缠绕导线电气连接的修理REPAIR OF WRAPPED WIRE ELECTRICAL CONNECTIONS

1. INTRODUCTION 介绍

A. A wrapped wire connection consists of a helix of continuous, solid, uninsulated wire tightly wrapped around a terminal post to produce a mechanically and electrically stable connection. The number of turns required depends on the wire size used. In addition to the uninsulated wire wrap turns, an additional turn of insulated wire is wrapped around the terminal to absorb vibration. The insulated turn is at the bottom of the wrapped section. The wrap proceeds upward on the terminal post to the end of the wire.

缠绕导线连接是将连续、实心、无绝缘导线螺旋形紧紧缠绕在接线柱上,以产生机械和电气上稳定的连接。所需的绕线匝数取决于所用导线的尺寸。除了无绝缘导线的缠绕匝数,端子上还缠绕有一圈绝缘导线以吸收振动。绝缘匝位于缠绕部分的底部。包线在接线柱上向上进行,直至导线末端。

B. Definitions

定义

(1) End Tail – The end of the last turn of uninsulated wire.

端尾 – 未绝缘导线最后一匝的末端。

(2) End Turn – The last or top turn of a wrapped wire connection.

末圈 – 包线连接的最后一匝或顶匝。

(3) Gas-Tight Area – The contact area between the terminal post and wire which will exclude gas fumes when properly wrapped.

气密区 – 接线柱与导线之间的接触区域,在正确包扎后可排除气体。

(4) Lead Turn – The first (lowest) turn of a wrapped wire connection

端头 – 导线连接的第一圈(最低圈)。

(5) Terminal Post (or Terminal) – A rigid metallic post of rectangular or square cross section on which a solid round wire is wrapped to provide a mechanical and electrical connection.

接线柱(或端子)–矩形或方形截面的刚性金属柱,在其上缠绕实心圆导线,以提供机械和电气连接。

(6) Unwrapping Tool – A tool used to unwrap the wire turns to remove a wrapped wire connection.

拆线工具 – 用于剥开线圈以去除包线连接的工具。

(7) Wire Dress – The direction or positioning of wiring between connections within the mechanical assembly to obtain optimum routing and spacing.

线衣 – 在机械组件内各连接处之间布线的方向或位置,以获得最佳的布线和间距。

(8) Wire Routing – The physical placement or orientation of wire.

布线 – 导线的实际放置或定向。

(9) Wire Stripping – The removal of insulation from wire.

剥线 – 去除导线的绝缘层。

(10) Wire Turn (or Turn) – One complete turn of wire around the terminal post that touches all corners. To count turns, find the first corner touched by the wire. Count the number of turns crossing this corner above this point.

线匝(或 匝) – 导线绕接线柱转一圈,接触所有角。要计算圈数,请找到导线接触的第一个角。在此点之上计算穿过该角的圈数。

(11) Wrapping Level – The section of terminal occupied by a wrapped wire connection. The first level is at the base of the terminal post. The second level is the middle wrapping area. The third level is nearest the free end of the terminal post.

裹线层 – 裹线连接所占的接线柱部分。第一层位于接线柱底部。第二层是中间包裹区域。第三层最靠近接线柱的自由端。

(12) Wrapping Tool – A tool consisting of a bit and sleeve assembly used to wrap a solid conductor wire around a terminal post.

绕线工具 – 由刀头和套管组件组成的工具,用于将实心导线绕在接线柱上。

(13) Manual Wire-wrapping – Application of the wire wrap connection with a hand-held and manually-positioned tool.

手动绕线- 用手持和手动定位工具进行绕线连接。

(14) High Turn – A turn of wire raised off the post by interference with an adjacent turn of wire. This condition may be caused by excessive pressure applied to the tool.

高匝 – 由于与相邻导线的干扰,导线从接线柱上翘起。这种情况可能是工具压力过大造成的。

(15) Overwrap – A wire turn piled up on a previously made turn within the same wrapped wire

connection.

过缠绕 – 在同一缠绕导线连接中,一个导线圈数堆积在先前转数上。

C. General Process

通用工艺

(1) Wires to be removed may be unwrapped, or may be clipped close to the terminal post. If the wire to be removed is on a lower level, clipping may be preferable to unwrapping wires on levels above.

需要拆除的电线可以拆开,也可以在靠近接线柱的地方剪断。如果要拆除的电线在较低位,剪断可能比在较高位拆除电线更可取。

(2) Wires to be attached must be stripped of insulation for a specified length at the end, inserted in the wrapping tool, and the wrap applied to the terminal post.

需要连接的导线必须在末端剥去规定长度的绝缘层,插入绕线工具,并将包线套在接线柱上。

(3) The section of unwrapped wire may not be re-used. A fresh section of the same wire may be stripped and wrapped. However, sufficient slack must be available to avoid any strain on the connection. This extra length is not normally available on original wiring.

未缠绕的电线不得重复使用。新的同一段导线可以剥线和绕线。但必须有足够的松弛长度,以避免对连接造成任何拉力。原装电线通常不具备这种额外长度。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

有关所有供应商的名称和地址,请参阅 SOPM 20-00-00。

2. MATERIALS 材料

NOTE: Equivalent substitutes may be used.

注:可使用等效替代品。

A. Topical antistatic solution (V85670)

局部抗静电溶液(V85670)

(1) Rescue Solution

(2) Rescue-2 Chloride-Free

(3) No. 70504 (spray bottle)

(4) No. 70508 (gallon)

B. Aqua regia solution (1 to 1 concentrated hydrochloric and nitric acids).

王水溶液(1 比 1 的浓盐酸和浓硝酸)。

C. Concentrated ammonium sulfide solution

浓缩硫化铵溶液

D. Adhesive — Type 70 or 82 (Ref SOPM 20-50-12)

70 型或 82 型粘合剂(参考 SOPM 20-50-12)

3. TOOLS 工具

A. General

通用

(1) When wire wrapping or unwrapping is performed on wire bundles with electrostatic discharge sensitive devices attached, one of the following conditions must be met:

在装有静电放电敏感器件的线束上进行绕线或拆线时,必须满足以下条件之一:

(a) The tool must be air-powered.

工具必须以空气为动力。

(b) The tool may be electrically powered and used in conjunction with an ionized air blower blowing air over the work surface.

工具可由电力驱动,并与向工作面吹气的离子风机结合使用。

(c) The tool may be electrically powered with the tip of the tool grounded and the plastic case of the tool treated with topical antistatic solution.

可使用电力驱动的工具,工具顶端接地,工具塑料外壳经局部防静电溶液处理。

(2) Equivalent tools may be substituted for those listed.

可用等效工具代替所列工具。

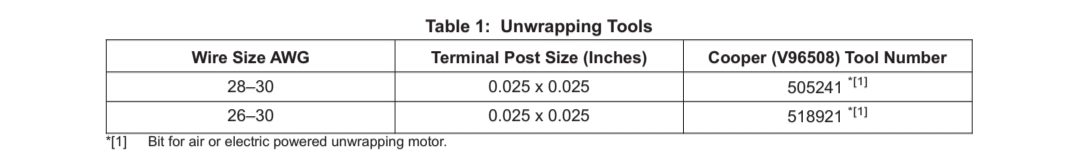

B. Unwrapping Tools — See Table 1

拆线工具 — 见表 1

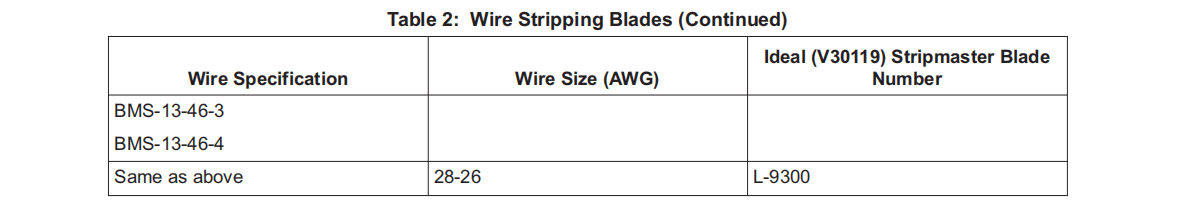

C. Wrapping Tools — See Figure 1

包裹工具 — 见图 1

D. Insulation Stripping Tools

绝缘层剥离工具

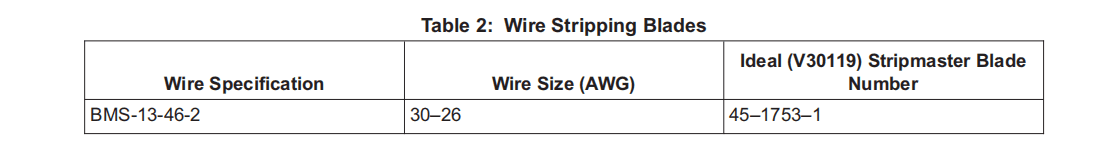

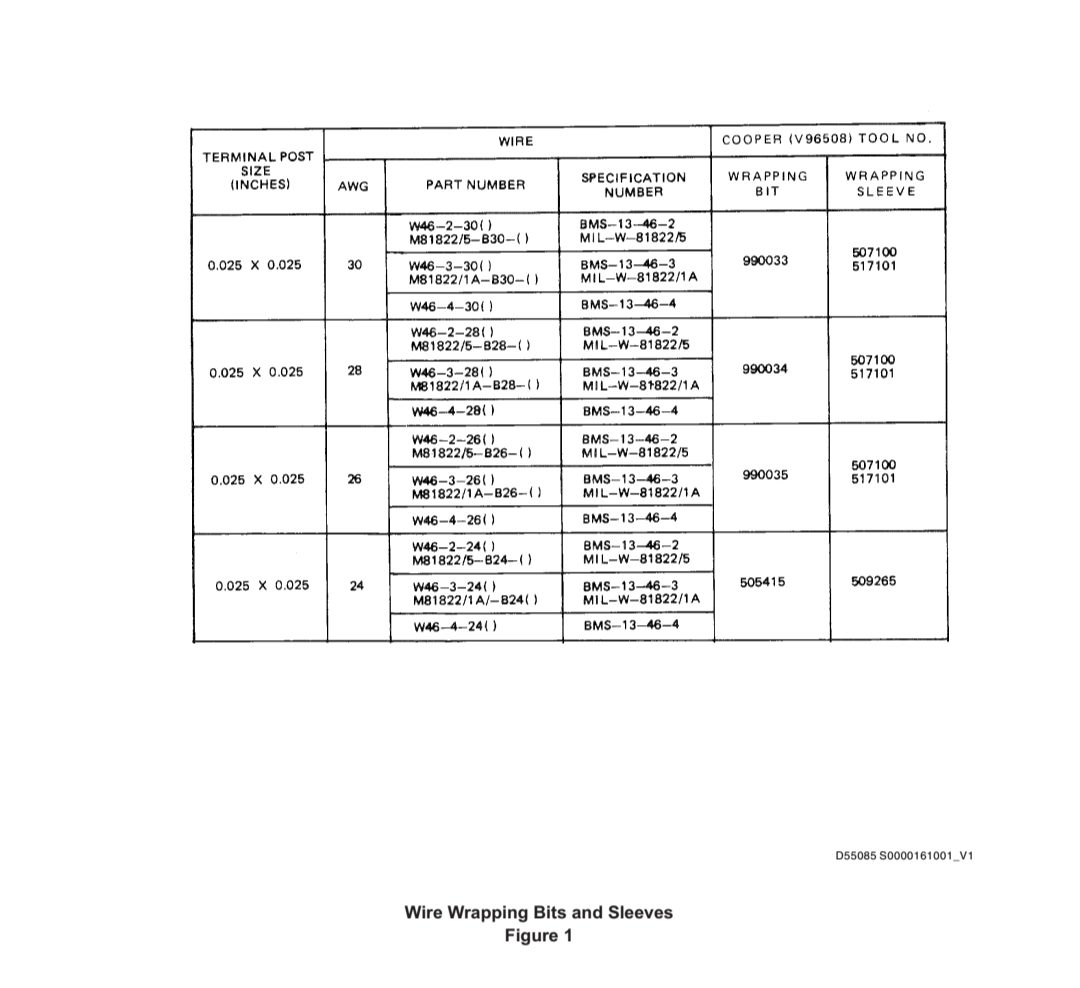

(1) Use Ideal Industries Stripmaster hand tool with appropriate blades per Table 2.

使用 Ideal Industries Stripmaster 手动工具,并按表 2 配备适当的刀片。

E. Wrapped Connection Test Tools (for quality control sample testing)

缠绕连接测试工具(用于质量控制样品测试)

(1) DC Power Supply, variable

直流电源,可变

(2) Millivoltmeter

毫伏表

(3) DC Ammeter (0 to 10 amperes)

直流电流表(0 至 10 安培)

(4) Terminal Stripping Tool (for Terminal Stripping Force Test). Boeing tool A20007-1 may be used.

端子剥离工具(用于端子剥离力测试)。可使用波音工具 A20007-1。

(5) Device such as a spring scale to apply and measure 2 to 10 pounds force.

弹簧秤等装置,用于施加和测量 2 至 10 磅的力。

F. Wire Wrap Post Connector Cover Installation/Removal Tools

绕接线柱连接器盖安装/拆除工具

(1) Hot air gun — Mamco model HG-S-751-10 (V12642)

热风枪 — Mamco 型号 HG-S-751-10 (V12642)

(2) Heat nozzle gun — Ideal Model 46-013 (V30119)

热喷嘴枪 — Ideal 型号 46-013 (V30119)

4. PROCEDURES 程序

A. Preparation

准备工作

(1) The terminal posts in ARINC 600 boxes may or may not be accessible for application of wire wrap tools. If not accessible, some disassembly will be required.

ARINC 600 接线盒中的接线柱可能可以使用绕线工具,也可能无法使用。如果不可以,则需要进行一些拆卸。

(2) The wire wrap connections are originally applied with the printed circuit assembly connectors and all other components laid out in a horizontal plane. The entire wire bundle may be removed and returned to this condition for rework. The printed circuits assembly connectors need not be removed from the mounting bracket.

缠线连接最初是在印刷电路组件连接器和所有其他组件水平放置的情况下进行的。可将整个线束拆下,恢复到这种状态进行重做。印刷电路组件连接器不必从安装支架上拆下。

(3) Remove all printed circuit assemblies and other chassis-mounted subassemblies as required. This will normally remove all electrostatic sensitive devices. If it does not, see paragraph on tool precautions when electrostatic sensitive devices are connected to the wire bundle. Use electrostatic sensitive packaging as required for removed assemblies.

根据需要拆除所有印刷电路组件和其他安装在底盘上的子组件。这通常会拆除所有静电敏感设备。如果没有,请参阅 “静电敏感设备与线束连接时的工具预防措施 “段落。对拆下的组件按要求使用静电敏感包装。

(4) Remove screws at chassis sides holding printed circuit assembly guide brackets.

拆除底盘侧面固定印刷电路组件导向支架的螺钉。

(5) Remove rear connector mounting screws.

拆除后部连接器的安装螺钉。

(6) Remove all other component mounting hardware as required to free wire bundle from chassis including ground studs. Front panel may be removed, or individual components on front panel may be removed as necessary.

根据需要卸下所有其他元件安装硬件,以便将线束从底盘中释放出来,包括接地螺栓。可根据需要拆下前面板或前面板上的单个元件。

(7) Carefully remove wire bundle with attached components and lay out as required for access to terminal posts.

小心取下带连接元件的线束,并按要求摆放,以便接触接线柱。

B. Removal of Wrapped Wire Connections

拆除绕线连接

(1) Select the proper unwrapping tool per Table 1. Place tool over terminal post and engage leading edge between the wrap end and next wrap turn. Rotate counterclockwise until all wire has been transferred to tool, or the wrap is sufficiently loose to slide free of post.

根据表 1 选择合适的拆线工具。将工具放在接线柱上,在包线端和下一圈包线之间啮合前缘。逆时针旋转,直到所有导线都转移到工具上,或包线足够松动,可以从接线柱上滑脱。

(2) Upper level wraps must be removed to gain access to lower level wraps.

必须取下上层包线,才能接触到下层包线。

(3) Do not attempt to remove lower level wraps, and then slide the upper level wraps down the post. Once wrapped, the turns may not be moved on the post.

不要试图取下下层包线,然后将上层包线滑下支柱。一旦包扎完毕,不得在立柱上移动。

C. Installation of Wrapped Wire Connections

安装包线连接

(1) Examine terminal post for misalignment. Realign, if required, with any tool that will fit over the terminal to the base and not damage terminal (such as an unwrapping tool).

检查接线柱是否错位。如有需要,可使用任何可穿过接线柱与底座且不会损坏接线柱的工具(如拆线工具)重新对齐。

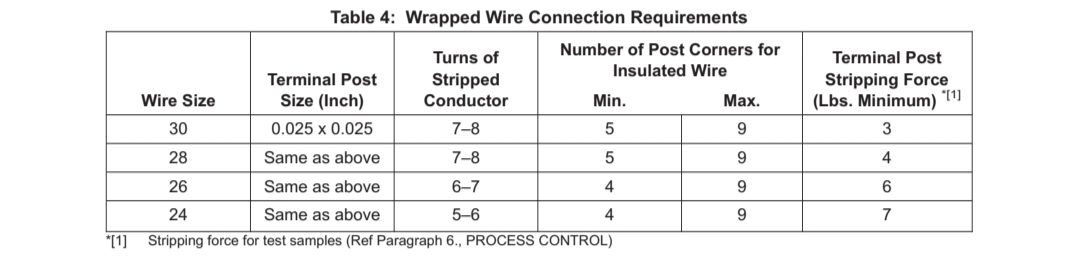

(2) Select wire size required and cut to length. The wire should be dressed such that the routing of the wire or any applied tension on the wire will not unwrap the connection to less than the minimum requirements of Table 4. Wire shall have sufficient slack to prevent tension on wire or post.

选择所需的导线尺寸并按长度剪切。导线的敷设应确保导线的走向或导线上施加的任何张力不会使连接的松开程度低于表 4 的最低要求。导线应具有足够的松弛度,以防止导线或支柱受到拉力。

(3) Silver coated conductors tarnished black may not be used.

不得使用被玷污成黑色的镀银导线。

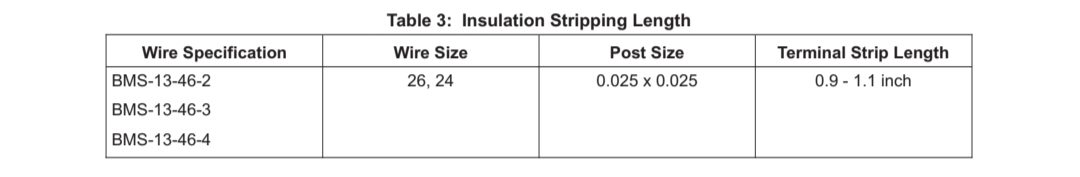

(4) Strip insulation from ends of wire per Table 3. Use stripping tool per Table 2.

按表 3 从导线两端剥去绝缘层。使用表 2 中的剥线工具。

(5) Wrap on the lowest vacant level. When wrapping on level 1, be certain to bottom out the wrapping tool.

在最低的空置层上缠绕。在第 1 层缠绕时,一定要将缠绕工具垫底。

(6) Apply wrapping turns of insulated and uninsulated wire as listed in Table 4.

按照表 4 列出的绝缘和非绝缘导线的缠绕圈数进行缠绕。

(7) Insulation between posts shall not be cut, torn, crushed, or charred. Indentations such as tool marks are acceptable.

支柱之间的绝缘不得被切割、撕裂、压碎或烧焦。工具痕迹等压痕可以接受。

(8) Dress wire so that it does not extend above the plane of the terminal post tips.

敷设导线时,导线不得超出接线柱端头的平面。

(9) Do not route wire outside of, or along, the outer periphery of the terminal post assembly.

不要在接线柱组件外围或沿接线柱组件外围布线。

(10) Wires that lie between the terminal posts of any terminal post array shall not be tied together.

位于任何接线柱阵列的接线柱之间的导线不得捆绑在一起。

(11) Do not slide a completed wrap along the axis of the terminal post.

不要沿接线柱的轴线滑动已完成的包覆材料。

(12) Unwrap and replace defective wraps. Unwrapped portion of wire may not be re-used.

拆开并更换有缺陷的绕组。不得重复使用未包扎的导线部分。

(13) Straighten misaligned wrapped terminal posts:

调直错位的包线接线柱:

(a) When posts are bent 30° or less, realign sufficiently to establish one post thickness spacing between conducting surfaces.

当接线柱弯曲 30°或更小时,充分对齐以在导电表面之间建立一个接线柱厚度的间距。

(b) When posts are bent more than 30°, unwrap connection and straighten post. After alignment, examine with 5X magnification. If cracks are found on terminal post, post is not acceptable for wire wrapping.

当接线柱弯曲超过 30° 时,拆开连接并校直接线柱。对齐后,用 5 倍放大镜检查。如果在接线柱上发现裂纹,接线柱不能用于绕线。

(14) Shield Terminations

屏蔽终端

(a) Use solder sleeve method for installation of shield termination pigtail. It is not necessary to fold shield braid back over wire jacket.

使用焊接套管法安装屏蔽终端尾纤。不必将屏蔽编织层折回导线护套。

(b) Use BMS 13-46-2 wire for pigtail jumper, minimum length of 2 inches.

尾纤跳线使用 BMS 13-46-2 电线,最小长度为 2 英寸。

(c) Pigtail jumper shall extend from forward end.

尾纤跳线应从前端伸出。

(15) Do not route unshielded and unjacketed multiple conductor cable or shielded and jacketed multiconductor cable between wire wrap contacts.

不要在绕线触点之间铺设未屏蔽和未护套的多导体电缆或屏蔽和护套的多导体电缆。

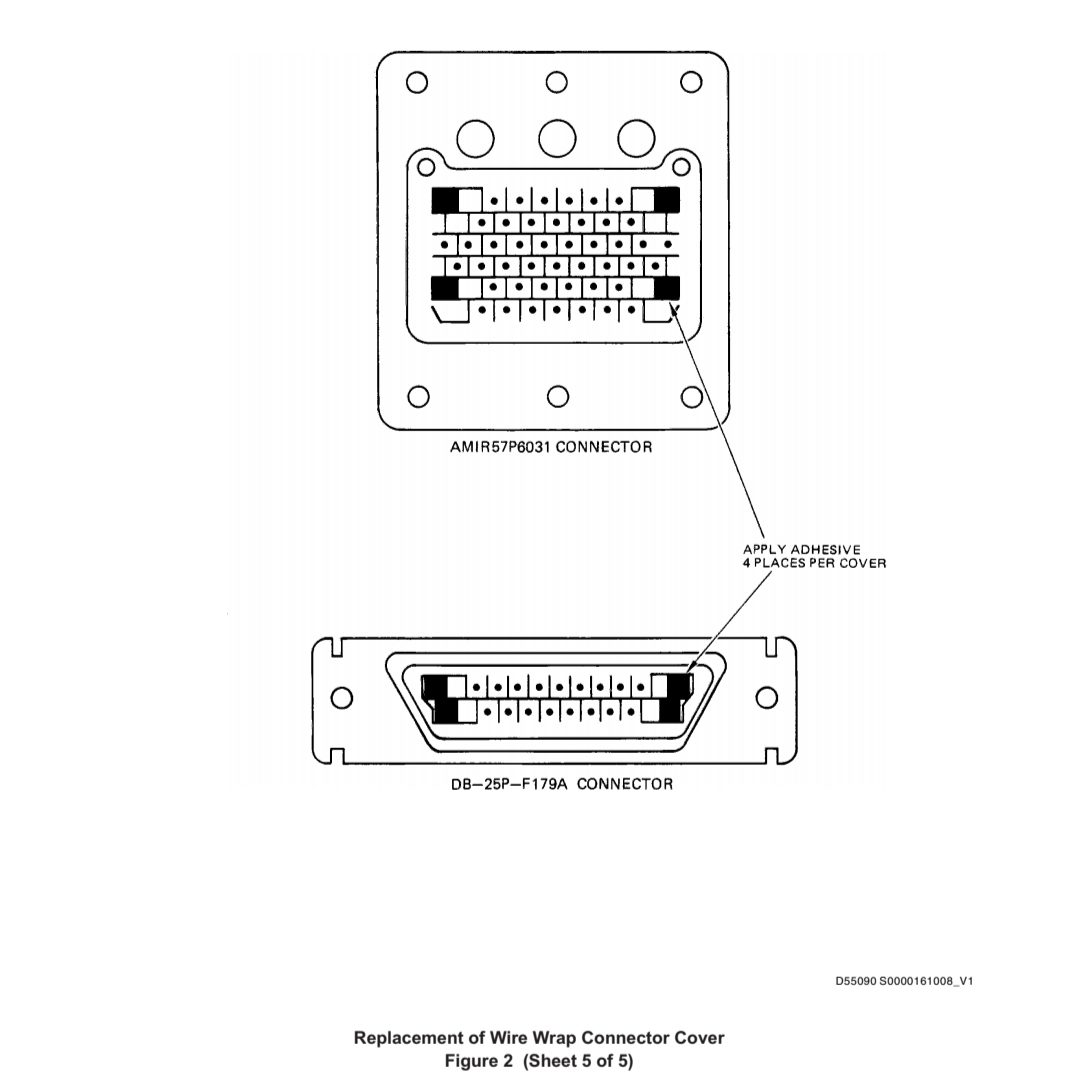

D. Installation and Removal of Wire Wrap Post Connector Covers

安装和拆除绕线柱连接器盖板

(1) Installation

安装

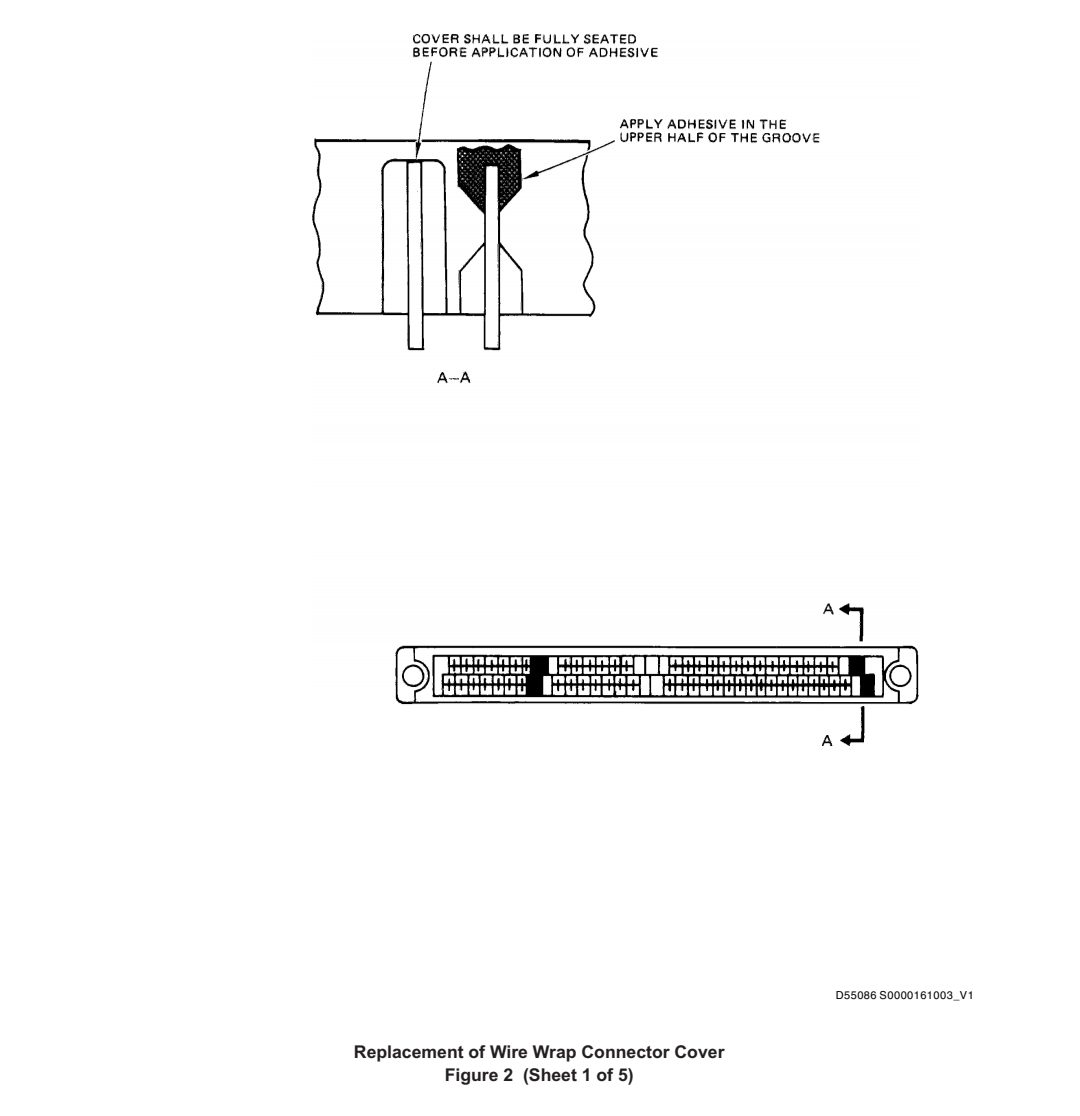

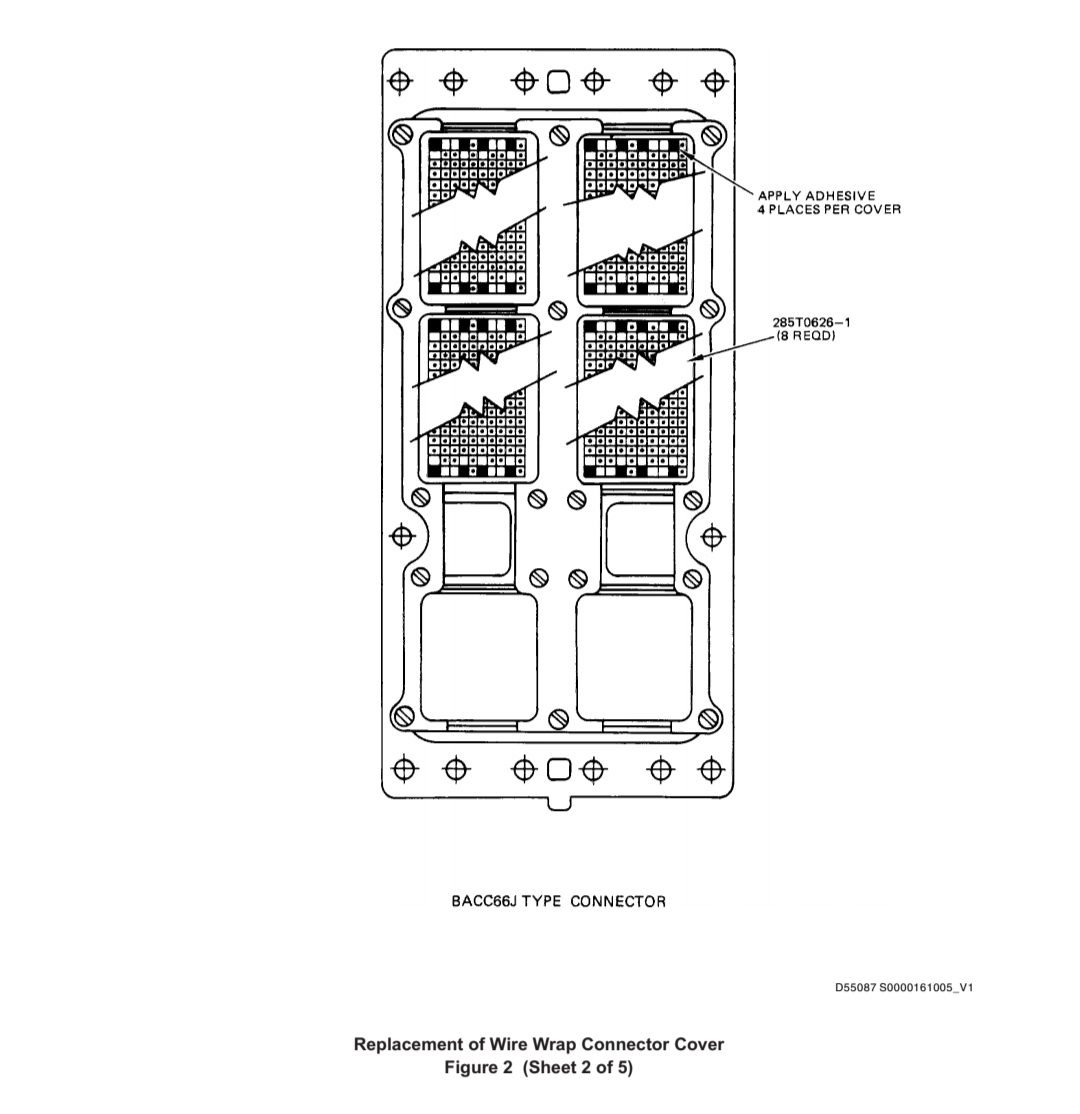

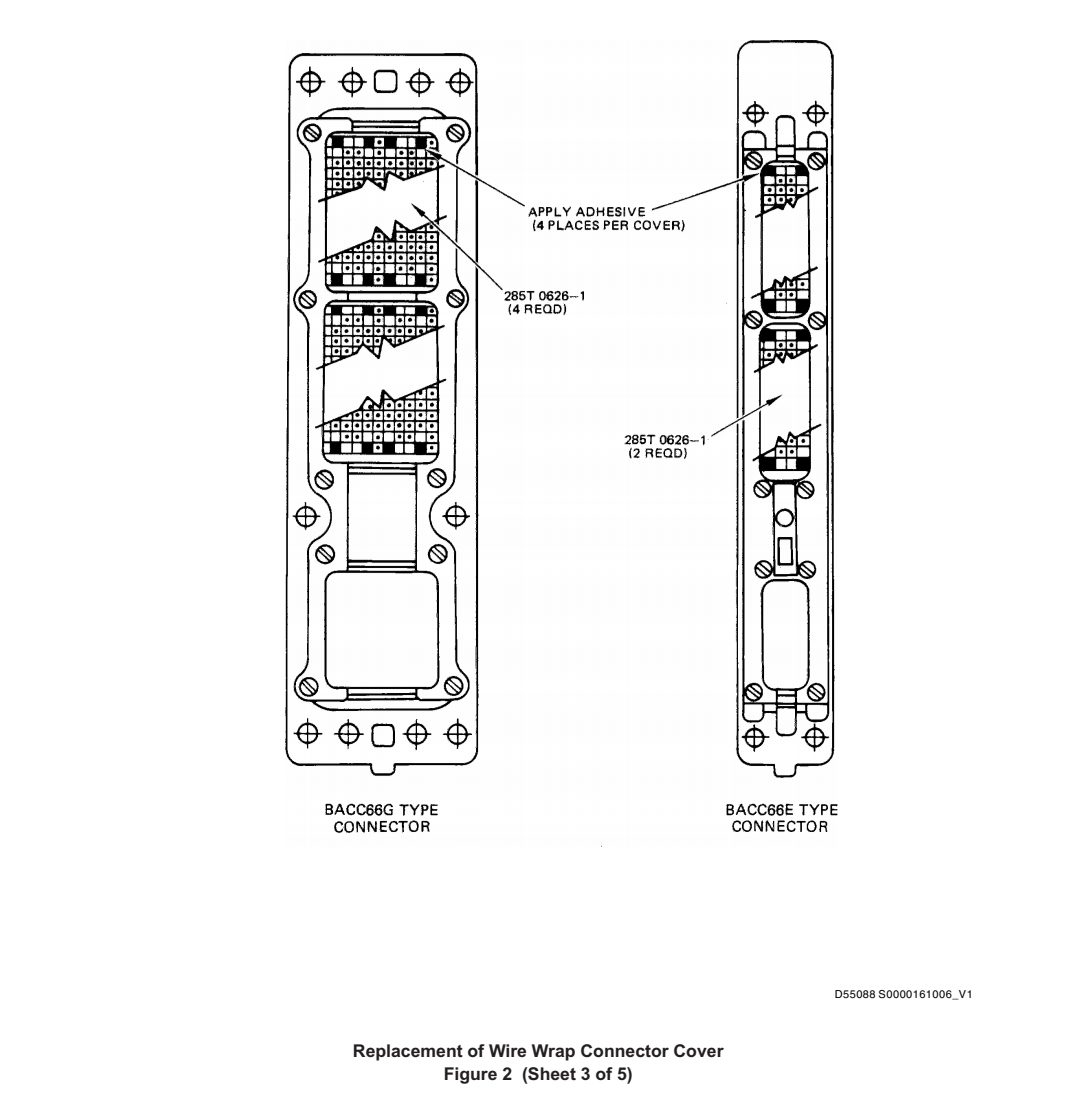

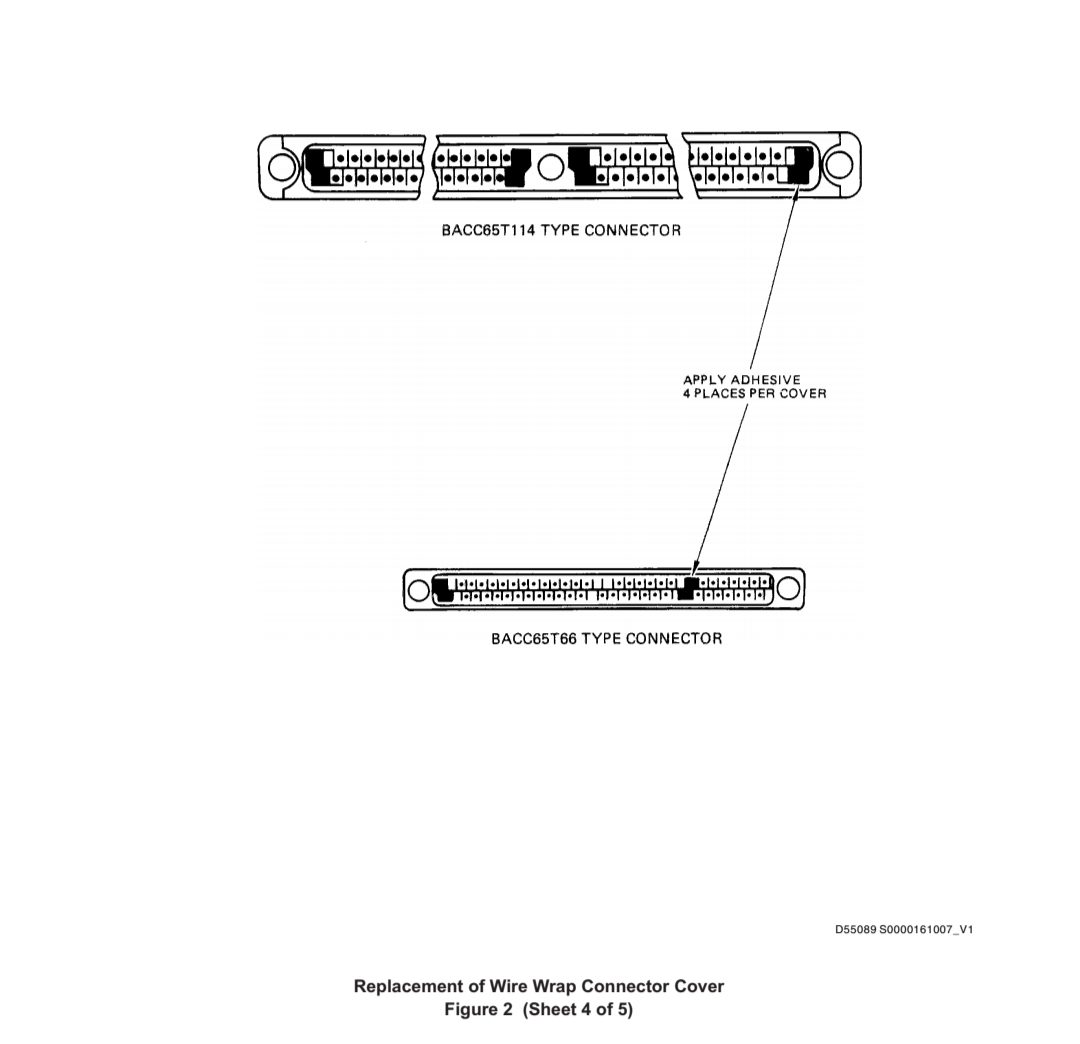

(a) Install wire wrap post connector covers by properly orienting the indicated cover over the connector and pushing it on until it is fully seated on the cap pins. Cover shall be fully seated before the application of adhesive.

安装绕接线柱连接器盖板时,应适当调整盖板在连接器上的方向,并将其推上,直至完全固定在盖销上。在涂抹粘合剂之前,盖子必须完全就位。

(b) Apply adhesive per SOPM 20-50-12 in the upper half of the groove as shown in Figure 2 to provide maximum coverage of the pin.

如图 2 所示,按照 SOPM 20-50-12 在凹槽的上半部分涂抹粘合剂,以最大限度地覆盖插针。

(2) Removal

拆除

(a) Remove the printed circuit board assembly mated to the contact assembly having the pin cover to be replaced and any other assemblies required to gain access to the connector.

拆下与插针组件相连的印刷电路板组件,该组件上有要更换的插针盖,以及进入连接器所需的任何其他组件。

(b) Use a heat gun to remove the cover. Hold the heat gun at least one inch from the cover and point it at the adhesive. Apply heat to cover until the adhesive softens, but do not exceed 20 seconds in any one area to prevent overheating of wiring.

使用热风枪取下盖子。将热风枪拿在离盖至少一英寸的地方,对准粘合剂。加热盖子,直到粘合剂软化,但在任何一个区域都不要超过 20 秒,以防止接线过热。

(c) After adhesive is softened, remove cover by applying an evenly distributed amount of upward force on the connector cover.

在粘合剂软化后,用均匀分布的力向上推连接器盖,取下盖子。

5. CONFIGURATION OF COMPLETED CONNECTIONS 已完成连接的结构

A. Wrapped connections shall meet the turns requirements of Table 4 for both stripped and insulated portions of wire.

缠绕连接的剥线和绝缘部分均应符合表 4 的圈数要求。

B. There shall be no damage which exposes base metal that is visible under 5X magnification.

在 5 倍放大镜下不得有可见的露出基底金属的损坏。

C. Cuts, tears, or crushing of insulation on the insulated turns are acceptable except that no conductor shall be visible (unaided eye) on the last half turn before the wire leaves the terminal.

除导线离开端子前的最后半圈不得有导体可见外,绝缘匝上的切割、撕裂或挤压均可接受。

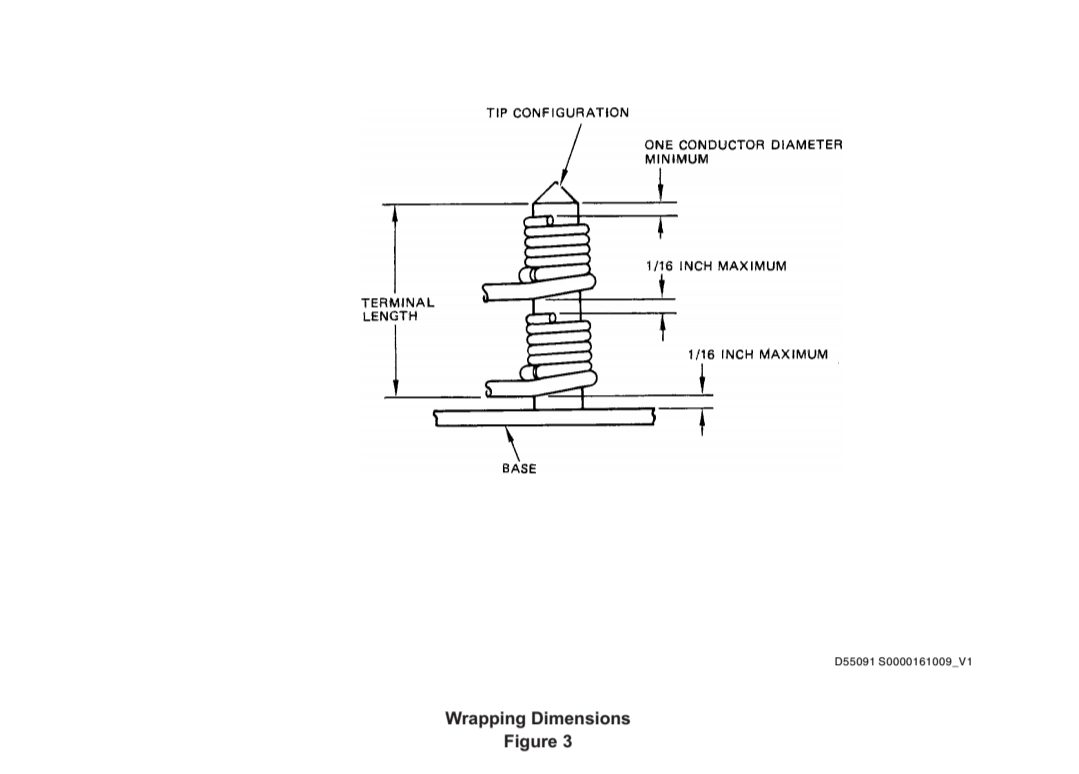

D. Space between adjacent turns of the wrap shall not exceed one half the diameter of the bare conductor except on the first and last turns where the space shall not exceed one diameter of the bare conductor. The sum of all gaps shall not exceed one diameter excluding the first and last turn (Figure 3).

相邻匝之间的间隙不得超过裸导体直径的一半,但第一匝和最后一匝的间隙不得超过裸导体直径的一个直径。除第一圈和最后一圈外,所有间隙的总和不得超过一个直径(图 3)。

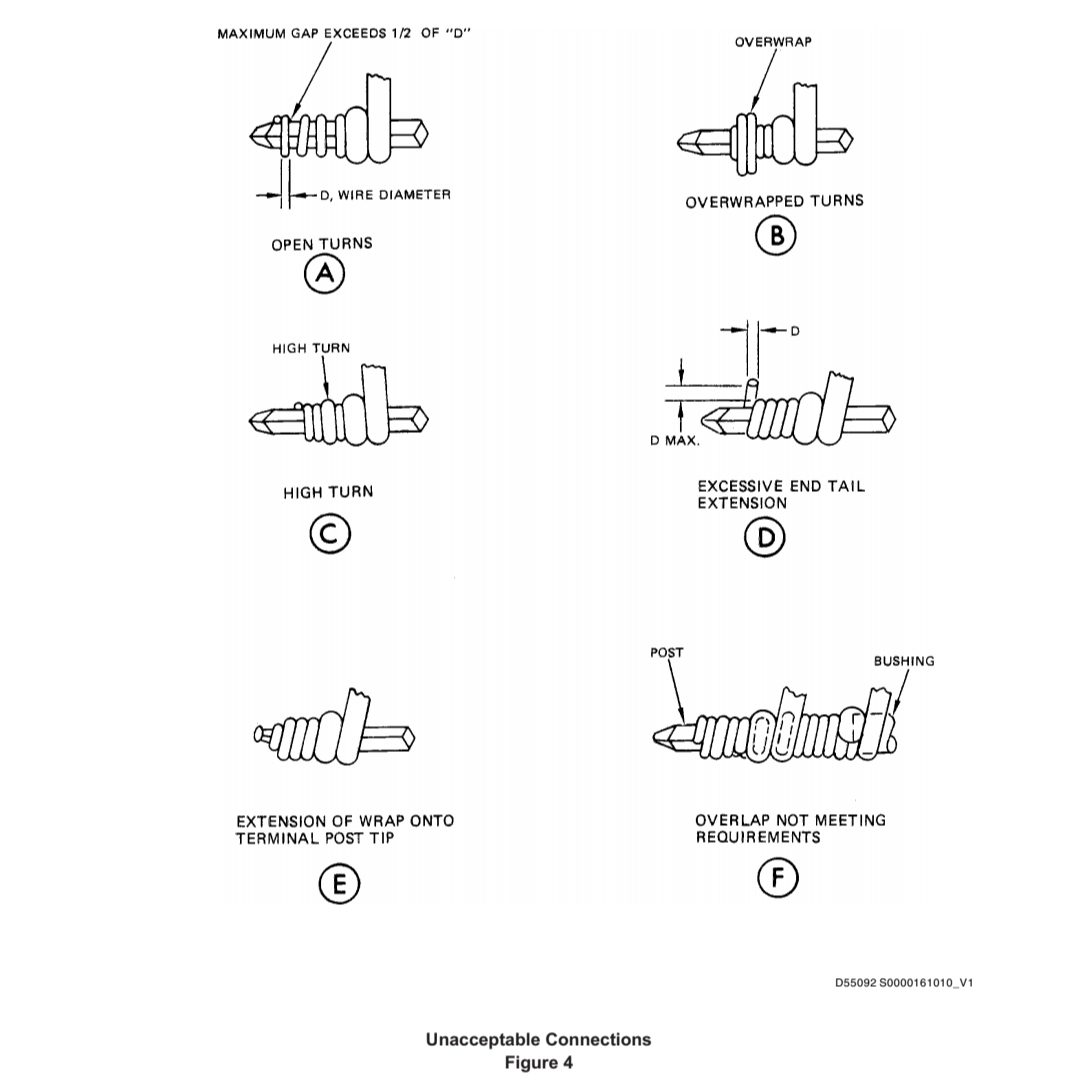

E. High turns, open turns, and overwrap (Figure 4, Views A, B, C) are not acceptable.

高匝、开匝和包覆(图 4,视图 A、B、C)是不可接受的。

F. The last turn (end tail) shall not extend more than one conductor diameter beyond the outer diameter of the stripped wire (Figure 4, View D). A blunt tool may be used to bend the excess end tail around the post; however, care must be used to avoid damage to the terminal, wire, or wrap.

最后一圈(尾部)不得超出剥线外径一个导体直径以上(图 4,D 视图)。可使用钝器将多余的尾端绕柱弯曲,但必须小心,以免损坏端子、导线或包线。

G. Wraps must not extend over the rounded, tapered, or bevelled end of the terminal post (Figure 4, View E). There shall be one conductor diameter minimum between the completion of the wrap and the beginning of the post tip configuration.

裹线不得超出接线柱的圆形、锥形或斜角端(图 4,视图 E)。包线完成处与接线柱端头结构的起始处之间应至少有一个导体直径。

H. The first turn of insulated wire may overlap the turns of uninsulated wire in a connection below it on the same terminal post. On the first wrapping level, the first turn of insulated wire may overlap the terminal post bushing below. The requirements for insulated wire covering corners (Table 4) still apply.

在同一接线柱上,绝缘导线的第一圈可与其下方连接中的非绝缘导线重叠。在第一层缠绕时,第一圈绝缘导线可与下面的接线柱套管重叠。绝缘导线包角的要求(表 4)仍然适用。

I. Maximum distance between the start of insulated wire turn and the bushing or base of the terminal post shall be one-sixteenth inch. Maximum distance between wraps shall be one-sixteenth inch (Figure 3).

绝缘导线起始端与接线柱套管或底座之间的最大距离应为十六分之一英寸。缠绕之间的最大距离应为十六分之一英寸(图 3)。

6. PROCESS CONTROL 过程控制

A. General

通用

(1) Certain checks on the quality of the wire wrap process can, and should, be made on each wire wrap connection. These checks are listed in Paragraph 5..

可以而且应该对每个绕线连接进行绕线工艺质量的某些检查。这些检查见第 5 段。

(2) Certain checks cannot be made or are impractical to make on each wire wrap connection. These checks are listed in this section:

某些检查无法或不可能在每个包线连接上进行。本节列出了这些检查:

(a) Electrical resistance check between terminal post and wrapped conductor.

接线柱与包线导体之间的电阻检查。

(b) Gas tight integrity check between wrap and terminal post.

绕组与接线柱之间的气密完整性检查。

(c) Stripping force required to slide wiring along terminal post axis.

沿接线柱轴线滑动导线所需的剥离力。

(d) Unwrapping tests

拆线试验

(3) The checks listed in this section should be made on the conditions listed, at selected time intervals dependent upon extent of usage of the tool, and at any time the potential performance of the tool to be used is in doubt.

本节所列检查应在所列条件下进行,时间间隔视工具的使用程度而定,并在对所使用工具的潜在性能产生怀疑的任何时候进行。

(4) Wrap a set of 24 samples for initial tests. Wrap a set of 6 samples for periodic tests.

包扎一组 24 个样品,用于初始测试。包扎一组 6 个样本,用于定期测试。

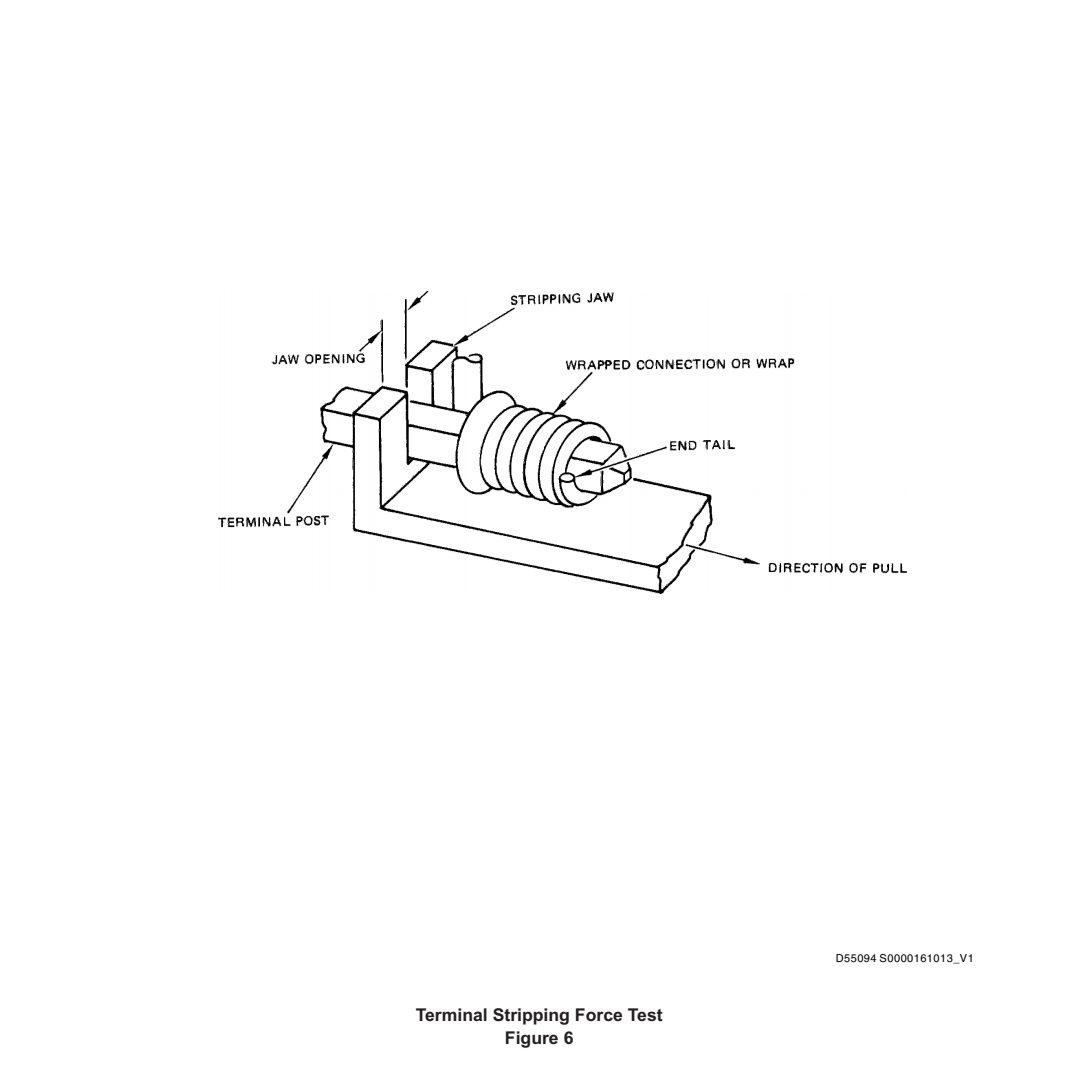

(a) Apply wrap samples two-to-the-post with some space between wraps. Leave sufficient space between the lower wrap and the terminal base for insertion of a stripping tool (Figure 6).

两个样品对一个样品进行包扎,包扎之间留出一定的空间。在下包层和接线柱底座之间留出足够的空间,以便插入剥线工具(图 6)。

B. Initial Tests

初始测试

(1) Perform initial tests on new tools; on tools that have been repaired, adjusted, or modified; on tools that have not had initial tests for a six month period; or every ten working days on tools in constant use.

对新工具、修理、调整或改装过的工具、六个月内未进行过初步测试的工具、 或对经常使用的工具每十个工作日进行一次初步测试。

(2) Perform the following tests on twelve sample wraps in the order listed:

按所列顺序对十二个样本包覆材料进行以下测试:

(a) Resistance test

电阻测试

(b) Terminal stripping force test

末端剥离力测试

(c) Unwrap test

拆线测试

(3) Perform gas tight test on twelve sample wraps.

对十二个样本包装进行气密性测试。

C. Periodic Tests

定期测试

(1) Perform periodic tests daily on tools in constant use; after each change of tool bit, sleeve, or wrapper; or when dropping or mishandling causes tool performance to be suspect.

每天对经常使用的工具进行定期测试;每次更换刀头、套管或包装材料后;或当掉落或误操作导致工具性能可疑时。

(2) Perform the following tests on six sample wraps in the order listed:

按所列顺序对六个样本包装进行以下测试:

(a) Terminal stripping force test

末端剥离力测试

(b) Unwrap test

拆线测试

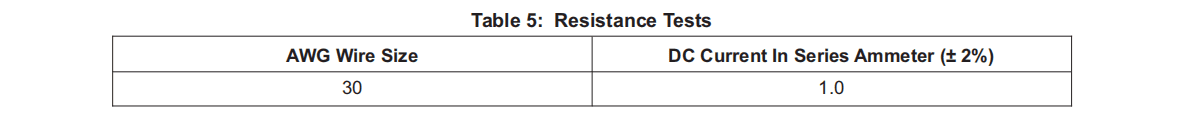

D. Resistance Tests

电阻测试

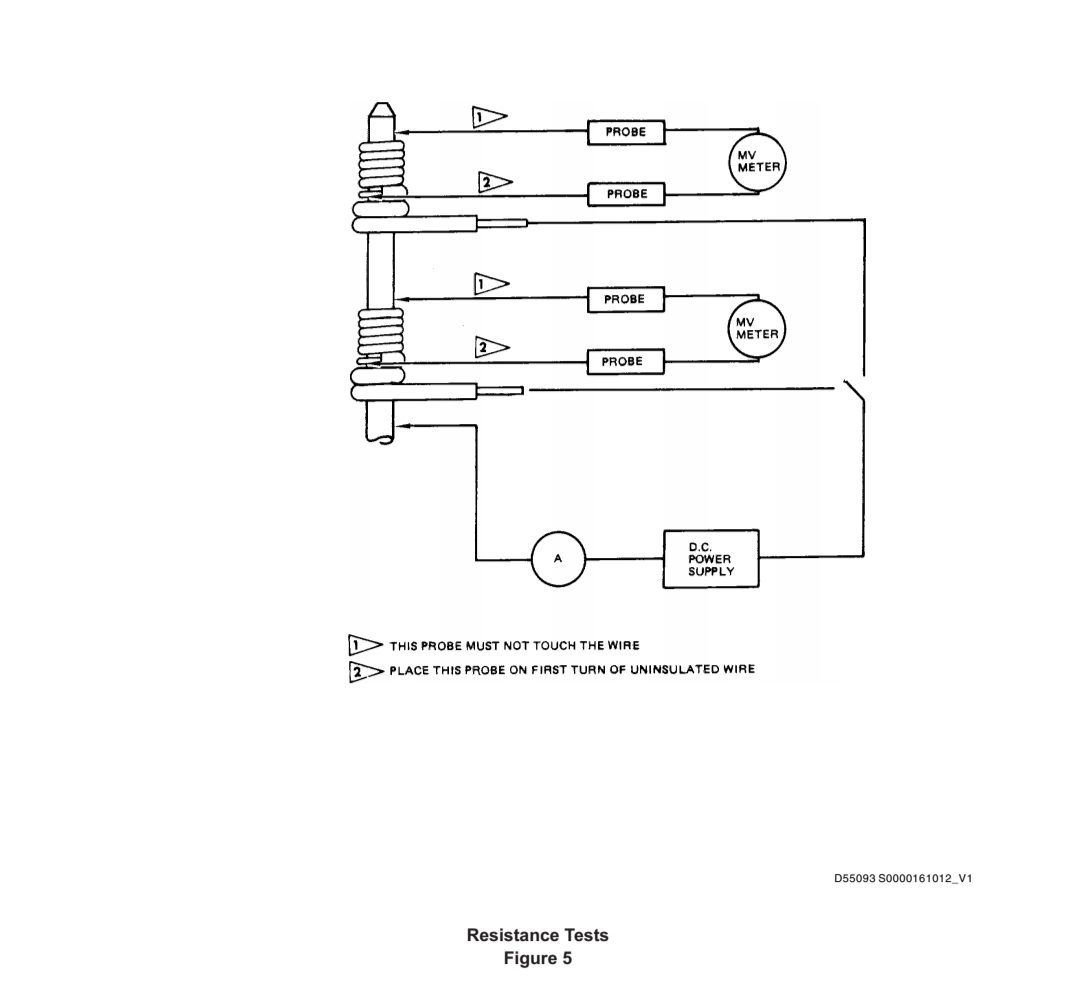

(1) Make connections as shown in Figure 5 with power supply set to zero.

按图 5 所示进行连接,电源设置为零。

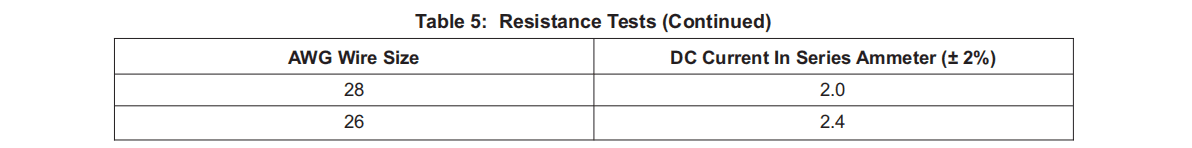

(2) Slowly increase voltage until series ammeter reads as shown in Table 5. Millivoltmeter shall not indicate more than 4 millivolts.

缓慢增加电压,直至串联电流表读数如表 5 所示。毫伏表的指示不得超过 4 毫伏。

E. Terminal Stripping Force Test

端子剥离力测试

(1) Use stripping tool as shown in Figure 6.

使用图 6 所示的剥线工具。

(a) The stripping tool jaw shall engage at 80°-100° to the axis of the terminal post.

剥线钳须与接线柱的轴线成 80-100°。

(b) Total clearance between the terminal post and stripping tool jaw shall not exceed 0.7 times the diameter of the uninsulated wire. There shall be a minimum clearance such that the there is no binding between the tool and terminal post.

接线柱与剥线钳之间的总间隙不得超过未绝缘导线直径的 0.7 倍。最小间隙应保证工具与接线柱之间无粘连。

(c) Both sides of the stripping tool jaw shall be in the same plane creating a flat surface contact with the wire on each side of the post.

剥线工具钳口的两侧应在同一平面上,在接线柱的两侧与导线形成平面接触。

(2) Apply a stripping force along the axis of the terminal post at a uniform rate of one to ten inches per minute until the maximum force as listed in Table 4 is reached or exceeded. The stripping force is defined as the force in pounds required to displace the entire wrap one connection length. If such displacement occurs before the maximum listed in Table 4 is reached, the wrap is not acceptable.

以每分钟一至十英寸的均匀速度沿接线柱轴线施加剥离力,直至达到或超过表 4 所列的最大力。剥离力的定义是将整个包覆材料移开一个连接长度所需的力,单位为磅。如果在达到表 4 所列最大值之前就发生了这种位移,则包覆材料不可接受。

F. Unwrapping Test

拆线测试

(1) Select the proper unwrap tool per Table 1.

根据表 1 选择合适的拆线工具。

(2) Place tool over terminal post and engage leading edge between the wrap end and next wrap turn. Rotate tool counterclockwise until all wire has been transferred to tool, or wire wrap is loosened and removed from post. If wire did not transfer to tool, place a round shaft of a size that will fit inside to support the wire wrap spiral during unwrapping and straightening.

将工具放在接线柱上,在缠绕端和下一个缠绕圈之间啮合前缘。逆时针旋转工具,直到所有导线都转移到工具上,或导线缠绕松开并从接线柱上取下。如果导线没有转移到工具上,则在拆卸和拉直过程中,在工具内放置一根尺寸合适的圆轴,以支撑绕线螺旋。

(3) Hold the insulated portion of the wire firmly. Rotate the tool or shaft to unwind the wire into a straight length. The wire need not be perfectly straight. Waves and deformations in the wire are acceptable. Wire shall withstand unwrap and straightening without breaking of the conductor.

紧紧抓住电线的绝缘部分。旋转工具或轴,将电线绕成直线。电线不必完全平直。导线的波浪和变形是可以接受的。导线应能承受开卷和拉直而不断裂。

G. Gas Tight Test

气密试验

(1) The test consists of exposing the wrap to aqua regia fumes, then darkening the wrap with ammonium sulfide gas. The wrapped wire connection, except for the first and last turn, shall have a gas tight area on at least 75 percent of the corners in contact with uninsulated wire. The gas tight area should appear in bright, sharp contrast with the darkened post.

试验包括将包线置于王水烟雾中,然后用硫化铵气体使包线变暗。除第一圈和最后一圈外,包覆导线连接处与未绝缘导线接触的至少 75% 的角上必须有气密区。气密区应与漆黑的柱子形成鲜明的对比。

(2) The wrap should not contact the solutions during test.

包覆材料在测试期间不得接触溶液。

(3) Suspend the wrap in a 16 x 15 milliliter test tube containing 1 to 2 milliliters of aqua regia solution (1 to 1 concentrated hydrochloric and nitric acids). Cork tube and expose wrap to fumes for 10 minutes minimum.

将包覆材料悬挂在装有 1 至 2 毫升王水溶液(1 比 1 的浓盐酸和浓硝酸)的 16 x 15 毫升试管中。用软木塞塞住试管,将包材暴露在烟雾中至少 10 分钟。

(4) Transfer wrap to another test tube of similar size containing 1 milliliter of concentrated ammonium sulfide solution. Cork tube and expose wrap to fumes until wrap turns dark. Copper and gold sulfide color should develop on exposed areas.

将包覆材料转移到另一个装有 1 毫升浓硫化铵溶液的类似大小的试管中。用软木塞塞住试管,让包覆材料暴露在烟雾中,直到包覆材料变黑。暴露区域应出现硫化铜和硫化金的颜色。

(5) Remove and dry sample wrap. Unwrap with tool that does not scratch post. Verify bright contrasting areas meet requirements stated above.

取下并擦干样品包覆材料。用不会刮伤管柱的工具揭开包装。确认明亮的对比区域符合上述要求。

H. Retest

重新测试

(1) If wire wrapped connections fail to meet test requirements repair and adjust the tool, and perform another set of tests.

如果包线连接不符合测试要求,修理和调整工具,并进行另一套测试。

(2) If a tool fails to perform properly under routine testing, the quality of previously performed work is suspect and should be inspected.

如果工具在例行测试中表现不佳,则怀疑先前所做工作的质量,应进行检查。