防腐化合物的应用APPLICATION OF CORROSION INHIBITING COMPOUNDS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5877. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自波音工艺规范 BAC5877。航空公司有一本《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use it as a guide to help you write minimum standards.

数据是通用的。它不涉及所有情况或特定安装。请将其作为指南,帮助您编写最低标准。

C. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. COMPOUND DESCRIPTIONS 化合物说明

A. Corrosion inhibiting compounds are used with finish systems to prevent corrosion, or to stop corrosion when the finish system is damaged. Many can get into very small cavities and push out water. Thus they can go in between faying surfaces or between fasteners and holes, where the finish is broken.

防腐化合物与饰面系统(表面处理)一起使用,可防止腐蚀,或在饰面系统受损时阻止腐蚀。许多防腐化合物可以进入很小的空腔并将水挤出。因此,它们可以进入饰面破损的表面之间或紧固件和孔之间。

B. Make an analysis of your airplane’s environment, the inhibitor used, and the application schedule, to be sure of sufficient corrosion protection. Other water displacing corrosion inhibiting compounds could be satisfactory.

对飞机的环境、所使用的抑制剂和使用计划进行分析,以确保提供足够的腐蚀保护。其他的水置换防腐化合物也可能令人满意。

C. BMS 3-23 Corrosion Inhibiting Compound

BMS 3-23 防腐化合物

(1) This is an organic compound of nonvolatile base materials in solvents to make a fluid. It does not contain silicones. This compound can be dipped, brushed, or sprayed. The liquid carrier evaporates quickly to put a thin layer of wax-like material on the surface. The coating is not easily rubbed or worn off, but must be applied again if the surface is washed frequently.

这是一种在溶剂中非挥发性基料形成液体的有机化合物。它不含有机硅。这种化合物可以浸渍、涂刷或喷洒。液体载体迅速蒸发,在表面形成一层薄薄的蜡状物质。涂层不易被摩擦或磨损,但如果表面经常清洗,则必须再次涂抹。

(2) BMS 3-23 compound stays tacky and thus will collect unwanted material. The areas where it is applied must be regularly cleaned and then more of the corrosion inhibitor must be applied. The time between applications of the compound will change with the location in the airplane. Refer to the Maintenance Planning Document for details.

BMS 3-23 化合物保持粘性,因此会聚集不需要的物质。必须定期清洁涂抹区域,然后涂抹更多的防腐化合物。使用化合物的间隔时间将随飞机的位置而变化。详情请参见维护计划文件。

(3) Types of BMS 3-23

BMS 3-23 的类型

(a) Type 1 — Makes a transparent colorless layer which can be seen only with ultraviolet light.

类型 1 — 形成无色透明层,只能在紫外线下看到。

D. BMS 3-26 Corrosion Inhibiting Compound

BMS 3-26 防腐化合物

(1) This is an organic compound of non-volatile base materials in solvents to make a fluid. It does not contain silicones. This compound can be dipped, brushed or sprayed. After it dries, it makes a transparent but visible protective layer. Coated surfaces become dry to the touch after 24 hours. The layer is not easily rubbed or worn off, but must be applied again if the surface is washed frequently.

这是一种在溶剂中非挥发性基料形成液体的有机化合物。不含有机硅。这种化合物可以浸渍、涂刷或喷洒。干燥后可形成透明但可见的保护层。24 小时后,涂层表面会变得干爽。该保护层不易被擦掉或磨损,但如果表面经常清洗,则必须再次涂抹。

(2) Types of BMS 3-26

BMS 3-26 的类型

(a) Type 1 — Makes a continuous layer of medium thickness with a drop melting point of 140°F minimum.

类型 1 — 可形成中等厚度的连续涂层,熔点最低为 140°F。

(b) Type 2 — Makes a continuous thick layer with a drop melting point of 200°F minimum.

类型 2 — 形成连续的厚层,滴熔点最低为 200°F。

E. BMS 3-29 Corrosion Inhibiting Compound

BMS 3-29 防腐化合物

(1) This is an organic compound of non-volatile base materials in solvents to make a fluid. It does not contain silicones. This compound can be dipped, brushed or sprayed. After it dries, it makes a transparent but visible layer. Coated surfaces become dry to the touch after 24 hours. The layer is not easily rubbed or worn off, but must be applied again if the surface is washed frequently.

这是一种在溶剂中非挥发性基料形成液体的有机化合物。不含有机硅。这种化合物可以浸渍、涂刷或喷洒。干燥后会形成一层透明但可见的涂层。24 小时后,涂层表面会变得干爽。涂层不易被擦掉或磨损,但如果表面经常清洗,则必须再次涂抹。

(2) BMS 3-29 compound can replace the two-layer system of BMS 3-26 compound over BMS 3-23 compound.

BMS 3-29 复合物可取代 BMS 3-26 复合物在 BMS 3-23 复合物上的双层体系。

F. BMS 3-35 Corrosion Inhibiting Compound

BMS 3-35 防腐化合物

(1) This is an organic compound of non-volatile base materials in solvents to make a fluid. It does not contain silicones. This compound can be dipped, brushed or sprayed. After it dries, it makes a transparent but visible protective layer. Coated surfaces becomes dry to the touch after 24 hours. The layer is not easily rubbed or worn off, but must be applied again if the surface is washed frequently.

这是一种在溶剂中非挥发性基料形成液体的有机化合物。不含有机硅。这种化合物可以浸渍、涂刷或喷洒。干燥后可形成透明但可见的保护层。24 小时后,涂层表面会变得干爽。这层保护层不易被摩擦或磨损,但如果表面经常清洗,则必须再次涂抹。

G. MIL-C-16173 Corrosion Preventive Compound

MIL-C-16173 防腐化合物

(1) This compound contains non-volatile base materials in solvents to make a fluid. It can be sprayed or brushed. After it dries, it makes a thin layer that can be removed easily with a solvent. This compound gives a more resistant surface protection than the BMS 3-23 and 3-26 compounds. The Grade 1 compound gives a hard film, but does not have the penetrating or water displacing qualities of the BMS 3-23 or equivalent corrosion inhibiting compounds.

这是一种在溶剂中非挥发性基料形成液体的有机化合物。可以喷涂或刷涂。干燥后会形成薄薄的一层,可以用溶剂轻易去除。与 BMS 3-23 和 3-26 化合物相比,这种化合物能提供更强的表面保护。1 级化合物可形成一层坚硬的薄膜,但不具备 BMS 3-23 或同等防腐化合物的渗透性或水置换性。

(2) Types of MIL-C-16173

MIL-C-16173 的类型

(a) Grade 1 compounds make a hard layer like a hard grease. This layer is sufficiently dry to be touched in 4 hours. But it will not go into crevices or push out water.

1 级化合物会形成一层像硬脂一样的硬膜。该层足够干燥,可在 4 小时内触摸。但它不会进入缝隙或挤出水分。

(b) Grade 2 compounds make a film layer which stays soft after it dries. This compound does not push out water.

2 级化合物能形成一层薄膜,干燥后保持柔软。这种化合物不会挤出水分。

(c) Grade 3 compounds make a layer which stays soft after it dries. This compound will push out water.

3 级化合物形成的膜层在干燥后保持柔软。这种化合物会挤出水分。

(d) Grade 4 compounds make a transparent layer. This layer is sufficiently dry to be touched in 4 hours, and is not tacky after 24 hours.

4 级化合物可形成透明层。该层在 4 小时内充分干燥,可以触摸,24 小时后不粘。

(e) Grade 5 compounds make a layer which stays soft after it dries. The layer can be removed with low-pressure steam. This compound will push out water.

5 级化合物可形成一层干燥后保持柔软的涂层。可使用低压蒸汽去除该层。这种化合物会挤出水分。

3. PRECAUTIONS 预防措施

A. Do not apply or let corrosion inhibiting compounds get on insulation blankets. These compounds decrease the water-repellent quality and increase flammable quality of the blankets. If corrosion inhibiting compounds get on blankets, refer to Paragraph 6. for instructions.

不要在隔热毯上涂抹或让其沾上防腐化合物。这些化合物会降低保温毯的憎水性,增加其易燃性。如果保温毯上沾有防腐化合物,请参阅第 6 段的说明。

WARNING :WHEN MIXED, THE COMPOUND AND OXYGEN CAN BE EXPLOSIVE. KEEP THE COMPOUND AWAY FROM OXYGEN SYSTEM COMPONENTS.

警告 :化合物和氧气混合后会产生爆炸。请勿将化合物与氧气系统部件接触。

B. Because these compounds are hydrocarbons, they can be dangerous when mixed with oxygen. Give all oxygen system components protection from all direct or indirect contamination from these compounds.

由于这些化合物是碳氢化合物,与氧气混合后会有危险。保护所有氧气系统部件免受这些化合物的直接或间接污染。

C. Do not apply corrosion inhibiting compounds on interior materials such as cargo liners. The compounds change the flammable quality of these materials.

不要在货物内衬等内部材料上使用腐蚀抑制化合物。这些化合物会改变这些材料的易燃性。

WARNING :AS A FIRE SAFETY PRECAUTION, DO NOT APPLY COMPOUND TO ANY SURFACE THAT WILL GET HOTTER THAN 300°F (149°C) IN SERVICE. THE DRY FILM FLASH POINT IS 500°F (260°C)

警告:作为防火安全措施,请勿在使用中温度超过 300°F (149°C) 的任何表面上涂抹化合物。干膜闪点为 260°C (500°F)。

D. Give protection to all surfaces that will get hotter than 300°F in service to keep the compound off these surfaces. Do not apply corrosion inhibiting compounds near engines, cowling, or other areas of high temperature, or where firewall sealant is used. The high temperatures can cause deterioration of the compounds. Corrosion inhibiting compounds can cause damage to the sealant. Corrosion inhibiting compounds can be used on fiberglass fairings and ducts if the temperature of the duct will not be hotter than 220°F.

对所有在使用中温度会超过300°F的表面进行保护,以防止这些表面沾上化合物。不要在发动机、整流罩或其他高温区域附近或使用防火墙密封剂的地方涂抹防腐化合物。高温会导致化合物变质。防腐化合物可能会损坏密封胶。如果玻璃纤维整流罩和管道的温度不超过 220°F,则可在玻璃纤维整流罩和管道上使用防腐化合物。

WARNING :CORROSION INHIBITING COMPOUNDS CONTAIN FLAMMABLE COMPONENTS. DO NOT PUT OR USE THESE MATERIALS NEAR OPEN FLAMES, ACTIVE CIRCUITS, OR OTHER COMPONENTS WHERE THERE IS A RISK OF FIRE. THE VOLATILE CARRIER IS ALSO FLAMMABLE. OBEY SAFETY PRECAUTIONS UNTIL THE CARRIER IS FULLY EVAPORATED.

警告 :防腐化合物含有易燃成分。请勿在明火、有源电路或其他有起火危险的部件附近放置或使用这些材料。挥发性载体也是易燃物。在载体完全挥发之前,请遵守安全预防措施。

E. Mask electrical connectors where contamination of electrical contacts could occur.

屏蔽可能污染电气触点的电气连接器。

CAUTION :THE CARRIERS USED IN THE COMPOUND ARE VOLATILE HYDROCARBONS WHICH WILL WASH OUT LUBRICANTS FROM COMPONENTS.

注意 :化合物中使用的载体是挥发性碳氢化合物,碳氢化合物会冲掉部件上的润滑剂。

F. Give protection to pulleys, control cables, bearings, pivot pins, and other lubricated surfaces, from direction application of compound. Do not apply corrosion inhibiting compounds on grease joints or sealed bearings. These compounds dissolve greases and other lubricants. They are penetrating compounds and get around the seals and into the bearings.

保护滑轮、控制电缆、轴承、枢轴销和其他润滑表面免受化合物方向的影响。不要在油脂接头或密封轴承上涂抹防腐化合物。这些化合物会溶解润滑脂和其他润滑剂。它们是渗透性化合物,会从密封件周围进入轴承。

CAUTION :REMOVE UNWANTED CORROSION INHIBITING COMPOUNDS FROM MECHANISMS AND MOVING PARTS WITH A CLEAN, DRY WIPER. THE REMAINING THIN LAYER IS SUFFICIENT FOR CORROSION PROTECTION. TOO MUCH OF A LAYER BUILDUP COULD BECOME HARD IN COLD TEMPERATURES AND CAUSE OPERATING DIFFICULTIES.

注意 :用干净、干燥的擦拭布清除机构和活动零件上多余的防腐化合物。剩余的薄层足以提供腐蚀保护。过厚的防腐层在低温下会变硬,造成运转困难。

G. Corrosion inhibiting compounds on control cables are not a good substitute for the cleaning and corrosion protection procedures in the maintenance and overhaul instructions. Laboratory tests show that the service life of carbon steel cable is decreased by the direct application of these compounds. But overspray on the cables as you apply these compounds to adjacent structure is not an important problem for cable life.

控制电缆上的防腐化合物不能很好地替代维护和大修说明中的清洁和腐蚀保护程序。实验室测试表明,直接使用这些化合物会缩短碳钢电缆的使用寿命。但在邻近结构上使用这些化合物时,电缆上的过喷不会对电缆寿命造成严重影响。

CAUTION :CORROSION INHIBITING COMPOUNDS CAN CAUSE SILICONE RUBBER AND BMS 3-11 RESISTANT SEALS TO BECOME LARGER.

注意:防腐化合物会导致硅橡胶和 BMS 3-11 耐腐蚀密封件变大。

H. Be careful when you apply corrosion-inhibiting compound near door or emergency hatch seals, grease seals in bearing assemblies or rubber-lined clamps for tubing or wiring. Do not apply these compounds on actuator rods, because the compound will get on the hydraulic seals.

在门或紧急舱口密封件、轴承组件中的油脂密封件或内衬橡胶的管道或电线夹附近涂抹防腐化合物时要小心。不要在传动杆上涂抹这些化合物,因为化合物会沾到液压密封件上。

I. Corrosion inhibiting compounds can be used on bladder fuel tanks and fuel vapor barriers.

防腐化合物可用于囊式燃料箱和燃料隔汽层。

J. Do not spray these compounds on surfaces that must move freely against other surfaces, such as in linkages, mechanisms, solenoids or cable feed-throughs. Some compounds dry tack free, but if the surfaces touch, the compound layers could increase friction in the joints, or bond the surfaces together.

不要将这些化合物喷涂在必须相对于其他表面自由移动的表面上,如连杆、机构、螺线管或电缆馈通处。有些化合物干后无粘性,但如果表面接触,化合物层会增加接缝处的摩擦力,或将表面粘合在一起。

4. SURFACE PREPARATION 表面处理

A. A fully clean surface is not necessary before you apply these compounds. But the compounds will more easily soak into joints if the area is cleaned before application. The recommended cleaning procedure is:

在涂抹这些化合物之前,不需要完全清洁表面。但是,如果在涂抹前对涂抹区域进行了清洁,化合物会更容易渗入接缝中。建议的清洁程序是:

(1) Remove all moisture and loose unwanted material with vacuum cleaner, brush, or clean cloth.

用吸尘器、刷子或干净的布清除所有水分和松散的杂质。

(2) If the surface is very dirty or greasy, clean per BAC 5744 or BAC 5750 (Ref SOPM 20-30-03). Water-break-free surfaces are not necessary.

如果表面非常脏或油腻,则按照 BAC 5744 或 BAC 5750(参考 SOPM 20-30-03)进行清洁。不需要无断水的表面。

5. APPLICATION OF COMPOUND 化合物的使用

WARNING :CORROSION INHIBITING COMPOUNDS ARE APPROXIMATELY AS POISONOUS AS KEROSENE OR ALIPHATIC NAPHTHA. FOR SKIN PROTECTION, USE THE SAME PRECAUTIONS AS FOR KEROSENE. WHEN YOU SPRAY THESE COMPOUNDS IN AN ENCLOSED AREA, A VAPOR CONCENTRATION OF 500 PARTS PER MILLION IS THE MAXIMUM COMFORTABLE WORKING LIMIT. AT THIS CONCENTRATION A PERSON CAN WORK AN 8-HOUR SHIFT. VAPOR LEVELS HIGHER THAN 500 PPM ARE NOT DIRECTLY TOXIC, BUT FORCED VENTILATION COULD BE NECESSARY TO KEEP A COMFORTABLE LEVEL. PERCHLOROETHYLENE IS A PREFERRED SOLVENT BECAUSE IT IS NONFLAMMABLE, BUT PERCHLOROETHYLENE IS POISONOUS. IF USED IN CONFINED AREAS, MECHANICAL VENTILATION IS MANDATORY. RESPIRATORY AND SKIN PROTECTION COULD BE NECESSARY.

警告:防腐化合物的毒性与煤油或脂肪族石脑油差不多。为保护皮肤,应采取与煤油相同的预防措施。在密闭区域喷洒这些化合物时,最大舒适工作浓度为百万分之 500。在此浓度下,一个人可以工作 8 小时。蒸汽浓度高于百万分之 500 不会直接引起中毒,但为了保持舒适的工作环境,必须进行强制通风。四氯乙烯是首选溶剂,因为它不易燃,但四氯乙烯有毒。如果在密闭区域使用,必须进行机械通风。有必要采取呼吸防护和皮肤防护措施。

A. General

通用

(1) Compatibility: Because these materials are usually hydrocarbons, new layers of a different compound can be applied over old layers of corrosion inhibitors without problems.

兼容性: 因为这些材料通常是碳氢化合物,所以在旧的缓蚀剂上再涂一层不同的化合物不会有问题。

(2) Before you apply the compound, let BMS 10-11 primers and enamels, and BMS 10-103 primers, cure for a minimum of 1 hour, and let all primers and enamels cure for a minimum of 8 hours.

在使用化合物之前,应让 BMS 10-11 底漆和瓷漆以及 BMS 10-103 底漆固化至少 1 小时,让所有底漆和瓷漆固化至少 8 小时。

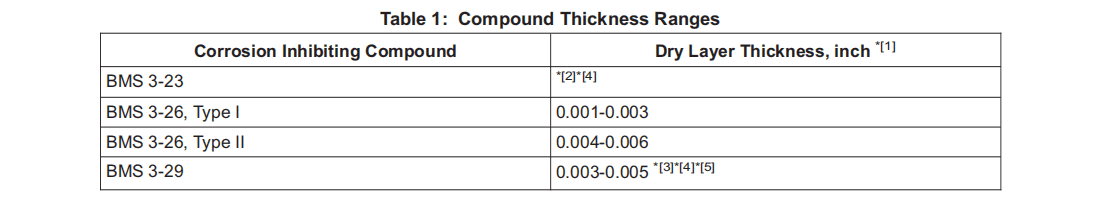

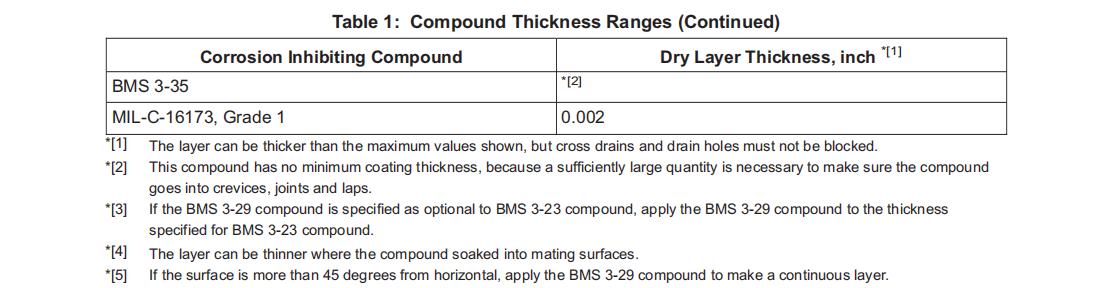

(3) Apply a continuous wet layer of compound by spray, brush, or swab to get the dry thickness per Table 1. Make sure that the layer is continuous on all crevices, joints, and laps to let the compound soak in by capillary action. Equipment that applies the compound under pressure directly to a joint or lap will help it to soak in.

用喷雾、刷子或棉签涂上一层连续的湿涂料,以达到表 1 所列的干厚度。确保在所有缝隙、接缝和搭接处连续涂抹,让化合物通过毛细作用浸入。在接缝或搭接处直接加压涂抹胶料的设备将有助于胶料的浸透。

(4) The minimum layer thickness limits are to make sure the surfaces have corrosion protection. The maximum layer thickness limits are to make sure the compound does not add too much weight to the airplane.

最小涂层厚度限制是为了确保表面具有防腐蚀保护。最大涂层厚度限制是为了确保复合物不会给飞机增加过多重量。

(5) For BMS 3-23 compounds, let the compound stay on the surface a minimum of 60 minutes. Then wipe away puddles with clean gauze or cloth. For BMS 3-26, BMS 3-29, BMS 3-35, and MIL-C-16173 compounds, do not wipe the coating. Let the compound dry tack-free if the coated surface will touch another surface, such as insulation blankets. (Do not apply corrosion inhibiting compounds on insulation blankets. The compounds reduce the water-repellent quality and increase flammable quality of the blankets. If corrosion inhibiting compounds get on blankets, refer to Paragraph 6. for instructions.)

对于 BMS 3-23 化合物,让其在表面上停留至少 60 分钟。然后用干净的纱布或布擦去积水。对于 BMS 3-26、BMS 3-29、BMS 3-35 和 MIL-C-16173 复合物,不要擦拭涂层。如果涂层表面会接触到其他表面(如绝缘毯),则应让化合物干透无粘性。(不要在隔热毯上涂抹腐蚀抑制化合物。这些化合物会降低保温毯的憎水性并增加其易燃性。如果保温毯上沾有缓蚀剂,请参阅第 6 段的说明)。

(6) Give the area a good flow of air until the solvents are completely evaporated.

让该区域空气流通,直至溶剂完全挥发。

(7) Remove the masks or shields.

取下面罩或防护罩。

B. Spray Application

喷涂

(1) For BMS 3-23 compound, this procedure will make a layer of 0.0003 inch thick.

对于 BMS 3-23 化合物,此程序可喷涂 0.0003 英寸厚的一层

(a) Adjust the application rate to one gallon per hour.

将喷涂速度调至每小时一加仑。

(b) Hold the nozzle 12 inches maximum from the surface.

将喷嘴固定在距表面最大 12 英寸处。

(c) Apply compound at a coverage rate of 15-20 square feet per minute.

以每分钟 15-20 平方英尺的覆盖率涂抹化合物。

(2) You can use aerosol cans and plastic nozzle extensions. But we cannot recommend these because of their cost and amount of overspray they cause.

您可以使用气雾罐和塑料喷嘴加长杆。但我们不推荐使用,因为成本太高,而且会造成大量过喷。

(3) The preferred application method uses standard pressure pot equipment with an airless spray gun operated at low pressure (45 psi). You can get such spray equipment from the following suppliers:

首选的喷涂方法是使用标准压力罐设备和低压(45 psi)操作的无气喷枪。您可以从以下供应商处获得此类喷涂设备:

(a) Nordson Corporation (V07036 or V2R369)

(b) The DeVilbiss Company (V17431)

(c) Binks Manufacturing Company (V07334)

(d) Graco Incorporated (V25980)

(4) You will find access easier if you use accessories such as spray gun extension kits and swivel adapters for the nozzle.

如果使用喷枪加长套件和喷嘴旋转适配器等附件,您会发现使用更加方便。

(5) You can use standard air atomizing equipment (siphon or pressure pot) when access is sufficient to let you apply a wet coat. When you spray with a pressure pot, you can make a suitable extension as follows:

当喷涂湿涂层时,可以使用标准的空气雾化设备(虹吸式或压力罐)。使用压力罐喷涂时,可按以下方法制作合适的加长杆:

(a) Remove and keep the air cap.

取下并保留空气帽。

(b) Remove the fluid tip. Solder or braze 1/8-inch annealed copper tubing of a necessary length on the end of the tip.

取下液体喷嘴。在喷嘴末端焊接或钎焊必要长度的 1/8 英寸退火铜管。

(c) To make a nozzle at the end of the tubing, clamp the tube end around a 0.010-inch diameter wire.

要在管端制作喷嘴,用直径为 0.010 英寸的金属丝缠绕来卡住管端。

(d) Do not connect air hose to spray gun.

不要将空气软管连接到喷枪上。

(e) Spray with a pot pressure of 20-30 psi.

使罐子压力为 20-30 psi来喷洒。

C. Brush Application

刷涂

(1) Use an ordinary paint brush or a clean cloth. This method is best for local areas or where you must be careful to keep the corrosion-inhibiting compound away from adjacent equipment.

使用普通油漆刷或干净的布。这种方法最适合局部区域或必须注意使防腐化合物远离邻近设备的地方。

(2) For large areas or where confinement is not a problem, spray application is the best method to use.

对于大面积区域或封闭性没有问题的地方,最好使用喷涂方法。

D. The fill and drain procedure can be used to apply corrosion inhibiting compounds to surfaces such as interiors where a brush or sprayer cannot be used.

在无法使用刷子或喷雾器的内部等表面,可使用填充和排放程序来涂抹防腐化合物。

6. REMOVAL OF COMPOUND 清除化合物

A. You must remove all of the corrosion-inhibiting compounds before you paint the surface. You must also clean with a solvent before penetrant inspection.

在给表面上漆之前,必须清除所有的防腐化合物。在进行渗透检查之前,还必须使用溶剂进行清洁。

B. These solvents (Ref SOPM 20-60-01) can remove BMS 3-23, BMS 3-26, and BMS 3-29, and BMS 3-35 compounds:

这些溶剂 (参考 SOPM 20-60-01)可以清除 BMS 3-23、BMS 3-26 和 BMS 3-29 以及 BMS 3-35 化合物:

NOTE: Acetone is not recommended.

注:不建议使用丙酮。

(1) Perchloroethylene

全氯乙烯

(2) Trichloroethylene

三氯乙烯

(3) Trichloroethane

三氯乙烷

(4) Aliphatic Naphtha, TT-N-95

脂肪族石脑油,TT-N-95

(5) Magnaflux Corp. solvent

Magnaflux 公司溶剂

(6) Dry cleaning solvent, P-D-680

干洗溶剂,P-D-680

(7) Biogenic SE377C cleaner (V13091) (preferred for removal of BMS 3-23 compound from areas with faying surfaces).

Biogenic SE377C 清洁剂 (V13091)(首选用于清除有粘合表面区域的 BMS 3-23 化合物)。

(8) Citra Safe

(9) Methyl propyl ketone (MPK)

甲基丙基酮 (MPK)

(10) Methyl ethyl ketone (MEK)

甲基乙基酮 (MEK)

C. These solvents (Ref SOPM 20-60-01) can be used to remove BMS 3-29 and BMS 3-35 compounds, and also BMS 3-26 compounds of the type indicated:

这些溶剂(参考 SOPM 20-60-01)可用于清除 BMS 3-29 和 BMS 3-35 化合物,以及所示类型的 BMS 3-26 化合物:

(1) Type 1 removal

类型 1 去除

(a) Varsol No. 1

(b) Shell-Sol 345

(c) Skellysolve S

(d) Chevron 325

(e) Union No. 5 Thinner

(f) S-76 Cleaning Solvent

(g) Klenzine

(h) Sikkens 96.126

(2) Type 2 removal

类型 2 去除

(a) Skellysolve V

(b) Standard 245 Thinner

(c) Sikkens 96.131

D. To remove MIL-C-16173 compounds, use dry cleaning solvent P-D-680. Do not use methyl ethyl ketone (MEK) or acetone.

要清除 MIL-C-16173 化合物,请使用干洗溶剂 P-D-680。切勿使用甲乙酮 (MEK) 或丙酮。

E. When you use solvents to remove the corrosion inhibiting compounds, give the area a good flow of air until the solvents evaporate.

使用溶剂清防腐化合物时,要保持该区域空气流通,直到溶剂挥发。

F. Contamination of insulation blankets by corrosion inhibiting compounds is not recommended. Contamination is permitted if it is on not more than 12 percent of the total surface area of the blanket. This includes spot contamination and large areas of contamination. A large continuous area of contamination must be no more than 4 square inches, and must be a minimum of 6 inches from adjacent areas of contamination in any direction. Corrosion inhibiting compounds can be removed from the blanket with Biogenic SE377C, aliphatic naphtha, Citra Safe, BMS 11-9 or BMS 11-7 solvent, or methyl ethyl ketone.

绝缘毯被防腐化合物污染是不推荐的。如果污染面积不超过绝缘毯总表面积的 12%,则允许被污染。这包括点污染和大面积污染。大面积的连续污染区面积不得超过 4 平方英寸,且在任何方向上与相邻污染区的距离均不得小于 6 英寸。可使用 Biogenic SE377C、脂肪族石脑油、Citra Safe、BMS 11-9 或 BMS 11-7 溶剂或甲乙酮清除绝缘毯上的防腐化合物。