通用清洗程序GENERAL CLEANING PROCEDURES

1. INTRODUCTION 介绍

A. The data in this subject comes from these Boeing Process Specifications:

本主题中的数据来自波音工艺规范:

BAC5402, Oxygen Systems

BAC5402,氧气系统

BAC5408, Vapor Degreasing

BAC5408, 蒸汽脱脂

BAC5625, Surface Treatments for Ferrous Alloys (Replaces BAC5751)

BAC5625,铁合金表面处理(取代 BAC5751)

BAC5722, Copper Plating

BAC5722,镀铜

BAC5744, Manual Cleaning (Cold Alkaline, Solvent Emulsion and Foam Cleaners)

BAC5744,手工清洁(冷碱性、溶剂乳液和泡沫清洁剂)

BAC5748, Abrasive Cleaning

BAC5748,研磨剂清洗

BAC5749, Alkaline Cleaning

BAC5749,碱性清洗

BAC5750, Solvent Cleaning

BAC5750,溶剂清洗

BAC5753, Cleaning, Descaling and Surface Preparation of Titanium and Titanium Alloys

BAC5753,钛和钛合金的清洁、除锈和表面处理

BAC5758, Cleaning, Descaling and Surface Preparation of Nickel and Cobalt Base Alloys

BAC5758,镍和钴基合金的清洗、除锈和表面处理

BAC5763, Emulsion Cleaning and Aqueous Degreasing

BAC5763,乳液清洗和水性脱脂

BAC5766, Steam Cleaning (withdrawn)

BAC5766,蒸汽清洗(已撤销)

BAC5770, Cleaning, Descaling and Surface Preparation of Copper and Copper Alloys

BAC5770,铜和铜合金的清洁、除锈和表面处理

BAC5833, Cleaning Beryllium

BAC5833,清洗铍

D6-7127, Cleaning Interiors of Commercial Transport Aircraft

D6-7127,清洁商用运输机的内饰

B. This data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

本数据为通用数据。并非适用于所有情况或特定安装。请将此数据作为帮助您制定最低标准的指南。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. GENERAL 通用

A. Some of the materials specified in these procedures can cause injury to persons if they get it on skin or in eyes. Be sure to use eye and skin protection and obey safety precautions.

如果皮肤或眼睛沾上这些程序规定的某些材料,可能会对人造成伤害。请务必使用眼睛和皮肤保护装置并遵守安全预防措施。

B. All cleaning materials to be used on oxygen or hydraulic system components must be for those systems.

用于氧气或液压系统部件的所有清洁材料必须是用于这些系统的。

C. Be careful when you clean and do related work around windows, plastics, access doors to integral fuel tanks, fuel cells or electrical components. Materials used in these areas can be damaged by the agents you use.

在窗户、塑料、整体式燃料箱的检修门、燃料电池或电气组件周围进行清洁和相关工作时要小心。您使用的药剂可能会损坏这些区域使用的材料。

D. Steam clean only the landing gear components, removed cowling or other very dirty parts that do not have electrical or electronic components or other parts that could be damaged by steam.

仅对起落架部件、拆下的整流罩或其他非常脏的部件进行蒸汽清洁,这些部件中没有电气或电子元件或其他可能被蒸汽损坏的零件。

E. Types of dirt you could find:

可能发现的污垢类型:

(1) Oils, such as hydraulic oils, lubrication oil

油类,如液压油、润滑油

(2) Semisolids, such as greases, heavy rust preventives

半固体,如油脂、重防锈剂

(3) Solids, such as mud, carbonized oils, corrosion products.

固体,如泥浆、碳化油、腐蚀产物。

3. VAPOR DEGREASING 蒸汽脱脂

WARNING :TRICHLOROETHYLENE IS TOXIC AND A MILD ANESTHETIC. AVOID PROLONGED OR REPEATED CONTACT WITH THE SKIN OR BREATHING OF SOLVENT VAPOR. FULL FACE RESPIRATORY EQUIPMENT AND PLASTIC OR RUBBER GLOVES AND APRONS MUST BE WORN WHEN MANUALLY FLUSHING PARTS EITHER EXTERNALLY OR INTERNALLY WITH LIQUID SOLVENT.

警告:三氯乙烯有毒,是一种温和的麻醉剂。避免长时间或反复接触皮肤或吸入溶剂蒸汽。用液态溶剂手动冲洗外部或内部零件时,必须穿戴全罩式呼吸设备、塑料或橡胶手套和围裙。

WARNING :VAPOR DEGREASING OF OXYGEN AND HYDRAULIC TUBING ASSEMBLIES MUST BE DONE CAREFULLY TO PREVENT INJURY TO PERSONS OR DAMAGE TO PARTS. BE SURE TO REFER TO LOCAL REGULATIONS WHICH COULD CONTROL THE RELEASE OF VAPORS.

警告 :氧气和液压管组件的蒸汽脱脂操作必须小心谨慎,以防伤人或损坏零件。请务必参考当地有关控制蒸汽释放的规定。

CAUTION :DO NOT VAPOR DEGREASE TITANIUM OR TITANIUM ALLOY PARTS IF THEY WILL BE IN TEMPERATURES OF 550°F OR HOTTER DURING SUBSEQUENT WORK OR ON THE AIRPLANE.

注意 :如果钛或钛合金零件在随后的工作中或在飞机上将处于 550°F 或更高的温度下,请勿对其进行脱脂处理。

A. General

通用

NOTE: Aqueous degreasing as specified in BAC5763, Type 2 can be used as an option to this procedure, but not on honeycomb core.

注:BAC5763 第 2 类规定的水性脱脂可作为本程序的选项,但不适用于蜂窝芯。

(1) Put the degreaser in a well ventilated room and away from drafts that could go over the top of the unit. Keep it covered when not used.

将脱脂剂放在通风良好的房间内,避免气流进入设备顶部。不用时盖上盖子。

(2) Water in the degreaser causes malfunctions and also causes trichloroethylene to decompose. Do not try to degrease wet parts. Do not let water condense on the cooling coils.

除油剂中的水会导致故障,并使三氯乙烯分解。不要尝试给潮湿的零件除油。不要让水在冷却线圈上凝结。

(3) When nonmetallic spacers or holders are specified, use nylon, polyethylene or other material that will not become soft or melt in trichloroethylene. Do not use wood, cloth, rope or equivalent materials.

如果规定的是非金属垫片或支架,应使用尼龙、聚乙烯或其他在三氯乙烯中不会变软或熔化的材料。不得使用木材、布、绳索或类似材料。

(4) Use racks that drain quickly and fully. Stay away from thick, heavy racks that could drain away or soak up heat, or which could push away the vapor when the racks are lowered.

使用排水迅速而充分的架子。避免使用厚重的架子,因为它们会吸走或吸收热量,或在放下架子时会推走蒸汽。

(5) After degreasing, parts must have no visible oil, grease, or pockets of solvent.

脱脂后,零件上不得有可见的油、油脂或溶剂袋。

(6) Heat the unit slowly until the liquid starts to boil in the sump.

缓慢加热设备,直至底盘中的液体开始沸腾。

(7) Keep the vapor level at approximately 2/3 of the height of cooling coils or condensing area.

保持蒸汽水平约为冷却盘管或冷凝区高度的 2/3。

(8) Control the temperature of the water at the exit of the cooling coils and cooling jacket at 90-120°F. Do not let the water temperature be low enough to cause moisture to condense on any part of cooling jacket where it can come into the degreaser.

将冷却盘管和冷却套出口处的水温控制在 90-120°F。不要让水温低到足以导致湿气在冷却夹套的任何零件上凝结而进入除油器。

(9) Do not put too much work in the degreaser.

不要在脱脂剂中投入过多的工作。

(10) Monitor the water separator for satisfactory operation. Drain if necessary.

监控水分离器的运行是否令人满意。必要时排水。

(11) If your degreaser has extra heater units to let you clean large metal parts, turn the units on one minute before you put the part in the vapor zone and turn them off immediately after the work is completely in the vapor and the vapor level comes back up.

如果您的脱脂剂有额外的加热器装置,可以让您清洗大型金属零件,请在将零件放入蒸气区前一分钟打开加热器装置,并在工件完全进入蒸气区且蒸气液面回升后立即关闭加热器装置。

(12) Limitations for EnSolv-5408:

EnSolv-5408 的限制:

(a) The total cumulative exposure must not be more than 15 minutes on these surfaces:

在这些表面上的总累积暴露时间不得超过 15 分钟:

1) Conversion coated

转换涂层

2) Anodized

阳极氧化

3) Cadmium plate

镀镉

4) Primer

底漆

5) Paint

油漆

(b) You can use EnSolv-5408 on these surfaces:

EnSolv-5408 可用于以下表面:

1) BMS 10-11, Type 1 primer

BMS 10-11,1 类底漆

2) BMS 10-20, Type 2 coating

BMS 10-20,2 类涂层

3) BMS 10-79, Type 3 primer

BMS 10-79,3 类底漆

4) BMS 10-79 Type 2 primer and BMS 10-60, Type 2 enamel

BMS 10-79,2 类底漆和 BMS 10-60,2 类瓷漆

5) BMS 10-79, Type 3 primer and BMS 10-100 coating

BMS 10-79,3 类底漆和 BMS 10-100 涂料

6) BMS 10-11, Type 1, Grade A primer and BMS 10-11, Type 2, Grade D enamel

BMS 10-11,1 类 A 级底漆和 BMS 10-11,2 类 D 级瓷漆

(c) Do not use EnSolv-5408 on oxygen system components or parts that contain sealants or adhesives.

不要将 EnSolv-5408 用于含密封剂或粘合剂的氧气系统部件或零件。

(d) Do not use Ensolv-5408 on unsealed anodize.

请勿将 Ensolv-5408 用于未密封的阳极氧化处理剂中。

(e) You can use EnSolv-Spec 490 stabilizer.

可使用 EnSolv-Spec 490 稳定剂。

(f) The acid acceptance tests of EnSolv-5408 must be done as specified by the EnSolv-5408 acid acceptance procedures. Discard the solvent when the acid acceptance value decreases below 0.1 weight percent sodium hydroxide.

EnSolv-5408 的酸验收测试必须按照 EnSolv-5408 酸验收程序的规定进行。当酸度验收值降至 0.1 重量百分比氢氧化钠以下时,丢弃溶剂。

B. Materials

材料

(1) Chlorinated solvents (SOPM 20-60-01)

氯化溶剂(SOPM 20-60-01)

(a) Tetrachloroethylene (Perchloroethylene), Technical, O-T-236

四氯乙烯(全氯乙烯),工业级,O-T-236

(b) 1,1,1-Trichloroethane (Methyl Chloroform), MIL-T-81533

1,1,1-三氯乙烷(甲基氯仿),MIL-T-81533

(c) Trichloroethylene, BMS 11-6 Types 1 and 2

三氯乙烯,BMS 11-6 类型 1 和 2

(2) Ensolv-5408, V0S8S8

(3) Ensolv-Spec 490, V0S8S8

C. Procedure

程序

(1) Put the parts in the rack to let the solvent easily drain from the parts.

将零件放在架子上,使溶剂容易从零件中流出。

(2) Lower the work into the degreaser slowly, not more than 12 feet per minute. If your equipment cannot move this slowly, use the slowest rate possible, because faster rates will cause more vapor to be released into the atmosphere. Also, refer to local regulations which could control the release of such vapors.

将工件缓慢放入脱脂剂中,每分钟不超过 12 英尺。如果您的设备无法如此缓慢地移动,请尽可能使用最慢的速度,因为较快的速度会导致更多的蒸汽释放到大气中。此外,请参考当地有关控制此类蒸汽释放的规定。

(3) For light dirt on parts use the vapor method as follows:

对于零件上的轻微污垢,使用蒸汽法如下:

(a) Lower parts into the vapor. Be sure to refer to local regulations which could control the release of the vapor.

将零件放入蒸汽中。请务必参考当地可能控制蒸汽释放的法规。

NOTE: If your degreaser has only the vapor phase, the parts must be removed, cooled, and run through again until clean.

注:如果脱脂剂只有气相,则必须卸下零件,冷却后再次清洗,直到干净为止。

(b) Hold the work in the vapor until no more solvent condenses on the parts. To remove pockets of solvent, put the parts or the rack at an angle.

将工件保持在蒸汽中,直到零件上不再有溶剂凝结。要清除溶剂袋,可将零件或机架倾斜放置。

(意思是如果零件有凹槽,凹槽中的溶剂无法排出,就倾斜放置)

(c) Slowly remove the parts from the degreaser. Let the liquid drain from the parts. Be sure to refer to local regulations which could control the release of the vapors.

从脱脂剂中慢慢取出零件。让液体从零件上流出。请务必参考当地可能控制蒸汽释放的法规。

(d) Put the parts through the procedure again if cleaning is not satisfactory. Let the parts cool to room temperature before you clean them again.

如果清洗效果不理想,则再次对零件进行上述程序。让零件冷却到室温后再清洗。

(4) For heavy dirt or dirt that dissolves slowly, use this warm liquid-vapor method:

对于较重的污垢或溶解较慢的污垢,可使用温液体-蒸汽法:

(a) Hold parts in warm liquid (condensate) until some of the dirt becomes soft or comes off.

将零件放在温液体(冷凝水)中,直到部分污垢变软或脱落。

(b) Move the parts to the vapor phase and do Paragraph 3.C.(3)(b), Paragraph 3.C.(3)(c) and Paragraph 3.C.(3)(d) above. Keep the parts below the vapor line for best results.

将零件移至汽相,然后执行上文第 3.C.(3)(b)段、第 3.C.(3)(c)段和第 3.C.(3)(d)段。为达到最佳效果,请将零件放在蒸汽线以下。

(5) For parts with heavy dirt or dirt that does not dissolve, use this vapor-flush-vapor method:

对于污垢较重或污垢不溶解的零件,可采用这种蒸汽-绒毛-蒸汽法:

(a) Hold the work in the vapor until no more solvent condenses on the parts.

将工件置于蒸汽中,直至零件上不再有溶剂凝结。

(b) Flush dirt away with clean liquid solvent. Do not use solvent directly from the boiling sump. Keep nozzle and parts at least 6 inches below vapor line. Point the nozzle downward onto the parts.

用干净的液体溶剂将污垢冲走。不要直接使用沸腾槽中的溶剂。将喷嘴和零件保持在蒸汽线以下至少 6 英寸处。将喷嘴朝下对准零件。

(c) Move the parts to the vapor phase and do Paragraph 3.C.(3)(b), Paragraph 3.C.(3)(c) and Paragraph 3.C.(3)(d) above.

将零件移至气相,然后执行上述第 3.C.(3)(b)、第 3.C.(3)(c)和第 3.C.(3)(d)段。

D. Oxygen System Components

氧气系统组件

(1) Fittings and Protective Metal Caps and Plugs

接头及保护性金属帽和塞子

(a) Put the fittings in the vapor or liquid phase of the degreaser for a minimum of 12 minutes. Maximum descent rate is 12 ft/min. If your equipment cannot move this slowly, use the slowest rate possible, because faster rates will cause more vapor to be released into the atmosphere. Also, refer to local regulations which could control the release of such vapors.

将接头置于脱脂剂的气相或液相中至少 12 分钟。最大下降速度为 12 英尺/分钟。如果您的设备不能如此缓慢地移动,请尽可能使用最慢的速度,因为较快的速度会导致更多的蒸汽释放到大气中。此外,请参考当地可能控制此类蒸汽释放的法规。

(b) While the parts are in the vapor phase, fully wash all fittings with a pressurized stream of chlorinated solvent.

当零件处于蒸汽阶段时,用加压的氯化溶剂流充分清洗所有接头。

(c) Put the parts at an angle to let pockets of entrapped solvent drain out.

将零件倾斜放置,让夹带的溶剂排出。

(d) Slowly remove the parts from the degreaser. Be sure to refer to local regulations which could control the release of the vapors.

从脱脂剂中缓慢取出零件。务必参考当地可能控制蒸汽释放的法规。

(e) Let the parts drain. Put the parts or the basket at an angle to help. Do not use compressed air or gas to remove the solvent.

让零件沥干。将零件或篮子倾斜放置以帮助排出。不要使用压缩空气或气体清除溶剂。

(f) Examine the cleaned parts to make sure they are clean. If necessary, clean them again. Let the parts cool to room temperature before you do the procedure again. Use cotton gloves on cleaned fittings and protective metal caps.

检查已清洗的零件,确保它们是干净的。如有必要,可再次清洗。让零件冷却至室温后再执行一次程序。在清洗接头和保护性金属帽时要戴上棉手套。

(g) Immediately after they are dry, give cleaned parts protection as specified in SOPM 20-70-01.

待零件干燥后,立即按照 SOPM 20-70-01 的规定对已清洁的零件进行保护。

(2) Tube Assemblies

管组件

CAUTION :DO NOT PUT THE ASSEMBLIES IN THE BOILING CHAMBER OF THE DEGREASER.

注意 :不要将组件放入脱脂剂的沸腾室中。

(a) Put the tube assemblies in the liquid phase of the degreaser for a minimum of 10 minutes. Maximum descent rate is 12 ft/min. If your equipment cannot move this slowly, use the slowest rate possible, because faster rates will cause more vapor to be released into the atmosphere. Also, refer to local regulations which could control the release of such vapors.

将管道组件放入脱脂剂的液相中至少 10 分钟。最大下降速度为 12 英尺/分钟。如果您的设备不能如此缓慢地移动,请尽可能使用最慢的速度,因为较快的速度会导致更多的蒸汽释放到大气中。此外,请参考当地可能控制此类蒸汽释放的法规。

(b) Move the basket to the vapor phase, and put the parts or the basket at an angle to drain the solvent. Let the tube assemblies stay in the vapor phase for a minimum of 5 minutes.

将篮子移到汽相处,将零件或篮子成一定角度放置,以便排出溶剂。让卡套管组件在气相中至少停留 5 分钟。

CAUTION :DO NOT USE SOLVENT FROM THE BOILING SUMP OF THE DEGREASER.

注意 :不要使用脱脂剂沸腾槽中的溶剂。

(c) With chlorinated solvent, internally flush all tube assemblies until there is a continuous flow from the other end of the tube assembly for a minimum of 1 minute. Keep parts at least 6 inches below the vapor level.

用氯化溶剂对所有管道组件进行内部冲洗,直到管道组件的另一端持续流出溶剂至少 1 分钟。保持零件至少低于蒸汽水平 6 英寸。

(d) Put the parts at an angle to drain the solvent.

将零件倾斜放置,以排出溶剂。

(e) Slowly remove the parts from the degreaser. Be sure to refer to local regulations which could control the release of the vapors.

从脱脂剂中缓慢取出零件。务必参考当地可能控制蒸汽释放的规定。

(f) Let the parts drain. Put the parts or the basket at an angle to help. Do not use compressed air or gas to remove the solvent.

让零件沥干。将零件或篮子倾斜放置,以帮助排水。不要使用压缩空气或气体清除溶剂。

(g) Examine the tubes to make sure they are clean. Clean them again if necessary.

检查管道,确保其清洁。必要时再次清洗。

(h) Immediately install protective plugs or caps to give the tube interiors protection from contamination.

立即安装保护塞或盖,以保护管道内部不受污染。

NOTE: Until the tubes are capped or plugged, use clean cotton gloves on the cleaned tubes.

注:在对管道进行封盖或堵塞之前,应使用干净的棉质手套接触清洗过的管道。

(i) Give the tubes protection and put them away with standard industry practices and the instructions in SOPM 20-44-02 and SOPM 20-70-01.

按照行业标准做法和 SOPM 20-44-02 和 SOPM 20-70-01 中的说明,对管道进行保护并将其放好。

E. Hydraulic Tube Assemblies

液压管组件

(1) Flush the tubes with liquid solvent, when necessary, to remove deposits of dirt, chips, etc. on the outer surface of the tubing. Keep nozzle and parts 6 inches below the vapor level. Do not use solvent directly from the degreaser sump.

必要时用液体溶剂冲洗管道,清除管道外表面的污垢、碎屑等。将喷嘴和零件保持在蒸汽水平面以下 6 英寸处。不要直接使用脱脂剂槽中的溶剂。

(2) For tubes 0.5 inch outside diameter or smaller, flush until there is a continuous flow from the other end of the tube for 1 minute minimum. For tubes larger than 0.5 inch outside diameter, flush until there is a continuous flow from the other end of the tube.

对于外径 0.5 英寸或更小的管子,至少冲洗 1 分钟,直到管子的另一端有持续的水流出。对于外径大于 0.5 英寸的管子,冲洗直至管子的另一端有持续的水流出。

(3) Put the parts in the warm liquid (condensate) phase for a minimum of 10 minutes.

将零件置于温液体(冷凝水)阶段至少 10 分钟。

(4) Move the basket to the vapor phase. Hold the parts in the vapor for a minimum of 5 minutes or until solvent stops condensing on parts.

将篮子移至蒸汽阶段。将零件放在蒸汽中至少 5 分钟,或直到溶剂停止在零件上凝结。

(5) Put the parts at an angle to drain the solvent.

将零件倾斜放置以排出溶剂。

(6) Slowly remove the parts from the degreaser. Be sure to refer to local regulations which could control the release of the vapor.

从脱脂剂中缓慢取出零件。务必参考当地可能控制蒸汽释放的规定。

(7) Let the parts drain. Put the parts on the basket at an angle to help. Do not use compressed air or gas to remove the solvent.

让零件沥干。将零件以一定角度放在篮子上,以帮助排出。不要使用压缩空气或气体清除溶剂。

(8) If necessary, clean the parts again. Let the parts cool to room temperature before you do the procedure again.

如有必要,再次清洗零件。让零件冷却到室温后再执行一次程序。

4. SOLVENT CLEANING 溶剂清洗

A. You can use this procedure to clean metals, painted surfaces and plastic parts (but not windows).

您可以使用此程序清洗金属、油漆表面和塑料零件(但不包括窗户)。

B. Methods of cleaning include manual cleaning, immersion and spray and flush.

清洗方法包括手工清洗、浸泡和喷淋冲洗。

C. Materials

材料

NOTE: Equivalent substitutes can be used.

注:可使用同等替代品。

(1) Acetone, technical (SOPM 20-60-01)

工业级丙酮 (SOPM 20-60-01)

(2) BIOACT 108 Precision Cleaner, Petroferm, 3938 Porett Drive, Gurnee, Illinois 60031

BIOACT 108 精密清洁剂,Petroferm, 3938 Porett Drive, Gurnee, Illinois 60031

(3) Butyl alcohol (SOPM 20-60-01)

丁醇(SOPM 20-60-01)

(4) Cee Bee A-916, V5K793

(5) Citra-Safe, V0K209

(6) Cleaning solvent (SOPM 20-60-01)

清洁溶剂(SOPM 20-60-01)

(a) BMS 11-7

(b) CDG-110, V0STM5

NOTE: A 1:1 mixture (by weight, +/-2%) of aliphatic naphtha and isopropyl alcohol is an acceptable substitute.

(c) CDG-211, V0STM5

NOTE: A 2:1:1 mixture (by weight, +/-2%) of aliphatic naphtha, isopropyl alcohol, and denatured ethyl alcohol is an acceptable substitute.

注:脂肪族石脑油、异丙醇和变性乙醇的 2:1:1 混合物(按重量计,+/-2%)是可接受的替代品。

(d) FCC-55, V0STM5

NOTE: A 1:1 mixture (by weight, +/-2%) of aliphatic naphtha and methyl propyl ketone is an acceptable substitute.

注:脂肪族石脑油和异丙醇的 1:1 混合物(按重量计,+/-2%)是可接受的替代品。

(7) Compound, fingerprint remover — MIL-C-15074 (SOPM 20-60-01)

复合物,指纹清除剂 — MIL-C-15074 (SOPM 20-60-01)

(8) Cotton gloves, lightweight, white, knitted

轻质白色针织棉手套

(9) DBE, DBE5, DBE-5 SPG, V18873

(10) Diethylene glycol monobutyl ether (butyl carbitol), V80524

二乙二醇单丁醚(丁基卡必醇),V80524

(11) Diethylene glycol monohexyl ether (hexyl carbitol), V80524

二乙二醇单己醚(己基卡比醇),V80524

(12) Ethyl alcohol, denatured, 95% (SOPM 20-60-01)

变性乙醇,95%(SOPM 20-60-01)

(13) Ethyl 3-ethoxyproprionate, technical, V74364

3-乙氧基丙酸乙酯,工业级,V74364

(14) Ethylene diacetate, technical, V74364

二乙酸乙酯,工业品,V74364

(15) 2-Ethylhexyl acetate, technical, V74364

2-乙基己基乙酸酯,工业级,V74364

(16) Extra Solv, V0TZ07

额外溶剂,V0TZ07

(17) Fluorinated solvents

含氟溶剂

(a) Freon TES, V18873

(b) Freon TF, V18873

(c) Genesolv D, V40991

(d) Genesolv DES, V40991

(e) Trichlorotrifluoroethane — MIL-C-81302, Type 1

三氯三氟乙烷–MIL-C-81302,类型 1

(18) FO 145 Special Tee Solvent, V01490

FO 145 特殊三通溶剂,V01490

(19) Isopropyl alcohol (SOPM 20-60-01)

异丙醇(SOPM 20-60-01)

(20) Ketate, V80524

酮酸酯,V80524

(21) Methyl ethyl ketone (MEK) (SOPM 20-60-01)

甲基乙基酮(MEK)(SOPM 20-60-01)

(22) Methyl isobutyl ketone (MIBK) (SOPM 20-60-01)

甲基异丁基酮(MIBK)(SOPM 20-60-01)

(23) Methyl propyl ketone (MPK) (SOPM 20-60-01)

甲基丙基酮(MPK)(SOPM 20-60-01)

(24) M.O.K., technical, V19630 or V36701

工业级 M.O.K.,V19630 或 V36701

(25) Naphtha/petroleum distillates

石脑油/石油馏分

(a) C-1470 solvent blend, V29672 or V86024

C-1470 混合溶剂,V29672 或 V86024

(b) P-D-680, Type 1, 2 or 3 (SOPM 20-60-01)

P-D-680, 类型 1、2 或 3 (SOPM 20-60-01)

(c) Aliphatic naphtha (SOPM 20-60-01)

脂肪族石脑油(SOPM 20-60-01)

(d) Mineral spirits (SOPM 20-60-01)

矿油精(SOPM 20-60-01)

(26) n-Octanol, technical

工业用正辛醇

(27) 1, 2-Propylene glycol

1, 2-丙二醇

(28) Soft-bristle fiber brush — Bay Bristle, V96383

软毛纤维刷 — Bay Bristle, V96383

(29) Tetrachloroethylene (perchloroethylene) (SOPM 20-60-01)

四氯乙烯(全氯乙烯)(SOPM 20-60-01)

(30) Toluene (SOPM 20-60-01)

甲苯(SOPM 20-60-01)

(31) 1,1,1 – Trichloroethane (methyl chloroform) (SOPM 20-60-01)

1,1,1-三氯乙烷(甲基氯仿)(SOPM 20-60-01)

(32) Trichloroethylene (SOPM 20-60-01)

三氯乙烯(SOPM 20-60-01)

(33) Wedco 3500, V0VMT4

(34) Winsol solvent blend No. 1 or SR-350, V62976

Winsol 1 号混合溶剂或 SR-350,V62976

(35) Wipers — BMS 15-5, Class A and B

抹布–BMS 15-5,A 级和 B 级

(36) Wipers, oil absorbing

吸油抹布

(a) P-110 pads, Powersorb Universal Sorbent, V76381

P-110 盘,Powersorb 通用吸油剂,V76381

(b) TO151 pads, Powersorb General Purpose Oil Sorbent, V76381

TO151 盘,Powersorb 通用油类吸附剂,V76381

(37) Xylene (SOPM 20-60-01)

二甲苯(SOPM 20-60-01)

D. General

通用

WARNING :WITHOUT PRECAUTIONS, THE CHEMICALS USED IN SOLVENT CLEANING CAN BE DANGEROUS TO PERSONS AND EQUIPMENT.

警告 :如不采取预防措施,溶剂清洗中使用的化学品可能对人员和设备造成危险。

CAUTION :DO NOT USE CHLORINATED SOLVENTS ON TITANIUM AND TITANIUM ALLOYS WHICH WILL BE IN TEMPERATURES OF 600°F (316°C) OR HOTTER DURING SUBSEQUENT PROCEDURES OR ON THE AIRPLANE. DO NOT LET SOLVENTS STAY ON THERMOPLASTIC MATERIALS. MOST THERMOPLASTICS (ACRYLIC, POLYCARBONATE, POLYSULFONE, ABS, ETC.) ARE SOLVENT SENSITIVE. USE ONLY SOLVENTS AND CLEANERS SHOWN IN TABLE 2 WHEN YOU CLEAN THERMOPLASTIC MATERIALS. DO NOT USE SOLVENTS ON COMPOSITE SURFACES THAT HAVE ONLY STATIC CONDITIONER FILLER 28-C-1 ON THEM. DO NOT LET SOLVENT FLOW INTO FAYING SURFACES OR BONDED JOINTS. DO NOT LET SOLVENT TOUCH CONTROL CABLES OR LUBRICATED SURFACES.

注意 :在随后的程序中或在飞机上,不要在温度为 600°F (316°C) 或更高的钛和钛合金上使用氯化溶剂。不要让溶剂残留在热塑材料上。大多数热塑性塑料(丙烯酸、聚碳酸酯、聚砜、ABS 等)对溶剂敏感。清洁热塑材料时,只能使用表 2 所示的溶剂和清洁剂。不要在只有静电调节填充剂 28-c-1 的复合材料表面上使用溶剂。不要让溶剂流入粘合表面或粘合接头。不要让溶剂接触控制电缆或润滑表面。

(1) Solvent cleaning will not remove such contamination as scale, corrosion products, paint and stains.

溶剂清洗不能清除污垢、腐蚀产物、油漆和污渍等污染物。

(2) Use clean gloves or suitable hooks or tongs on cleaned parts or surfaces.

在清洗过的零件或表面上使用干净的手套或合适的钩子或钳子。

CAUTION :DO NOT CONTAMINATE OR DAMAGE OTHER PARTS OR SURFACES WHEN YOU USE COMPRESSED AIR.

注意 :使用压缩空气时,不要污染或损坏其他零件或表面。

(3) Keep solvent out of faying surfaces, crevices, cracks, or other confined spaces. If solvent goes in, remove it with compressed air or hot air oven. Compressed air used to dry parts must be filtered to remove moisture, oil and solid particles.

让溶剂远离粘合表面、缝隙、裂缝或其他密闭空间。如果溶剂进入,用压缩空气或热风炉清除。用于干燥零件的压缩空气必须经过过滤,以去除湿气、油和固体颗粒。

(4) Paints, plastics, polymeric materials, adhesives, and equivalent materials must be fully cured before cleaning.

油漆、塑料、聚合材料、粘合剂和类似材料必须完全固化后才能清洗。

E. General cleaning

通用清洁

NOTE: This method is used to remove dirt when subsequent cleaning is specified by overhaul instructions. Use this method when preclean or precleaning is specified.

注: 在大修说明规定的后续清洁时,使用此方法清除污垢。在规定的预清洁或预清洗时使用此方法。

(1) Remove loose dirt, unwanted grease, or oil by wiping, scrubbing, or other physical means. Oil absorbing wipers will help oil removal without a solvent. Be careful not to smear the dirt over a larger area than necessary.

通过擦拭、擦洗或其他物理方法清除松散的污垢、不需要的油脂或油。吸油抹布有助于在不使用溶剂的情况下清除油污。注意不要将污垢涂抹在超过必要面积的地方。

(2) Get the applicable solvent for the material or coating to be cleaned. The solvent can be used again as necessary to remove the contamination.

为要清洗的材料或涂层准备适用的溶剂。必要时可再次使用溶剂清除污染物。

(3) Clean the surface by one or more of these three steps. Repeat as necessary to remove the dirt.

用上述三个步骤中的一个或多个步骤清洁表面。必要时可重复进行,以清除污垢。

(a) Wet the surface with solvent and wipe or scrub with a wiper, sponge, or brush.

用溶剂打湿表面,然后用抹布、海绵或刷子擦拭或刷洗。

(b) Put the part in solvent and let the dirt soak. If necessary, wipe or scrub the surface with a wiper, sponge, or brush.

将零件放入溶剂中,让污垢浸泡。如有必要,用抹布、海绵或刷子擦拭或刷洗表面。

(c) Spray or flow the solvent on the surface to help in cleaning or rinsing.

在表面上喷洒或流动溶剂,以帮助清洁或冲洗。

(4) Rinse the surface with clean solvent and clean wipers.

用干净的溶剂和干净的抹布冲洗表面。

(5) Wipe up excess solvent and let the surface drain dry.

擦去多余的溶剂,让表面晾干。

F. Final Cleaning

最后清洗

NOTE: This method is used when a thoroughly cleaned surface is necessary for subsequent procedures such as painting, adhesive bonding.

注:此方法用于需要彻底清洁的表面,以便进行后续程序,如喷漆、粘接。

(1) If necessary, clean as specified in Paragraph 4.E.

如有必要,按第 4.E 段规定的方法清洁。

(2) Get the applicable solvent for the material or coating to be cleaned. Mixtures of the applicable solvents can be used. Do not final clean with solvents which have more than 50 ppm of non-volatile solids.

为要清洗的材料或涂层获取适用的溶剂。可使用适用溶剂的混合物。不要使用非挥发性固体含量超过 50 ppm 的溶剂进行最终清洁。

(3) Soak a clean wiper with solvent. Apply the solvent to the wiper; do not put the wiper into the solvent container.

用溶剂浸泡干净的抹布。将溶剂涂抹在抹布上;不要将抹布放入溶剂容器中。

(4) Rub the surface with the solvent soaked wiper. Immediately wipe dry. Do not let the solvent evaporate from the surface.

用浸过溶剂的抹布擦拭表面。立即擦干。不要让溶剂从表面挥发。

(5) Do Paragraph 4.F.(4) again until the wiper shows no dirt. Frequently change dirty wipers for clean ones.

再次执行第 4.F.(4)段,直到抹布上没有污垢为止。经常把脏抹布更换成干净的。

(6) Examine for complete cleanliness as follows:

按以下步骤检查是否完全清洁:

(a) With reflected light, examine the surface. The surface must have no dirt, corrosion, oil, grease or unwanted matter.

用反射光检查表面。表面不得有污垢、腐蚀、油、油脂或不需要的物质。

(b) When wiped with a clean, dry, white or light-colored lint-free wiper, the parts must not put contamination on the wiper or change its color.

用干净、干燥、白色或浅色的无绒毛抹布擦拭时,零件不得沾染抹布上的污物或改变其颜色。

(7) Clean the parts again by this procedure, if necessary.

如有必要,可按此程序再次清洁零件。

(8) Give the cleaned surfaces protection from dust, fingerprints, or other contamination.

保护已清洁的表面,防止灰尘、指纹或其他污染。

G. Spot Cleaning on Solid Surfaces

固体表面的污点清洁

(1) Remove loose dirt, grease, or oil with a clean wiper. Be careful not to make the dirty area larger or rub the contamination into the surface.

用干净的抹布清除松散的污垢、油脂或油。注意不要扩大脏污区域或将污染物擦入表面。

(2) Use a clean wiper wet with solvent. Make it into a pad to control the area it will touch.

使用沾有溶剂的干净抹布。将其做成盘状,以控制其接触的面积。

(3) Rub this wet pad around the outside edge of the spot and gradually go into the center. Change to a clean surface of the wiper, or to a clean wiper, as the dirt is collected.

用这块湿盘在污点外缘擦拭,然后逐渐进入中心。随着污垢的收集,换上干净的抹布表面,或者换上干净的抹布。

(4) Clean again until the spot is gone.

再次清洁,直到污点消失。

(5) Dry with a clean, dry wiper. Clean solvent can be permitted to dry by evaporation or with compressed air.

用干净的干抹布擦干。清洁溶剂可通过蒸发或压缩空气干燥。

H. Spot Cleaning on Fabric

织物上的污点清洁

(1) Put a clean, dry absorbent wiper under the spot on the fabric material.

在织物材料上的污点下放一块干净、干燥的吸水抹布。

(2) Let the solvent go through the fabric into the dry wiper. Change the wiper frequently to put a clean, dry surface under the spot.

让溶剂穿过织物进入干抹布。经常更换抹布,使污点处有一个干净、干燥的表面。

(3) When the stain is gone, use clean, dry wipers to dry the area. Do not rub.

当污点消失后,用干净的干抹布擦干该区域。切勿摩擦。

I. Removal of Hydraulic Fluid, Fuel, and Soils

清除液压油、燃料和泥土

NOTE: Manual alkaline cleaning as specified in Paragraph 6. can be used instead of this procedure. When paint, adhesive, sealant, or other protective finish is to be applied, this procedure must be followed by final cleaning as specified in Paragraph 4.F.

注: 可使用第 6.段规定的手工碱性清洗代替此程序。如果要涂漆、粘合剂、密封胶或其他保护性饰面,则必须按照第 4.F 段规定的最终清洁程序进行此程序。

(1) Use one of the following solvents:

使用下列溶剂之一:

CAUTION :DO NOT LET P-D-680 OR TT-N-95 SOLVENTS GET ON CONTROL CABLES OR LUBRICATED AREAS.

警告 :不要让 P-D-680 或 TT-N-95 溶剂沾到控制电缆或润滑部位。

(a) P-D-680 Type 1, 2, or 3 or TT-N-95, Type 2

P-D-680 1、2 或 3 型或 TT-N-95 2 型

CAUTION :DO NOT LET THESE TWO SOLVENTS GET ON CONTROL CABLES, LUBRICATED AREAS, ACRYLIC, PLASTIC, DECALS, OR NON SKYDROL-RESISTANT FINISHES.

警告 :切勿让这两种溶剂沾到控制电缆、润滑部位、丙烯酸树脂、塑料、贴花或非防尘饰面上。

(b) Tetrachloroethylene, or 1,1,1-trichloroethane.

四氯乙烯或 1,1,1-三氯乙烷。

(c) 40 percent ethyl alcohol in water.

40%乙醇水溶液。

NOTE: The cleaning efficiency of this alcohol-water mixture is limited. Oily contamination is removed by flushing action rather than by dissolving. A slight oily film could remain.

注意: 酒精-水混合物的清洁效率有限。油性污染物是通过冲洗作用而不是溶解作用去除的。可能会残留轻微的油膜。

(2) Soak a clean wiper with solvent and wring out excess solvent. If you use the alcohol-water mixture, the wiper must be thoroughly saturated and not wrung out. A soft-bristle brush can be used on rough surfaces, such as epoxy walkway coating.

用溶剂浸泡干净的抹布,拧出多余的溶剂。如果使用酒精和水的混合物,抹布必须完全浸透,不能拧干。软毛刷可用于粗糙表面,如环氧走道涂层。

(3) Rub the surface with the wet wiper or brush to remove the hydraulic fluid, fuel, or dirt. Do not let solvent get into faying surfaces.

用湿抹布或刷子擦拭表面,清除液压油、燃料或污垢。不要让溶剂进入粘合表面。

(4) With a clean wiper, immediately wipe dry all surfaces touched by the solvent.

用干净的抹布立即擦干溶剂接触到的所有表面。

5. FINGERPRINT REMOVAL 清除指纹

A. General

通用

(1) Use fingerprint removal compound MIL-C-15074, isopropyl alcohol, or a mixture of equal volumes of acetone and isopropyl alcohol. Oil-absorbing wipers can be used without solvent to remove most fingerprints from nonporous surfaces.

使用 MIL-C-15074 指纹清除剂、异丙醇或等量丙酮和异丙醇的混合物。不使用溶剂也可使用吸油抹布清除无孔表面上的大部分指纹。

(2) Use tongs, clean gloves, or equivalent protection on the parts.

在零件上使用钳子、干净的手套或同等保护措施。

B. Small Parts

小零件

(1) Put the parts into the solution as specified in Paragraph 5.A.(1) and shake them for 2 minutes.

将零件放入第 5.A.(1)段规定的溶液中,摇晃 2 分钟。

(2) Shake the parts in two successive clean portions of naphtha (Table 1) for 1 minute each.

连续两次将零件放入干净的石脑油(表 1)中摇晃,每次 1 分钟。

(3) Drain excess solvent.

排出多余的溶剂。

(4) Wipe parts dry with clean, dry cloth or dry them with clean, dry compressed air.

用干净的干布擦干零件,或用干净的干燥压缩空气吹干。

(5) Give the cleaned parts protection from dust, fingerprints or other contamination. Wrap if necessary.

保护清洁后的零件,防止灰尘、指纹或其他污染。必要时进行包扎。

C. Large Parts

大型零件

(1) Final clean as specified in Paragraph 4.F. with the solution specified in Paragraph 5.A.(1).

用第 5.A.(1)段规定的溶液按第 4.F.段规定进行最后清洗。

(2) Rinse at least twice with clean naphtha (Table 1).

至少用干净石脑油(表 1)冲洗两次。

6. ALKALINE CLEANING 碱性清洗

WARNING :ALKALINE CLEANING MATERIALS USUALLY REACT WITH MUCH FORCE WHEN MIXED WITH WATER. CONCENTRATED SOLUTIONS CAN BADLY BURN SKIN AND EYES. WEAR FACE SHIELDS AND PROTECTIVE CLOTHING WHEN YOU USE THESE MATERIALS. OBEY ALL SAFETY PRECAUTIONS.

警告 :碱性清洗剂与水混合时通常会发生剧烈反应。高浓度溶液会严重灼伤皮肤和眼睛。使用这些材料时,请戴上面罩并穿上防护服。遵守所有安全注意事项。

A. General

通用

(1) Alkaline cleaning is used to clean surfaces when a water-break-free surface is specified by procedures such as those which apply organic or inorganic finishes. A water-break-free surface is a surface which keeps a continuous water film for at least 30 seconds after the surface was sprayed or immersion rinsed in clean water colder than 100°F.

碱性清洗用于清洗按程序规定的无断水表面,如有机或无机饰面的表面。无断水表面是指在温度低于 100°F的清水中喷洒或浸泡冲洗表面后,至少 30 秒钟内表面仍能保持一层连续的水膜。

(2) Cleaning methods

清洁方法

(a) Method 1 — Soak cleaning – generally used for all metals. The surface action of the cleaner does most of the work, because there is not much agitation of the solution.

方法 1 — 浸泡清洗 — 通用于所有金属。清洗剂的表面作用起了大部分作用,因为溶液的搅拌作用不大。

(b) Method 2 — Spray cleaning – a good cleaning method because there is forced agitation of the solution on the surface of the part.

方法 2 — 喷雾清洗 — 这是一种很好的清洗方法,因为溶液会在零件表面强力搅拌。

(c) Method 3 — Electrolytic cleaning – preferred for cleaning metals before plating. A very good method because there is much agitation of the solution on the surface of the part.

方法 3 — 电解清洗 — 这是电镀前清洗金属的首选方法。这是一种非常好的方法,因为溶液会在零件表面进行大量搅拌。

(3) Visually examine the surfaces of the parts to make sure they do not have grease or oil. This will keep to a minimum the contamination of cleaning tanks and solutions, and make the alkaline cleaning work better. To remove oil and grease, vapor degrease, emulsion clean, manually solvent clean, or manually clean the surfaces. Be sure to fully dry the parts to prevent contamination of the alkaline cleaner with solvent.

目视检查零件表面,确保没有油脂。这样可以将清洗槽和溶液的污染降到最低,使碱性清洗效果更好。要清除油脂,可采用蒸汽脱脂、乳化液清洗、手工溶剂清洗或手工清洗表面。注意要充分擦干零件,防止碱性清洗剂被溶剂污染。

(4) Put all parts in positions or in the racks to make sure there is a good flow of solutions over all of the surfaces. Do not let parallel flat surfaces touch each other.

将所有零件摆放到位或放在架子上,确保所有表面都有良好的溶液流动。不要让平行的平面相互接触。

(5) When possible, after you use a heated solution, include a water-fog curtain above the rinse tank, to not let the solution dry on the part.

在可能的情况下,使用加热溶液后,在冲洗槽上方加一个水雾帘,以免溶液在零件上变干。

(6) If the parts are made of BMI reinforced composite, be sure to use the special Method 2 procedure in Paragraph 6.H.

如果零件由 BMI 增强复合材料制成,请务必使用第 6.H 段中的特殊方法 2 程序。

B. Materials

材料

NOTE: Equivalent substitutes can be used.

注:可使用同等替代品。

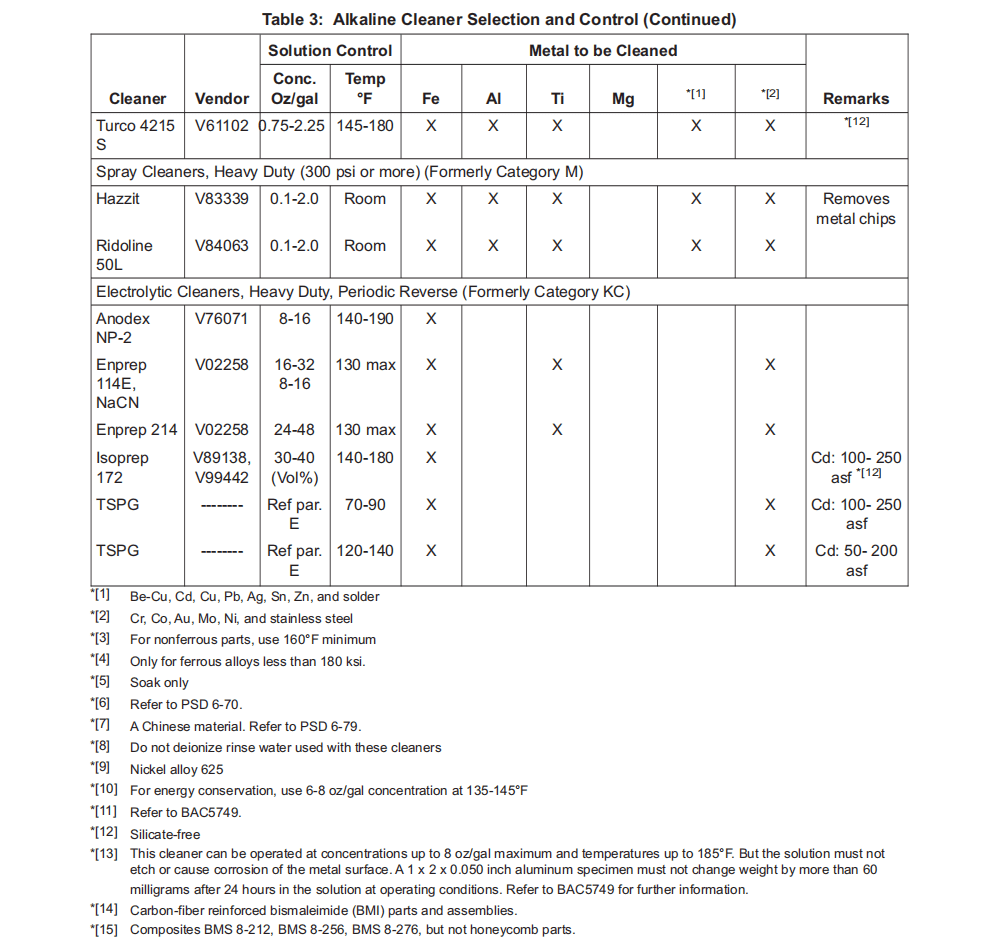

(1) Alkaline Cleaners — Refer to Table 3 for the recommended cleaners for each method.

碱性清洁剂 — 每种方法推荐的清洁剂参见表 3。

(2) Abrasive Materials

磨料

(a) Pumice grade FF

FF 级浮石

(b) Pumice detergent compound — Diversey-Wyandotte F1013, V83339

浮石洗涤剂化合物 — Diversey-Wyandotte F1013, V83339

(c) Tripoli powder

Tripoli 粉末

(3) Brushes, plater

电镀刷

(4) Cleaning pads — Scotch-Brite, Type A, I or S, V76381

清洁盘 — Scotch-Brite,A、I 或 S 型,V76381

(5) Wetting Agents

润湿剂

(a) Nacconol 90G, V87570 (Replaces Nacconol 90F)

Nacconol 90G,V87570(替代 Nacconol 90F)。

(b) Surfactant 9N9, V36701

表面活性剂 9N9,V36701

(c) Other nonionic water-soluble detergent as specified in MIL-D-16791, Type 1

MIL-D-16791,类型 1 规定的其他非离子水溶性洗涤剂

(6) Wipers — BMS 15-5, Classes A and B

抹布–BMS 15-5,A 级和 B 级

(7) Sodium chromate, technical

工业铬酸钠

C. Preparation of Compounded-Formula Cleaner Solutions

配制复合配方清洁剂溶液

NOTE: For periodic-reverse cleaners, refer to Paragraph 6.D. thru Paragraph 6.G. For caustic-soak cleaner, refer to Paragraph 6.H.

注: 对于定期反向清洁剂,请参见第 6.D 至 6.G 段;腐蚀性浸泡清洁剂,请参见第 6.H 段。

(1) For the cleaner to be used, refer to Table 3 for the concentrations and temperatures ranges.

所用清洁剂的浓度和温度范围参见表 3。

(2) Fill the tank approximately 1/2 full of cold water.

将冷水注入槽约 1/2 满。

(3) Add the compounded cleaner to the middle of the concentration range. Add the cleaners slowly and mix until they dissolve. These alkaline materials will give out heat as they dissolve.

将复合清洁剂加入浓度范围的中间值。缓慢加入清洁剂并搅拌至溶解。这些碱性材料在溶解时会放出热量。

(4) Add water to the operating level.

加水至操作水平。

(5) Heat the solution to the correct temperature range. Make analyses and adjust the solution as necessary. Mix well after you add the chemicals to the solution.

将溶液加热到正确的温度范围。进行分析并根据需要调整溶液。将化学品加入溶液后,充分混合。

(6) Mix all cleaning solutions after they are not used a long time, or after you add chemicals or water, to make sure the concentration stays constant.

在长时间不使用后,或在添加化学品或水后,混合所有清洁溶液,以确保浓度恒定。

D. Preparation of Enprep Periodic-Reverse Cleaner Solutions

配制 Enprep 周期性还原清洁剂溶液

(1) Fill the tank approximately 1/2 full of water.

将水箱注满大约 1/2 的水。

(2) For each 10 gallons of final solution, slowly apply 25 pounds of Enprep 214 cleaner solution equally across the water surface. Mix well.

对于每 10 加仑的最终溶液,缓慢地将 25 磅的 Enprep 214 清洁剂溶液平均涂抹在水面上。充分混合。

NOTE: As an alternative to Enprep 214, you can use 15 pounds of Enprep 114E and 7.5 pounds of sodium cyanide.

注: 作为 Enprep 214 的替代品,可使用 15 磅 Enprep 114E 和 7.5 磅氰化钠。

(3) Heat the solution to the correct temperature, add water to the operating level and mix well.

将溶液加热至正确温度,加水至操作水平并混合均匀。

(4) Make analyses and adjust the solution as necessary. Refer to Table 3 for the concentration and temperature ranges.

分析并根据需要调整溶液。浓度和温度范围参见表 3。

(5) When the Enprep 214 solution causes smut on the parts, dummy plate at 1 to 2 volts (in the plating polarity) overnight with a corrugated sheet of mild steel.

当 Enprep 214 溶液在零件上造成污点时,用波纹状的低碳钢板在 1 至 2 伏特(电镀极性)下假镀一夜。

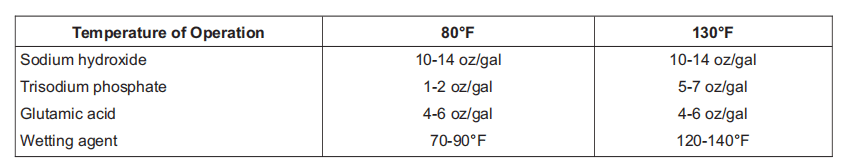

E. Preparation of Trisodium Phosphate – Glutomic (TSPG) Cleaner Solutions

制备磷酸三钠-谷氨酰胺 (TSPG) 清洗剂溶液

NOTE: This solution can be operated at 80°F or 130°F.

注: 该溶液可在 80°F 或 130°F 下操作。

(1) Fill a cleaned tank to the 3/4 level with water. Slowly add these chemicals. Mix well after you add each chemical.

将水注入清洁槽至 3/4 水位。慢慢加入这些化学品。加入每种化学品后都要充分混合。

(2) Add water to the operating level.

加水至操作水平。

(3) Make analyses and adjust the solution to be in these limits:

分析并调整溶液,使其在上述范围内:

(4) To use the solution again after it was cooled, heat the solution to the correct temperature and mix until all of the chemicals are dissolved again.

若要再次使用冷却后的溶液,可将溶液加热到正确的温度并混合,直到所有化学物质再次溶解。

F. Preparation of Isoprep 172 Cleaner Solution

配制 Isoprep 172 清洗剂溶液

(1) Fill the tank approximately ½ full of water.

将水箱注满大约 1/2 的水。

(2) For each 100 gallons of solution, add 35 gallons of Isoprep 35 liquid concentrate.

每 100 加仑溶液加入 35 加仑 Isoprep 35 浓缩液。

(3) Add water to the operating level. Stir the solution as you add the water.

加水至操作水平。加水时搅拌溶液。

(4) Heat the solution to the operating temperature.

将溶液加热至操作温度。

(5) Make analyses and adjust the solution as necessary. Refer to Table 3 for the concentration and temperature range. Control the temperature to within 10 degrees of the value you set.

进行分析并根据需要调整溶液。浓度和温度范围请参见表 3。将温度控制在所设定值的 10 度以内。

G. Preparation of Anodex Cleaner Solution

配制 Anodex 清洁剂溶液

(1) Fill the tank approximately ½ full of water.

将水箱注满大约 1/2 的水。

(2) For each gallon of final solution, add 12 ounces of Anodex NP2 cleaner and stir continuously.

每加仑最终溶液加入 12 盎司 Anodex NP2 清洁剂并不断搅拌。

(3) Add water to the operating level and mix fully.

加水至操作水平并充分混合。

(4) Make analyses and adjust the solution as necessary. Refer to Table 3 for the concentration and temperature range.

根据需要分析和调整溶液。浓度和温度范围参见表 3。

H. Preparation of Caustic-Soak Cleaner Solution

配制苛性钠浸泡清洁剂溶液

(1) Fill the tank approximately 1/2 full with water.

将槽注满大约 1/2 的水。

(2) For each gallon of final solution, apply 1 pound of sodium hydroxide over the water surface. Apply it slowly and mix well.

每加仑最终溶液在水面上涂抹 1 磅氢氧化钠。缓慢涂抹并充分混合。

(3) Heat the solution to the operating temperature. Add water to the operating level and mix well.

将溶液加热至工作温度。加水至操作水位并搅拌均匀。

(4) Add 0.1 ounce (fluid or dry) of wetting agent for each gallon of final solution. Mix well.

每加仑最终溶液加入 0.1 盎司(液体或干性)润湿剂。充分混合。

(5) Make analyses and adjust the solution as necessary. Refer to Table 3 for the concentration and temperature limits.

根据需要对溶液进行分析和调整。有关浓度和温度限制,请参见表 3。

I. Method 1 — Soak Cleaning

方法 1 — 浸泡清洗

(1) Mix all cleaning solutions again after they are not used for a long time, and after you add chemicals or water, to make sure the concentration stays constant.

在长时间不使用、添加化学品或水后,重新混合所有清洁溶液,以确保浓度恒定。

(2) Put the parts fully into the cleaning solutions. When possible, shake the parts during the procedure. You can use ultrasonic methods.

将零件完全放入清洗液中。可能的话,在程序中摇晃零件。可以使用超声波方法。

(3) Let the parts soak until the dirt is removed and the surface is water break free after the rinse. If necessary, remove dirt and ink marks with alkaline cleaner, solvents, Grade FF pumice or Tripoli powder.

让零件浸泡,直到污垢去除,冲洗后表面无水。如有必要,可使用碱性清洁剂、溶剂、FF 级浮石或Tripoli粉清除污垢和墨迹。

J. Method 2 — Spray Cleaning

方法 2 — 喷雾清洁

NOTE: This method is not to be used on magnesium parts.

注:此方法不适用于镁质零件。

(1) Light Duty

轻度脏污

(a) Metals

金属

1) Spray clean until the contamination is removed and the surface is water-break-free after the rinse.

喷淋清洗,直至污染物被清除,且表面在冲洗后无水渍。

2) Keep a constant flow of solution at 10-80 psi through a minimum of 90 percent of the nozzles at all times.

至少 90% 的喷嘴始终保持 10-80 psi 的恒定溶液流量。

(b) BMI composite parts and assemblies

BMI 复合零件和组件

1) Use ALK-660 cleaner as indicated in Table 3.

按照表 3 中的说明使用 ALK-660 清洁剂。

2) Spray the solution on the parts and let it soak approximately 5 minutes. If necessary, use plater brushes, Scotch-Brite pads or BMS 15-5 wipers and apply more cleaner. Do not let the cleaner dry on the surfaces or collect in pockets.

将溶液喷洒在零件上,让其浸泡约 5 分钟。如有必要,使用电镀刷、Scotch-Brite 盘或 BMS 15-5 抹布,并涂抹更多的清洁剂。不要让清洁剂在表面上变干或积聚成袋。

3) Fully rinse as shown in paragraph (9)(b) below.

如下文第 (9)(b) 段所示,充分冲洗。

4) Clean and rinse again as necessary until the contamination is gone from the surfaces.

根据需要再次清洁和冲洗,直到表面上的污染物消失为止。

5) Keep a constant flow of solution at 10-80 psi through a minimum of 90 percent of the nozzles at all times.

始终保持 10-80 psi 的恒定溶液流通过至少 90%的喷嘴。

(c) Epoxy composite parts

环氧树脂复合零件

1) Spray the solution on the parts and let it soak approximately 1-5 minutes. If necessary, use plater brushes, Scotch-Brite pads or BMS 15-5 wipers and apply more cleaner. Do not let the cleaner dry on the surfaces or collect in pockets.

将溶液喷洒在零件上,让其浸泡约 1-5 分钟。如有必要,使用电镀刷、Scotch-Brite 盘或 BMS 15-5 抹布,并涂抹更多的清洁剂。不要让清洁剂在表面上变干或聚集成袋。

2) Be sure to clean along rows of fastener holes on each side of the part to remove such unwanted matter as chips and drill lubricant from the holes.

确保沿着零件两侧的紧固件孔进行清洁,以清除孔中的碎屑和钻孔润滑剂等不需要的物质。

(2) High pressure

高压

(a) Adjust the nozzle pressure to 300-400 psi.

将喷嘴压力调至 300-400 psi。

(b) Spray on the solution and then the rinse water, but do not let the part surfaces stay in the spray for more than 10 seconds at a time.

先喷溶液,再喷冲洗水,但每次不要让零件表面在喷液中停留超过 10 秒钟。

(c) Spray rinse at line pressure.

以管路压力喷淋冲洗水。

(d) Visually examine the parts to make sure all metal chips and other solid particles are gone. Clean again if necessary.

目测检查零件,确保所有金属屑和其他固体颗粒都已清除。必要时再次清洗。

K. Method 3 — Electrolytic Cleaning

方法 3 – 电解清洗

NOTE: This method is preferred for parts which are to be subsequently plated.

注:对于随后要电镀的零件,最好采用此方法。

(1) Make electrical connections to the parts. Use a sufficiently large contact area to let the current flow without local heating or metal damage.

对零件进行电气连接。使用足够大的接触面积,让电流流动而不会造成局部发热或金属损坏。

(2) Make your selection of cleaner, prepare the solution as specified in Paragraph 6.B. above, and clean the parts as specified in Paragraph 6.K.(3) and on which follow.

选择清洁剂,按照上文第 6.B 段的规定配制溶液,并按照第 6.K.(3)段和下文的规定清洁零件。

(3) Enprep periodic-reverse-clean procedure for low alloy steel, chromium, cobalt, molybdenum, and titanium.

低合金钢、铬、钴、钼和钛的 Enprep 定期反向清洁程序。

(a) Put the parts in the solution. Start cathodic for 10 to 15 seconds then switch to anodic for 15 to 20 seconds. Use approximately 25-100 amps for each square foot, at 6 to 9 volts.

将零件放入溶液中。开始阴极清洗 10 至 15 秒,然后转为阳极清洗 15 至 20 秒。每平方英尺大约使用 25-100 安培,电压为 6 至 9 伏。

(b) Continue the periodic reverse cleaning for 5 to 10 minutes or until descaled and water break-free surface is obtained. You can use Scotch-Brite pads or pumice or Tripoli powder to help remove the dirt, but this must be followed by periodic reverse cleaning.

继续定期反向清洗 5 至 10 分钟,直至表面除垢、无水渍。您可以使用 Scotch-Brite 盘或浮石粉或Tripoli粉帮助清除污垢,但随后必须定期反向清洁。

CAUTION :ALWAYS END WITH ANODIC CLEANING.

注意:始终以阳极清洗结束。

(c) Switch to anodic cleaning at 2.5 to 5.0 volts for 2 to 5 minutes.

转为阳极清洗,电压为 2.5 至 5.0 伏,时间为 2 至 5 分钟。

(4) Enprep periodic-reverse-clean procedure for nickel

镍的 Enprep 定期反向清洁程序

(a) If the surfaces have smut, anodically clean for 5 minutes maximum at 30-75 amps for each square foot. Then switch to cathodic for 3 seconds at 25-75 amps for each square foot. Then switch back to anodic for 10-15 seconds at the same current. Do not use voltage control.

如果表面有污垢,每平方英尺用 30-75 安培阳极清洗最多 5 分钟。然后转为用每平方英尺 25-75 安培阴极清洗 3 秒钟。然后以相同的电流转回阳极清洗 10-15 秒。不要使用电压控制。

(b) Continue this as necessary. Then remove loose dirt with Type S Scotch-Brite pads.

根据需要继续这样做。然后用 S 型 Scotch-Brite 盘清除松动的污垢。

(5) TSPG periodic-reverse-clean procedure for low alloy steel, corrosion resistant steel, nickel and chromium.

用于低合金钢、耐腐蚀钢、镍和铬的 TSPG 定期反向清洁程序。

NOTE: This solution can be operated at 80°F or 130°F.

注:该溶液可在 80°F 或 130°F 下使用。

(a) If the solution is used at 80°F, periodic reverse clean at 100-250 amps for each square foot. Use a 20-second anodic cycle and then a 10-second cathodic cycle. Continue this as necessary. For scale removal, 5-20 minutes will be necessary. For activation before plating, 1-2 minutes will be necessary. Always complete the procedure on the anodic cycle.

如果溶液在 80°F 温度下使用,则以每平方英尺 100-250 安培的电流进行定期反向清洁。阳极循环 20 秒,阴极循环 10 秒。必要时继续这样做。除垢需要 5-20 分钟。对于电镀前的活化,需要 1-2 分钟。始终在阳极循环中完成程序。

(b) If the solution is used at 130°F, periodic reverse clean at 50-200 amps for each square foot. Use a 20-second anodic cycle and then a 10-second cathodic cycle. Continue this as necessary. For scale removal, 5-10 minutes will be necessary. For activation before plating, 1-2 minutes will be necessary. Always complete the procedure on the anodic cycle.

如果溶液在 130°F 温度下使用,则以每平方英尺 50-200 安培的电流定期反向清洁。阳极循环 20 秒,阴极循环 10 秒。必要时继续这样做。除垢需要 5-10 分钟。对于电镀前的活化,需要 1-2 分钟。始终在阳极循环中完成程序。

(6) Isoprep 172 periodic-reverse-clean procedure for low alloy steel, corrosion resistant steel, nickel and chromium

低合金钢、耐腐蚀钢、镍和铬的 Isoprep 172 定期反向清洗程序

(a) Put the parts completely in the solution.

将零件完全放入溶液中。

(b) Periodic reverse clean at 25-70 amps for each square foot, with the part alternately anodic for approximately 20 seconds and cathodic for approximately 10 seconds. Always start and end on the anodic cycle. Use only current control. Then the voltage will typically be 1.7-4 volts dc.

以每平方英尺 25-70 安培的电流定期反向清洗,零件交替阳极约 20 秒,阴极约 10 秒。始终以阳极循环开始和结束。仅使用电流控制。电压一般为 1.7-4 伏直流。

(c) On low alloy steel, for removal of heavy scale or rust, 5 to 15 minutes will be necessary. For activation of abrasive cleaned surfaces, 4 to 10 minutes will be necessary.

在低合金钢上,要清除严重的垢或铁锈,需要 5 至 15 分钟。要活化磨料清洁过的表面,则需要 4 至 10 分钟。

(d) On PH steel, for removal of heavy scale or rust, 5 to 20 minutes will be necessary, along with a light abrasive cleaning. For activation of abrasive cleaned surfaces, 3 to 10 minutes will be necessary.

在 PH 钢上,要清除严重的垢或铁锈,需要 5 至 20 分钟,同时进行轻度磨料清洁。如要活化研磨剂清洗过的表面,则需要 3 至 10 分钟。

(7) Anodic Cleaning

阳极清洗

(a) Put the parts completely in the electrolytic solution.

将零件完全放入电解溶液中。

(b) Anodically clean for 1 to 10 minutes at the indicated current density:

以指定的电流密度进行阳极清洗 1 至 10 分钟:

1) Cobalt, nickel — 5-10 amps per square foot

钴、镍 — 每平方英尺 5-10 安培

2) Ferrous, silver, tungsten or their alloys — 5-50 amps per square foot

铁、银、钨或其合金 — 每平方英尺 5-50 安培

3) Copper — 5-15 amps per square foot for 5-15 seconds. As an option, you can switch to cathodic for 5-15 seconds.

铜 — 每平方英尺 5-15 安培,持续 5-15 秒。可选择改用阴极法,持续 5-15 秒。

(c) Do not use acid activation after this anodic cleaning-activation step.

在阳极清洗-活化步骤之后,不要使用酸活化。

(8) Rinsing

漂洗

(a) Metal parts

金属零件

1) Parts can be spray rinsed or immersion rinsed after they are alkaline cleaned. Do not immersion rinse parts from alkaline solutions in tanks used to rinse parts from acid solutions, unless there is a sufficient flow of water into the tank to be sure that insoluble materials stay mixed in the solution and do not collect on part surfaces.

在对零件进行碱性清洗后,可对其进行喷淋漂洗或浸泡漂洗。不要将碱性溶液中的零件浸入用来冲洗酸性溶液零件的槽中,除非槽中有足够的水流,以确保不溶性物质一直混在溶液中,不会聚集在零件表面。

2) When you rinse the parts, do not let the cleaner dry on the surfaces. Make sure you hit all surfaces of the parts with the spray. Parts must be water-break-free after the rinse.

冲洗零件时,不要让清洁剂在零件表面变干。确保喷洒到零件的所有表面。冲洗后,零件必须没有水渍。

3) A spray rinse is recommended before the immersion rinse to remove cleaner and to prevent dried cleaner. In the immersion rinse, soak the parts for 5 minutes or more, and shake the part or the rinse water to help remove the cleaner.

建议在浸泡冲洗前进行喷淋冲洗,以去除清洁剂并防止清洁剂变干。在浸泡冲洗时,应将零件浸泡 5 分钟或更长时间,并晃动零件或冲洗水以帮助去除清洁剂。

(b) Composite parts

复合零件

1) Rinse a minimum of three times with clean water, 120 degrees F. or cooler. Spray the water on the parts with pressure of 200 psi maximum, or flush the parts. In areas which could collect water, rub with a clean wet cloth or sponge. Wring out the cloth or sponge with fresh water and wipe the surfaces a minimum of two more times. Be sure to rinse all holes for fasteners.

至少用华氏 120 度或更低温度的清水冲洗三次。用最大 200 psi 的压力将水喷在零件上,或冲洗零件。在可能积水的地方,用干净的湿布或海绵擦拭。用清水拧干抹布或海绵,再擦拭表面至少两遍。确保冲洗所有紧固件孔。

2) Examine the surfaces for complete removal of contamination. Clean again if necessary.

检查表面的污染物是否完全清除。必要时再次清洁。

3) Spray rinse the parts. Do not let cleaner dry on the parts. Make sure you hit all surfaces of the parts with the spray. Water break free surfaces are not necessary, but if the rinse water makes beads on the surfaces it is a sign of incomplete contamination removal.

喷水冲洗零件。不要让清洁剂在零件上变干。确保喷洒到零件的所有表面。不一定要在表面断水,但如果冲洗水在表面形成水珠,则表明污染物清除不彻底。

(9) Post Rinse

冲洗后

(a) Dry the metal and composite parts unless a wet procedure immediately follows. Keep the parts dry and free from oils, grease, fingerprints or other contamination. Wrap parts in paper if necessary.

擦干金属和复合材料零件,除非随后立即进行湿程序。保持零件干燥,避免油、油脂、指纹或其他污染物。必要时用纸包好零件。

(b) Unless a wet procedure follows, composite parts must be fully dried, by ambient air or heated air, or for a maximum of 30 minutes in a dryer with air no hotter than 140 degrees F.

除非随后进行湿程序,否则必须用环境空气或加热空气将复合材料零件完全烘干,或在空气温度不超过华氏 140 度的烘干机中最多烘干 30 分钟。

7. EMULSION CLEANING (IMMERSION AND SPRAY) 乳液清洗(浸泡和喷淋)

A. Emulsion cleaners are used to remove heavy soils, oil and grease from parts or to prevent carryover of contaminants into subsequent processing tanks. This is Type 1 cleaning as specified in BAC5763.

乳液清洁剂用于清除零件上的重垢、油脂或防止污染物带入后续加工槽。这是 BAC5763 规定的第 1 类清洗。

B. Materials

材料

(1) Formula 28, V82726

(2) Aerowash, V0XVD0

(3) Cee-Bee A-7X7, V5K793

(4) Cee-Bee A-7X7 LF, V5K793

(5) GMC 528-B, V1WF68

(6) Solvent – Aliphatic naphtha, TT-N-95, Type 1 (Replaces BMS 3-2 Type 1) (Ref SOPM 20-60-01)

(7) Turco Jet Clean C, V61102

(8) Turco 3878 (Formerly Emul-Klene), V61102

(9) Turco 3878 LF-NC (Formerly Emul-Klene LTNF), V61102

C. Preparation of Type I Emulsion Cleaner Solutions

配制 I 型乳液清洁剂溶液

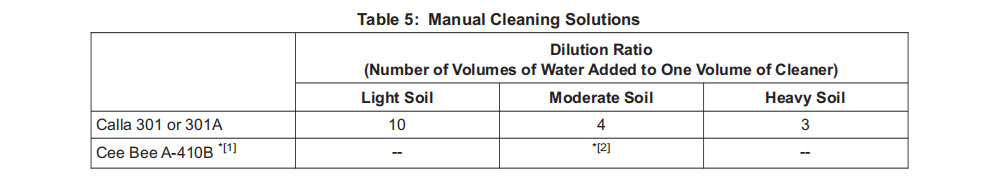

(1) For each 100 gallons of final solution as specified in Table 4, add the water and cleaner in the sequence that follows:

对于表 4 规定的每 100 加仑最终溶液,按以下顺序加入水和清洁剂:

(a) Add 20 to 25 gallons of water to the tank.

向槽中加入 20 至 25 加仑的水。

(b) Slowly add the quantity of cleaner specified in Table 4 and mix fully.

缓慢加入表 4 规定数量的清洁剂并充分混合。

(c) Slowly add the remaining water to make up 100 gallons of final solution and mix thoroughly.

缓慢加入剩余的水,配成 100 加仑的最终溶液并充分混合。

NOTE: As an alternative, for Formula 28 Cleaner, slowly add 64 gallons of aliphatic naphtha and mix thoroughly. Then add water to make 100 gallons of final solution and mix thoroughly.

注: 作为 28 号配方清洁剂的替代方法,缓慢加入 64 加仑脂肪族石脑油并充分混合。然后加水至 100 加仑最终溶液并充分混合。

D. Operation and Maintenance of Type I Emulsion Cleaner Solutions

I 型乳化液清洁剂溶液的操作和维护

(1) Make an analysis as necessary to keep the correct dilutions throughout the life of the solution.

根据需要进行分析,以便在溶液的整个使用期内保持正确的稀释度。

(2) Skim or filter the solutions as often as necessary to keep clean parts.

根据需要经常撇去或过滤溶液,以保持零件清洁。

(3) Operate and keep Type I cleaner solutions as specified in Table 4.

按表 4 规定的方法操作和保存 I 型清洁剂溶液。

E. Immersion Cleaning

浸入式清洗

(1) Put parts in the solution for 5-30 minutes as necessary for the dirt to be removed.

视污垢去除的需要,将零件放入溶液中 5-30 分钟。

(2) Unless tank solutions are vigorously agitated, lift out and put parts back into the solution again at least three times during the procedure to remove all oils and greases.

除非槽内溶液被剧烈搅拌,否则在程序中至少三次将零件抬出并再次放入溶液中,以去除所有油脂。

(3) Rinse fully, best in warm water (90-140°F), for 5 minutes minimum. A spray or agitated immersion rinse is best to help emulsification and dirt removal.

充分冲洗,最好用温水(90-140°F)冲洗至少 5 分钟。最好采用喷淋或搅拌浸泡冲洗,以帮助乳化和清除污垢。

(4) Continue with other procedures as quickly as possible after emulsion cleaning.

在乳化液清洗后,尽快继续执行其他程序。

F. Spray Cleaning

喷雾清洗

(1) Spray parts with cleaning solution for 5-20 minutes. Parts must be in racks to let the spray touch all portions of parts.

用清洁液喷洗零件 5-20 分钟。零件必须放在架子上,让喷雾接触到零件的所有部分。

(2) Rinse fully, best in warm water (90-140°F), for 5 minutes minimum. A spray or agitated immersion rinse is best to help emulsification and dirt removal.

充分冲洗,最好用温水(90-140°F)冲洗至少 5 分钟。最好采用喷淋或搅拌浸泡冲洗,以帮助乳化和清除污垢。

(3) Continue with other procedures as quickly as possible after emulsion cleaning.

乳化清洗后,尽快继续其他程序。

G. After this procedure, the surfaces must be free from all grease, oil, grease pencil marks and other organic contamination. Because this Type 1 emulsion cleaning is usually followed by other cleaning procedures, a water-break-free surface is not necessary at this time.

完成此程序后,表面必须没有任何油脂、油、油笔迹和其他有机污染物。由于此 1 类乳化液清洗后通常还要进行其他清洗程序,因此此时不需要无断水表面。

8. MANUAL CLEANING (COLD ALKALINE, SOLVENT EMULSION AND FOAM CLEANERS) 手工清洗(冷碱性、溶剂型乳液和泡沫清洗剂)

A. This manual cleaning of surfaces with liquid water base alkaline cleaners, solvent emulsion cleaners, and foam cleaners comes from BAC5744. This procedure can be used on all metals, plastic, and painted surfaces.

使用液态水碱性清洗剂、溶剂乳液清洗剂和泡沫清洗剂对表面进行手工清洗的方法源自 BAC5744。该程序可用于所有金属、塑料和油漆表面。

B. Materials

材料

(1) Calla 301 or 301A, V19457

(2) Cee Bee A-410B, V5K793

(3) Cee Bee 280, V5K793

(4) Cee Bee 280TC, V5K793

(5) Cleaners as specified in MIL-C-25769

(6) DuBois C-1102, V72008

(7) Formula 28, V89138 or V99442

(8) Hydrex 09, V8V521

(9) Intex 8201, V78304

(10) Intex 8239, V78304

(11) Metaclean AC, V98364

(12) Navee 427, V56883

(13) Oakite 202, V44389

(14) Oakite 204, V44389

(15) Pacific B-82, V93965

(16) Pennwalt 2271R, V99987

(17) Solvent P-D-680 (Ref SOPM 20-60-01)

(18) Tec No. 1, V25227

(19) Tec 82-2, V25227

(20) Turco Jet Clean C, V61102

(21) Turco Jet Clean E, V61102

C. General

通用

CAUTION :BE SURE NOT TO LET CLEANERS OR RINSE WATER GET INTO INTERFACES BETWEEN TOOLS (SUCH AS LIFT FITTINGS) AND THE PART. FLUIDS CAUGHT BETWEEN TOOLS AND PARTS WILL CAUSE CORROSION OF METAL SURFACES.

注意 :一定不要让清洁剂或冲洗水进入工具(如升降接头)和零件之间的界面。工具和零件之间的液体会导致金属表面腐蚀。

CAUTION :CONCENTRATED CLEANERS CAN CAUSE DETERIORATION OF PAINTED SURFACES, CADMIUM PLATING AND ALUMINUM ALLOYS. WE DO NOT RECOMMEND CONCENTRATED CLEANERS ON THE COMPLETED AIRPLANE, OR ON PAINTED SURFACES.

注意 :浓缩清洁剂会导致油漆表面、镀镉层和铝合金变质。我们不建议在已完工的飞机或油漆表面使用浓缩清洁剂。

(1) Use equipment such as power brushes, nonatomizing liquid spray, or low pressure liquid flush.

使用电动刷子、非雾化液体喷雾或低压液体冲洗等设备。

(2) Mask off all areas not to be cleaned. This includes lubricated or waxed surfaces. Use a water resistant maskant such as polyethylene sheet, grease proof paper, or laminated waterproof paper. Use masking tape when necessary.

遮盖所有不需清洁的区域。这包括润滑或打蜡的表面。使用防水遮蔽剂,如聚乙烯薄板、防油纸或层压防水纸。必要时使用遮蔽胶带。

(3) Dry the cleaned surfaces unless wet processing immediately follows. Keep the surfaces dry and free of all contamination when they will get conversion coating, paint or sealant.

擦干已清洁的表面,除非随后立即进行湿处理。当表面需要涂上转换涂层、油漆或密封胶时,应保持干燥,避免污染。

D. Method 1 – General Cleaning with Water Base Alkaline Cleaners

方法 1 – 使用水基碱性清洁剂进行通用清洁

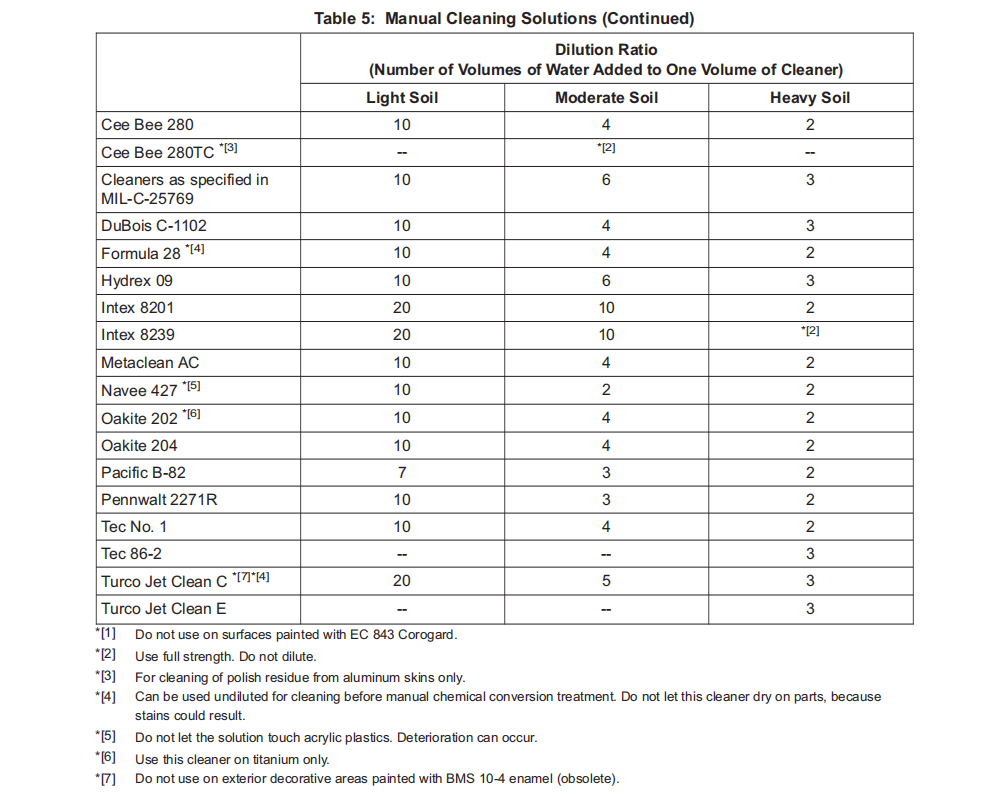

(1) Mix the cleaning solution as specified in Table 5.

按表 5 规定的方法混合清洗液。

(2) Apply the cleaning solution. For large assemblies, use nonatomizing spray equipment, swabs, or brushes. For small areas, use clean rags, brushes, or sponges. Do not clean too large an area at one time.

涂抹清洗液。对于大型组件,使用非雾化喷雾设备、棉签或刷子。对于小区域,可使用干净的抹布、刷子或海绵。一次清洁的面积不要太大。

(3) Let the cleaners soak for approximately 5 minutes. Do not let the cleaner dry on the surface. Scrub if necessary, and apply more cleaner if the dirt is not gone.

让清洁剂浸泡约 5 分钟。不要让清洁剂在表面上变干。必要时进行擦洗,如果污垢未清除干净,可使用更多清洁剂。

(4) Rinse fully with clean water. Warm water (120°F maximum) is recommended. Rinse three or more times. Apply water by pressure spray or flush with water if possible. For confined areas, small touchup, or where water could be caught, rinse with a clean wet cloth or sponge. Wring out the cloth or sponge with clean water and rinse again two or more times.

用清水充分冲洗。建议使用温水(最高 120°F)。冲洗三次或更多次。如果可能,用压力喷雾器喷水或用水冲洗。对于狭窄区域、小修小补或可能进水的地方,可用干净的湿布或海绵冲洗。用清水拧干抹布或海绵,再冲洗两遍或更多遍。

(5) Look for remaining dirt on the surface during the rinse. Look for water breaks if a water break free surface is specified.

在冲洗过程中,查看表面是否有残留污垢。如果规定的是无断水表面,则查看是否有断水。

(6) Clean again if necessary.

如有必要,再次清洗。

(7) Dry the surfaces unless wet processing immediately follows.

擦干表面,除非随后立即进行湿处理。

E. Method 2 — Heavy Duty Cleaning using Solvent Emulsion Cleaners

方法 2 — 使用溶剂乳液清洁剂进行重型清洁

CAUTION :CONCENTRATED CLEANERS WILL CAUSE PAINTED SURFACES TO DETERIORATE AND CAN ATTACK CADMIUM PLATING AND ALUMINUM ALLOYS UNLESS USED WITH DISCRETION. USE OF CONCENTRATED CLEANERS ON COMPLETED AIRCRAFT, OR PAINTED SURFACES, IS NOT RECOMMENDED.

注意 :除非谨慎使用,否则浓缩清洁剂会导致油漆表面老化,并可能侵蚀镉镀层和铝合金。不建议在已完工的飞机或油漆表面使用浓缩清洁剂。

(1) This method of cleaning shall be used for cleaning and/or precleaning of areas and surfaces containing heavy concentrations of soil, grease or carbon deposits. It will not produce a water break free surface.

此清洁方法用于清洁和/或预清洁含有大量泥土、油脂或积炭的区域和表面。该方法不会产生无水表面。

(2) Mask off all areas not to be cleaned.

遮盖所有不需清洗的区域。

(3) Static ground all aircraft or large assemblies.

静电接地所有飞机或大型组件。

(4) Mix one part by volume alkaline cleaner with two parts water and five to six parts solvent. Vigorously agitate solution until thick creamy emulsion is formed.

按体积将一份碱性清洁剂与两份水和五至六份溶剂混合。用力搅拌溶液,直至形成浓稠的奶油乳状液。

(5) Thoroughly mix solution before each application.

每次使用前彻底混合溶液。

(6) Apply solution with swabs, brushes or sponge.

用棉签、刷子或海绵涂抹溶液。

(7) Allow cleaner to soak for 5 to 10 minutes. Do not allow cleaners to dry on surface. Scrub if necessary and reapply cleaner if soil has not been removed.

让清洁剂浸泡 5 至 10 分钟。不要让清洁剂在表面上变干。必要时进行擦洗,如果污垢未去除,则重新涂抹清洁剂。

(8) Thoroughly rinse, then check surfaces for complete soil removal during rinsing. Reclean and rinse as necessary.

彻底冲洗,然后在冲洗过程中检查表面是否完全去污。必要时重新清洁和冲洗。

(9) Dry parts unless subsequent wet processing is to follow.

擦干零件,除非随后要进行湿处理。

(10) On parts to be painted and all parts that must have a water break free surface, clean as specified in Method 1 (Paragraph 8.D. above).

对于要涂漆的零件和所有表面必须不漏水的零件,按方法 1(上文第 8.D. 段)规定的方法进行清洗。

(11) Dry the surfaces unless wet processing immediately follows.

除非随后立即进行湿处理,否则应将表面擦干。

F. Method 3 — Foam Cleaning

方法 3 — 泡沫清洗

(1) Foam cleaning is used where prolonged contact without drying or draining is necessary. Cleaning by this method is similar to Method 1 except in the application of the cleaner.

泡沫清洗用于需要长时间接触而不需干燥或排水的情况。除使用清洁剂外,该方法与方法 1 类似。

(2) Fill tank of a foam generator with a solution of 1 part alkaline cleaner mixed with 10-20 parts water. If foam generator is not available, produce foam from same solution by whipping or other means of agitation.

将 1 份碱性清洁剂与 10-20 份水混合的溶液注入泡沫发生器的槽中。如果没有泡沫发生器,则用鞭打或其他搅拌方法从相同的溶液中产生泡沫。

(3) Apply heavy coating of foam to all soiled areas. Surface may be wet with water before applying foam.

在所有脏污区域涂上一层厚厚的泡沫。在使用泡沫之前,可先用水浸湿表面。

(4) Allow cleaner to soak 5-15 minutes. Do not allow cleaner to dry on surface. Scrub if necessary and reapply cleaner if soil has not been removed.

让清洁剂浸泡 5-15 分钟。不要让清洁剂在表面上变干。必要时进行擦洗,如果污垢未去除,则重新涂抹清洁剂。

(5) Thoroughly rinse as specified in Paragraph 8.. Examine the surface for complete soil removal during the rinse. Clean again and rinse as necessary.

按照第 8 段规定的方法彻底冲洗。在冲洗过程中检查表面是否完全去污。必要时再次清洁和冲洗。

(6) Look for water breaks if a water break free surface is necessary.

如果需要无断水表面,则查看是否有断水。

(7) Dry the surface unless wet processing immediately follows.

擦干表面,除非随后立即进行湿处理。

G. Method 4 — Cleaning Interior Surfaces of Vessels or Tubes

方法 4 — 清洁容器或管道的内表面

(1) When the interior surfaces are partially accessible, manual cleaning methods can be used to supplement other methods of cleaning. For vessels or tubes that cannot be shaken or inverted, follow procedure except completely fill the vessel and agitate the solvent or solution if possible. If agitation is impractical, allow the solvent or solution to contact the surfaces for at least 5-10 minutes.

内表面可部分接触时,可使用手工清洗方法来补充其他清洗方法。对于无法摇动或倒置的容器或管子,除尽可能完全装满容器并搅拌溶剂或溶液外,应按照程序进行清洗。如果搅拌不可行,则让溶剂或溶液接触表面至少 5-10 分钟。

(2) If the interior surface is coated with excess oil or grease and vapor degreasing is not practicable, remove the unwanted oil or grease by flushing with solvent. Then fill the vessel or tube 1/4 to 1/3 full with solvent and shake or agitate the solvent to wet all surfaces. Drain the used solvent.

如果内表面涂有多余的油或油脂,且无法进行蒸汽脱脂,则用溶剂冲洗去除多余的油或油脂。然后在容器或管道中注入 1/4 至 1/3 的溶剂,并摇晃或搅拌溶剂,以润湿所有表面。排出用过的溶剂。

(3) Mix alkaline cleaner as specified in Table 5. Use dilution ratio for heavy soil unless it is known that the soil on the interior surface can be removed with a more dilute solution.

按照表 5 规定的比例混合碱性清洁剂。除非已知内表面的泥土可以用更稀释的溶液清除,否则应使用稀释比例来清除严重的泥土。

(4) Plug holes as necessary to retain liquid cleaner.

根据需要堵塞孔洞,以保留清洁剂液体。

(5) Fill vessel or tube 1/4 to 1/3 full with cleaning solution. Use appropriate methods to invert or shake the parts. Be sure to wet all surfaces. Allow cleaner to contact surfaces for at least 5 minutes.

将清洁液注入容器或管道 1/4 至 1/3。使用适当的方法倒置或摇晃零件。确保浸湿所有表面。让清洁剂接触表面至少 5 分钟。

(6) Drain used cleaner from the part. Repeat preceding step with fresh cleaning solution.

从零件中排出用过的清洁剂。用新的清洗液重复上一步。

(7) Rinse thoroughly with clean water, preferably warm (120°F maximum). Rinse until the water does not appear foamy (three times minimum).

用干净的水彻底冲洗,最好是温水(最高 120°F)。冲洗直至水不出现泡沫(最少三次)。

(8) Dry the surface unless wet processing immediately follows.

擦干表面,除非随后立即进行湿处理。

H. Method 5 — Immersion Cleaning

方法 5 — 浸泡清洗

(1) When the part can be put into a solution, make a solution of alkaline cleaner as specified in Table 5 and let the part soak in it for 5 minutes minimum. Scrub if necessary. Soak the part again if necessary. Do not let the cleaner dry on the surface of the part.

当零件可以放入溶液中时,按表 5 规定的碱性清洁剂配成溶液,让零件在其中浸泡至少 5 分钟。必要时进行擦洗。必要时再次浸泡零件。不要让清洁剂在零件表面变干。

(2) Fully rinse with clean water, preferably warm (120°F maximum).

最好用温水(最高 120°F)充分冲洗。

(3) Examine the surface for complete dirt removal during rinsing, and for water breaks if a water break free surface is specified. Clean again and rinse as necessary.

在冲洗过程中检查表面是否完全去污,如果规定的是无断水表面,则检查是否有断水。必要时再次清洁和冲洗。

(4) Dry the surface unless wet processing immediately follows.

擦干表面,除非随后立即进行湿处理。

9. ABRASIVE CLEANING 研磨清洁

A. General

通用

WARNING :DO NOT BREATHE ABRASIVE DUSTS. PROVIDE VENTILATION AS REQUIRED.

警告 :切勿吸入研磨粉尘。根据需要进行通风。

(1) Preclean the parts before you abrasive clean them.

在对零件进行研磨清洗之前,请预先清洁零件。

CAUTION :DO NOT VAPOR DEGREASE OR USE CHLORINATED SOLVENTS ON TITANIUM PARTS THAT WILL BE IN TEMPERATURES OF 600°F (316°C) OR ABOVE DURING SUBSEQUENT WORK OR ON THE AIRPLANE.

警告 :在随后的工作中或在飞机上,不要对温度达到或超过600°F (316°C)的钛零件进行蒸汽脱脂或使用含氯溶剂。

(a) Metal parts — vapor degrease, manual solvent, emulsion, or alkaline clean, as applicable.

金属零件 – 视情况采用蒸气脱脂、手工溶剂、乳剂或碱性清洁。

(b) Plastic, wood, or painted parts — manual solvent, emulsion, or alkaline clean as applicable.

塑料、木质或喷漆零件 – 视情况采用手工溶剂、乳剂或碱性清洁。

(2) Penetrant examine, if specified, before blast cleaning.

如果有规定的,在吹砂清洗前进行渗透检查。

(3) Be careful not to blast local areas too much. Use fine abrasives and low air pressure on thin or low strength sections.

注意不要过度吹砂局部区域。在较薄或强度较低的部分使用细磨料和低气压。

(4) When you blast plastic laminates, be careful not to remove material down to the glass fibers. Adjust the nozzle-to-work distance, air pressure and nozzle traverse rate as necessary to prevent damage.

在吹砂塑料层压板时,注意不要清除到玻璃纤维以下的材料。根据需要调整喷嘴到工作区的距离、空气压力和喷嘴移动速度,以防止损坏。

(5) When you blast clean before plating or painting, use abrasives that are without contamination such as grease, plastics or silicones.

在电镀或喷漆前进行吹砂清洁时,应使用不含油脂、塑料或硅等污染物的磨料。

(6) Do not let corrosion-resistant steel, and nickel and cobalt base alloys, become contaminated during abrasive cleaning.

在磨料清理过程中,不要让耐腐蚀钢材以及镍和钴基合金受到污染。

(a) Corrosion resistant steel, nickel and cobalt base alloys can all use the same abrasives. Use only nonmetallic abrasives on these metals. Label these abrasives “For Use on Corrosion Resistant Steel and Nickel and Cobalt Base Alloys Only.”

耐腐蚀钢、镍基和钴基合金均可使用相同的磨料。在这些金属上只能使用非金属磨料。在这些磨料上标明 “仅用于耐腐蚀钢、镍和钴基合金”。

(b) Use completely different abrasives on titanium, molybdenum, columbium, tantalum, and tungsten.

对钛、钼、铌、钽和钨使用完全不同的磨料。

(7) Glass Beads

玻璃珠

(a) For precision cleaning, glass beads must be spherical. Broken beads are abrasive and cause faster material removal as the parts are blast cleaned. Screen the beads as necessary to remove broken beads.

要进行精密清洗,玻璃珠必须是球形的。破碎的玻璃珠是研磨剂,在零件喷砂清理时会导致材料去除更快。必要时对玻璃珠进行筛选,以去除破碎的玻璃珠。

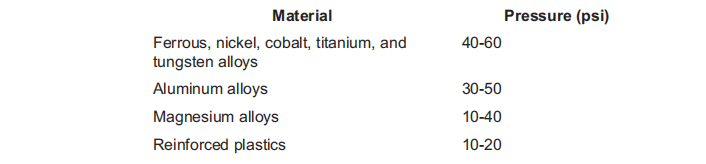

(b) Recommended air pressures are as follows:

建议的空气压力如下:

B. Dry Abrasive Cleaning

干磨清洁

(1) Preclean as necessary.

按需进行预清洁。

(2) Mask as necessary, with materials resistant to the abrasive blast, such as wood, rubber, vinyl tape, or Teflon tape.

必要时使用耐喷砂的材料(如木材、橡胶、乙烯基胶带或特氟龙胶带)进行遮蔽。

(3) Get the abrasive. Recommended abrasives for steels heat treated to 220 ksi and over are 100-180 grit aluminum-oxide, garnet, zirconia-alumina, novaculite silica, or 170-400 mesh glass beads. For class 3 chrome plating (SOPM 20-42-03), 80-120 grit abrasive of these materials is recommended. BAC5748 gives more details.

获取磨料。对于热处理到 220 ksi 及以上的钢材,建议使用 100-180 粒度的氧化铝、石榴石、氧化锆、硅酸钙或 170-400 目玻璃珠。对于 3 级镀铬(SOPM 20-42-03),建议使用这些材料的 80-120 粒度磨料。BAC5748 提供了更多详细信息。

(4) Dry abrasive blast.

干喷砂。

(5) Remove all grit and other contamination from the part.

清除零件上的所有砂粒和其他污染物。

(6) Clean with clean, dry, filtered air.

用清洁、干燥、过滤的空气进行清洗。

(7) When subsequent processing cannot be completed in 24 hours (4 hours for steel heat treated 220 ksi or over) give the parts protection immediately after cleaning. Use water soluble rust preventive compounds such as Oakite 98 (V44389) or Wyandotte R-2 (V89339), or preservative oil such as Oakite Special Protective Oil (V44389) or as specified in 20-44-02, Type 3, Class 2, Grade B.

如果后续加工无法在 24 小时内完成(热处理 220 ksi 或以上的钢材为 4 小时),则应在清洗后立即对零件进行保护。使用水溶性防锈化合物,如 Oakite 98 (V44389) 或 Wyandotte R-2 (V89339),或防腐油,如 Oakite Special Protective Oil (V44389),或 20-44-02 规定的 3 类 2 级 B 等。

C. Wet Abrasive Cleaning

湿式喷砂清理

CAUTION :DO NOT USE WET ABRASIVE BLASTING ON STEEL HEAT TREATED 220 KSI OR ABOVE.

注意 :不要在热处理 220 ksi 或以上的钢材上使用湿喷砂。

(1) Preclean as necessary.

必要时进行预清洁。

(2) Mask as necessary.

必要时戴上口罩。

(3) Get the abrasive. BAC5748 gives recommended selections.

获取磨料。BAC5748 提供了推荐的选择。

(4) Wet abrasive blast.

湿式喷砂。

(5) Rinse metal parts with water or clean with clean, dry, filtered air. Do not use air pressure over 50 psi.

用清水冲洗金属零件,或用清洁、干燥、过滤的空气清洁。空气压力不要超过 50 psi。

(6) Dry parts unless more wet processing immediately follows. Keep parts clean. Wrap parts or apply protective coatings as necessary.

除非随后立即进行更多的湿处理,否则应将零件擦干。保持零件清洁。必要时包裹零件或涂抹保护层。

10. STEAM CLEANING 蒸汽清洗

A. This procedure covers steam cleaning where special equipment is used to discharge a mixture of steam and hot cleaning solution under pressure. The discharge provides for pressure blast washing to remove soil.

本程序包括使用特殊设备在压力下排放蒸汽和热清洗液混合物的蒸汽清洗。排出的蒸汽用于压力喷射清洗,以清除污垢。

CAUTION :DO NOT STEAM CLEAN STEEL PARTS HEAT-TREATED ABOVE 220 KSI. THIS RESTRICTION APPLIES TO BARE METAL, AND CADMIUM OR CADMIUM-TITANIUM PLATED PARTS.

注意 :不要用蒸汽清洗经过 220 ksi 以上热处理的钢制零件。此限制适用于裸金属、镀镉或镀镉钛的零件。

B. Except as noted, steam cleaning is acceptable on most bare metals and some painted surfaces. It is used especially for removing heavy soils from assemblies.

除特别说明外,大多数裸金属和某些涂漆表面均可接受蒸汽清洗。蒸汽清洗尤其适用于清除组件上的严重污垢。

C. Steam cleaning equipment usually includes a steam generator, mixing tank, controls, discharge nozzles, and all associated hoses.

蒸汽清洗设备通常包括蒸汽发生器、混合槽、控制装置、排放喷嘴及所有相关软管。

D. General

通用

(1) After cleaning, the surfaces must be free of oil, grease, dirt, and other soil.

清洗后,表面必须没有油、油脂、灰尘和其他污物。

(2) When you mask windows or cavities, or to protect other parts, use materials that are strong enough, when wet, to withstand direct blast from nozzle.

遮盖窗户或空腔,或保护其他零件时,应使用足够坚固的材料,潮湿时可承受喷嘴的直接喷射。

WARNING :RESTRAINING FORCE IS REQUIRED TO DIRECT DISCHARGE NOZZLE. BE SURE THAT OPERATOR IS FIRMLY STATIONED BEFORE TURNING NOZZLE ON.

警告 :引导喷嘴出料时需要用力。在打开喷嘴之前,确保操作员站稳。

CAUTION :STEAM CLEANING CAUSES DAMAGE TO SOME PAINTED SURFACES. CLEAN ONLY SURFACES AS AUTHORIZED IN SPECIFIC OVERHAUL INSTRUCTIONS AND DO NOT ALLOW OVERSPRAY TO CONTACT RESTRICTED SURFACES.

警告 :蒸汽清洗会损坏某些油漆表面。仅清洗具体大修说明中授权的表面,不要让过喷接触受限表面。

E. Cleaning

清洗

NOTE: The following are general instructions on use of steam cleaning equipment. Use instructions furnished with equipment, or techniques for special cleaning problems, to supplement general instructions.

注:以下是使用蒸汽清洗设备的通用说明。使用随设备提供的说明或特殊清洗问题的技术来补充通用说明。

(1) Fill the mixing tank with 2 to 4 ounces of steam cleaning compound (Ref SOPM 20-60-01) for each gallon of water.

在混合槽中,每加仑水中加入 2 至 4 盎司的蒸汽清洗剂 (参考 SOPM 20-60-01)。

(2) Adjust the equipment until the discharge from the nozzle is a mixture of steam, water and cleaning solution at approximately 0.2 to 0.5 ounce for each gallon. At this rate, the total discharge from nozzle is approximately 10 times the volume of dilute cleaner solution used.

调节设备,直至从喷嘴排出的蒸汽、水和清洁溶液的混合物约为每加仑 0.2 至 0.5 盎司。按此速度,喷嘴的总排放量约为所用稀释清洁剂溶液量的 10 倍。

(3) Hold nozzle at an angle of approximately 45 degrees and 8 to 10 inches from the surface being cleaned. Nozzle may be held at greater distance for removing light soil or for rinsing.

以大约 45 度的角度握住喷嘴,喷嘴距离被清洁表面 8 到 10 英寸。在清除轻微污垢或冲洗时,可将喷嘴保持在更远的距离。

(4) Move nozzle over surface at approximately 6 inches per second. Several rapid passes are better than one slow pass.

以每秒约 6 英寸的速度在表面上移动喷嘴。多次快速通过比一次缓慢通过效果更好。

(5) Clean only as large an area as can be kept wet with cleaner starting with lower surfaces and working up. Do not allow cleaning solution to dry on metal surfaces.

清洗面积越大越好,先从较低的表面开始,然后向上清洗。不要让清洁液在金属表面干涸。

(6) Rinse surface with condensate or warm water. Rinse at least three times.

用冷凝水或温水冲洗表面。至少冲洗三次。

(7) Determine adequate rinsing by touching wet surface with red litmus paper. If the paper becomes blue, rinse again until red litmus paper does not become blue.

用红色石蕊试纸接触湿表面,确定冲洗是否充分。如果石蕊试纸变蓝,则再次冲洗,直到红色石蕊试纸不再变蓝为止。

NOTE: Check for adequate rinsing, especially at faying surfaces and other places where cleaner may be entrapped.

注:检查冲洗是否充分,特别是在粘合表面和其他可能夹带清洁剂的地方。

(8) Let the surface to drain dry.

让表面晾干。

F. Removal of BMS 10-17 Coating

去除 BMS 10-17 涂层

(1) BMS 10-17 is a water soluble antiscuff and anticorrosion coating, sometimes applied to spare aluminum alloy sheets and panels for shipment and storage. BMS 10-17 coating shall be removed before or immediately after assembly of the part.

BMS 10-17 是一种水溶性防擦和防腐涂层,有时会涂在备用铝合金板和面板上,以备装运和储存。BMS 10-17 涂层应在组装零件之前或之后立即清除。

(2) Remove BMS 10-17 coating as follows:

按以下步骤清除 BMS 10-17 涂层:

(a) Adjust equipment so that discharge from nozzle is mixture of steam and cleaner solution, with a concentration of 0.2 to 0.5 oz/gal cleaning compound in solution at nozzle.

调整设备,使喷嘴排出的是蒸汽和清洗剂溶液的混合物,喷嘴处溶液的浓度为 0.2 至 0.5 盎司/加仑清洗剂。

(b) Direct steam cleaning solution from nozzle at an angle approximately 45 degrees to, and at a distance of 8 to 12 inches from, the surface being cleaned.

从喷嘴喷出的蒸汽清洁溶液与被清洁表面成约 45 度角,距离被清洁表面 8 至 12 英寸。

(c) Speed of pass over area shall be approximately 6 inches per second. Do not direct steam at one place on the surface for any length of time. Several rapid passes are better than one slow pass.

蒸汽通过该区域的速度应约为每秒 6 英寸。不要将蒸汽长时间直接喷射在表面上的一个地方。多次快速通过比一次缓慢通过要好。

(d) Starting from lower surfaces and working up, work only as large an area as can be kept wet with cleaner solution.

从较低的表面开始往上冲洗,冲洗面积以清洁剂能保持湿润为宜。

(e) Rinse each of these areas, including those areas splashed with cleaner solution, with steam condensate, pressurized hot or cold water.

用蒸汽冷凝水、加压热水或冷水冲洗每个区域,包括被清洁剂溶液溅湿的区域。

(f) Scrub the surface lightly with brush while it is still wet, to remove white residue.

趁表面未干时,用刷子轻轻擦洗,清除白色残留物。

11. CLEANING OF INTERIOR PAINTED AND PLASTIC SURFACES 内部油漆和塑料表面的清洁

A. This procedure is used for removing soft or cured soils on all interior plastics and painted surfaces except windows. Refer to Document D6-7127 for more data.

本程序用于清除除窗户以外的所有内饰塑料和油漆表面上的软质或固化的污垢。更多数据请参阅文件 D6-7127。

CAUTION :USE ONLY THE CLEANING MATERIALS SPECIFIED. OTHER MATERIALS COULD DAMAGE PLASTICS. THE DAMAGE COULD BE IMMEDIATE BUT NOT DETECTABLE VISUALLY.

注意 :只能使用规定的清洁材料。其他材料可能会损坏塑料。其他材料可能会损坏塑料。

B. Materials

材料

(1) Detergent Cleaners

洗涤剂清洁剂

*[1] Other detergent cleaners can be used if they are acceptable in the polycarbonate crazing test of Paragraph 11.C..

*[1]如果其他清洁剂在第 11.C 段的聚碳酸酯开裂测试中合格,也可以使用。

(2) Solvent Cleaners

溶剂清洁剂

(a) Aliphatic Naphtha — TT-N-95

脂肪族石脑油 — TT-N-95

(b) Freon TF, V18873

氟里昂 TF,V18873

(3) Miscellaneous Materials

杂项材料

(a) Wipers (cheesecloth, gauze, cotton cloths, rymple cloth) — BMS 15-5, Class A

抹布(奶酪布、纱布、棉布、莱姆布)–BMS 15-5,A 级

(b) Sponges, cellulose — L-S-626

纤维素海绵 — L-S-626

(c) Hand brush, soft fiber

软纤维手刷

C. Polycarbonate Crazing Test

聚碳酸酯裂纹测试

(1) Test specimens — Two Lexan 9600-116 sheets 0.055-0.065 inch thick

测试样本 — 两张 0.055-0.065 英寸厚的 Lexan 9600-116 薄板

(2) Equipment

设备

(a) Cylinder with 10.2-inch outside diameter

外径 10.2 英寸的圆筒

(b) Cotton swatches

棉布色板

(3) Test Procedure

测试程序

(a) Load each specimen to give it an outer fiber stress of 2000 psi. You can get this stress if you wrap the test specimen around the 10.2-inch diameter cylinder.

给每个试样加载,使其外纤维应力达到 2000 psi。如果将试样缠绕在直径为 10.2 英寸的圆筒上,就可以得到这个应力。

(b) Give the edges of the specimen protection from the cleaner to be tested.

保护试样边缘不受待测清洁剂的影响。

(c) With each specimen under stress, put an absorbent cotton swatch wet with the undiluted cleaner to be tested on one specimen. Put another cotton swatch wet with the diluted cleaner on the other specimen. Be careful not to let the cleaners touch the edges of the specimens.

在每个受压试样上,在一个试样上放一块用未稀释清洁剂浸湿的吸水棉布。将另一块用稀释清洁剂浸湿的棉布放在另一个试样上。注意不要让清洁剂接触到试样的边缘。

(d) After 10 minutes, remove the load and the cotton swatches. Examine the specimens for cracks or crazing.

10 分钟后,取下负载和棉签。检查试样是否有裂纹或龟裂。

(e) If the specimens have signs of cracks or crazing, the tested cleaner is unacceptable.

如果试样有裂纹或龟裂的迹象,说明测试的清洁剂不可接受。

D. Opaque Plastics and Painted Surfaces

不透明塑料和喷漆表面

(1) Regular Cleaning

定期清洗

(a) Make detergent solution as specified in Paragraph 11.B.(1) above.

按上文第 11.B.(1)段的规定配制清洁剂溶液。

(b) Apply the detergent solution with a sprayer or a sponge.

用喷雾器或海绵涂抹清洁剂溶液。

(c) Let the solution stay on the surface 30 seconds to 2 minutes. Then wipe with a damp cloth.

让溶液在表面停留 30 秒至 2 分钟。然后用湿布擦拭。

(d) Rinse the surface with a clean wiper soaked with clean water.

用干净的抹布蘸清水冲洗表面。

(e) Wipe the surface dry with a clean dry cloth.

用干净的干布将表面擦干。

(2) Spot Cleaning of Soft or Uncured Dirt

软垢或未固化污垢的污点清洁

(a) If applicable, remove excess dirt with a dry wiper. Do not smear or spread the dirt or force the dirt into textured or perforated surfaces, or joints or seams.

如果适用,用干抹布清除多余的污垢。不要涂抹或散布污垢,也不要将污垢强行塞入有纹理或穿孔的表面、接缝或接缝处。

(b) Make detergent solution as specified in Paragraph 11.B.(1) above.

按照上文第 11.B.(1)段的规定配制清洁剂溶液。

(c) Apply the detergent solution to the dirty area with a hand sprayer or a sponge.

用手动喷雾器或海绵将清洁剂溶液涂抹在脏污区域。

(d) Carefully wipe the area clean. When you clean textured surfaces, use a soft fiber brush. Lightly scrub the dirty area to remove dirt from recessed areas.

仔细擦拭干净。清洁有纹理的表面时,使用软纤维刷。轻轻擦洗脏污区域,清除凹陷区域的污垢。

(e) Rinse the area with a sponge wet with clean water.

用清水浸湿海绵冲洗该区域。

(f) Wipe the area dry with absorbent paper toweling, with parallel strokes. If the dirt is not gone, use the procedure for cured or set dirt in Paragraph 11.D.(3) below.

用吸水性纸巾平行擦干该区域。如果污垢仍未清除,则使用下文第 11.D.(3)段中针对固化或凝固污垢的程序。

(3) Spot Cleaning of Cured or Set Dirt

对固化或凝固污垢的污点清洁

CAUTION :DO NOT USE THIS PROCEDURE ON ABS, ACRYLIC, POLYCARBONATE, POLYCARBONATE LAMINATES, OR POLYSULFONE PLASTICS, BECAUSE THE SOLVENTS USED COULD PERMANENTLY DAMAGE THESE PLASTICS.

注意 :请勿将此程序用于ABS、丙烯酸、聚碳酸酯、聚碳酸酯层压板或聚砜塑料,因为所使用的溶剂可能会永久性地损坏这些塑料。

CAUTION :DO NOT USE THIS PROCEDURE TO CLEAN AREAS PAINTED WITH WATER-BASED PAINT, BECAUSE THE SOLVENTS WILL DAMAGE SUCH PAINT. IF DETERGENTS CANNOT REMOVE CURED OR SET DIRT FROM THE WATER-BASED PAINTED SURFACE, THEN THE SURFACE MUST BE PAINTED AGAIN. NAPHTHA CAN BE USED, BUT THE PARTS MUST BE REMOVED FROM THE AIRPLANE.

注意 :不要用此程序清洗涂有水性漆的区域,因为溶剂会损坏这些漆。如果清洁剂不能清除水性油漆表面的固化或凝固污垢,则必须重新喷漆。可以使用石脑油,但必须将零件从飞机上拆下。

(a) When you use this procedure, keep to minimum the time the solvent is on the surface. Do not use too much solvent.

使用该程序时,应尽量缩短溶剂在表面上的停留时间。不要使用过多溶剂。

(b) Apply trichloroethane, tetrachloroethylene, or Freon TF solvent to a wiper.

将三氯乙烷、四氯乙烯或氟里昂 TF 溶剂涂抹在抹布上。