钛的机械加工MACHINING OF TITANIUM

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5492, and Boeing Operators Handbook 6M59-553, “Machining Titanium”.

本主题中的数据来自波音工艺规范BAC5492和波音操作员手册6M59-553“钛加工”。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。它不是关于所有情况或特定的安装。使用这些数据作为指导,帮助您制定最低标准。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

有关所有供应商名称和地址的列表,请参阅SOPM 20-00-00。

2. MATERIALS 材料

A. Cutting Fluids

切削液

(1) Water soluble — Refer to BAC5008

(2) DuPont TB-1, V18873

(3) Freon – Cetyl Alcohol

(4) Boelube 100A or 100F, V18554

(5) Microcut 26, V0FCP2

3. GENERAL 概述

A. Some titanium alloys are easier to machine than others. Also, the recommended cutting speeds are different with each alloy and heat-treat condition. Table 1 gives relative index numbers for typical alloys and conditions. Annealed alloy 6Al-4V, a frequently-used titanium alloy, has an index of 100 to let you use this as a reference standard. If you know good cutting speeds for annealed alloy 6Al-4V, you can compare others. For example, an index of 90 for annealed alloy 6Al-6V-2Sn tells you to decrease the speed on this alloy to 90% of the value you use on annealed alloy 6Al-4V for the same type of cut.

有些钛合金比其他合金更容易加工。此外,建议的切割速度因每种合金和热处理条件而异。表1给出了典型合金和条件的相对指数。退火合金6Al-4V是一种常用的钛合金,其指数为100,可以作为参考标准。如果你知道退火合金6Al-4V的良好切割速度,你可以比较其他合金。例如,退火合金6Al-6V-2Sn的指数为90,这会告诉您将该合金的速度降低到相同类型切割的退火合金6Al-4V的速度值的90%。

B. The data in this subject is for base material that has no surface contamination. But titanium alloy can have “alpha case,” an embrittled surface layer that is usually thin, but can be as hard as Rockwell C 55. Tool failure can occur quickly on such a surface. Alpha case is frequently found on the surface of rolled plate, forging, extrusions, and thermally cut edges. It can also be caused by heat treatment and stress relief operations. The alpha case layer is usually removed as the part is made, but it could occur on parts in for overhaul. Then slower-than usual tool speeds must be used, and tool life will be shorter.

本主题中的数据适用于没有表面污染的基材。但钛合金可能有“alpha case”,一种脆化的表面层,通常很薄,但可以像Rockwell C 55一样硬。在这样的表面上,刀具故障可能很快发生。Alpha case经常出现在轧制板材、锻件、挤压件和热切割边缘的表面。它也可能是由热处理和应力消除操作引起的。alpha case层通常在零件制造时被去除,但它可能发生在需要大修的零件上。然后必须使用比通常慢的刀具速度,刀具寿命会更短。

C. Lead, tin, cadmium and zinc must not touch the surface of titanium. These metals cause contamination and are not easy to remove. The contamination can cause the titanium part to crack on the airplane or during repair. Thus, do not use tools, permanent or temporary fasteners, or bushings of, or plated by, these metals on titanium parts.

铅、锡、镉和锌不得接触钛表面。这些金属会造成污染,不容易去除。污染可能导致钛部件在飞机上或维修过程中破裂。因此,不要在钛零件上使用这些金属的工具、永久或临时紧固件、衬套或镀层。

D. Titanium can be made brittle by methyl alcohol, anhydrous ethyl alcohol, and BMS 3-11 hydraulic fluid (above 270°F).

甲醇、无水乙醇和BMS 3-11液压液(高于270°F)可使钛变脆。

E. Keep liquid oxygen away from titanium. Liquid oxygen on a bare titanium surface can start a violent reaction.

使液氧远离钛。液态氧在裸露的钛表面上会引发剧烈反应。

F. Water-based cutting fluids can be used on titanium if the parts are wiped or blown dry after the operation. Do not use Freon-based fluids if the part will be in temperatures above 600°F during repair or on the airplane. Cutting fluids are optional with hand-held drill motors. See Table 2 for recommended cutting fluids.

如果在操作后擦拭或吹干零件,则可以在钛上使用水基切削液。如果零件在维修或飞机上的温度将超过600°F,则不要使用氟利昂基液体。切削液可选用手持式钻机电机。推荐的切削液见表2。

G. Fire Safety

消防安全

(1) In most forms, titanium is not flammable. But very finely divided titanium, such as very thin machining chips or dust from grinders, can be ignited and will burn.

在大多数形式下,钛是不易燃的。但是,非常细的钛,如非常薄的加工碎屑或研磨机产生的灰尘,可能会被点燃并燃烧。

(2) Titanium chips do not ignite as easily or burn as violently as magnesium. But in some conditions they will ignite and burn, and quickly become a hot, glowing mass.

钛片不像镁那样容易点燃或燃烧剧烈。但在某些情况下,它们会被点燃和燃烧,并迅速变成一团炽热的发光物质。

(3) Emergency Procedure for Titanium Fires

钛火灾应急程序

(a) Tell the fire unit.

告诉消防队。

(b) Extinguish fires of titanium chips with fully dry talc, calcium carbonate, sand, graphite, or water. Do not use carbon dioxide, carbon tetrachloride or the usual dry chemical fire extinguishers.

用完全干燥的滑石、碳酸钙、沙子、石墨或水对钛片进行灭火。不要使用二氧化碳、四氯化碳或常用的干粉灭火器。

(c) If talc or equivalent powered agent is used, apply the powder in a continuous layer 1/2 inch deep or more, but do not scatter the burning metal. If the burning metal is on a surface that could burn, apply a 2-inch layer of powder on this surface and shovel the burning metal onto the powder. Carefully apply more powder if smoke continues in some areas.

如果使用滑石粉或同等粉末,则将粉末涂成1/2英寸深或以上的连续层,但不要使燃烧的金属散开。如果燃烧的金属在可能燃烧的表面上,在该表面上涂一层2英寸的粉末,并将燃烧的金属铲到粉末上。如果某些区域持续冒烟,请小心地涂抹更多粉末。

(d) Water pump type fire extinguishers are recommended on fires in small piles of titanium chips. Apply the water at the base of the fire.

对于小堆钛屑的火灾,建议使用水泵式灭火器。在火的底部浇水。

(e) If possible without risk of injury, confine the fire and scrape off the titanium metal that is not on fire.

如果可能,在没有受伤风险的情况下,控制火势,刮去未着火的钛金属。

(f) Do not let the burning metal get on concrete floors.

不要让燃烧的金属沾到混凝土地板上。

(g) For fires in large piles of titanium chips, give protection to surfaces and items that can burn.

对于大块钛片的火灾,要保护可能燃烧的表面和物品。

(h) Wear safety approved dark goggles or other eye protection when you fight titanium fires.

当扑灭钛火时,请佩戴安全认可的深色护目镜或其他护目镜。

(4) Fire prevention

防火

(a) Keep a good flow of a water-base coolant on the part and the chips. Water-base coolants extinguish titanium fires, and wet chips do not ignite as easily.

使水基冷却液在零件和碎片上保持良好流动。水基冷却剂可以扑灭钛火,而湿碎片则不容易点燃。

(b) Replace the cutters at the first sign they are dull. A dull cutter makes hot chips that could ignite.

一有迹象表明刀具变钝,就更换刀具。钝的刀具会产生可能点燃的热碎片。

(c) Cut at a decreased speed if the surface of titanium has contamination. Contamination can cause a spark that can start a fire.

如果钛表面受到污染,则以较低的速度进行切割。污染会引起火花,进而引发火灾。

(d) Keep the feed rate high. Thick chips do not ignite as easily as thin chips.

保持高进料速率。厚碎片不像薄碎片那样容易点燃。

(e) Do not let a large number of chips collect. The fewer the chips, the smaller the fire that could occur. Remove the chips from the machine frequently, and store them in approved and correctly identified containers.

不要让大量碎片聚集。碎片越少,可能发生的火灾就越小。经常从机器上取下碎屑,并将其存放在经过批准且标识正确的容器中。

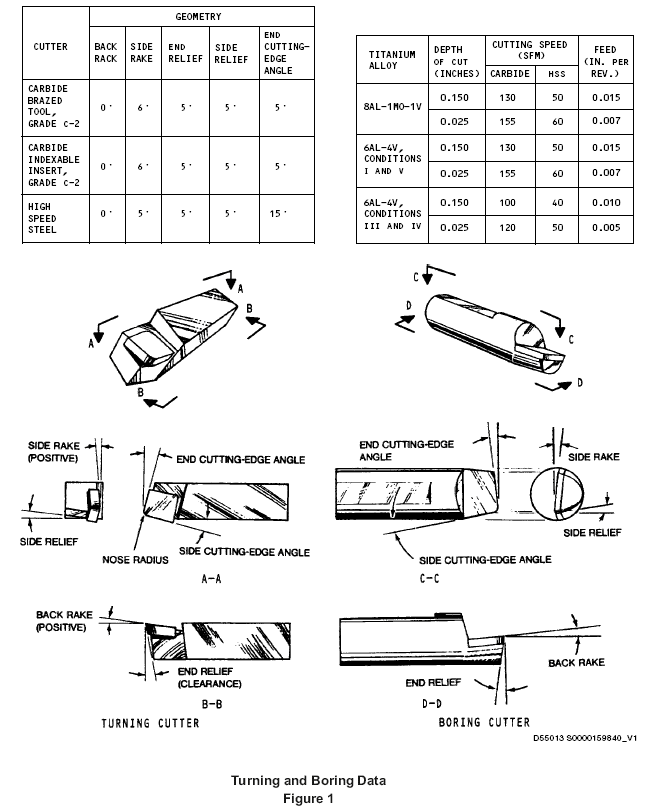

4. TURNING AND BORING

A. Use carbide tools if possible. Indexable disposable insert types are recommended.

尽可能使用硬质合金工具。建议使用可转位的一次性插入物类型。

(1) Use sub-micro-grain carbide inserts when possible, as an alternative to the older grades C-1, C-2, and C-3.

尽可能使用亚微米级硬质合金刀片,作为旧等级C-1、C-2和C-3的替代品。

(2) If sub-micro-grain carbide is not available, use carbide grade C-1 or C-2 for heavy roughing cuts and when impact loading is moderately high.

如果没有亚微米级碳化物,则在冲击载荷中等高时,使用C-1或C-2级碳化物进行粗切削。

(3) If sub-micro-grain carbide is not available, use carbide grade C-3 for light, continuous cuts because it has a better abrasion resistance.

如果没有亚微米级碳化物,则使用C-3级碳化物进行轻连续切割,因为它具有更好的耐磨性。

(4) If disposable insert tools are used, a positive rake angle is recommended unless impact loads are very high.

如果使用一次性插入工具,除非冲击载荷非常高,否则建议使用正前角。

B. If carbide is not used, use high speed steel to make grooves, to cut pieces off, to make interrupted cuts, and for operations with form tools. Use PM high speed steels when possible.

如果不使用碳化物,则使用高速钢制作凹槽、切割工件、进行间断切割以及使用成型工具进行操作。尽可能使用PM高速钢。

C. If possible, use a cutting tool with side-cutting edge angle (lead angle) of 15 degrees or more. To avoid smearing on the flank of the tool, use a relief angle of 10 degrees for facing and a minimum of 5 degrees for all other operations.

如果可能,使用侧切削刃角度(超前角)为15度或以上的切削工具。为避免弄坏在刀具侧面,端面应使用10度的后倾角,所有其他操作应至少使用5度的后角。

D. When you bore, decrease the cutting loads if the boring bar is not rigid.

镗孔时,如果镗杆不是刚性的,则应减小切削载荷。

E. See Figure 1 for recommended data.

推荐数据见图1。

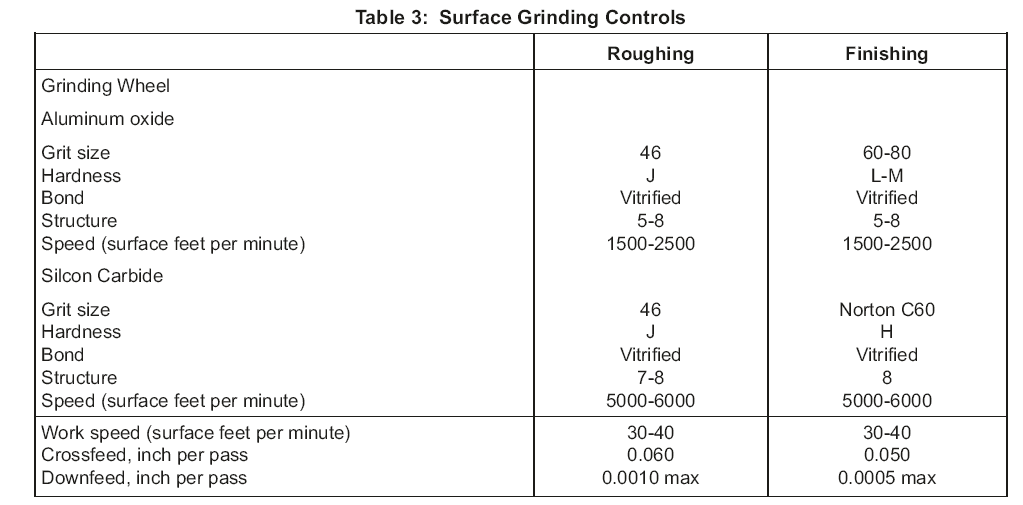

5. GRINDING 研磨

A. Rough grinding (by hand or machine) can be used for all surfaces, but then a minimum of 0.020 inch of metal must be removed by a finishing operation. Finish grinding is not permitted on important surfaces, such as those identified by BAC5492 class 1 or 2.

可以对所有表面进行粗磨(手动或机器),但必须通过精加工去除至少0.020英寸的金属。不允许在重要表面上进行精磨,例如BAC5492 1级或2级所确定的表面。

B. Use a good flow of cutting fluid per BAC5008 during the grind.

在研磨过程中,根据BAC5008使用良好流量的切削液。

C. See Table 3 for recommended values.

建议值见表3。

6. MILLING 铣削

A. General

概述

(1) Carbide cutters are recommended unless easily-broken cutters (such as small endmills or slitting saws) must be used. Sub-micro-grain carbide is recommended first, then carbide grade C-2, and then grade C-3. Inserts can be brazed, clamped mechanically, or held in place with a screw.

除非必须使用易损坏的刀具(如小型立铣刀或纵切锯),否则建议使用硬质合金刀具。建议首先使用亚微米级碳化物,然后使用C-2级碳化物,再使用C-3级碳化物。插入件可以钎焊、机械夹紧或用螺钉固定到位。

(2) If high speed steel cutters must be used, a PM type is better than standard grades. PM lets you use a higher cutting speed or has a longer tool life.

如果必须使用高速钢刀具,PM型刀具比标准级刀具更好。PM可以让您使用更高的切削速度或更长的刀具寿命。

(3) In some operations, a titanium aluminum nitride coating on the cutter can help.

在某些操作中,刀具上的氮化钛铝涂层会有所帮助。

(4) Use a mill cutter with as many teeth as possible, but which has necessary strength and chip clearance. The greater the number of teeth, the higher the feed rate you can use.

使用具有尽可能多的齿,但具有必要强度和碎片间隙的铣刀。齿数越多,可以使用的进给速度就越高。

(5) If possible, for longer tool life, mill with the edge of the cutter (end mill or slab mill) and not the end of cutter (face mill or end of an end mill).

如果可能,为了延长刀具寿命,使用刀具的边缘(立铣刀或板坯轧机)进行铣削,而不是使用刀具的末端(面铣刀或立铣刀的末端)。

B. Conventional and climb milling

逆铣和顺铣

(1) In conventional milling, the cutter turns in a direction opposite to the feed as seen at the point of contact. The thinnest part of the wedge-shaped chip is made first. Conventional milling is best used only to remove when alpha case or scale from the surface of a part with a high-speed steel cutter. In all other situations, climb milling is recommended.

在逆铣中,从接触点看,刀具沿与进给相反的方向转动。首先制作楔形碎片的最薄部分。逆铣最好仅用于使用高速钢刀具去除零件表面的alpha外壳或氧化皮。在所有其他情况下,建议进行顺铣。

(2) In climb milling, the cutter turns in the same direction as the feed as seen at the point of contact. The thickest part of the wedge-shaped chip is made first. Much less chip welding occurs and a better surface finish is made. But climb milling machines must have antibacklash devices.

在顺铣中,铣刀的旋转方向与进给方向相同,就像在接触点上看到的那样。先加工楔形切屑最厚的部分。这样切屑焊接的情况会少得多,表面光洁度也会更好。但顺铣床必须有反齿隙装置。

C. Face Milling (Figure 2, Figure 3, Table 4, Table 5)

面铣(图 2、图 3、表 4、表 5)

(1) Carbide face mills can be used. Cutters with indexable inserts or ground-in-place inserts are recommended. Some indexable insert face mills have special finishing (wiper) teeth that can make a finish of 32 microinches or smoother and thus can be used for finishing cuts.

可使用硬质合金面铣。建议使用带可转位刀片或就地研磨刀片的铣刀。有些可转位刀片面铣刀具有特殊的精加工(刮刀)齿,可加工出 32 微英寸或更光滑的表面,因此可用于精加工切削。

(2) As the titanium chips are cut from the work material, they can weld to the face of cutter teeth. The risk of this is greater as the chip thickness increases at the exit point. Chip welding is a special problem during face milling. It decreases tool life and could cause sudden tool failure. When you face mill titanium, to decrease chip welding and increase tool life:

钛屑从工件材料上切削下来时,可能会焊接到刀齿表面。随着切屑在出口处厚度的增加,这种风险也随之增大。切屑焊接是端面铣削过程中的一个特殊问题。它会降低刀具寿命,并可能导致刀具突然失效。在端面铣削钛合金时,要减少切屑焊接并延长刀具寿命,可采取以下措施

(a) Use a cutting fluid.

使用切削液。

(b) Decrease the feed rate per tooth to 0.002-0.003 inch when you start a cut or machine over holes or irregular surfaces.

开始切削或在孔或不规则表面上加工时,将每齿进给量降至 0.002-0.003 英寸。

(c) Climb mill, and always align the exit side of the cutter with the edge of the part or the cut.

顺铣,并始终将刀具的出口侧对准零件边缘或切口。

(3) Use the general cutter (Figure 3) unless you cut an internal corner at a shoulder. Use the other cutter shown in Figure 3, when it is necessary to cut an internal corner radius.

使用通用铣刀(图 3),除非在肩部切割内角。需要切割内角半径时,请使用图 3 所示的另一种刀具。

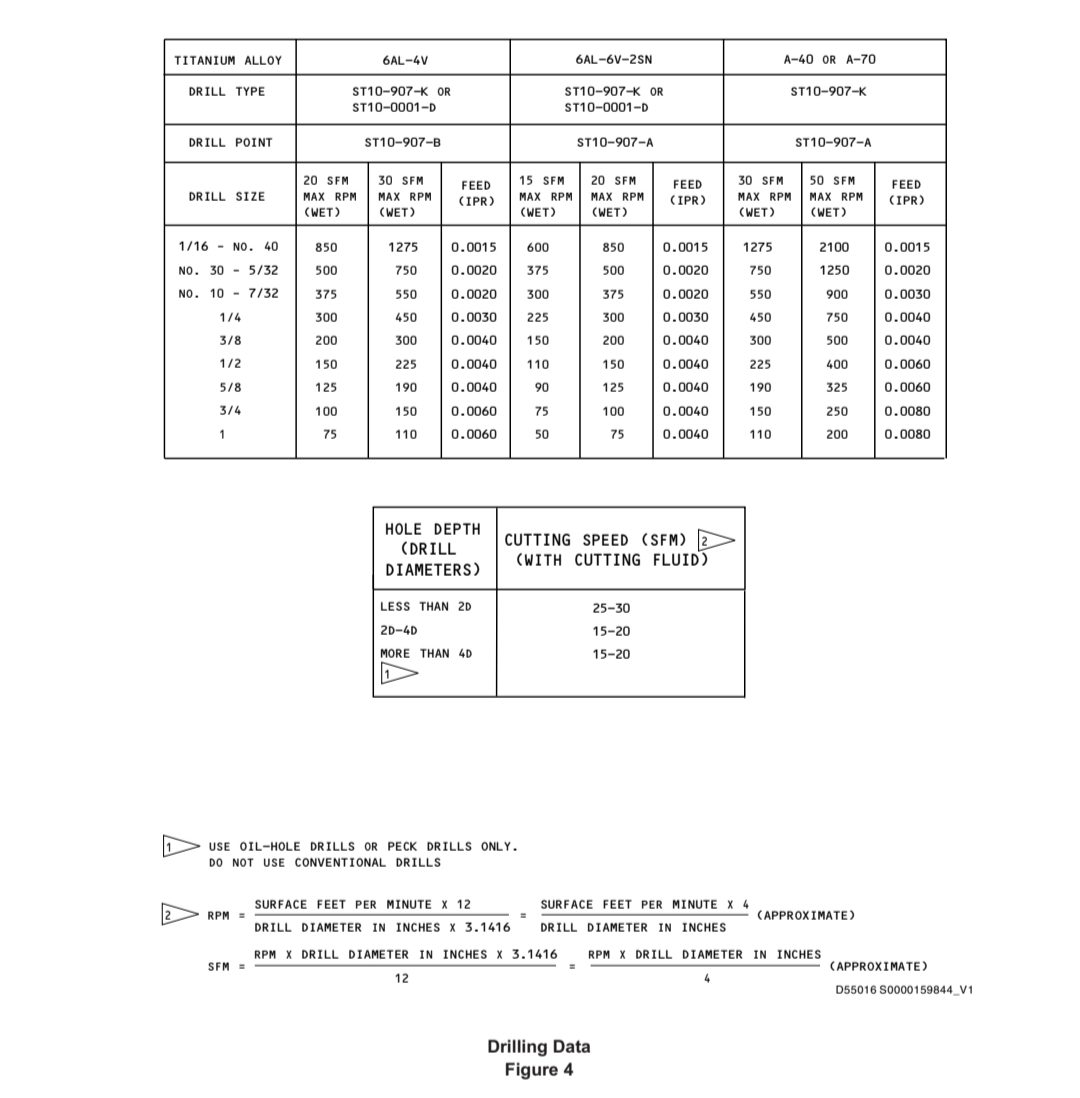

7. DRILLING 钻孔

A. Use a jobber-length drill with a ST10-907A or B point (135-degree split point and reduced rake) on an ST10-907J drill body. If a short-flute drill is not available, or if a longer flute length is necessary, use the ST10-907K drill with the ST10-907B point. For maximum drill life, use as short a drill length as possible. See Figure 4 for recommended speeds and feeds.

在 ST10-907J 钻头上使用带有 ST10-907A 或 B 刀尖(135 度切削刃和较小斜度)的钻头。如果没有短刃钻头,或需要较长的刃长,可使用带有 ST10-907B 刀尖的 ST10-907K 钻头。为延长钻头寿命,钻头长度应尽可能短。推荐转速和进给量见图 4。

B. If the drill diameter is less than 1 inch, use cobalt high-speed steel. If the drill diameter is more than 1 inch, use standard high-speed steel.

如果钻头直径小于 1 英寸,请使用钴高速钢。如果钻头直径大于 1 英寸,则使用标准高速钢。

C. Use a good flow of cutting fluid as specified in Table 2.

使用表 2 规定的流动性良好的切削液。

D. Dull drills usually break suddenly. A drill could be dull if one or more of these signs occur. If you are not sure, replace the drill.

钝钻通常会突然断裂。如果出现上述一种或多种迹象,则可能是钻头钝了。如果不能确定,请更换钻头。

(1) A change in chip shape or quality, such as smearing, rough edges, different colors, or local hot spots.

切屑形状或质量发生变化,例如出现污点、边缘粗糙、颜色不同或局部热点。

(2) A change in the sound of the drill, such as squeaks or chatters.

钻头声音发生变化,如吱吱声或颤振声。

(3) A change in hole quality, such as of surface finish or diameter.

孔的质量发生变化,如表面光洁度或直径。

(4) An increased amount of burrs.

毛刺增多。

(5) A change in power is necessary. (Monitor the load meter if available.)

需要改变功率。(如果有负载计,请对其进行监控)。

E. Always use solid clamping and backup devices to prevent vibration and burrs.

始终使用坚固的夹具和备用装置,以防止振动和毛刺。

8. REAMING 铰

A. Tolerance and tool life are controlled by reamer geometry, cutting speeds and feeds. Cutting fluids must be used.

公差和刀具寿命由铰刀的几何形状、切削速度和进给量控制。必须使用切削液。

B. Standard high speed steel or carbide insert reamers can be used. But standard high speed steel is satisfactory for most applications. Straight-flute chucking reamers with maximum margins (such as 0.010-0.015 inch) are recommended.

可使用标准高速钢或硬质合金刀片铰刀。但标准高速钢可满足大多数应用要求。建议使用具有最大余量(如 0.010-0.015 英寸)的直刃夹持铰刀。

C. See Figure 5 for recommended controls.

推荐的控制方法见图 5。

D. Close-toleranced holes are not easy to ream in titanium. Careful control of reamer geometry and shop procedures can give a tolerance of -0.0000/+0.0015 inch. When you machine ream, cut a minimum of 1/64 (0.0156) inch on the diameter for holes up to 5/16 (0.3125) inch diameter. For larger holes, a 1/32 (0.0312) inch cut on the diameter could be necessary to remove drill marks.

在钛材上铰削公差较小的孔并不容易。仔细控制铰刀的几何形状和车间程序,可以获得 -0.0000/+0.0015 英寸的公差。机铰时,直径不超过 5/16 (0.3125) 英寸的孔,至少要在直径上切 1/64 (0.0156) 英寸。对于较大的孔,可能需要在直径上切削 1/32 (0.0312) 英寸以去除钻痕。

9. SANDING 打磨

A. Titanium can be sanded manually or with power tools. The power tools must not hold the abrasive tightly against the surface. The operation must not make sparks or melted fine particles.

钛可用手工或电动工具打磨。电动工具不得将磨料紧贴表面。操作时不得产生火花或熔化细小颗粒。

B. For class 1 and 2 surfaces, the surface speed of the power sanding tool must be a maximum of 2000 surface feet per minute, measured at the abrasive.

对于 1 级和 2 级表面,电动打磨工具的表面速度必须最大为每分钟 2000 平方英尺(在磨料处测量)。

C. Do not stop the sander in one location as you sand. Do not let the surfaces become too hot. If color changes occur that cannot be removed with solvent, the part must be rejected.

打磨时不要将打磨机停在一个位置。不要让表面温度过高。如果出现无法用溶剂去除的颜色变化,则必须报废该零件。

D. Class 1 surfaces which are sanded must be shot peened (SOPM 20-10-03).

经过打磨的 1 级表面必须进行喷丸处理 (SOPM 20-10-03)。

10. OTHER FINISHING OPERATIONS 其他表面处理作业

A. Hone with 120-grit or finer stones at a speed less than 150 surface feet per minute.

以每分钟小于 150 平方英尺的速度用 120 粒或更细的石子珩磨。

B. Do not use abrasives bonded to a rigid backing (other than the hones) on BAC5492, class 1 or 2 surfaces.

不得在 BAC5492 1 级或 2 级表面上使用粘结在硬质衬底上的磨料(珩磨机除外)。

C. Do not use wire brushes as a finishing operation on BAC5492, class 1 or 2 surfaces unless there will be a subsequent operation to remove the wire brush marks.

不得在 BAC5492 1 级或 2 级表面上使用钢丝刷作为精加工操作,除非随后将进行操作以去除钢丝刷痕迹。

D. Break sharp corners and remove burrs with hand scrapers or files. Rotary files can be used if this does not make the surface too hot and cause color changes.

用手刮刀或锉刀去除尖角和毛刺。如果不会使表面温度过高而导致颜色变化,可使用旋转锉。

11. STRESS RELIEF AFTER MACHINING 加工后的应力消除

A. It is not necessary to bake titanium for stress relief after the machining operations.

加工后无需烘烤钛金属以消除应力。