEN THE POST-TREATMENTS OF STEP 2.B. ARE APPLICABLE.

注意:如果此操作会产生火花,则与研磨相同。则步骤2.B的后续处理是适用的。

(1)Polish scratches out by hand with 240 grit or finer aluminum oxide abrasive cloth. Subsequent heat-treatment, shot peening and magnetic inspection is not necessary.

用240目或更细的氧化铝砂布手工抛光划痕。无需进行后续热处理、喷丸处理和磁性检查。

E.Honing

珩磨

(1)Honing of bores in steel parts is not necessary unless specified by the applicable overhaul instructions.

除非适用的大修说明另有规定,否则不需要对钢制零件的孔进行珩磨。

(2)Refer to SOPM 20-10-02 for material removal requirements.

有关材料清除要求,请参阅SOPM 20-10-02。

(3)When you hone for bushing installation:

当为衬套安装进行珩磨时:

a)To prevent bell-mouth bore shapes during honing of bores, a correct setting of stroke length and stroke position is necessary. On dead spots, use an overrun of one-third of the stone length, and keep two-thirds of the stone length inside the bore.

为了防止在珩磨孔过程中形成喇叭口孔形状,需要正确设置行程长度和行程位置。在死点上,使用三分之一油石长度的限制,并将三分之二石头长度保持在钻孔内。

b)Remove bell-mouth bore shapes with a smaller overrun than one-third.

去除超限小于三分之一的喇叭口孔形状。

c)Correct a barrel-shaped bore with a larger stroke length and overrun.

修正冲程长度较大且超限的筒形孔。

d)For bores with a length-to-diameter ratio less than 1.00, hone with a stone length smaller than the bore diameter, and use an overrun of only one fourth of the stone length. Use a high axial stone speed, with a circumferential speed the same as for longer bores.

对于长度与直径之比小于1.00的孔,用小于钻孔直径的油石长度进行珩磨,并仅使用石块长度的四分之一。使用较高的轴向磨石速度,圆周速度与较长钻孔相同。

F.Corrosion Removal

腐蚀去除

(1)Remove corrosion by machining per Paragraph 2.B. or localized blending per Paragraph 2.H.

根据第2.B.段通过机械加工或根据第2.H.段通过局部混合去除腐蚀。

(2)Abrasive blasting must not be used, because it does not remove active corrosion at the bottom of corrosion pits.

不得使用喷砂,因为它不能去除腐蚀坑底部的活性腐蚀。

G.Repair of Shaft with Shoulders

修理有衬套的轴

(1)Some repairs to an outside diameter let you make a relief at an adjacent shoulder to make grinding easier. The diameter of this relief must not be smaller than the repair diameter for the shaft given in the applicable overhaul instructions.

对外径的一些修理可以在相邻的衬套上设置退刀槽,使研磨更容易。该退刀槽的直径不得小于适用的大修说明中给出的轴的修理直径。

H.Local Blends to Remove Defects

去除缺陷的局部混合物

(1)Refer to SOPM 20-10-02 for instructions about hand-powered and portable hand-held power tools.

有关手动和便携式手持电动工具的说明,请参阅SOPM 20-10-02。

(2)Local blends must not decrease the cross-sectional area or section thickness more than permitted by the overhaul instructions.

局部混合物不能减少横截面积或截面厚度超过大修说明所允许的范围。

(3)Make the blend radii the maximum possible that will agree with local part geometry, minimum area removal requirements and the overhaul instructions.

使混合半径尽可能大,以符合局部零件几何形状、最小面积去除要求和大修说明。

(4)The surface finish of the blend area must be the same as or smoother than that of the adjacent base metal.

混合区域的表面光洁度必须与相邻基底金属的表面光洁程度相同或更光滑。

(5)The repaired area must be shot or flap peened.

修复区域必须进行喷丸或旋片喷丸处理。

(6)Refinish the repaired area to agree with the finish on adjacent area and these steps, as applicable:

重新修整修理区域,使其与相邻区域的光洁度一致,并执行以下步骤(如适用):

a)If the part is removed from all other parts, remove all of the plating from the part before blending. Then refinish per overhaul instructions.

如果从所有其他零件上移除零件,则在混合之前移除零件上的所有镀层。然后按照大修说明进行表面处理。

b)If the part is installed but the load on it is removed, such as on the landing gear from which weight is removed by jacking up the airplane, stylus cadmium plate the repair area per SOPM 20-42-10. Then apply a minimum of two layers of BMS 10-11, Type 1 primer and one layer of BMS 10-11 enamel.

如果零件已安装,但移除了其上的负载,例如起落架上的负载(通过顶起飞机来移除其重量),则根据SOPM 20-42-10,对修理区域镀镉。然后涂上至少两层BMS 10-11 1型底漆和一层BMS 10-111瓷漆。

c)If the part is installed and the load cannot be removed, paint the repair area with a minimum of two layers of BMS 10-11, Type 1 primer and one layer of BMS 10-11 enamel. This primer and enamel on areas without cadmium plating is not a permanent finish and must be kept on until the part can be refinished per Paragraph 2.H.(6)(b).

如果零件已安装且无法移除负载,则在维修区域至少涂上两层BMS 10-11 1型底漆和一层BMS 10-12瓷漆。未镀镉区域上的底漆和搪瓷不是永久性表面处理,必须保持使用,直到可以根据第2.H.(6)(b) 段对零件进行再次表面处理。

3. REFINISH INSTRUCTIONS再次表面处理说明

A.Refer to these subjects, as applicable, for removal of the original finish and the different types of plating :

如适用,请参考这些主题,以去除原始表面处理和不同类型的镀层:

(1)SOPM 20-30-02, Stripping of Protective Finishes

SOPM 20-30-02,保护层的剥离

(2)SOPM 20-42-05, Bright Cadmium Plating (for parts heat-treated up to 220 ksi)

SOPM 20-42-05,亮镉电镀(用于热处理至220 ksi的零件)

(3)SOPM 20-42-01, Low Hydrogen Embrittlement Cadmium Plating

SOPM 20-42-01,低氢脆镉电镀

(4)SOPM 20-42-02, Low Hydrogen Embrittlement Cadmium-Titanium Alloy Plating (for parts heat-treated above 220 ksi)

SOPM 20-42-02,低氢脆性镉钛合金电镀(用于220 ksi以上热处理的零件)

(5)SOPM 20-42-03, Hard Chrome Plating

SOPM 20-42-03,镀硬铬

(6)SOPM 20-42-09, Electrodeposited Nickel Plating

SOPM 20-42-09,电沉积镀镍

B.Baking after Plating

电镀后烘烤

(1)As an alternative to the baking instructions given in each applicable plating subject, one bake is permitted when the part gets two or more plating operations (other than nickel plating), if the time between the first and the last plating operation is not more than 8 hours (steel parts heat-treated up to 220 ksi), or 3 hours (steel parts heat-treated above 220 ksi).

作为每个适用电镀主题中给出的烘烤说明的替代方案,如果第一次和最后一次电镀之间的时间不超过8小时(热处理至220 ksi的钢制零件)或3小时(热处理至220 ksi方英寸以上的钢制部件),则当零件进行两次或两次以上电镀操作(镀镍除外)时,允许进行一次烘烤。

(2)Magnetic particle examine the part per SOPM 20-20-01 after baking.

烘烤后,根据SOPM 20-20-01对零件进行磁粉检测。

C.Unless plated to final dimensions, grind chrome plated parts per SOPM 20-10-04.

除非镀到最终尺寸,否则应按照SOPM 20-10-04研磨镀铬零件。