更换球栅阵列(BGA)零件

REPLACEMENT OF BALL GRID ARRAY (BGA) PARTS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Document D906-00016.

本主题中的数据来自波音文件 D906-00016。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum requirements.

数据为通用数据。并不涉及所有情况或特定安装。请使用此数据帮助您编写最低要求。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. BACKGROUND 背景资料

A. The repair of ball grid array components uses an automated rework system, which is a special machine to do the replacement work, because the components are too small for the usual hand procedures. The machine makes, stores and uses special programs, called profiles, for removal of the old parts and installation of the replacement parts.

球栅阵列部件的修理使用自动返工系统,这是一种特殊的机器来完成更换工作,因为部件太小,无法使用通常的手工程序。该机器制作、存储和使用特殊程序,称为配置文件,用于拆除旧零件和安装替换零件。

B. Removal and replacement profiles (temperature vs. time) are necessary for each combination of part type and printed wiring assembly (PWA).

对于每种零件类型和印刷线路组件(PWA)的组合,都必须有拆卸和更换配置文件(温度与时间的关系)。

(1) To make a profile, the part is given a sequence of temperature cycles, each cycle hotter than the last, until the part can be removed with a minimum of force. This removal profile is then also used during the part replacement and soldering procedure.

要制作一个配置文件,需要对零件进行一连串的温度循环,每个循环的温度都比上一个循环高,直到可以用最小的力拆卸零件为止。然后,在更换零件和焊接程序中也会用到这个拆卸配置文件。

(2) The rework system automatically makes and records (learns) the profiles with user-specified process parameters.

返工系统根据用户规定的工艺参数自动制作和记录(学习)配置文件。

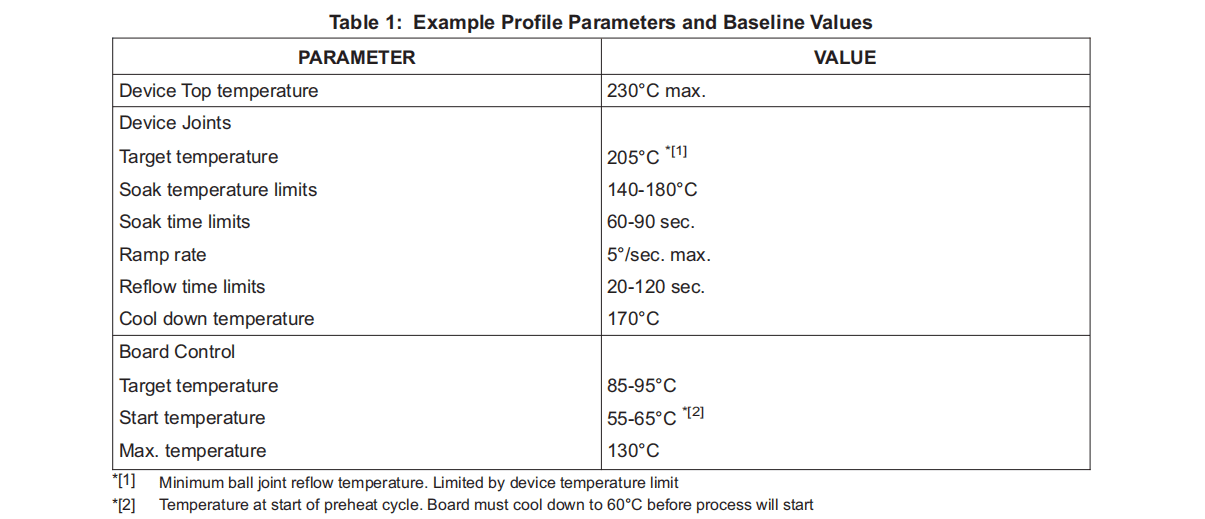

(3) The rework system can start with the baseline profile data parameters (Table 1), or with a profile it already knows to make new profiles.

返工系统可以从基准配置文件数据参数(表 1)开始,也可以从已经知道的配置文件开始制作新的配置文件。

C. Site cleaning processes are used to remove unwanted remaining solder from the location on the PWA where the old part was removed.

现场清洗工艺用于清除 PWA 上拆卸旧零件位置上不需要的剩余焊料。

(1) It is best to clean the location immediately after the part was removed, before the solder can cool. You can clean the location later, but then the solder will be less easy to remove.

拆除零件后,最好在焊料冷却前立即清理该位置。您可以稍后再清洁该位置,但这样焊料就不那么容易清除了。

(2) The cleaning procedure can be part of an automatic system function. As an alternative, you can use the usual hand procedures, such as a soldering iron and desoldering braid, to remove the unwanted solder.

清洁程序可以是自动系统功能的一部分。作为替代方法,您可以使用常用的手工程序,如烙铁和拆焊编织带来清除不需要的焊料。

(3) The recommended rework system gives automatic site cleaning processes.

推荐的返工系统提供自动现场清洁程序。

(a) A special cleaning nozzle gives a controlled vacuum to remove the unwanted solder.

特制的清洗喷嘴可提供受控真空,清除多余的焊料。

(b) Stored site cleaning profiles control the vacuum, the temperature of the PWA, and the hot air that flows through the cleaning nozzle.

储存的现场清洗配置文件可控制真空度、PWA 的温度以及流经清洗喷嘴的热空气。

(c) The site cleaning profiles are made from baseline profiles supplied with the rework system.

现场清洁配置文件是根据返工系统提供的基准曲线制作的。

3. EQUIPMENT 设备

NOTE: Equivalent substitutes can be used.

注:可使用同等替代品。

A. Rework system — Air Vac DR24C.2D, V18887

返工系统 – Air Vac DR24C.2D, V18887

The rework system must:

返工系统必须:

(1) Put parts in position with a minimum of 0.001-inch alignment precision.

以至少 0.001 英寸的对齐精度将零件就位。

(2) Learn (record) removal and replacement profiles.

学习(记录)拆卸和更换配置文件。

(3) Clean and remove unwanted solder from the PWA, if hand methods will not be used.

果不使用手工方法,则清洁和清除 PWA 上不需要的焊料。

(4) Save (store) removal and replacement profile data.

保存(存储)拆卸和更换配置文件数据。

B. Inspection system — Ersascope 3000, VD5370

检测系统 – Ersascope 3000、VD5370

The inspection system must show the outer set of ball grid array bonds with sufficient resolution to let you find out the quality of the bonds made during the repair procedure.

检测系统必须以足够的分辨率显示球栅阵列外侧的粘接,以便让您发现修理程序中的粘接质量。

4. MATERIALS 材料

A. Acetone (SOPM 20-60-01).

丙酮(SOPM 20-60-01)。

B. Isopropyl alcohol (SOPM 20-60-01)

异丙醇(SOPM 20-60-01)。

C. Flux paste — Kester TSF 6522, V75297

助焊膏 – Kester TSF 6522, V75297

D. Tape — Scotch 5413, V76381

胶带 — Scotch 5413,V76381 5.

5. REMOVAL OF BGA PARTS 拆卸 BGA 零件

A. Remove conformal coating from the top surface of the component body.

清除部件主体上表面的保形涂料。

B. Remove the parts with the rework system by this procedure:

按以下程序用返工系统拆卸零件:

(1) Run the warm-up profile if the machine’s heaters were off more than one hour.

如果机器的加热器关闭超过一小时,则运行预热程序。

(2) Select the removal profile for the type of part to be removed.

根据要拆卸的零件类型选择拆卸配置文件。

(3) Load the nozzle specified for the part to be replaced.

为要更换的零件装上规定的喷嘴。

(4) Adjust the board rails and load the printed wiring assembly.

调整电路板导轨并装入印刷线路板。

(5) If your system uses a site cleaning profile, prepare it to operate immediately after the part removal is complete (next step). Make sure the cleaning nozzle is available, the solder screen is clear, and the vacuum is on. If you do not use an automatic cleaning profile, go to Paragraph 5.B.(8).

如果您的系统使用现场清洁配置文件,请准备好在零件拆卸完成后立即运行(下一步)。确保清洁喷嘴可用、焊网清晰、真空打开。如果不使用自动清洗程序,请转至第 5.B.(8)段。

(6) Run the removal profile by the instructions supplied with the system.

按照系统随附的说明运行移除程序。

(7) Remove the part nozzle. Install the cleaning nozzle. Select the site cleaning profile.

取下零件喷嘴。安装清洁喷嘴。选择现场清洁配置文件。

CAUTION :BE CAREFUL NOT TO LIFT THE SOLDER PADS DURING THE CLEANING PROCEDURE.

注意 :在清洗程序中小心不要抬起焊盘。

(8) Run the site cleaning profile, or use an equivalent hand method, to remove the unwanted solder from the pads.

运行现场清洁配置文件,或使用等效的手工方法,清除焊盘上不需要的焊料。

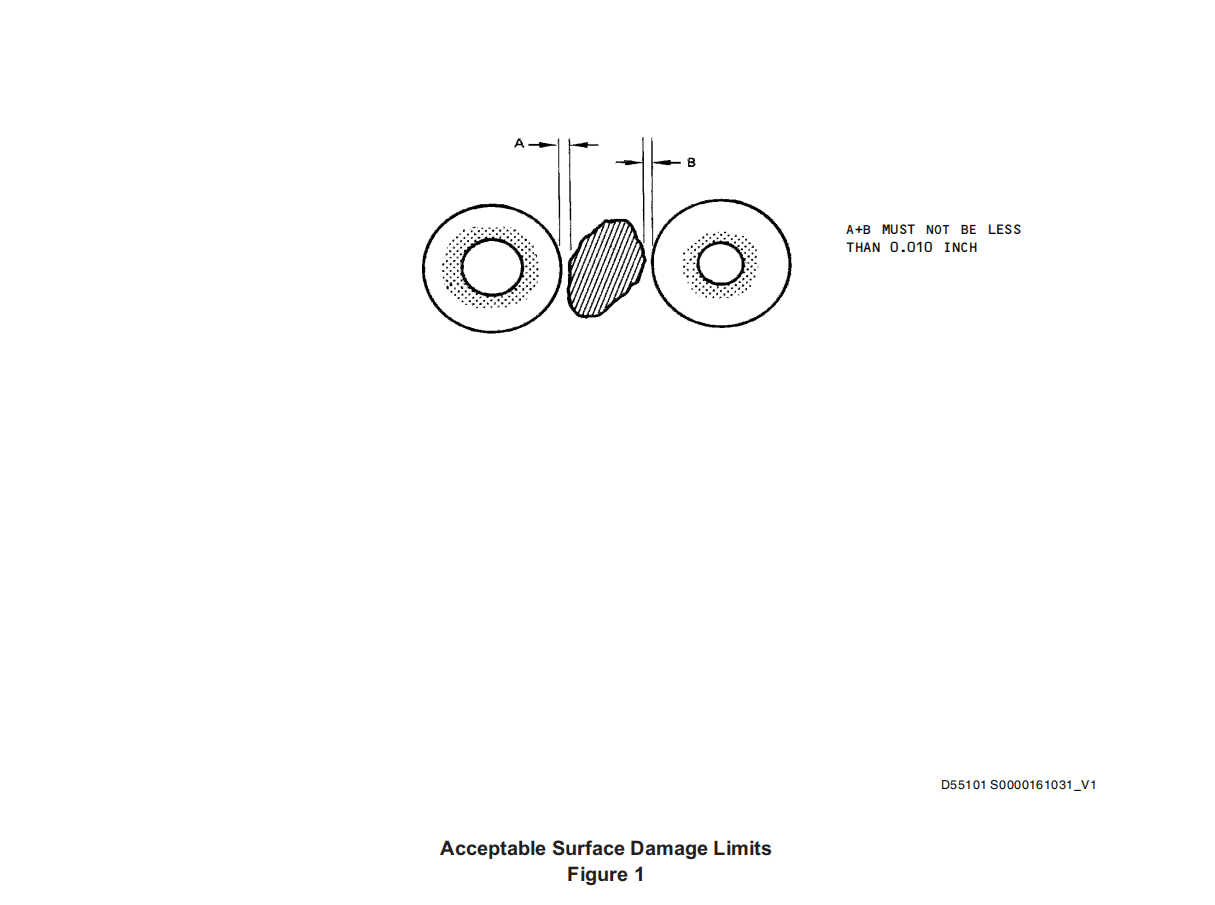

(9) Examine the circuit board for defects. The circuit board or pads must not be damaged. Reject a damaged or melted board that exposes glass fibers and decreases the spacing between conductors to less than 0.010 inch (Figure 1). Reject a board with lifted circuit pads.

检查电路板是否有缺陷。电路板或盘不得损坏。如果电路板损坏或熔化,玻璃纤维外露,导体间距小于 0.010 英寸(图 1),则报废该电路板。报废电路板上的电路盘。

(10) Clean the pads with isopropyl alcohol. Acetone is not necessary for acrylic conformal coatings, which are the only coatings used on Boeing units with BGA devices. Acetone is necessary only if the boards had polyurethane conformal coating.

用异丙醇清洗盘。丙烯酸保形涂料不需要丙酮,这是波音设备上唯一使用的 BGA 器件涂料。只有当电路板上有聚氨酯保形涂层时才需要丙酮。

6. REPLACEMENT OF BGA PARTS 更换 BGA 零件

A. Select the replacement (soldering) profile for the type part to be replaced.

选择要更换的零件类型的更换(焊接)配置文件。

B. Load the nozzle specified for the type of part to be replaced.

装上为要更换的零件类型规定的喷嘴。

C. Adjust the board rails and load the printed wiring assembly.

调整电路板导轨并装载印刷布线组件。

D. Load the replacement part and align the part over the location on the circuit board. The part is sufficiently aligned when the position error is less than approximately 25% of the pad center. The part will usually align itself when released from the nozzle as the bonds become solid.

装入替换零件并将零件对准电路板上的位置。当位置误差小于盘中心约 25% 时,零件已充分对准。从喷嘴释放时,随着粘合剂变得牢固,零件通常会自动对齐。

E. Run the replacement (soldering) profile by the instructions supplied with the system.

按照系统随附的说明运行更换(焊接)配置文件。

F. Remove the assembly. Be careful, because the unit and its components will be hot.

取下组件。要小心,因为设备及其部件会发热。

G. Examine the part installation.

检查零件安装情况。

(1) Make sure the part is correctly aligned.

确保零件正确对齐。

(2) With the inspection tool, examine the outer rows of bonds to make sure the solder bonds were made correctly. The solder bond must:

使用检查工具,检查外排焊点,确保焊点焊接正确。焊点必须 :

(a) Be shiny, not dull.

有光泽,不暗淡。

(b) Show sings of good wetting (flow) between the solder, the pads, and the PWA.

焊料、盘和 PWA 之间显示良好的润湿(流动)。

(3) If the bonds are not OK, then remove this part and install a new part. Do not use the removed part again.

如果粘接不正常,则卸下该零件并安装新零件。不要再使用拆下的零件。

(4) When you remove a part, record a new replacement profile. Refer to the vendor’s instructions to make the machine learn new profiles.

拆除零件时,请记录新的更换配置文件。请参阅供应商的说明,使机器学习新的配置文件。

(5) Compare the new profile with the last one used, to see how the replacement profile must be adjusted to correct the problem.

将新的配置文件与上次使用的配置文件进行比较,查看必须如何调整替换配置文件以纠正问题。

(6) Examine the removal location on the PWA. Make sure it is clean.

检查 PWA 上的拆卸位置。确保清洁。

(7) As necessary, revise the site cleaning profile or the replacement profile, or both, as indicated by the analysis of the unsatisfactory bond. Refer to the vendor’s instructions to make the machine learn new profiles. Then do the replacement procedure again with the revised site cleaning and replacement profiles.

如有需要,根据对不合格粘结剂的分析结果,修改现场清洁配置文件或替换配置文件,或同时执行两者。参考供应商的说明,让机器学习新的配置文件。然后用修改后的现场清洁和替换配置文件再次执行替换程序。

(8) Make a note, in the repair records for the unit, of the number of BGA part replacements made before the repair was satisfactory.

在设备的修理记录中,记下在修理合格前更换 BGA 零件的次数。