热喷涂涂层的应用和表面处理APPLICATION AND FINISHING OF THERMAL SPRAY COATINGS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5851 and BAC5855. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5851 和 BAC5855。可查阅波音过程规范。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并非针对所有情况或特定安装。请将此数据作为帮助您编写最低标准的指南。

C. BAC5851 coatings have these classes:

BAC5851 涂料具有以下等级:

(1) Class 1 uses the usual plasma spray equipment.

等级 1 使用普通的等离子喷涂设备。

(2) Class 2 uses high velocity oxy-fuel (HVOF) equipment, which gives a coating with smaller pores.

等级 2 使用高速纯氧燃料(HVOF)设备,该设备可提供孔隙更小的涂层。

(3) Class 3 uses a Detonation Gun (D-Gun) and a proprietary procedure

等级 3 使用Detonation Gun(D-Gun)和专有程序

(4) Class 4 uses a Super D-Gun (SDG) and a proprietary procedure.

等级4 使用Super D-Gun(SDG)和专有程序。

(5) Class 5 uses small diameter extended length directed plasma spray equipment. This is for inner diameters of two inches or larger.

等级 5 使用小直径加长型定向等离子喷涂设备。适用于内径为两英寸或更大的情况。

(6) If the overhaul instructions specify Class 1, you can use Class 2, 3 or 4 if the application of the coating is approved for these alternatives.

如果大修说明指定使用等级1,如果涂层的应用已被批准用于这些替代方法,则可使用等级2、3 或 4。

(7) If the overhaul instructions do not specify the class, use Class 2, 3 or 4.

如果大修说明没有指定等级,则使用等级 2、3 或 4 。

D. BAC5851 coatings also have these grades.

BAC5851 涂料还有以下等级。

(1) Grade A: General use coatings.

A 级:一般用途涂层。

(2) Grade B: Coatings that have fatigue safety margins as specified by the applicable Boeing Structural Damage Technology Organization.

B 级:具有波音结构损伤技术组织规定的疲劳安全系数的涂层。

(3) If the Grade is not specified, use Grade A.

如未指明等级,则使用 A 级。

(4) When Grade B approval is given for a specific coating, independently of the base metal used during the qualification, that coating is also qualified and approved for Grade A applications on all base metal substrates.

当特定涂层获得 B 级批准时,与认证过程中使用的基体金属无关,该涂层也获得了在所有基体金属基材上应用 A 级的资格和批准。

E. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商的名称和地址清单请参见 SOPM 20-00-00。

2. EQUIPMENT 设备

NOTE: BAC5851 par. 6.2 gives general requirements for the guns and related equipment, and recommends the equipment shown below. Other systems can be used if they are qualified as specified in BAC5851 par. 13.

注: BAC5851 第 6.2 段对喷枪和相关设备提出了通用要求,并推荐使用以下设备。如果其他系统符合 BAC5851 标准第 13.1 段的规定,也可使用。

A. Systems

系统

(1) For Class 1 coatings, a plasma gun such as:

对于 等级1 的涂层,可使用等离子喷枪,如

(a) SG100 (V33870)

(b) Sulzer Metco 3M (V01FK3)

(c) Sulzer Metco 7M (V01FK3)

(d) Sulzer Metco 9M (V01FK3)

(2) For Class 2 coatings, HVOF equipment, such as:

对于等级 2 的涂层,HVOF 设备,如

(a) Diamond Jet 2600/2700 (V01FK3),

(b) Jet Kote II (V1C774)

(c) JP 5000 (V33870)

(3) For Class 3 coatings, a Praxair D-Gun (V33870).

对于等级3的涂层,Praxair D-Gun (V33870)

(4) For Class 4 coatings, a Praxair Super D-Gun (V33870).

对于等级 4 的涂层,Praxair Super D-Gun (V33870)

(5) For Class 5 coatings, a small diameter plasma gun, such as:

对于 等级5 的涂层,使用小直径等离子枪,例如

(a) Praxair Model 2700 Mini-Gun III (V33870)

(b) 13MB (V01FK3)

B. Fixtures to hold the part and gun at a constant distance and move it at controlled speeds and depths of feeds.

将工件和喷枪固定在恒定距离,并以受控速度和进给深度移动的夹具。

C. Fixtures to hold the part during grinding or honing.

在研磨或珩磨过程中固定零件件的夹具。

D. Grit blasting equipment to supply 36 to 60 mesh particles at air pressures up to 60 psi, with a desiccant air dryer or draining separator and an oil removal filter.

喷砂设备,提供 36 至 60 目颗粒,气压高达 60 psi,配有含干燥剂的空气干燥器或排水分离器和除油过滤器。

E. Auxiliary cooling system such as nitrogen, carbon dioxide or air spray, with something to monitor temperature, such as a surface pyrometer or temperature sensitive crayons.

辅助冷却系统,如氮气、二氧化碳或空气喷淋,并配有监测温度的装置,如表面高温计或感温笔。

F. Carbide tipped machining tools (C-2 grade or better) such as Carboloy 883 or Vascoloy-Ramet 2A7. Do not use milling tools to machine flame sprayed coatings. This includes end mills and face mills.

硬质合金加工工具(C-2 级或更高),如 Carboloy 883 或 Vascoloy-Ramet 2A7。不得使用铣削工具加工火焰喷涂涂层。这包括立铣刀和端面铣刀。

G. Grinding wheel — Resin bonded diamond, silicon carbide or aluminum oxide (as applicable), 100-400 grit; hardness L, M, or N.

砂轮 — 树脂结合金刚石、碳化硅或氧化铝(视情况而定),100-400 目;硬度 L、M 或 N。

H. Honing stones — Diamond, aluminum oxide or silicon carbide (as applicable).

珩磨石(油石) — 金刚石、氧化铝或碳化硅(视适用情况而定)。

3. MATERIALS 材料

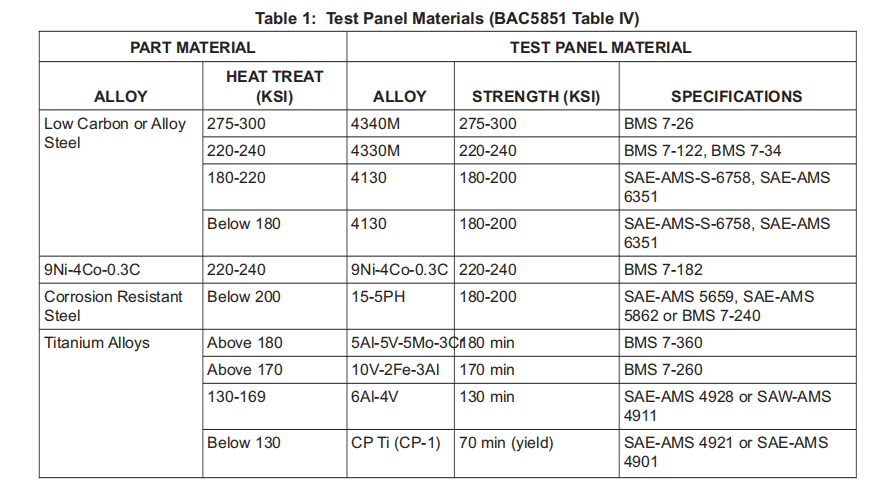

A. Test panel of the same material as the part to be coated or as specified in Table 1. Refer to BAC5851 for more details.

与待涂层部件相同材料的测试板或表 1 中规定的测试板。详情请参阅 BAC5851。

B. Primers(SOPM 20-60-02)

底漆

(1) BMS 10-11, Type 1

(2) BMS 10-79, Type 2 or Type 3

C. Sealers

密封剂

(1) Metcoseal AP, V01FK3 (new supply not available)

(2) Metcoseal URS (replaces Metcoseal AP), V01FK3

(3) UCAR 100, V33870

D. Silicon carbide stick, to clean the grinding wheel.

碳化硅棒,用于清洁砂轮。

E. Abrasive grit, aluminum oxide or silicon carbide, 16-60 mesh, maximum free silica 0.75% by weight — V2U971, V01FK3.

氧化铝或碳化硅磨粒,16-60 目,最大游离二氧化硅 0.75%(按重量计) — V2U971、V01FK3。

F. Grit blast resistant tape, rubber backed — Scotch 507, V76381 or Mystik 9710, V88301.

背面带橡胶的防砂胶带 — Scotch 507, V76381 或 Mystik 9710, V88301。

G. Heat reflective tape, aluminum foil backed, glass cloth laminated — Scotch Y-9050, V76381.

玻璃布层压背面带铝箔的热反射胶带 –Scotch Y-9050,V76381。

H. Temperature indicating devices (V82682)

温度指示装置(V82682)

(1) Crayons蜡笔: Tempilstiks

(2) Liquids液体: Tempilaq G

(3) Labels标签: Tempilabels

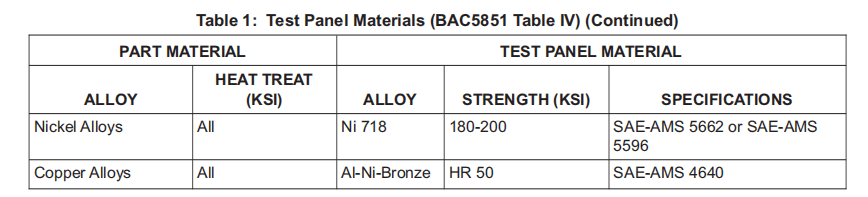

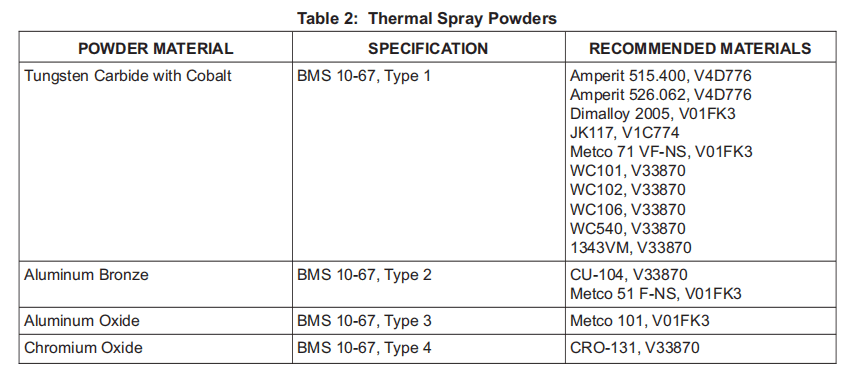

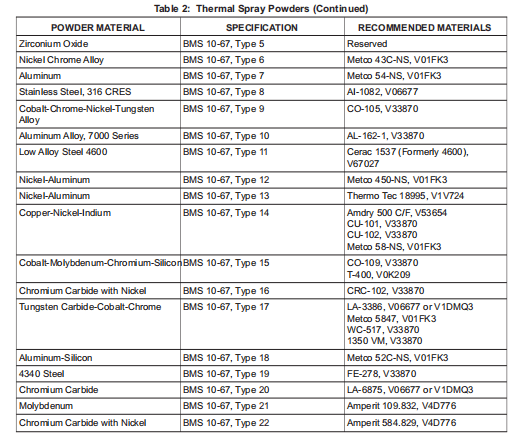

I. Thermal spray powders — See Table 2.

热喷涂粉末 — 见表 2。

J. Wipers擦拭材料: BMS 15-5

4. GENERAL 通用

A. In some applications, thermal spray coatings can be an alternative to the more usual procedures, such as chrome or nickel plate buildup, to put back to design dimensions the steel parts which are undersize as a result of wear or defect removal. Thermal spray coatings could also be specified for parts made of aluminum, stainless steel, bronze, or titanium.

在某些应用中,热喷涂涂层可以替代铬板或镍板等常规工艺,将因磨损或缺陷去除而尺寸不足的钢制零件恢复到设计尺寸。也可以为铝、不锈钢、青铜或钛制成的部件指定热喷涂涂层。

B. Two HVOF repair alternatives are now available that can be used to repair blends in high strength steel components where the design specifies a hard surface layer such as chrome plate or BMS 10-67 Type 17 tungsten carbide cobalt chrome thermal spray coating. The component-specific overhaul instructions will specify if these repair alternatives can be used to repair the component:

现有两种 HVOF 修复替代方法,可用于修复高强度钢部件中的混合物,这些部件的设计规定了硬表面层,如铬板或 BMS 10-67 型 17 碳化钨钴铬热喷涂涂层。特定组件的大修说明将明确说明这些修理替代品是否可用于修复该组件:

(1) Alternative 1: Fill the blends with 0.020 inch maximum thickness of BMS 10-67, Type 12 nickel aluminum thermal spray, then apply a 0.005 inch maximum thick layer of BMS 10-67, Type 17 tungsten carbide cobalt chrome thermal spray. The maximum total thickness of the two layers of thermal spray coating is 0.025 inch.

替代方案 1:用最大厚度为 0.020 英寸的 BMS 10-67,12 型镍铝热喷涂层填充混合物,然后涂上最大厚度为 0.005 英寸的 BMS 10-67,17 型碳化钨钴铬热喷涂层。两层热喷涂涂层的最大总厚度为 0.025 英寸。

(2) Alternative 2: Fill the blends and build up the surface with BMS 10-67, Type 22 chromium carbide nickel chrome thermal spray coating. The maximum thickness of this thermal spray coating is 0.045 inch.

替代方案 2:用 BMS 10-67,22 型碳化铬镍铬热喷涂涂层填充混合物并盖满表面。这种热喷涂涂层的最大厚度为 0.045 英寸。

C. The decision to repair with thermal spray coating must include these precautions:

在决定使用热喷涂涂层进行维修时必须注意以下几点:

(1) The configuration of the part must let you apply the coating. Refer to Paragraph 4.D. for more details.

零件的构造必须允许进行喷涂。详情请参阅第 4.D 段。

(2) The coating must have good wear resistance, galvanic compatibility, thickness, and fatigue qualities.

涂层必须具有良好的耐磨性、电化相容性、厚度和疲劳质量。

(3) Surface preparation will be necessary. Refer to Paragraph 6. for details.

需要进行表面处理。详见第 6 段。

(4) Heat treatment, stress relief, or shot peening must be done first.

必须先进行热处理、应力消除或喷丸处理。

(5) The spray application and the grind must be carefully controlled.

必须仔细控制喷涂和研磨。

(6) Operations will be necessary to put back protection from corrosion, such as paint or equivalent finishes.

必须重新进行防腐蚀处理,如油漆或类似的表面处理。

D. Because the spray gun is free to be moved, the configuration of parts which can be coated is a function of available tools and fixtures to move the work or the torch. Here are some examples of part geometries that can be coated by most thermal spray shops:

由于喷枪可以自由移动,因此可喷涂零件的结构取决于移动零件或喷枪的可用工具和夹具。以下是大多数热喷涂车间可以喷涂的零件几何形状示例:

(1) Outside diameters of long cylindrical parts, 0.2 to 36 inches diameter up to 276 inches long.

长圆柱形零件的外径,直径 0.2 至 36 英寸,长度不超过 276 英寸。

(2) Outside diameters of short cylindrical parts, 0.2 to 90 inches diameter up to 12 inches long.

短圆柱形零件的外径,直径 0.2 至 90 英寸,长度不超过 12 英寸。

(3) Inside diameters (blind holes) 0.5 to 7 inches, to a depth equal to the diameter.

内径(盲孔)0.5 至 7 英寸,深度等于直径。

(4) Inside diameters (open holes) 0.5 to 7 inches, to a depth from both ends equal to 2 times the diameter.

内径(开孔)0.5 至 7 英寸,两端深度等于直径的 2 倍。

(5) Inside diameters as small as 2 inches can be coated 36 inches long by Union Carbide, Linde Division (V6D181).

内径小至 2 英寸,可使用Union Carbide, Linde Division (V6D181)的 36 英寸长涂层。

(6) Rectangular flat surfaces up to 5 feet by 23 feet.

长达 5 英尺乘 23 英尺的矩形平面。

(7) Circular flat surfaces 0.10 to 90 inches in diameter.

直径 0.10 至 90 英寸的圆形平面。

(8) Installed parts, if you can get at the surfaces.

已安装的部件,如果可以接触到表面的话。

5. COATING MATERIAL SELECTION涂层材料的选择

A. Wear Resistance

耐磨性

(1) For most situations, Type 1 (tungsten carbide cobalt) and Type 17 (tungsten carbide cobalt chrome) coatings have good wear resistance.

在大多数情况下,1 型(碳化钨钴)和 17 型(碳化钨钴铬)涂层具有良好的耐磨性。

(2) When the material of the mating part is softer than the tungsten carbide coating (Rc 65), the mating part will wear faster.

如果配合零件的材料比碳化钨涂层软(Rc 65),配合零件的磨损速度会更快。

B. Galvanic Compatibility

电化相容性

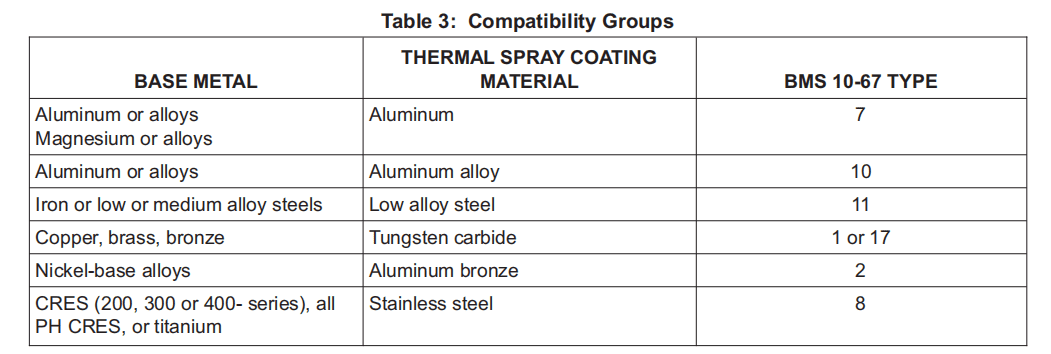

(1) If corrosion resistance is more important than wear resistance, the coating must be compatible with the base metal. Unless the overhaul instructions are different, make the selection within compatibility groups as shown in Table 3.

如果耐腐蚀性比耐磨性更重要,则涂层必须与基体金属相容。除非大修说明有所不同,否则应在表 3 所示的相容性组别内进行选择。

NOTE: Oxide coatings are inert and thus can be used on all base metals.

注:氧化物涂层是惰性的,因此可用于所有基体金属。

(2) If corrosion resistance and wear resistance are equally important, Types 1 and 17 coating can be used with satisfactory results if the coating is sealed with BMS 10-11, Type 1 primer before grinding, and if the coating porosity is within the specified limits (Paragraph 8.).

如果耐腐蚀性和耐磨损性同等重要,可使用 1 型和 17 型涂层,但涂层必须在研磨前用 BMS 10-11, 1 型底漆密封,且涂层孔隙率必须在规定范围内(第 8 段),效果会令人满意。

C. Fatigue Properties

疲劳特性

(1) BMS 10-67, Type 1 and 17 (tungsten carbide) and Type 8 (stainless steel) coatings could decrease the fatigue life of a part if the coating is incorrectly applied. Ask Boeing for a list of applicators which are approved for production. You can use these applicators until you get your own HVOF system.

BMS 10-67、1 型和 17 型(碳化钨)以及 8 型(不锈钢)涂层如果使用不当,可能会降低零件的疲劳寿命。请向波音公司索取已批准用于生产的涂抹器清单。在获得自己的 HVOF 系统之前,您可以使用这些喷涂器。

(2) As an alternative to a Boeing approved applicator, you can apply these coatings yourself if you are sure your materials and processes agree with the related Boeing specifications as indicated below. Boeing will help you with more data and advice as necessary. This can be used to get approval from the local regulatory agency for a new HVOF facility.

作为波音批准的涂抹器的替代物,如果您确信您的材料和工艺符合下面列出的波音的相关规范,您也可以自行喷涂这些涂层。必要时,波音公司将为您提供更多数据和建议。这可用于获得当地监管机构对新 HVOF 设备的批准。

(a) Be sure to use the correct thermal spray powders, as specified in the BMS 10-67 Qualified Products List, and also as shown in SOPM 20-10-05, Table 2. The Roman numerals in the specifications are equivalent to the Arabic numerals in the SOPM.

务必使用 BMS 10-67 合格产品列表中和 SOPM 20-10-05 表 2 中所规定的正确热喷涂粉末。规格中的罗马数字等同于 SOPM 中的阿拉伯数字。

(b) Be sure to apply the coating to agree with the BAC5851 specification. Make sure your facilities, procedures, and documentation can be qualified to BAC5851. This includes metallurgical evaluations and fatigue tests of coated specimens.

确保按照 BAC5851 规范进行涂装。确保您的设备、程序和文件符合 BAC5851 标准。这包括对涂层试样进行冶金评估和疲劳测试。

(c) After you have adjusted your parameters that apply the coating to give results that agree with the specifications, think of these as fixed process control requirements and be sure to use these each time you apply this type and class of coating in the future. If you change any of the parameters, you must do tests to make sure your changes give results that also agree with the specifications. We recommend that you make a record of the parameters on a form equivalent to the form in BAC5851, Fig. 2. Also, we recommend that you make and keep a certification and test report for each coating type and class you become qualified to apply.

在调整了涂覆参数,使结果与规范一致后,应将这些参数视为固定的过程控制要求,并确保今后每次涂覆该类型和等级的涂层时都使用这些参数。如果更改任何参数,必须进行测试,以确保更改后的结果也符合规范要求。我们建议您在与 BAC5851 图 2 相同的表格上记录参数。此外,我们还建议您为每种类型和等级的涂层制作并保存一份认证和测试报告。

(3) Measure the residual stresses in the thermal spray coating before and after you spray it on a component. To do this, get an Almen N shot peening test strip and a holder (SOPM 20-10-03) and use the procedure that follows. The test strip will bend after it is coated. If the coated side of the strip is convex, measure the deflection as a positive value. For example, if the deflection of a coated test strip is +0.003 to 0.015 inches, this indicates that the stress is compressive.

在部件上喷涂前和后,测量热喷涂涂层中的残余应力。要做到这一点,需要一个 Almen N 喷丸测试条和一个夹具(SOPM 20-10-03),并使用下面的步骤。测试条在喷涂后会弯曲。如果测试条的涂覆面是凸面,则测量挠度为正值。例如,如果涂层试样的挠度为 +0.003 至 0.015 英寸,则表明应力为压缩应力。

(a) Solvent clean (BAC5750) (SOPM 20-30-03) the Almen N test strip.

溶剂清洗(BAC5750)(SOPM 20-30-03)Almen N 测试条。

(b) Measure and record the initial arc height of the strip.

测量并记录测试条的初始弧高。

(c) Abrasive blast clean the strip (BAC5748, Type 1) (SOPM 20-30-03) with 36-60 grit aluminum oxide.

用 36-60 粗细度的氧化铝吹砂清洁测试条(BAC5748,类型 1)(SOPM 20-30-03)。

(d) Measure and record the arc height after the abrasive blast.

测量并记录吹砂后的弧高。

(e) Install the strip in the holder.

将测试条安装到夹具上。

(f) Spray the test strip with the coating by your usual procedure. Be sure to cover all of the area of the strip surface but the area covered by tooling.

按照常规程序在测试带上喷涂涂层。确保覆盖测试条表面的所有区域,但工具覆盖的区域除外。

(g) Let the strip cool to room temperature.

让测试带冷却至室温。

(h) Measure and record the arc height.

测量并记录弧高。

(i) Calculate the residual stress as follows: (Arc height after coating) – (Arc height after abrasive blast) = (arc height because of the coating). Compare your result with the values in BAC5851 Table III or BSS7072 Table V.

计算残余应力如下: (涂覆后的弧高)-(吹砂后的弧高)=(涂覆后的弧高)。将结果与 BAC5851 表 III 或 BSS7072 表 V 中的数值进行比较。

6. PREPARATION OF THE SURFACE 表面准备

A. Machine the surface as specified by the overhaul instructions, and Figure 1, to remove defects or corrosion.

按照大修说明和图 1 的规定加工表面,清除缺陷或腐蚀。

B. Magnetic particle examine the surface on steel parts as specified in SOPM 20-20-01. Penetrant examine the surface on nonmagnetic parts as specified in SOPM 20-20-02.

按照 SOPM 20-20-01 的规定,对铁零件表面进行磁粉检查。按照 SOPM 20-20-02 的规定对非磁性零件的表面进行渗透检查。

C. Shot peen the machined surface as specified in SOPM 20-10-03 as necessary.

必要时按 SOPM 20-10-03 的规定对机加工表面进行喷丸处理。

D. Vapor degrease, or solvent clean, or emulsion clean the surface as specified in SOPM 20-30-03.

按 SOPM 20-30-03的规定,对表面进行蒸汽脱脂、溶剂清洗或乳剂清洗。

E. Do not touch the cleaned surfaces before you apply the thermal spray coating unless you put on synthetic fiber or cotton gloves.

除非戴上合成纤维或棉质手套,否则在喷涂热喷涂涂层之前不要接触已清洁的表面。

F. Mask all areas not to get the coating. Use heat reflective or grit blast resistant tape.

遮盖所有不需要喷涂的区域。使用热反射胶带或防砂胶带。

(1) For landing gear components, unless specified differently by the applicable overhaul instructions, make the thermal spray coating runout within a 0.080 inch wide band at the edges of the coated area, as shown in Figure 2.

对于起落架部件,除非适用的大修说明另有规定,否则应使热喷涂涂层的跳动在涂层区域边缘 0.080 英寸宽的范围内,如图 2 所示。

G. To get a good bond with the coating, grit blast the area with 36-60 mesh silicon carbide or aluminum oxide grit and clean dry air, argon or nitrogen. The grit blasted surfaces must have a continuous matte texture without shiny areas, and have a surface roughness of 150-300 microinches. The grit blast must remove machining grooves. Examine the grit blasted areas for full treatment and grit blast again as necessary.

为了与涂层良好粘合,使用 36-60 目碳化硅或氧化铝砂粒和清洁干燥的空气、氩气或氮气对该区域进行吹砂处理。吹砂表面必须具有连续的无光泽纹理,没有发亮区域,表面粗糙度为 150-300 微英寸。吹砂必须去除加工槽。检查吹砂区域是否经过全面处理,必要时再次喷砂。

H. Remove grit from the surface with dry filtered air or nitrogen.

用干燥的过滤空气或氮气清除表面的砂粒。

I. Give protection to the grit blasted parts to prevent contamination. Continue with the procedure to apply the thermal spray application within 4 hours.

保护吹砂部件,防止污染。在 4 小时内继续执行热喷涂程序。

(1) If small areas of contamination occur (less than one square inch, on not more than 10 percent of the area to be coated), solvent clean (SOPM 20-30-03) the areas and abrasive blast them as specified in Paragraph 6.G.

如果出现小面积污染(小于一平方英寸,不超过待喷涂面积的 10%),则按照第 6.G 段的规定进行溶剂清洗(SOPM 20-30-03)和吹砂处理。

(2) If signs of corrosion, dirt or discoloration occur, solvent clean (SOPM 20-30-03) the parts and abrasive blast them again as specified in Paragraph 6.G.

如果出现腐蚀、污垢或褪色迹象,则按照第 6.G 段的规定,对部件进行溶剂清洗 (SOPM 20-30-03)并再次吹砂。

7. APPLICATION OF THERMAL SPRAY COATING 热喷涂涂层的应用

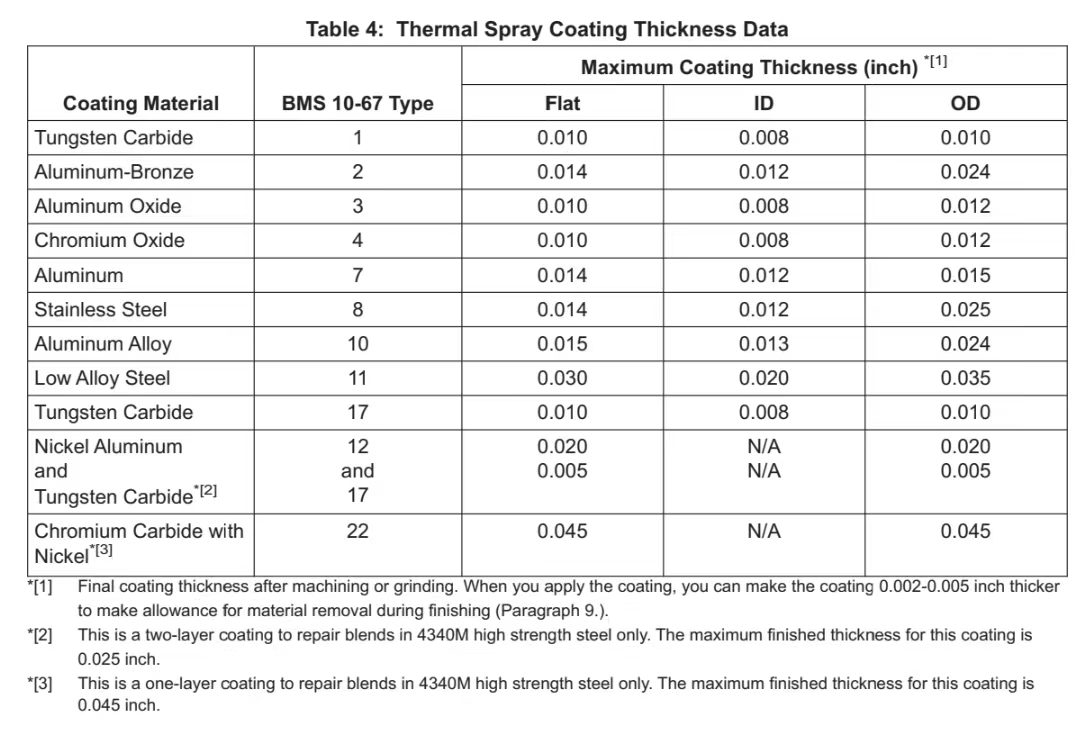

A. Coating Thickness — Use the data given by the overhaul instructions. If the overhaul instructions do not give the thickness, use the data given in Table 4 as a guide. Coatings thicker than these limits could have decreased quality or give less satisfactory results. The maximum thickness changes with the part configuration and the coating material.

涂层厚度 — 使用大修说明中给出的数据。如果大修说明中没有给出厚度,则使用表 4 中给出的数据作为指导。涂层厚度超过这些限制可能会降低质量或产生不理想的效果。最大厚度会随着部件结构和涂层材料的变化而变化。

*[1] Final coating thickness after machining or grinding. When you apply the coating, you can make the coating 0.002-0.005 inch thicker to make allowance for material removal during finishing (Paragraph 9.).

*[1] 机加工或磨削后的最终涂层厚度。涂敷涂层时,可将涂层加厚 0.002-0.005 英寸,以预留精加工时的材料去除量(第 9 段)。

*[2] This is a two-layer coating to repair blends in 4340M high strength steel only. The maximum finished thickness for this coating is 0.025 inch.

*[2] 这是一种双层涂层,仅用于修复 4340M 高强度钢中的混合物。该涂层的最大最终厚度为 0.025 英寸。

*[3] This is a one-layer coating to repair blends in 4340M high strength steel only. The maximum finished thickness for this coating is 0.045 inch.

*[3] 这是一种单层涂层,仅用于修复 4340M 高强度钢的混合物。该涂层的最大最终厚度为 0.045 英寸。

B. Application of Coating

喷涂

(1) Before you spray, heat the surface to approximately 150°F to be sure of full condensate removal. You could use the heat blast from the gun with the powder feed turned off.

喷涂前,先将表面加热至约 150°F,以确保冷凝物完全清除。可以在关闭进料装置的情况下使用喷枪喷出的热量。

(2) Spray the part with a constant gun-to-work distance, a constant traverse rate and a spray angle of 90 degrees if possible. Do not let the spray angle become less than 45 degrees.

尽可能以恒定的喷枪到工件距离、恒定的移动速度和 90 度的喷射角度喷涂零件。不要让喷射角小于 45 度。

(3) Spray a test panel before you spray the part.

在喷涂部件之前,先喷涂一块测试板。

(4) Spray continuously, but you can stop to measure the coating thickness and to let the surface cool.

连续喷涂,但可以停下来测量涂层厚度和让表面冷却。

(5) For coatings to be machined or ground to design dimensions, make the coating 0.002-0.005 inch thicker than the design dimensions given by the overhaul instructions or Table 4.

对于需要加工或研磨到设计尺寸的涂层,使涂层厚度比大修说明或表 4 给出的设计尺寸厚 0.002-0.005 英寸。

(6) Do not let the substrate metal become hotter than the limits shown in Table 5. Monitor the substrate temperature with thermocouples, pyrometers, or temperature indicating materials such as those in Paragraph 3.H.

不要让基体金属的温度超过表 5 所示的限度。用热电偶、高温计或温度指示材料(如第 3.H 段中的材料)监测基体温度。

(7) If you cool the surfaces with air, carbon dioxide or a nitrogen jet, make sure the blast does not change or blow away the spray pattern from the gun.

如果用空气、二氧化碳或氮气喷射冷却表面,应确保喷射不会改变或吹走喷枪的喷型。

(8) After the sprayed part is cool, remove protective masking material. Remove adhesive with a wiper and solvent. Wipe off the remaining solvent and let the surface dry.

待喷涂部件冷却后,取下保护性遮蔽材料。用抹布和溶剂清除粘合剂。擦去多余的溶剂,让表面干燥。

(9) Examine the coating for defects as specified in Paragraph 8.

按照第 8 段的规定检查涂层是否有缺陷。

(10) Unless the overhaul instructions are different, seal the BMS 10-67 coatings (other than Types 7 and 10) on low-alloy steels, aluminum or its alloys, or copper or its alloys. Use one of these procedures, now or after you machine or grind the surface to design dimensions.

除非大修说明有所不同,否则在低合金钢、铝或其合金、铜或其合金上密封 BMS 10-67 涂层(类型 7 和 10 除外)。现在或在将表面加工或研磨到设计尺寸后,使用其中一种程序。

(a) Wipe the surface with wet primer.

用湿底漆擦拭表面。

1) If the parts have grease or oil on them, vapor degrease or solvent clean them as specified in SOPM 20-30-03.

如果零件上有油脂或油,则按照 SOPM 20-30-03 中的规定进行蒸汽脱脂或溶剂清洗。

2) Rub the surface with a gauze pad wet with BMS 10-11, Type 1 primer, or BMS 10-79, Type 2 or Type 3 primer, or with the primer specified for the adjacent surfaces.

用蘸有 BMS 10-11 1 类底漆或 BMS 10-79 2 类或 3 类底漆的纱布擦拭表面,或用为邻近表面指定的底漆擦拭表面。

3) Before the primer dries, gently remove the unwanted primer with a dry gauze pad. Do not use a solvent.

在底漆干透之前,用干纱布垫轻轻去除不需要的底漆。不要使用溶剂。

4) Cure the BMS 10-11, Type 1 primer as specified in SOPM 20-41-02. Use an equivalent procedure for other primers.

按照 SOPM 20-41-02 的规定固化 BMS 10-11, 1 类底漆。对其他底漆使用相同的程序。

(b) Metcoseal Sealer

金属密封剂

1) If the parts have grease or oil on them, vapor degrease or solvent clean them as specified in SOPM 20-30-03.

如果部件上有油脂或油,则按照 SOPM 20-30-03 的规定进行蒸汽脱脂或溶剂清洗。

2) Apply the sealer with a brush or spray it on. If you spray it, thin the sealer with one part Metcoseal APT thinner to 2-3 parts sealer.

用刷子或喷雾器涂抹封闭剂。如果是喷涂,用一份 Metcoseal APT 稀释剂兑 2-3 份密封剂稀释密封剂。

3) Before the sealer dries, gently remove the excess with a dry gauze pad. Do not use a solvent.

在密封剂干透之前,用干纱布轻轻擦去多余的密封剂。不要使用溶剂。

4) Cure the sealer for 30-60 minutes at room temperature.

密封剂在室温下固化 30-60 分钟。

(c) UCAR 100 Sealer — Apply the sealer by the vendor’s instructions.

UCAR 100 密封剂 — 按照供应商的说明涂抹密封剂。

8. EXAMINATION OF SURFACE AFTER THERMAL SPRAY COATING 热喷涂涂层后的表面检查

A. All coatings must agree with the specifications of BAC5851 Section 11.

所有涂层必须符合 BAC5851 第 11 章的规格。

9. FINISHING OF THERMAL SPRAY-COATED SURFACES 热喷涂表面的表面处理

A. If adjustment of the coating surface roughness or thickness is necessary:

如需调整涂层表面的粗糙度或厚度,应采取以下措施

(1) These coating materials must be ground:

必须打磨这些涂层材料:

(a) BMS 10-67, Type 1 (tungsten carbide) (碳化钨)

(b) BMS 10-67, Type 3 (aluminum oxide) (氧化铝)

(c) BMS 10-67, Type 4 (chromium oxide) (氧化铬)

(d) BMS 10-67, Type 5 (zirconium oxide) (氧化锆)

(e) BMS 10-67, Type 6 (nickel-chrome) (镍铬)

(f) BMS 10-67, Type 9 (cobalt-chrome-nickel-tungsten) (钴铬镍钨)

(g) BMS 10-67, Type 15 (cobalt-molybdenum-chromium-silicon) (钴-钼-铬-硅)

(h) BMS 10-67, Type 16 (chromium carbide-nickel-chrome) (碳化铬-镍-铬)

(i) BMS 10-67, Type 17 (tungsten carbide-cobalt-chrome) (碳化钨-钴-铬)

(j) BMS 10-67, Type 19 (4340 Steel) (4340 钢)

(k) BMS 10-67, Type 20 (chromium carbide) (碳化铬)

(l) BMS 10-67, Type 21 (molybdenum) (钼)

(m) BMS 10-67, Type 22 (chromium carbide)(碳化铬)

(2) Machining is recommended for these coating materials:

建议对这些涂层材料进行机加工:

(a) BMS 10-67, Type 2 (aluminum-bronze) (铝青铜)

(b) BMS 10-67, Type 7 (aluminum) (铝)

(c) BMS 10-67, Type 8 (stainless steel) (不锈钢)

(d) BMS 10-67, Type 10 (aluminum alloy) (铝合金)

(e) BMS 10-67, Type 11 (low alloy steel) (低合金钢)

(f) BMS 10-67, Type 12 (nickel-aluminum) (镍铝合金)

(g) BMS 10-67, Type 13 (nickel-aluminum) (镍铝合金)

(h) BMS 10-67, Type 14 (copper-nickel-indium) (铜-镍-铟)

(i) BMS 10-67, Type 18 (aluminum-silicon)(铝-硅)

(3) Honing can be used to finish all coatings but BMS 10-67, Types 5, 12, 13, 19, 21. If more than 0.002-inch coating removal is necessary, grind or machine, as applicable, before you hone.

除 BMS 10-67、5、12、13、19、21 型外,珩磨可用于处理所有涂层。如果需要去除超过 0.002 英寸的涂层,则应在珩磨前酌情进行研磨或机加工。

B. Grinding of Thermal Sprayed Surfaces

热喷涂表面的研磨

(1) Before you grind the surfaces, vapor grease or solvent clean them as specified in SOPM 20-30-03

研磨表面前,应按照 SOPM 20-30-03 的规定进行蒸汽去脂或溶剂清洗。

(2) Use the diamond wheel for Types 1, 3, 4, 5, 16, 17, 20, 22. The silicon carbide or aluminium oxide wheel is recommended for Types 6, 8, 9, 15, 19, 21.

1、3、4、5、16、17、20、22 型使用金刚石砂轮。6、8、9、15、19、21 型建议使用碳化硅或氧化铝砂轮。

(3) Clean and make the grinding wheel true. Balance the wheel until it does not turn by itself.

清洁砂轮并使其垂直。平衡砂轮,直到其不能自行转动。

NOTE: A different wheel mount for each wheel will decrease the time necessary to install, balance, and clean a wheel each time you use it.

注意:为每个砂轮安装不同的砂轮座可减少每次使用砂轮时安装、平衡和清洁砂轮所需的时间。

(4) Clean the grinding wheel frequently with a silicon carbide stick to let the wheel cut correctly.

经常用碳化硅棒清洁砂轮,使砂轮正确切削。

(5) Grind these coated surfaces with a wheel speed at the outer edge of 4800-6500 surface feet per minute.

以每分钟 4800-6500 平方英尺的砂轮外缘速度研磨这些涂层表面。

(6) As you grind, give the wheel-work-interface area a good flow of continuously-filtered cutting fluid.

研磨时,要给砂轮与工作面之间的区域连续不断地注入经过过滤的切削液。

CAUTION:DO NOT TRY TO GET A SMOOTHER FINISH THAN THE GRIT SIZE IS DESIGNED TO GIVE. YOU CAN GET FINISHES OF APPROXIMATELY 20 MICROINCH WITH 100 GRIT, 10 MICROINCH WITH 220 GRIT, AND 6 MICROINCH WITH 400 GRIT WHEN A DIAMOND WHEEL IS USED.

注意:不要试图获得比磨粒设计尺寸更光滑的表面效果。使用金刚石砂轮时,100 粗细度可获得约 20 微英寸的光洁度,220 粗细度可获得 10 微英寸的光洁度,400 粗细度可获得 6 微英寸的光洁度。

(7) For cylindrical, internal, and surface grinding, infeeds must not be more than 0.0003 inch for 100 grit, 0.0002 inch for 220 grit or 0.0001 inch for 400 grit for each pass.

外圆、内圆和平面研磨时,每道进给量不得超过 0.0003 英寸(100 粗细度)、0.0002 英寸(220 粗细度)或 0.0001 英寸(400 粗细度)。

(8) When surface grinding, the cross-feed must not be more than 0.080 inch per pass .

表面研磨时,每次交叉进给不得超过 0.080 英寸。

NOTE: Traverse speeds of not more than 4 to 6 inches per minute are recommended on cylindrical surfaces.

注:建议圆柱形表面的移动速度不超过每分钟 4 至 6 英寸。

CAUTION :FASTER SURFACE SPEEDS CAN PULL PIECES OUT OF THE COATING AND CAUSE HEAT DAMAGE TO THE BASE MATERIAL.

注意 :较快的表面速度可能会从涂层中拉出碎片,并对基材造成热损伤。

(9) When you grind ID and OD surfaces, give the work a speed of 18-25 surface feet per minute. When you grind other surfaces, give the work a speed of 40-50 surface feet per minute.

研磨内径和外径表面时,工作速度为每分钟 18-25 平方英尺。研磨其他表面时,速度为每分钟 40-50 平方英尺。

(10) Cure all parts to remove moisture by one of these two steps:

通过以下两个步骤之一对所有零件进行固化,以去除水分:

(a) Bake the parts for 2 hours at 125-175°F, or

在 125-175°F 温度下烘烤部件 2 小时,或

(b) Oven dry the parts at 100°-200°F until the parts are fully dry

在 100°-200°F 温度下烘干零件,直至零件完全干燥。

C. Machining of Thermal Sprayed Surfaces

热喷涂表面的机加工

(1) Machine with carbide-tipped tools. Do not use milling tools.

使用硬质合金刀具进行加工。切勿使用铣刀。

(2) The depth of each individual cut must not be more than 0.005 inch.

每个切口的深度不得超过 0.005 英寸。

(3) Machine the surface as specified in Table 6 to the dimensions and the surface finish specified by the overhaul instructions.

按照表 6 的规定加工表面,使其达到大修说明规定的尺寸和表面光洁度。

(4) Cure all parts to remove moisture by one of these two steps:

通过以下两个步骤之一对所有零件进行固化,以去除水分:

(a) Bake the parts for 2 hours at 125-175°F, or

在 125-175 °F下烘烤零件 2 小时,或

(b) Oven dry the parts at 100-200°F until the parts are fully dry.

在 100-200°F 温度下烘干零件,直至零件完全干燥。

D. Honing of Thermal Sprayed Surfaces

热喷涂表面的珩磨

(1) Honing can be used to finish all coatings but BMS 10-67, Types 5, 12, 13, 19, 21. If more than 0.002 inch removal is necessary, grind or machine, as applicable, before you hone.

除 BMS 10-67,5、12、13、19、21 型外,所有涂层均可采用珩磨处理。如果需要去除超过 0.002 英寸的涂层,则在珩磨前酌情进行研磨或加工。

(2) Use diamond stones to hone BMS 10-67, Type 1, 3, 4, 16, 17, 20 and 22 coatings. Silicon carbide or aluminum oxide stones can be used to hone BMS 10-67 Type 6, 8, 9, 15 coatings.

使用金刚石珩磨 BMS 10-67,1、3、4、16、17、20 和 22 型涂层。碳化硅或氧化铝石可用于珩磨 BMS 10-67 6、8、9 和 15 型涂层。

(3) Make sure the edges of the stones have a chamfer or radius. Make sure the work is rigid in the tool or fixture.

确保磨石边缘有倒角或圆角。确保在工具或夹具中工作是刚硬的。

(4) Grind down or paper hone down all high spots or coating projections before the final hone.

在最终珩磨前,研磨掉或用纸张珩磨所有高点或涂层凸出部分。

(5) Hone surfaces with speeds as shown in Table 7.

以表 7 所示的速度珩磨表面。

(6) Cure all parts to remove moisture by one of these two steps:

用以下两个步骤之一固化所有部件以去除水分:

(a) Bake the parts for 2 hours at 125-175°F, or

在 125-175 °F下烘烤零件 2 小时,或

(b) Oven dry the parts at 100-200°F until the parts are fully dry.

在 100-200°F 下烘干零件,直至零件完全干燥。

10. EXAMINATION OF THE FINISHED SURFACE 处理过表面的检查

A. Visually examine the finished (machined or ground) coating with a maximum of 40-power magnification for heat checks, burnishing, and pull-outs.

用最大 40 倍的放大镜目视检查完成的(机加工或研磨的)涂层,看是否有热检查、烧伤和脱落。

B. Examine for cracks and separation from the base metal by penetrant inspection as specified in SOPM 20-20-02. The etch before the penetrant inspection is not necessary. As an alternative on Type 11 material, you can use magnetic particle inspection as specified in SOPM 20-20-01.

按照 SOPM 20-20-02 的规定,用渗透检查法检查是否有裂纹和与基体金属分离。无需在渗透检查前进行蚀刻。作为 11 类材料的替代方法,可使用 SOPM 20-20-01 中规定的磁粉检查。

C. The finished surface must be as smooth as specified by the overhaul instructions. Surface finishes that are smoother are acceptable.

表面处理过的表面必须与大修说明中规定的一样光滑。更光滑的表面也可接受。

D. Reject parts which have changed color (such as temper colors on steel) as a result of the grinding or machining operation. Barkhausen inspection (BAC5653) can be used on ferromagnetic parts.

报废因研磨或机加工操作而改变颜色(如钢的回火色)的部件。Barkhausen 检验 (BAC5653) 可用于铁磁性零件。

11. POST SPRAY PROCEDURES 喷涂后的程序

A. We recommend that the thermal spray coating be the last finish applied to a part unless the adjacent finish is paint.

建议将热喷涂涂层作为部件的最后一道饰面,除非相邻的饰面是油漆。

B. If the adjacent finish is paint, make an 1/8 inch wide overlap of the paint onto the thermal spray coating.

如果相邻面漆为油漆,则在热喷涂涂层上重叠 1/8 英寸宽的油漆。

C. If the part will go through a wet chemical procedure after the thermal spray coating is applied, mask the coating to give it protection from all solutions of that procedure.

如果零件在热喷涂涂层后要进行湿化学处理,则要对涂层进行遮蔽,使其免受处理过程中所有溶液的影响。

12. SPECIAL MARKING 特殊标识

A. We recommend that you paint an area of the part with yellow BMS 10-60, Type 2 enamel, and stencil or mark in black on the yellow area as follows:

建议在部件上涂刷黄色的 BMS 10-60, 2 型瓷漆,并在黄色区域用黑色钢印或标记如下:

(1) To help you identify a Type 1 or 17 thermal coating compared with chrome plating, identify the part with WC1 or WC17 for a Type 1 or Type 17 coating. (WC is the chemical formula for tungsten carbide.) This will also help during coating removal, because a much stronger agent is necessary to remove Type 17 coating.

与镀铬相比,为帮助识别 1 类或 17 类热处理涂层,在零件上标注 WC1 或 WC17,表示 1 类或 17 类涂层。(WC 是碳化钨的化学式。)这也有助于涂层的去除,因为要去除 17 型涂层需要使用更强的药剂。

(2) For the HVOF Alternatives, identify the part with:

对于 HVOF 替代品,用以下标识来识别零件:

(a) Type 12/17 for Alternative 1, or

替代品 1 为 12/17 型,或

(b) Type 22 for Alternative 2

替代品 2 为 22 型