耐化学和耐溶剂饰面的应用

APPLICATION OF CHEMICAL AND SOLVENT RESISTANT FINISHES

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5736 and BAC5807. The airline has a copy of the Boeing Process Specifications Manual.

本主题中的数据来自波音工艺规范 BAC5736 和 BAC5807。航空公司有一本《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并非适用于所有情况或特定安装。请将这些数据作为指南,帮助您制定最低标准。

C. This tells how to apply catalyzed BMS 10-11, Type 1 chemical and solvent resistant primer, MIL-PRF-23377 primer, and BMS 10-11, Type 2 enamel. Application is by spray, brush, dip, fill and drain, curtain coating, and flood coating.

说明如何涂抹催化 BMS 10-11 1 类抗化学和溶剂底漆、MIL-PRF-23377 底漆和 BMS 10-11 2 类瓷漆。涂装方法包括喷涂、刷涂、浸涂、填充和排干、帘涂和泛涂。

D. BMS 10-11 puts the materials in different classes and grades.

BMS 10-11 将材料分为不同类别和等级。

(1) Class A material is for usual application methods such as air or airless spray. Class B material is for application with the same methods as used for Class A and in addition, the electrostatic painting equipment can be used.

A 级材料适用于通常的喷涂方法,如空气或无气喷涂。B 级材料的涂装方法与 A 级相同,此外还可使用静电喷涂设备。

(2) Grade A primer has a volatile organic compound (VOC) content of approximately 600 grams/liter when mixed. Grade B primer has a maximum VOC of 350 grams/liter when mixed, and contains exempt solvents. Grade E primer can be thinned with water and has a maximum VOC of 350 grams/liter when mixed and thinned. If the grade of primer is not specified, you can use Grade A, B, or E. But use only Grade A or E for wet installation of such parts as fasteners, shims, and bushings.

A 级底漆在混合时的挥发性有机化合物(VOC)含量约为 600 克/升。B 级底漆在混合时的挥发性有机化合物含量最高为 350 克/升,且不含溶剂。E 级底漆可用水稀释,混合稀释时的最大挥发性有机化合物含量为 350 克/升。如果没有规定的底漆等级,可以使用 A 级、B 级或 E 级,但在紧固件、垫片和衬套等零件的湿式安装中只能使用 A 级或 E 级。

(3) Grade A enamel has a VOC of approximately 600 grams/liter when mixed. Grade D enamel has a maximum VOC of 420 grams/liter when mixed. If the grade of enamel is not specified, you can use Grade A or D.

A 级瓷漆在混合时的挥发性有机化合物含量约为 600 克/升。D 级瓷釉在混合时的挥发性有机化合物含量最高为 420 克/升。如果没有规定的瓷釉等级,可以使用 A 级或 D 级。

E. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商的名称和地址请参见 SOPM 20-00-00。

2. MATERIALS 材料

A. Coatings

涂料

WARNING :SOME OF THESE MATERIALS ARE POISONOUS AND FLAMMABLE. USE THEM IN A WELL-VENTILATED AREA. OBEY SAFETY AND FIRE PRECAUTIONS. DO NOT BREATHE VAPORS. IF MATERIAL GETS IN YOUR EYES, FLUSH WITH WATER FOR 15 MINUTES AND GET MEDICAL ATTENTION IMMEDIATELY. IF MATERIALS GET ON YOUR SKIN, WASH WITH WATER. WIPE UP SPILLS IMMEDIATELY.

警告 :其中一些材料有毒且易燃。请在通风良好的地方使用。遵守安全和防火措施。切勿吸入蒸汽。如果材料进入眼睛,用水冲洗 15 分钟,并立即就医。如果材料沾到皮肤上,用水冲洗。溅出物要立即擦掉。

(1) BMS 10-11, Type 1 epoxy primer

BMS 10-11,1 类环氧底漆

NOTE: This primer comes in green BAC452, BAC4910 or BAC3661, and yellow BAC377. When the color is not specified, use green. But if the surface will be topcoated, you can use green or yellow.

注: 该底漆有绿色 BAC452、BAC4910 或 BAC3661 和黄色 BAC377。当颜色没有规定的时候,使用绿色。但如果表面将进行面涂,则可使用绿色或黄色。

(2) BMS 10-11, Type 2 epoxy enamel

BMS 10-11,2 型环氧搪瓷

(3) MIL-PRF-23377 epoxy polyamide primer

MIL-PRF-23377 环氧聚酰胺底漆

B. Solvents

溶剂

(1) Methyl Ethyl Ketone (MEK), TT-M-261

甲基乙基酮(MEK),TT-M-261

(2) Methyl Isobutyl Ketone (MIBK), TT-M-268

甲基异丁基酮 (MIBK),TT-M-268

(3) Ardrox 241K (was TEC 902), V23373

(4) TL-52, V98502

(5) TL-82, V98502

(6) Toluene, TT-T-548 or JAN-T-171, Grade A

甲苯,TT-T-548 或 JAN-T-171,A 级

(7) Xylene, TT-X-916, Grade A

二甲苯,TT-X-916,A 级

(8) Series 86 (SOPM 20-30-80)

86 系列(SOPM 20-30-80)

C. Alkaline Cleaners

碱性清洁剂

(1) Ardrox 160-B, V23373

(2) Jet Clean E, V61102

(3) Formula 28, V99442

D. Wipers — BMS 15-5

擦拭布 – BMS 15-5

E. Tack Rags

抹布

(1) C-60, V0EK96

(2) No. 4B, V17359

F. Abrasives

研磨剂

(1) Abrasive paper, 240 grit or finer

240 目或更细的砂纸

(2) Scotch-Brite sheet, Type A, very fine, V76381

(3) Aluminum Oxide Abrasive Pad, very fine, V06565

氧化铝研磨盘,极细,V06565

3. SURFACE PREPARATION 表面处理

A. If the surface is metal with a treatment in this list, go directly to Paragraph 3.D. for contamination removal.

若表面为本清单所列处理过的金属,则直接转至第 3.D 段进行污染清除。

(1) Aluminum — Anodized as specified in BAC5619, BAC5022, BAC5632, MIL-A-8625 or SOPM 20-43-01 or chemical treated as specified in BAC5719 or MIL-C-5541 or SOPM 20-43-03.

铝 — 按 BAC5619、BAC5022、BAC5632、MIL-A-8625 或 SOPM 20-43-01 规定的阳极氧化处理,或按 BAC5719 或 MIL-C-5541 或 SOPM 20-43-03 规定的化学处理。

(2) Magnesium — Dow treated as specified in BAC5609, BAC5734, MIL-M-3171, MIL-M-45202 or SOPM 20-43-02).

镁–按 BAC5609、BAC5734、MIL-M-3171、MIL-M-45202 或 SOPM 20-43-02 规定的陶氏处理。)

(3) Titanium — Phosphate fluoride treated as specified in BAC5861.

钛 — 按 BAC5861 规定的磷酸盐氟化物处理。

(4) Carbon steel or low-alloy steel — Plated as specified in BAC5804 or phosphate treated as specified in BAC5810.

碳钢或低合金钢 — 按 BAC5804 规定的镀层或 BAC5810 规定的磷酸盐处理。

B. If the surface is bare metal (no plating or surface treatment), prepare it as specified in this list. Then go to Paragraph 3.D. for contamination removal.

如表面为裸金属(无电镀或表面处理),则按本表规定的方法准备。然后转至第 3.D 段进行污染物清除。

(1) Titanium — Abrasive clean as specified in BAC5748 (SOPM 20-30-03) or nitric-fluoride clean as specified in BAC5753 Method 2 (SOPM 20-30-03).

钛–按 BAC5748 (SOPM 20-30-03)规定的研磨清洁,或按 BAC5753 方法 2 (SOPM 20-30-03)规定的氟化硝清洁。

(2) Stainless steel — Abrasive clean as specified in BAC5748 (SOPM 20-30-03) or (for 300-series CRES) acid clean as specified in BAC5625 Method 3 (SOPM 20-30-03).

不锈钢 — 按 BAC5748(SOPM 20-30-03)规定的研磨清洁或(对于 300 系列 CRES)按 BAC5625 方法 3(SOPM 20-30-03)规定的酸清洁。

(3) Carbon steel or low-alloy steel — Abrasive clean as specified in BAC5748 (SOPM 20-30-03).

碳钢或低合金钢 — 按 BAC5748(SOPM 20-30-03)规定的方法进行研磨清洁。

(4) Copper — Abrasive clean as specified in BAC5748 (SOPM 20-30-03).

铜 — 按 BAC5748(SOPM 20-30-03)规定的研磨清洁。

(5) Nickel and cobalt alloys — Abrasive clean as specified in BAC5748 (SOPM 20-30-03).

镍及钴合金 — 按 BAC5748(SOPM 20-30-03)规定的研磨清洁。

(6) Lead — Abrasive clean as specified in BAC5748 (SOPM 20-30-03).

铅 — 按 BAC5748 (SOPM 20-30-03) 规定的研磨清洁。

(7) Tungsten — Abrasive clean as specified in BAC5748 (SOPM 20-30-03). Use aluminum oxide abrasive, 80-100 grit and 50-100 psi.

钨 — 按照 BAC5748(SOPM 20-30-03)规定的研磨清洁。使用氧化铝磨料,粒度 80-100 grit,压力 50-100 psi。

C. If the surface is not metal, without a layer of primer or enamel, prepare it as specified in this list. Then apply finish as specified in Paragraph 6.

如果表面不是金属,没有一层底漆或瓷漆,则按本清单规定的方法进行准备。然后按第 6 段规定的方法进行表面处理。

(1) Plastic — Treat as specified in BAC5837 or BAC5322 or SOPM 20-10-06. Then solvent clean as specified in BAC5750 (SOPM 20-30-03).

塑料 — 按 BAC5837 或 BAC5322 或 SOPM 20-10-06 规定的方法处理。然后按 BAC5750(SOPM 20-30-03)规定的溶剂清洗。

(2) Wood — Abrasive clean as specified in BAC5748 (SOPM 20-30-03). Then solvent clean as specified in BAC5750 (SOPM 20-30-03).

木材 — 按 BAC5748(SOPM 20-30-03)规定的方法进行研磨清洁。然后按 BAC5750(SOPM 20-30-03)规定的溶剂清洗。

(3) Adhesive — Abrasive clean as specified in BAC5748 (SOPM 20-30-03) unless this is adhesive primer or adhesive flash. For these last two, reactivate the surface as specified in Paragraph 3.D.(3) or Paragraph 3.D.(4). Then solvent clean as specified in BAC5750 (SOPM 20-30-03).

粘合剂 — 按 BAC5748(SOPM 20-30-03)规定的方法进行研磨清洁,除非这是粘合剂底漆或粘合剂闪光。对于后两种情况,按第 3.D.(3)段或第 3.D.(4)段规定的方法重新活化表面。然后按照 BAC5750(SOPM 20-30-03)规定的方法进行溶剂清洁。

(4) Sealant — Cure to a tack-free condition as specified in BAC5000 (SOPM 20-50-19). Then solvent clean as specified in BAC5750 (SOPM 20-30-03).

密封胶 — 按 BAC5000 (SOPM 20-50-19)规定的方法固化至无粘性状态。然后按 BAC5750 (SOPM 20-30-03) 中规定的溶剂清洗。

D. If the surfaces of Paragraph 3.A. or Paragraph 3.B. have contamination, clean as specified below. Then apply finish as specified in Paragraph 6.

若第 3.A 段或第 3.B 段所述表面有污染,则按以下规定的方法清洁。然后按第 6 段规定的方法进行饰面。

(1) Aluminum surfaces phosphoric acid anodized as specified in BAC5555

按 BAC5555 规定的磷酸阳极氧化铝表面

(a) If these are small areas of contamination such as tape adhesive or oil, solvent clean the small areas as specified in BAC5750 (SOPM 20-30-03). Do not solvent clean other areas or vapor degrease.

如果这些是胶带粘合剂或油等污染的小区域,则按照 BAC5750 (SOPM 20-30-03)规定的方法进行溶剂清洗。不要用溶剂清洗其他区域或蒸气脱脂。

(b) Alkaline clean as specified in BAC5749, Method 1, with a medium duty soak immersion cleaner (SOPM 20-30-03), but do not soak longer than 20 minutes.

按照 BAC5749 方法 1 的规定,用中型浸泡清洁剂进行碱性清洁 (SOPM 20-30-03),但浸泡时间不要超过 20 分钟。

(c) As an option after the alkaline cleaning, chemical treat the surface as specified in BAC5719, class B (SOPM 20-43-03), but do not deoxidize.

碱洗后,可选择按 BAC5719 规定的 B 级(SOPM 20-43-03)对表面进行化学处理,但不要脱氧。

(2) Other metal surfaces, unless cadmium-titanium plated

其他金属表面,镀镉钛除外

(a) Solvent clean as specified in BAC5750 (SOPM 20-30-03), or

按 BAC5750(SOPM 20-30-03)规定的溶剂清洗,或

(b) Alkaline clean as specified in BAC5749, Method 1, with a medium duty soak immersion cleaner (SOPM 20-30-03), but do not soak longer than 20 minutes, or

按 BAC5749 方法 1 规定的碱性清洗,使用中型浸泡浸入式清洗剂 (SOPM 20-30-03),但浸泡时间不得超过 20 分钟,或

(c) Vapor degrease as specified in BAC5408 (SOPM 20-30-03)

BAC5408 规定的蒸汽脱脂(SOPM 20-30-03)

(3) Metal surfaces cadmium-titanium plated — Solvent clean as specified in BAC5750 (SOPM 20-30-03) or vapor degrease as specified in BAC5408 (SOPM 20-30-03).

镀镉钛金属表面 — 按 BAC5750(SOPM 20-30-03)规定的溶剂清洗或 BAC5408(SOPM 20-30-03)规定的蒸汽脱脂。

(4) Tungsten surfaces — Solvent clean as specified in BAC5750 (SOPM 20-30-03). Do this again if the primer is not applied within 24 hours after the abrasive blast.

钨表面 — 按 BAC5750(SOPM 20-30-03)规定的溶剂清洗。如果在喷砂后 24 小时内未涂刷底漆,则再次进行此操作。

E. Surfaces with a layer of primer or enamel:

有一层底漆或瓷漆的表面:

(1) With BMS 10-11, Type 1, Grade A or E, or BMS 10-11, Type 2, BMS 10-20, BMS 10-103 MIL-PRF-23377 cured less than 48 hours, or BMS 10-11, Type 1, Grade B or BMS 10-79, Types 2 and 3 cured less than 24 hours — Solvent clean as specified in SOPM 20-30-03, or if necessary, sand with 240 grit or finer abrasive.

BMS 10-11,类型 1,A 级或 E 级,或 BMS 10-11,类型 2,BMS 10-20,BMS 10-103 MIL-PRF-23377 固化时间少于 48 小时,或 BMS 10-11,类型 1,B 级或 BMS 10-79,类型 2 和 3 固化时间少于 24 小时 – 按照 SOPM 20-30-03 规定的溶剂清洗,或必要时用 240 号或更细的砂纸打磨。

NOTE: For BMS 10-11, Types 1 and 2, Grade B, and BMS 10-79, Types 2 and 3, Grade B cured less than 24 hours, this cleaning is not necessary when the new paint is applied under conditions which prevent contamination.

注:对于 BMS 10-11,1 型和 2 型,B 级,以及 BMS 10-79,2 型和 3 型,B 级,固化时间少于 24 小时,如果新油漆是在防止污染的条件下涂刷的,则无需进行清洁。

(2) The same primers and enamels as in Paragraph 3.E.(1) but cured more than the limits given above:

与第 3.E.(1)段所述底漆和瓷漆相同,但固化时间超过上述限制:

(a) Grade A: Reactivate as specified in Paragraph 4., Methods 1, 2, 3, 4, 5 or 7.

A 级:按第 4 段方法 1、2、3、4、5 或 7 规定的方法重新激活。

(b) Grade B: Reactivate as specified in Paragraph 4., Methods 1 or 2.

B 级:按第 4 段方法 1 或 2 规定的方法重新激活。

(3) All adhesive primers applied as specified in BAC5514 or BAC5710, Type 60 — Reactivate as specified in Paragraph 4., Methods 1, 2, 3, 4, 5 or 6.

按 BAC5514 或 BAC5710 60 型规定涂抹的所有粘合剂底漆 — 按第 4 段方法 1、2、3、4、5 或 6 的规定重新激活。

(4) All adhesive flashes — Reactivate as specified in Paragraph 4., Method 3, or vapor degrease as specified in SOPM 20-30-03, or sand with 240 grit or finer and solvent clean. Or remove the flash as an organic coating as specified in SOPM 20-30-02 and solvent clean as specified in SOPM 20-30-03.

所有粘合剂闪光 — 按第 4 段方法 3 规定的方法重新激活,或按 SOPM 20-30-03 规定的方法蒸气脱脂,或用 240 号或更细的砂纸打磨并用溶剂清洗。或按 SOPM 20-30-02 规定的有机涂层清除闪光,并按 SOPM 20-30-03 规定的溶剂清洗。

(5) Surfaces touched by leak detection paint — Reactivate as specified in Paragraph 4., Methods 1, 2, 3, 4, 5, 6, or 7.

被检漏涂料接触的表面 — 按第 4 段方法 1、2、3、4、5、6 或 7 规定的方法重新激活。

4. PAINTED SURFACE REACTIVATION 涂漆表面的重新激活

A. Method 1

方法 1

(1) Manual solvent clean as specified in SOPM 20-30-03, unless you are sure the surfaces were given protection from contamination.

按照 SOPM 20-30-03 规定的方法进行手工溶剂清洗,除非确定表面已得到保护,免受污染。

(2) Abrasive clean with 320 grit or finer aluminum oxide abrasive paper. Be careful not to go through to the base material.

用 320 号或更细的氧化铝砂纸进行研磨清洁。注意不要伤及基材。

(3) Manual solvent clean as specified in SOPM 20-30-03.

按照 SOPM 20-30-03 规定的手工溶剂清洗。

B. Method 2

方法 2

(1) Clean with an alkaline cleaner as specified in BAC5744 (SOPM 20-30-02), or use one of the alkaline cleaners listed in Materials, diluted with 3 parts water, and clean by hand or pressure clean with nonatomizing spray gun. (If you use the gun, hit the part a minimum of 5 seconds and do not let the part wait more than 15 minutes). Do not let the cleaner dry on the part.

使用 BAC5744(SOPM 20-30-02)规定的碱性清洁剂进行清洁,或使用 “材料 “中所列的一种碱性清洁剂,用 3 份水稀释,然后用手清洁或用非雾化喷枪进行压力清洁。(如果使用喷枪,至少喷 5 秒钟,不要让零件等待超过 15 分钟)。不要让清洁剂在零件上变干。

(2) Rinse off the cleaner with clean water.

用清水冲洗干净清洁剂。

(3) Wipe and blow dry with filtered compressed air.

用过滤压缩空气擦拭并吹干。

(4) If you can see dirt, solvent clean it away as specified in SOPM 20-30-03. But removal of all the blue stains from leak detection paint is not necessary.

如果能看到污垢,按照 SOPM 20-30-03 规定的方法用溶剂清洗掉。但没有必要清除检漏漆上的所有蓝色污渍。

(5) Within 48 hours after you started this method, clean by hand or with a nonatomizing spray gun and Ardrox 241K. If you use the gun, hit the part a minimum of 5 seconds and do not let the part wait more than 2 minutes.

开始使用此方法后 48 小时内,用手或非雾化喷枪和 Ardrox 241K 进行清洁。如果使用喷枪,至少要喷 5 秒钟,不要让零件等待超过 2 分钟。

(6) Fully rinse with water before the cleaner evaporates.

在清洁剂挥发之前用水充分冲洗。

(7) Solvent clean with a Series 86 solvent (SOPM 20-30-86) by hand or with a nonatomizing spray gun. If you use the gun, hit the parts a minimum of 5 seconds.

使用 86 系列溶剂(SOPM 20-30-86)手工或非雾化喷枪进行溶剂清洗。如果使用喷枪,至少要喷洒 5 秒钟。

(8) Blow dry with filtered compressed air.

用过滤压缩空气吹干。

C. Method 3

方法 3

(1) Do Paragraph 4.B.(4) thru Paragraph 4.B.(8) of Method 2.

执行方法 2 的第 4.B.(4)至第 4.B.(8)段。

D. Method 4

方法 4

(1) Solvent clean as specified in BAC5750 (SOPM 20-30-03). Scotch-Brite pads are recommended to help remove the dirt.

按 BAC5750 (SOPM 20-30-03)规定的溶剂清洗。建议使用 Scotch-Brite 盘帮助清除污垢。

(2) Clean with Scotch-Brite pads and alkaline cleaners listed in Materials, diluted with 3 parts water by volume, until you get a water-break-free surface when you rinse the surface.

使用 Scotch-Brite 盘和《材料》中列出的碱性清洁剂,按体积用 3 份水稀释后进行清洁,直到冲洗表面时无断水现象。

(3) Rinse fully with clean water.

用清水充分冲洗。

(4) If you do not get a water-break-free surface, do Paragraph 4.D.(2) and Paragraph 4.D.(3) again.

如果表面没有断水,请再次执行第 4.D.(2)段和第 4.D.(3)段。

(5) If you went through to the base material, apply surface treatment specified by the overhaul instructions.

如果已处理到基材,则进行大修说明规定的表面处理。

(6) Fully dry before you apply the primer or enamel layer.

待完全干燥后再涂底漆或瓷漆层。

E. Method 5 (for BMS 10-11, Type 1 and BMS 5-89 primers only)

方法 5(仅适用于 BMS 10-11、1 型和 BMS 5-89 底漆)

(1) Soak alkaline clean the BMS 5-89 primer as specified in BAC5749 (SOPM 20-30-03) with Turco 4215 cleaner.

按 BAC5749(SOPM 20-30-03)规定的用 Turco 4215 清洁剂浸泡碱洗 BMS 5-89 底漆。

(2) Soak alkaline clean the BMS 10-11, Type 1 primer, as specified in BAC5749 (SOPM 20-30-03). Let the surface soak approximately 5 minutes. Then fully rinse. If you do not get a water-break-free surface, soak again and then rinse until you get a water-break-free surface. Then fully dry the surface.

按照 BAC5749(SOPM 20-30-03)规定的 BMS 10-11 型 1 类底漆进行浸碱清洗。让表面浸泡约 5 分钟。然后充分冲洗。如果表面没有断水,可再次浸泡,然后冲洗,直到表面断水为止。然后完全擦干表面。

F. Method 6

方法 6

(1) Manual solvent clean as specified in BAC5750 (SOPM 20-30-03) with a Series 86 solvent (SOPM 20-30-86).

按照 BAC5750(SOPM 20-30-03)规定的用 86 系列溶剂(SOPM 20-30-86)进行手工溶剂清洗。

(2) Do this again with clean wipers and more Series 86 solvent (SOPM 20-30-86).

用干净的抹布和更多的 86 系列溶剂(SOPM 20-30-86)再做一次。

(3) Dry fully before you apply the primer or enamel layer.

完全干燥后再涂底漆或瓷漆层。

G. Method 7

方法 7

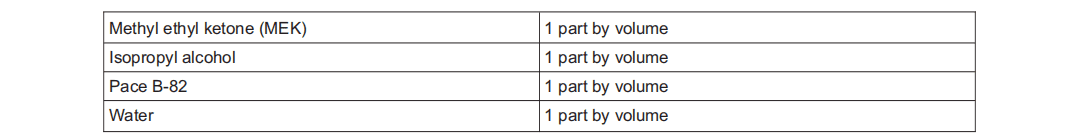

(1) Manual alkali emulsion clean with this mix:

使用此混合液进行手工碱乳液清洁:

(2) Mix these cleaners fully before you use the mix. Apply the cleaner to the surface. Clean with Scotch-Brite pads to remove contamination. Do not put the Scotch-Brite pads into the cleaner. Do not let the cleaner dry on the surface

在使用混合液之前,请将这些清洁剂充分混合。将清洁剂涂抹在表面上。用 Scotch-Brite 盘清洁以去除污染物。不要把 Scotch-Brite盘放入清洁剂中。不要让清洁剂在表面上干燥。

NOTE: Blue stains from leak detection tests can stay.

注:渗漏检测测试产生的蓝色污渍可能会残留。

(3) Rinse with clean water.

用清水冲洗。

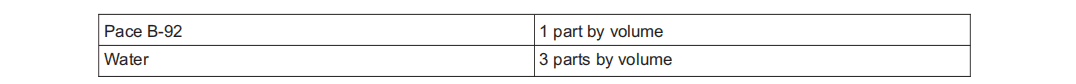

(4) Manual clean with this mix:

使用此混合液进行手动清洁:

(5) Clean with this mix and Scotch-Brite pads until you get a water-break-free surface after the rinse. Do not let the cleaner dry on the surface.

用这种混合液和 Scotch-Brite 盘进行清洁,直到冲洗后表面无断水为止。不要让清洁剂在表面上变干。

(6) Rinse with clean water. If you do not get a water-break-free surface, clean again as specified in Paragraph 4.G.(4) and Paragraph 4.G.(5).

用清水冲洗。如果表面没有形成无断水表面,则按照第 4.G.(4)段和第 4.G.(5)段规定的方法再次清洗。

(7) Use pH paper to make sure the alkaline cleaner is completely removed. When the cleaner is completely gone, the pH of the rinse water on the surface will be the same as the incoming rinse water.

使用 pH 试纸确保碱性清洁剂已完全清除。清洁剂完全清除后,表面冲洗水的 pH 值将与进入的冲洗水相同。

(8) If you went through to the bare metal, apply replacement surface treatments as necessary.

如果清洗到裸露的金属,则根据需要使用替代表面处理剂。

(9) Fully dry the surface.

完全擦干表面。

5. MIXING INSTRUCTIONS 混合说明

CAUTION :BASES, CATALYSTS, CONVERTERS, AND THINNER COMPONENTS FROM DIFFERENT MANUFACTURERS MUST NOT BE MIXED.

注意 :不同制造商生产的基料、催化剂、转化剂和稀释剂成分不得混合。

A. Mix base, catalyst, and thinner in the proportions shown in the Qualified Products List (QPL) of the paint specification or as shown in BAC5736.

按涂料规格的合格产品清单 (QPL) 或 BAC5736 中所示的比例混合基料、催化剂和稀释剂。

B. Shake each component by itself before you mix them together.

将每种成分混合在一起之前,先单独摇匀。

C. Let BMS 10-11, Type 1, Grade A and B primers wait 30 minutes before you apply them. No wait is necessary for BMS 10-11, Type 1, Grade E primer.

涂刷 BMS 10-11、1 类 A 级和 B 级底漆前,应等待 30 分钟。BMS 10-11 1 型 E 级底漆无需等待。

D. Let BMS 10-11, Type 2, Grade A enamel wait 1 hour before you apply it.

涂抹 BMS 10-11(2 型)A 级瓷漆前,请等待 1 小时。

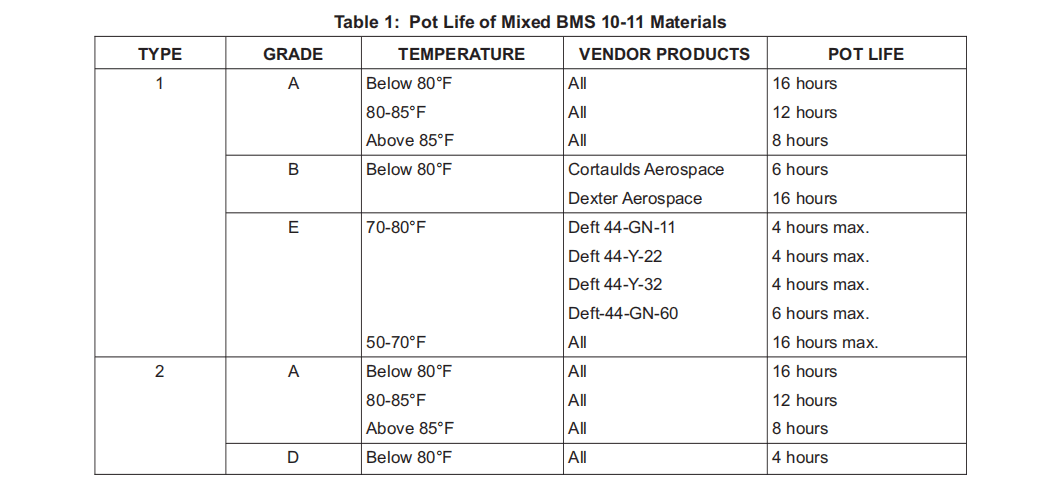

E. See Table 1 for the pot life of mixed BMS 10-11 materials.

BMS 10-11 混合材料的罐装寿命见表 1。

F. Mix the materials in clean containers. Do not use paper containers or containers that have organic coatings.

在干净的容器中混合涂料。不要使用纸容器或有有机涂层的容器。

6. APPLICATION OF COATING 涂层的涂抹

A. You can apply with:

可以用以下材料涂抹:

WARNING :SOME OF THESE MATERIALS ARE POISONOUS AND FLAMMABLE. USE THEM IN A WELL-VENTILATED AREA. OBEY SAFETY AND FIRE PRECAUTIONS. DO NOT BREATHE VAPORS. IF MATERIAL GETS IN YOUR EYES, FLUSH WITH WATER FOR 15 MINUTES AND GET MEDICAL ATTENTION IMMEDIATELY. IF MATERIALS GET ON YOUR SKIN, WASH WITH WATER. WIPE UP SPILLS IMMEDIATELY.

警告 :其中一些材料有毒且易燃。请在通风良好的地方使用。遵守安全和防火措施。切勿吸入蒸汽。如果材料进入眼睛,用水冲洗 15 分钟,并立即就医。如果材料沾到皮肤上,用水冲洗。立即擦掉溢出物。

(1) Spray (pressure feed, siphon feed, or electrostatic). Spray is preferred for external surface

喷涂(压力喷涂、虹吸喷涂或静电喷涂)。外表面首选喷雾

(2) Brush (optional to the spray procedure)

刷涂(喷涂程序的可选项)

(3) Dip coat

浸涂

(4) Fill and drain

填充和排干

(5) Curtain coat, with Steinman Model 130, or equivalent

帘涂,使用 Steinman 130 型或同类产品

(6) Flood coat, with Binks Model 31, or equivalent

泛涂,使用 Binks 31 型或同等设备。

B. Cotton swabs (such as Q-tips) can be used for touchup if this does not get cotton strands in the finish.

如果棉签(如 Q 型棉签)不会将棉线卷入表面处理面,则可用棉签进行修补。

C. Mask or give protection to all areas not to be cleaned and coated.

对所有未清洗和涂漆的区域进行遮盖或保护。

D. Apply these primers and enamels at 50°F minimum air temperature and 85% maximum relative humidity.

在最低气温 50°F 和最高相对湿度 85% 的条件下涂刷这些底漆和瓷漆。

E. Clean the equipment as quickly as possible after you are done. Methyl isobutyl ketone is recommended.

完成后尽快清洁设备。建议使用甲基异丁基酮。

F. Spray Application

喷涂

(1) If possible, use a spray booth.

如果可能,使用喷房。

(2) Tank-type pressure-feed spray guns can be used for high production painting of large areas. Siphon or pressure feed cup guns can be used for small areas or touchup.

罐式压送喷枪可用于大面积的高产量喷涂。虹吸式或压力进给杯式喷枪可用于小面积喷涂或修补。

(3) Give adjacent areas protection from overspray, fumes and dust.

保护邻近区域免受过喷、烟雾和灰尘的影响。

(4) Use a clean, dry air supply. Clean the air filters two or more times each day.

使用清洁、干燥的气源。每天清洁空气过滤器两次或两次以上。

(5) Use these pressures:

使用这些压力:

(a) Material pressure: 8-10 psig plus 2 psig for each 5 feet that the gun is located above the pressure pot gage.

材料压力:8-10 psig,喷枪位于压力罐压力计上方每 5 英尺加 2 psig。

(b) Line pressure: 40-60 psig (hose up to 25 feet long) or 65 psig (hose 25-50 feet long).

管路压力:40-60 psig (软管最长 25 英尺)或 65 psig (软管最长 25-50 英尺)。

(6) Use a wide fan spray nozzle for large areas such as panels. Use a medium fan spray nozzle for smaller work. Adjust the flow and paint pattern to apply a fine, continuous layer.

在面板等大面积区域使用宽扇形喷嘴。使用中型扇形喷嘴喷涂较小的面积。调整流量和喷涂模式,以喷涂出精细、连续的涂层。

(7) Hold the gun perpendicular to the surface and 6-10 inches away. Follow the contour if the surface is curved. Turn cylindrical items.

将喷枪垂直于表面,距离 6-10 英寸。如果表面有弧度,则顺着轮廓喷涂。转动圆柱形物品。

(8) Move the gun at a steady speed across and parallel to the work.

以稳定的速度横向移动喷枪,并与工件平行。

(9) Make an overlap of a minimum of one-third of the last pass.

至少重叠最后一遍的三分之一。

(10) Remove all runs and falls immediately with clean wiper and toluene.

立即用干净的擦拭布和甲苯清除所有的流痕和掉落物。

G. Brush Application

刷涂

(1) Thin as necessary. But do not use more thinner than recommended by the vendor instructions.

根据需要稀释。但使用的稀释剂不要超过供应商说明中的建议。

(2) Use good quality natural bristle paint brushes. Do not use synthetic bristle brushes because the material will dissolve them.

使用优质天然鬃毛油漆刷。不要使用合成毛刷,因为涂料会溶解它们。

(3) Apply the coating in one direction as much as possible. Use light pressure on the brush to make a smooth continuous layer.

尽可能顺着一个方向涂抹涂料。用刷子轻压,使涂层平滑连续。

(4) Try not to brush out the wet coating because pickup, air bubbles and voids could occur and make touchup necessary.

尽量不要将湿涂层刷掉,因为可能会出现吸附、气泡和空隙,从而需要进行修补。

H. Fill and Drain

填充和排干

(1) Prepare materials by the vendor’s instructions.

按照供应商的说明准备材料。

(2) Apply the coatings in a clean, dust-free area.

在干净无尘的地方涂抹涂料。

(3) Put plugs into the holes of the part.

将塞子塞入零件的孔中。

(4) Flush the part with toluene. Shake the part to clean all internal surfaces. If you can, push a clean wiper wet with toluene through the part. Then follow with a clean, dry wiper.

用甲苯冲洗零件。摇动零件以清洁所有内表面。如果可以,用沾有甲苯的干净抹布推过零件。然后再用干净的干抹布擦拭。

(5) Drain all solvent from the part. Remove all plugs. Fully dry with a good flow of warm air (160°F maximum) through the part.

从零件中排出所有溶剂。取下所有塞子。用暖风(最高 160°F)充分吹干零件。

(6) Put plugs back into the holes as necessary.

根据需要将塞子塞回孔中。

(7) Fill the part with primer. Shake and turn the part to make sure the primer gets on all of the surfaces.

给零件注入底漆。摇晃并转动零件,确保底漆涂满所有表面。

(8) Remove the plugs and let the primer drain. Turn the part as necessary to let all primer drain out. Then put the part in a vertical position, if you can.

取下塞子,让底漆流出。必要时转动零件,让底漆全部流出。然后尽可能将零件竖直放置。

(9) Now put an air supply tube into one or more of the holes and send warm filtered air (160°F maximum) through the part for 1 hour or more. Use an air pressure, measured at the regulator, of 10-15 psi. If the part has only one hole, put the air supply tube as far into the part as possible, but be careful not to touch more of the wet primer than necessary.

现在将供气管插入一个或多个孔中,将过滤后的暖空气(最高温度 160°F)送入零件,持续 1 小时或更长时间。在调节器处测量的气压为 10-15 psi。如果零件只有一个孔,则将供气管尽量伸入零件内,但要注意不要接触到比必要更多的湿底漆。

(10) If two layers are specified, reverse the part to let you fill it from the opposite end. Wait a minimum of 2 hours before you apply the second layer of primer. Then do Paragraph 6.H.(6) thru Paragraph 6.H.(8) again. Air circulation through the tubing as specified in Paragraph 6.H.(9) is optional.

如果规定的是两层,则将零件反过来,让您从另一端进行填充。至少等待 2 小时后再涂第二层底漆。然后再执行第 6.H.(6)至 6.H.(8)段。第 6.H.(9)段规定的通过管道的空气循环是可选的。

I. Wipe-on Primer for Plated Surfaces

电镀表面的擦拭式底漆

(1) Wipe the surface with solvent as specified in BAC5750 (SOPM 20-30-03).

用 BAC5750 (SOPM 20-30-03)规定的溶剂擦拭表面。

(2) Apply BMS 10-11, Type 1 primer on all of the specified surface with wipers soaked with primer. The primer can run onto adjacent surfaces, but you must remove that primer before it dries, as specified in Paragraph 6.I.(3).

用沾有底漆的抹布在所有规定的表面上涂抹 BMS 10-11 1 类底漆。底漆可以流到邻近表面,但必须按照第 6.I.(3)段的规定,在底漆干透前将其清除。

(3) Before the primer dries, carefully and lightly remove unwanted wet primer with wipers. Do not use a solvent.

在底漆干燥之前,用抹布小心、轻柔地清除不需要的湿底漆。不要使用溶剂。

(4) Cure the primer as specified in Paragraph 7.

按照第 7 段规定的方法固化底漆。

7. CURING 固化

A. Give the new coating protection from dust, moisture, or other contamination until cured.

保护新涂层,防止灰尘、湿气或其他污染,直至固化。

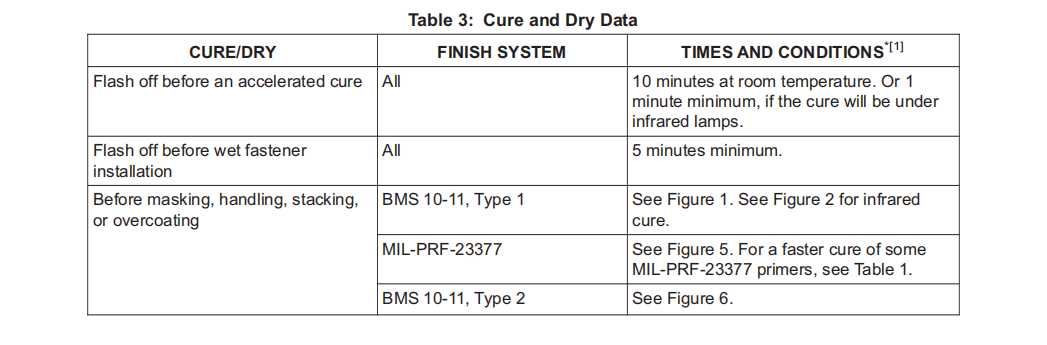

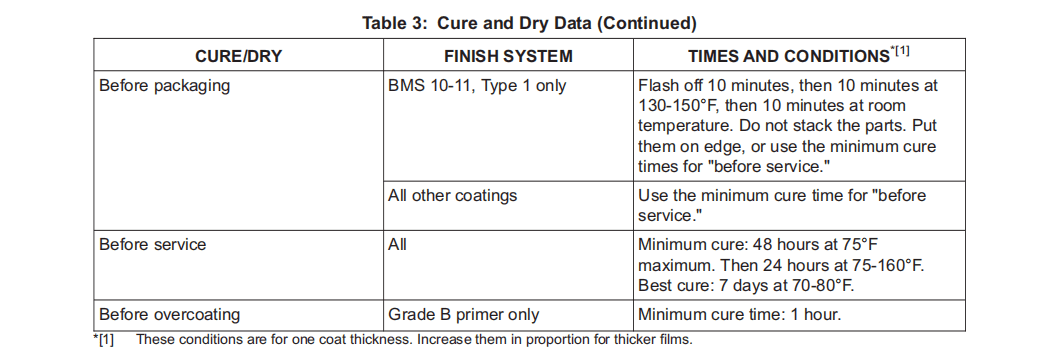

B. Cure coatings as specified in Table 3.

按表 3 规定的方法固化涂层。

(1) Do not heat or cure bonded assemblies higher than 180°F.

焊接组件的加热或固化温度不得高于 180°F。

(2) Do not heat or cure shot peened aluminum parts higher than 200°F. Do not heat or cure other aluminum parts higher than 250°F.

加热或固化喷丸铝质零件的温度不得高于 200°F。加热或固化其他铝质零件的温度不得高于 250°F。

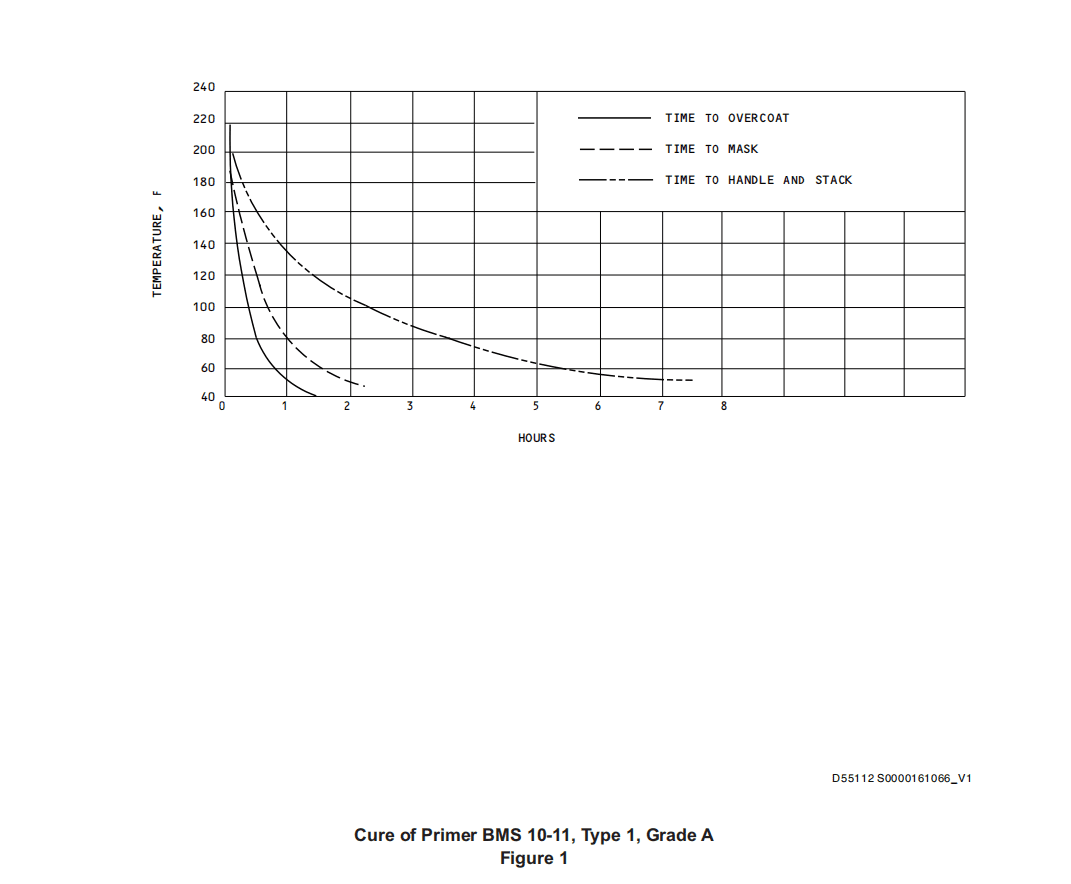

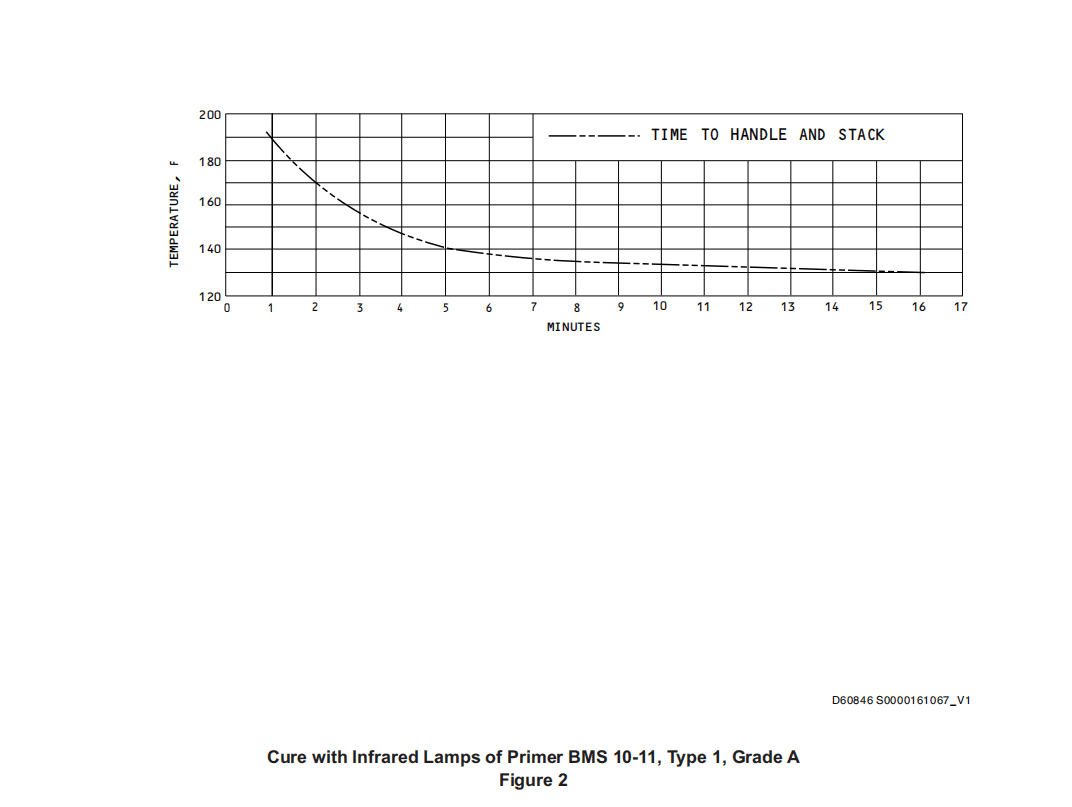

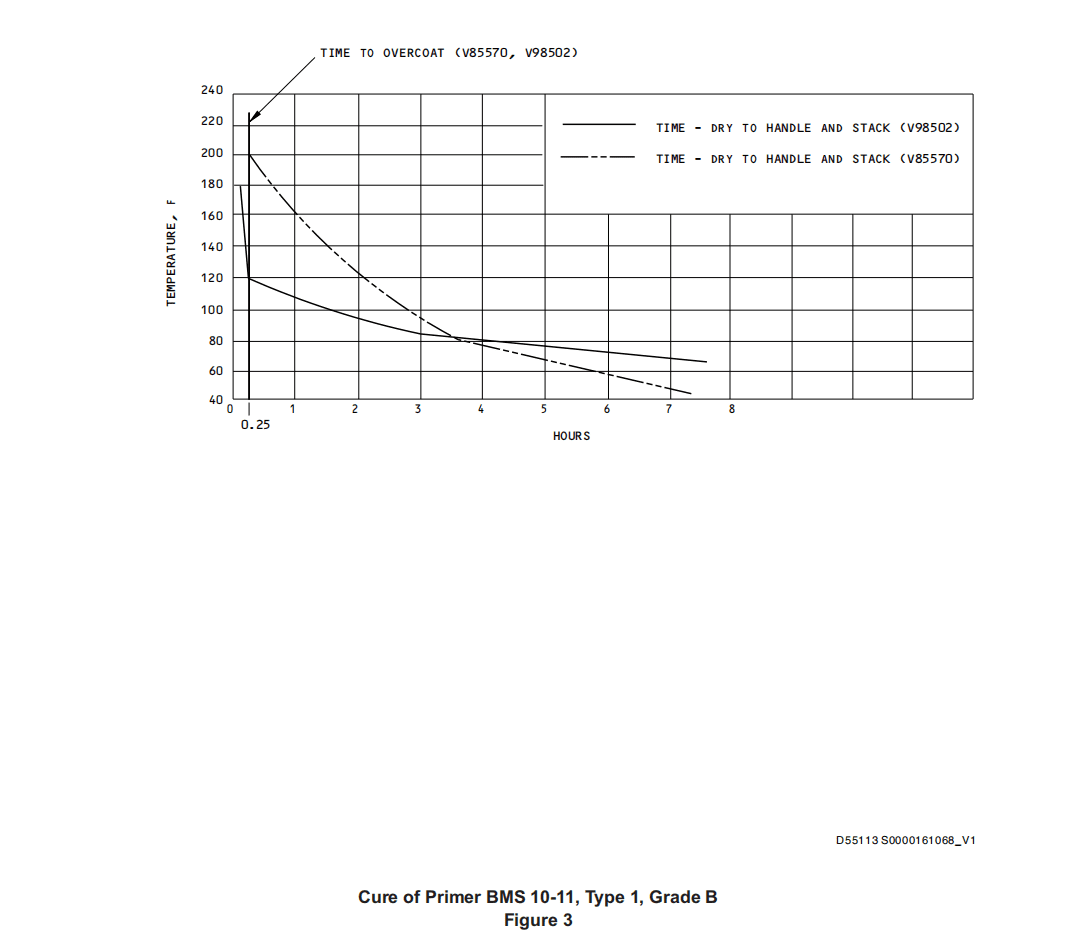

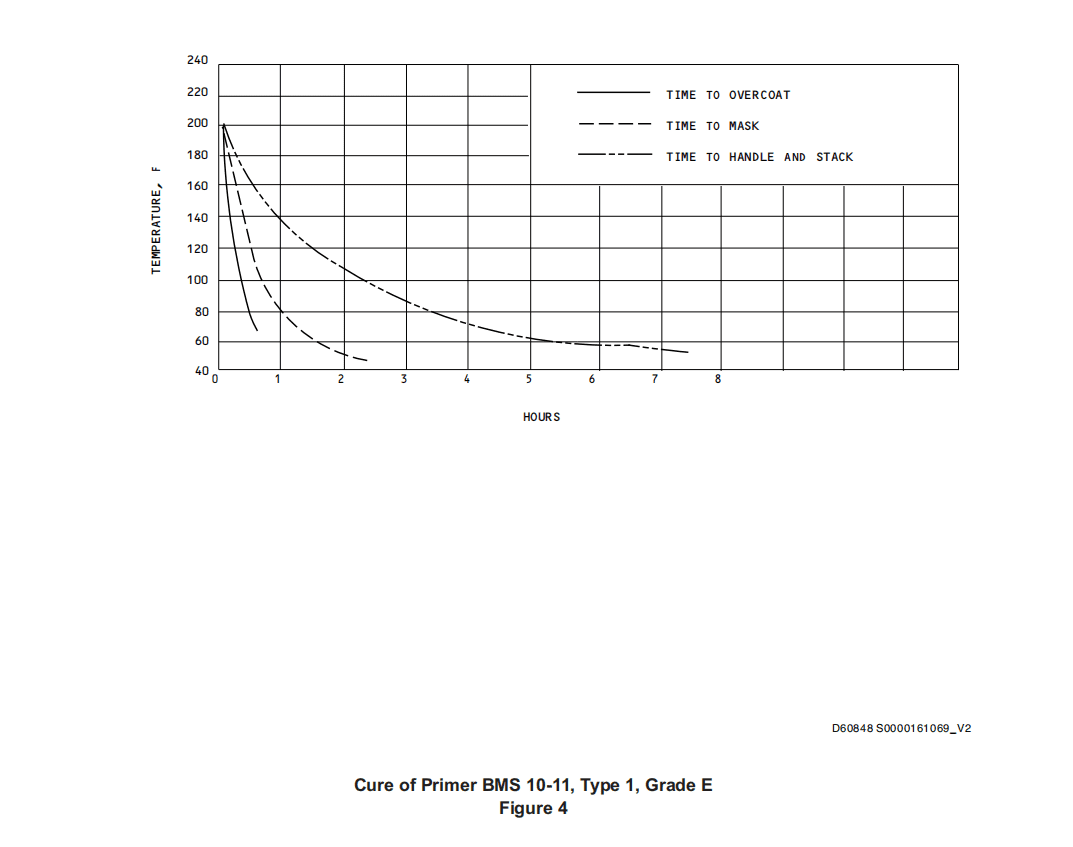

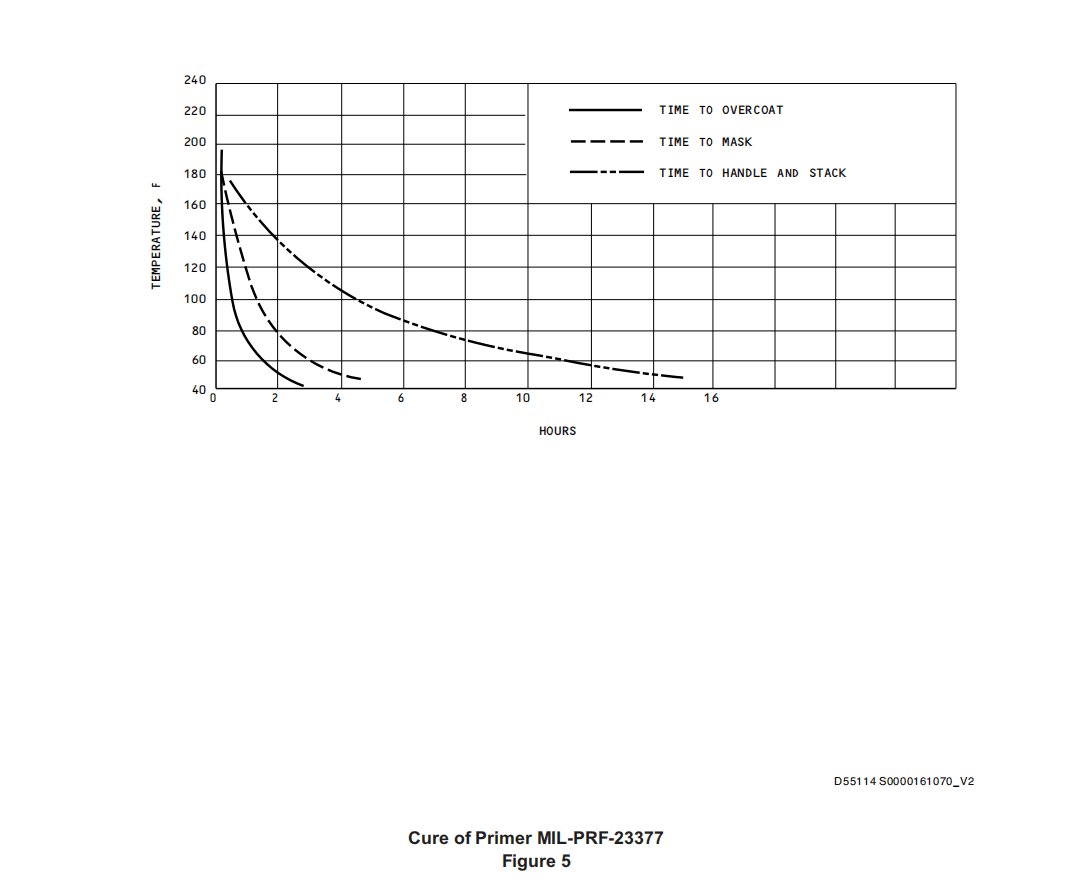

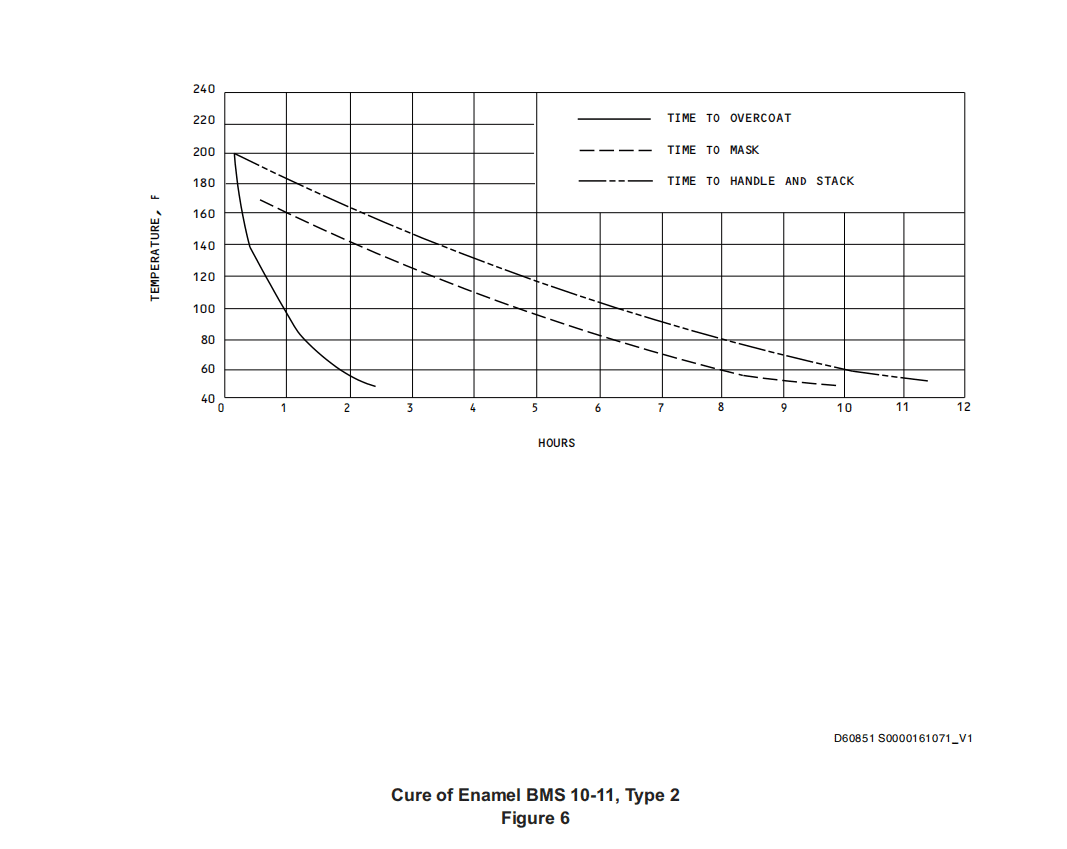

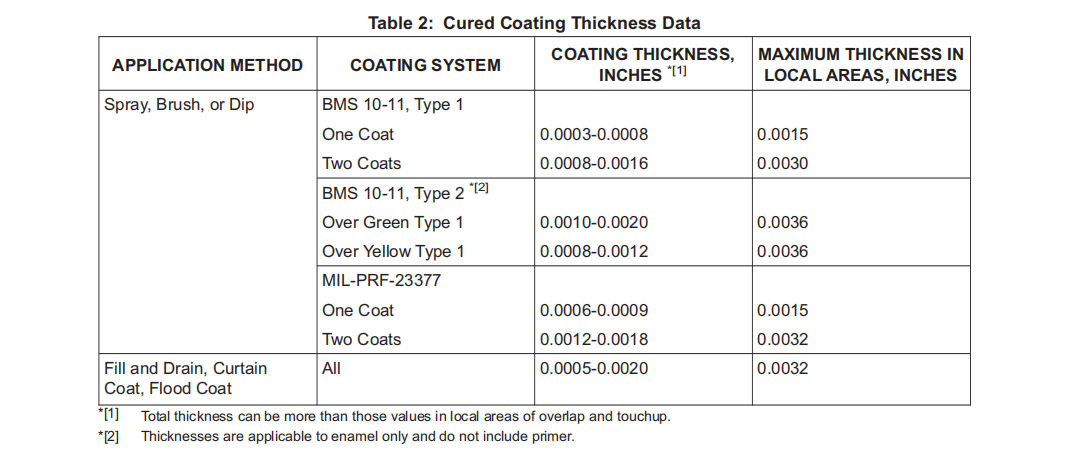

(3) The times given in Table 3, and Figure 1 thru Figure 6 are for the one-layer thicknesses given in Table 2. Increase the times in proportion for thicker layers. All times are approximate. Use them only as a guide.

表 3 和图 1 至图 6 中给出的时间是针对表 2 中给出的单层厚度。如果层数较厚,则按比例增加时间。所有时间均为近似值。仅供参考。

8. REPAIR 修理

A. If the damage goes through to the base material, remove the primer and enamel layers from the damaged area by the procedure for organic finishes in SOPM 20-30-02. If the damage is only scratches and other defects that do not go through to the base material, go to Paragraph 8.B.

如果损坏穿透基材,则按照 SOPM 20-30-02 中有机面漆的程序清除损坏区域的底漆和瓷漆层。如果损坏仅为划痕和其他缺陷,且未穿透基材,则转至第 8.B 段。

B. Solvent clean the area as specified in SOPM 20-30-03.

按 SOPM 20-30-03 规定的程序进行溶剂清洗。

C. Lightly sand the area with 240-grit or finer abrasive. Make the area smooth and blend into the adjacent area. Do not go through to the base material. Clean off the dust and dirt with tack rags, or solvent clean as specified in SOPM 20-30-03.

用 240 号或更细的砂纸轻轻打磨该区域。使该区域光滑并与邻近区域融为一体。不要打磨到基材。用粘性抹布或 SOPM 20-30-03 规定的溶剂清洁剂清除灰尘和污垢。

D. If the damaged area has bare base metal, manually repair the surface treatment (such as anodize or plating) as applicable.

如果受损区域有裸露的基底金属,则视情况手工修理表面处理(如阳极氧化或电镀)。

E. Apply new layers of primer and enamel, as applicable, as specified in Paragraph 6. Cure as specified in Paragraph 7.

按第 6 段的规定,酌情涂上新的底漆和瓷漆层。按第 7 段规定的方法固化。