电沉积镀镍ELECTRODEPOSITED NICKEL PLATING

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5746 for electrodeposited nickel plating. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音电镀镍的工艺规范 BAC5746。可查阅波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum standards.

数据具有通用性。并不涉及所有情况或特定安装。请使用这些数据来帮助您制定最低标准。

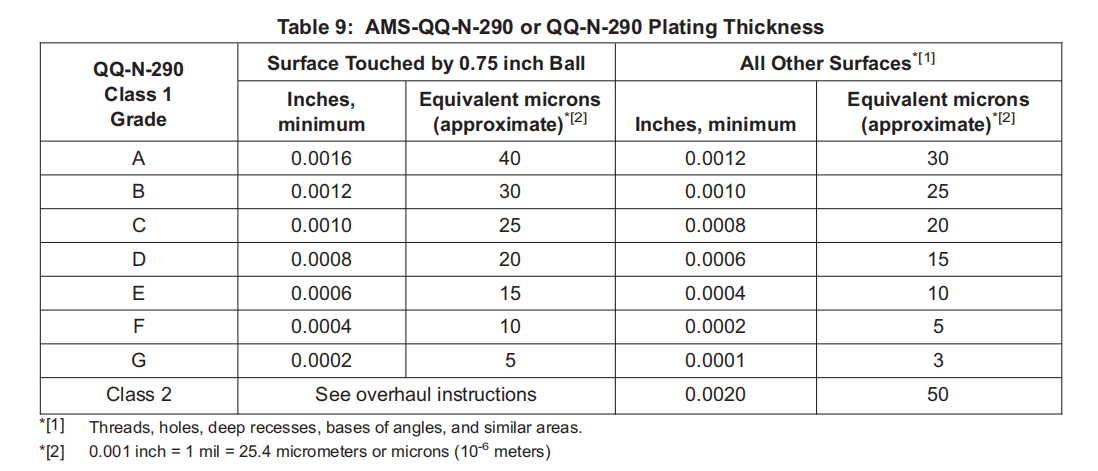

C. This procedure makes nickel electroplating that agrees with QQ-N-290 (now superseded by SAE AMS-QQ-N-290). When the overhaul instructions specify QQ-N-290 or AMS-QQ-N-290 nickel plating without a thickness, make the plating thickness as shown in Table 9.

本程序使电镀镍与 QQ-N-290(现已被 SAE AMS-QQ-N-290 取代)一致。当大修说明规定使用 QQ-N-290 或 AMS-QQ-N-290 电镀镍但未规定厚度时,请按照表 9 所示制作电镀厚度。

D. BAC5746 puts its nickel plating into Types and Classes.

BAC5746 将电镀镍分为类型和等级。

(1) Types

类型

(a) Type 1: Nickel plated parts heat treated below 220 ksi

类型 1:热处理温度低于 220 ksi 的电镀镍零件

(b) Type 2: Electroformed parts

类型 2:电铸零件

(c) Type 3: Nickel plated parts heat treated to 220 ksi and above

类型 3:热处理至 220 ksi 及以上的电镀零件

(2) Classes

等级

(a) Class 1: Tank (immersion) plating

第 1 类:槽(浸)电镀

(b) Class 2: Localized cup plating (flow process)

第 2 类:局部杯状电镀(流动过程)

(c) When the Class is not specified, use Class 1.

如未规定等级,则使用等级 1。

E. This nickel plating is a relatively soft, low stressed, ductile coating for the protection of steels and other alloys and for the buildup of surfaces for repair purposes. Do not use this nickel plating on steels heat-treated above 220 ksi unless specified by the applicable overhaul instructions.

本电镀镍层是一种相对较软、应力小、延展性好的电镀层,用于保护钢和其他合金,以及用于修复目的的表面堆积。除非适用的大修说明有规定,否则不得在热处理超过 220 ksi 的钢材上使用此电镀镍层。

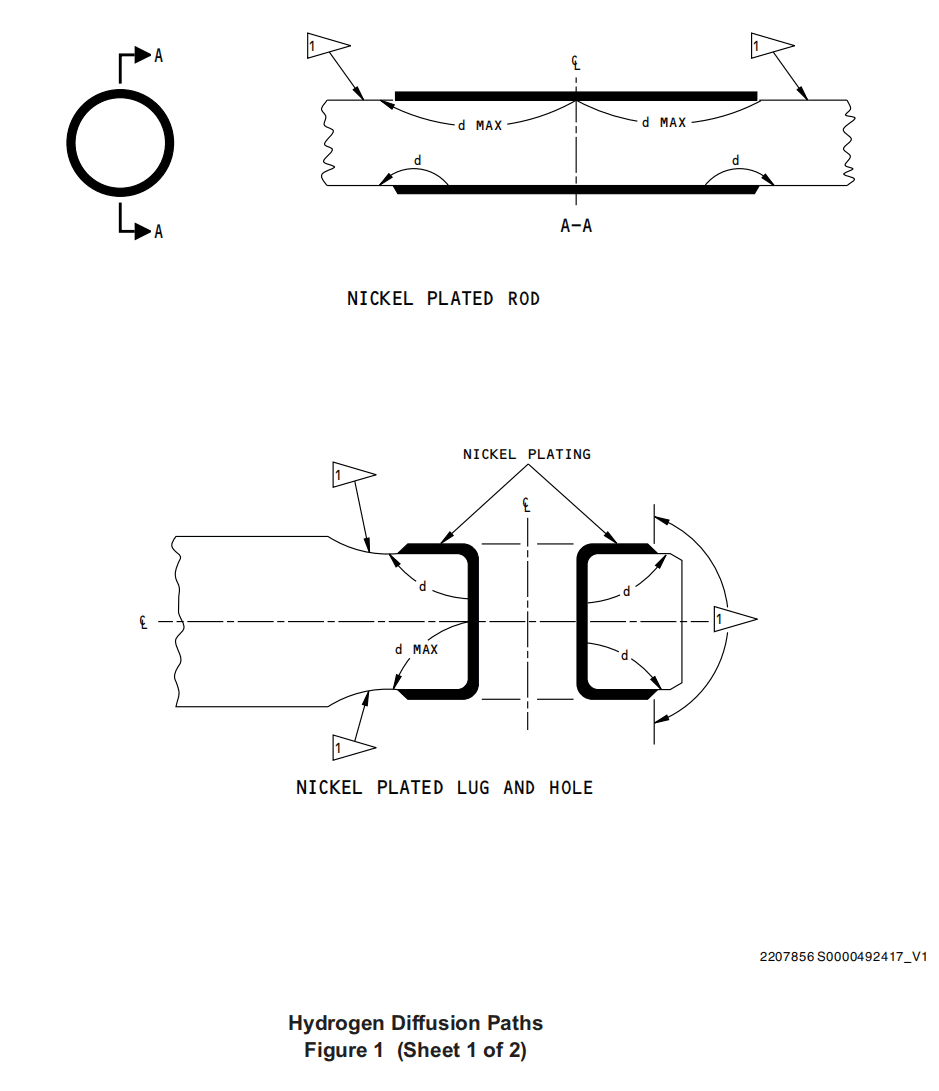

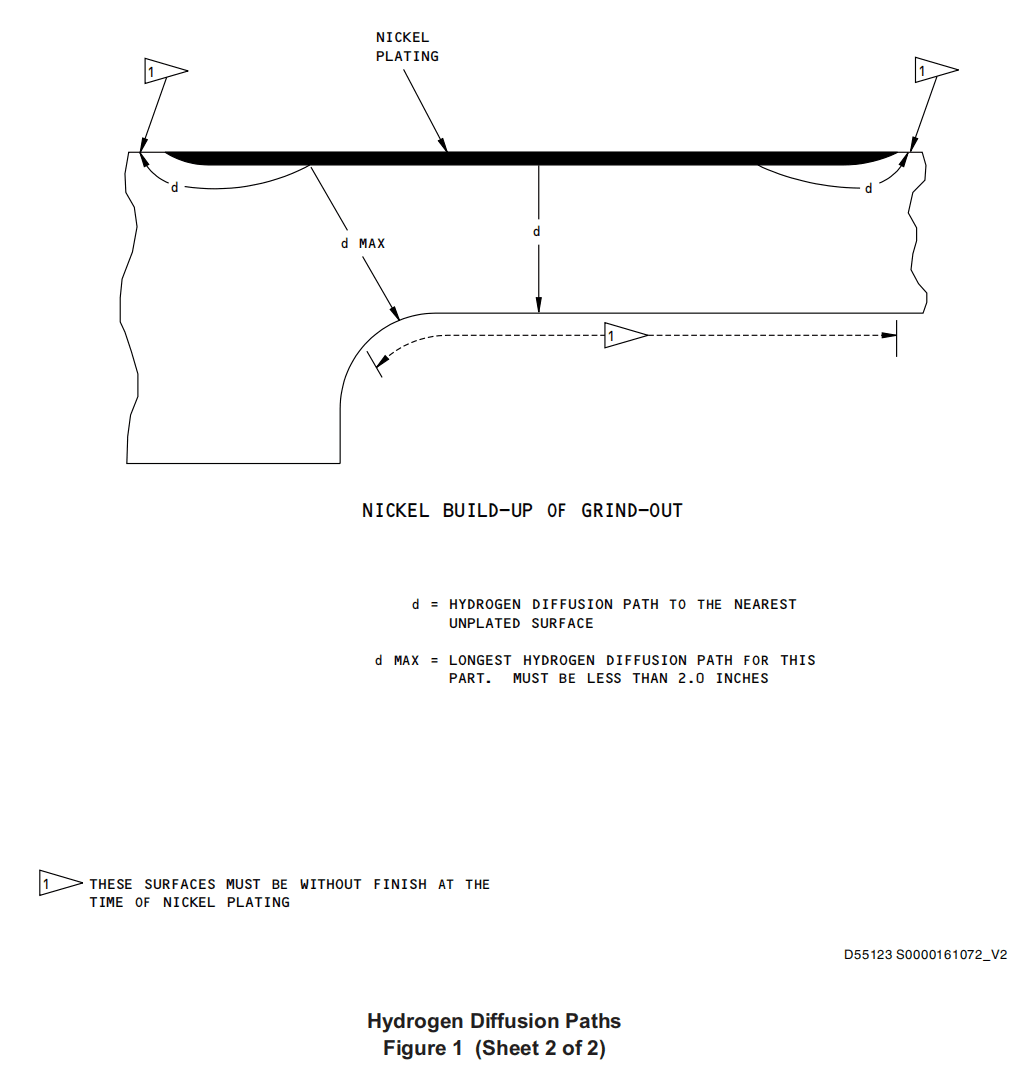

(1) The distance from the nickel plated surface through the base metal to the nearest unplated surface must be less than 2 inches (Figure 1). The unplated surface must have an area at least one-third that of the nickel plated surface to let the hydrogen be baked out.

从电镀镍表面穿过基体金属到最近的未电镀表面的距离必须小于 2 英寸(图 1)。未电镀表面的面积必须至少为镀镍表面的三分之一,以便让氢气被烤出。

(2) The surface must be shot peened before you plate it.

在电镀之前,表面必须经过喷丸处理。

F. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

有关所有供应商的名称和地址,请参阅 SOPM 20-00-00。

2. MATERIALS 材料

A. Activated charcoal, plating grade

电镀级活性炭

B. Additive A (chloride salt), V0PX54

添加剂 A(氯盐),V0PX54

C. Ammonium bifluoride, technical grade

工业级氟化氢铵

D. Anode bags: Unbleached muslin, Dynel, or napped polypropylene

阳极袋: 未经漂白的薄纱、Dynel 或有节聚丙烯

E. Anode basket and hooks, titanium

阳极篮和钛钩

F. Anodes

阳极

(1) Nickel

镍

(a) 99 percent nickel rolled depolarized or carbon-nickel cast and rolled

99% 镍轧制去极化或碳镍铸造和轧制

(b) Sulfur depolarized (SD) nickel chips

硫去极化(SD)镍片

(2) Carbon

碳

(a) Graphite, high purity and density, Union Carbide or V78429

高纯度、高密度石墨,联合碳化物或 V78429

(b) Carbon brick, chemically resistant, ASTM C 1160

ASTM C 1160 抗化学性碳砖

(3) Iron

铁

(a) Carbon steel, 1008, 1010, 1015, 1018

1008、1010、1015、1018 碳钢

G. Boric acid crystals, technical grade

工业级硼酸晶体

H. Bromide

溴化物

(1) Additive B, V89138

添加剂 B,V89138

(2) Nickel bromide (NiBr2 •3H2O) crystals, plating grade, V0309B

溴化镍(NiBr2 -3H2O)晶体,电镀级,V0309B

(3) Nickel bromide concentrate, 18 percent, V0309B

溴化镍浓缩物,18%,V0309B

(4) Sodium bromide, pure or USP grade

溴化钠,纯品或 USP 级

I. Citric acid, anhydrous

无水柠檬酸

J. Conductive coating — Conductive Silver Composition, DuPont 8535, V18873, or equivalent

导电涂层 — 导电银成分,DuPont 8535,V18873 或同等产品

K. Ferrous chloride tetrahydrate

四水氯化亚铁

L. Ferrous sulfate hexahydrate

六水硫酸亚铁

M. Filter aid: diatomaceous earth

助滤剂:硅藻土

N. Fluoboric acid, 48 percent, technical grade

氟硼酸,48%,工业级

O. Hydrochloric acid, 20 degree Baumé, O-H-765

盐酸,20 度 Baumé,O-H-765

P. Hydrofluoric acid, 70 percent, O-H-795

氢氟酸,70%,O-H-795

Q. Hydrogen peroxide, 35 percent

过氧化氢,35%

R. Masking materials as specified in BAC5849

BAC5849 规定的遮蔽材料

S. Nickel activator C1 and C1 Replenisher, J. B. Meyer Company (BAC5746 par. 5q, 5r)

镍活化剂 C1 和 C1 补充剂,J. B. Meyer 公司(BAC5746 第 5q、5r 段)

T. Nickel carbonate, plating grade

电镀级碳酸镍

U. Nickel chloride hexahydrate, plating grade

电镀级六水氯化镍

V. Nickel chloride liquid (contains 6 pounds of nickel chloride hexahydrate in each gallon), V86460

氯化镍液(每加仑含 6 磅六水氯化镍),V86460

W. Nickel sulfamate solution (purified concentrate) (Must not contain brighteners or stress reducers but can contain bromides)

氨基磺酸镍溶液(精制浓缩物)(不得含光亮剂或应力消除剂,但可含溴化物)

(1) SN (make up), SNR-24 (replenisher), V0PX54

SN(修补剂),SNR-24(补充剂),V0PX54

(2) Electropure 24, V86460

(3) Nickel sulfamate, V5K793

氨基磺酸镍,V5K793

X. Nickel sulfate hexahydrate, plating grade

六水硫酸镍,电镀级

Y. Scotch-Brite pads, Type A, V76381

Scotch-Brite盘,A 型,V76381

Z. Sodium hydroxide, flake or granulated, O-S-598 or better

片状或颗粒状氢氧化钠,O-S-598 或更好

AA. Sulfamic Acid, plating grade

氨基磺酸,电镀级

AB. Sulfuric acid, 66 degree Baumé, plating grade, O-S-809 or better

硫酸,66 度 Baumé,电镀级,O-S-809 或更好

AC. Wetting Agent (Anti-pit)

润湿剂(防滴)

(1) Anti-pit, SNAP, SNAP-L (liquid) and SNAP-AM, V0PX54 or V89138

防滴剂,SNAP、SNAP-L(液体)和 SNAP-AM,V0PX54 或 V89138

(2) Duponel ME, V18873

(3) NP-A, NP-A-91, V86460

AD. Enprep 214 cleaner solution (SOPM 20-30-03)

Enprep 214 清洁剂溶液(SOPM 20-30-03)

AE. Trisodium Phosphate – Glutamate (TSPG) cleaner solution (SOPM 20-30-03)

磷酸-谷氨酸三钠(TSPG)清洗溶液(SOPM 20-30-03)

3. DEFINITIONS 定义

A. ASF or asf — Amperes per square foot, a measure of the current density used during the plating procedure.

ASF 或 asf — 每平方英尺安培数,电镀程序中电流密度的量度。

B. Localized cup plating — Plating in which the solution is pumped from a reservoir to a sealed anode-cathode assembly and then back to the reservoir.

局部电镀 — 电镀过程中,溶液从储液罐泵到密封的阳极-阴极组件,然后再泵回储液罐。

C. Hydrogen embrittlement relief bake — A bake that removes hydrogen from high strength steels, to decrease the risk of embrittlement.

氢脆消除烘烤 — 从高强度钢中去除氢气的烘烤,以降低脆化风险。

D. Tank plating — The usual plating that puts the parts into a tank of the plating solutions.

电镀槽 — 将零件放入电镀溶液槽中的普通电镀。

E. Water-break-free-surface — A surface that keeps a continuous layer of water for a minimum of 30 seconds after it was spray or immersion rinsed in clean water colder than 100°F.

无断水表面 — 在温度低于 100°F 的清水中喷淋或浸泡冲洗后,表面能保持至少 30 秒钟的连续水层。

4. PREPARATION OF SOLUTIONS 溶液的配制

WARNING :SOLUTIONS USED FOR NICKEL PLATING ARE CORROSIVE AND TOXIC. USE ADEQUATE PRECAUTIONARY MEASURES TO AVOID INJURY TO PERSONNEL AND DAMAGE TO EQUIPMENT.

警告 :用于电镀镍的溶液具有腐蚀性和毒性。请采取适当的预防措施,以避免人员受伤和设备损坏。

A. Sulfamate Nickel Plating Bath or Solution

氨基磺酸镍电镀槽或溶液

(1) Clean the tank thoroughly. Fill it to the half level with nickel sulfamate concentrate, and mix in an equal volume of deionized or distilled water.

彻底清洗槽。将氨基磺酸镍浓缩液注入槽中至半满,然后加入等体积的去离子水或蒸馏水。

(2) You can make the bath with bromides or chlorides, or you can do without them if you use sulfur depolarized anodes.

可以在镀槽中加入溴化物或氯化物,如果使用硫去极化阳极,也可以不加溴化物或氯化物。

(a) Add bromide as necessary to get a bromine concentration of 0.2-1.5 oz/gal in the final solution.

根据需要添加溴化物,使最终溶液中的溴浓度达到 0.2-1.5 oz/gal。

(b) Or add nickel chloride hexahydrate to get a chlorine concentration of 0.45-0.65 oz/gal in the final solution.

或加入六水氯化镍,使最终溶液中的氯浓度达到 0.45-0.65 oz/gal。

(3) Add boric acid as necessary to get a boric acid concentration of 4.0 oz/gal minimum in the final solution. You can:

根据需要添加硼酸,使最终溶液中的硼酸浓度不低于 4.0 盎司/加仑。您可以

(a) dissolve the boric acid crystals in deionized or distilled water and add this solution to the bath, or

将硼酸晶体溶解在去离子水或蒸馏水中,然后将此溶液加入水浴中,或

(b) heat the bath to 150°F maximum and add the crystals directly. Add the crystals slowly and mix them into the solution.

将浴槽加热到最高温度 150°F 并直接加入晶体。缓慢加入晶体并将其混入溶液中。

(4) Add more nickel sulfamate concentrate as necessary to get a nickel concentration of 10-15 oz/gal in the final solution. Fill the tank to operating level with water.

根据需要加入更多的氨基磺酸镍浓缩液,使最终溶液中的镍浓度达到 10-15 oz/gal。用水将槽注满至操作水平。

NOTE: Nickel sulfamate concentrate can contain 20 oz/gal or 24 oz/gal of metallic nickel. To get 12 oz/gal of metallic nickel in the final solution, for each gallon of final bath, add (a) 75 fluid ounces of the 20 oz/gal concentrate, or (b) 64 fluid ounces of the 24 oz/gal concentrate.

注: 氨基磺酸镍浓缩液可含有 20 oz/gal 或 24 oz/gal 的金属镍。为使最终溶液中的金属镍含量达到 12 盎司/加仑,在每加仑最终溶液中加入 (a) 75 液盎司的 20 盎司/加仑浓缩液,或 (b) 64 液盎司的 24 盎司/加仑浓缩液。

(5) Adjust the pH of the solution, as necessary, as follows:

必要时按以下方法调节溶液的 pH 值:

(a) Decrease the pH with a solution of sulfamic acid and water.

用氨基磺酸和水的溶液降低 pH 值。

(b) Increase the pH with nickel carbonate, added through the filter.

通过过滤器加入碳酸镍,提高 pH 值。

(c) Add the chemicals carefully, and let the solution come back to equilibrium before you add more chemicals. If you added nickel carbonate, keep the solution at 120-140°F for a minimum of 2 hours before you plate with it.

小心添加化学品,待溶液恢复平衡后再添加更多化学品。如果添加了碳酸镍,请将溶液保持在 120-140°F 至少 2 小时后再电镀。

(6) Adjust the surface tension with wetting agent, if necessary. If you use powdered wetting agent, dissolve it at the rate of 6 ounces powder in a pint of warm water before you add it to the bath.

如有必要,用润湿剂调节表面张力。如果使用粉末状润湿剂,则在加入浴槽之前,先将 6 盎司粉末溶解在一品脱温水中。

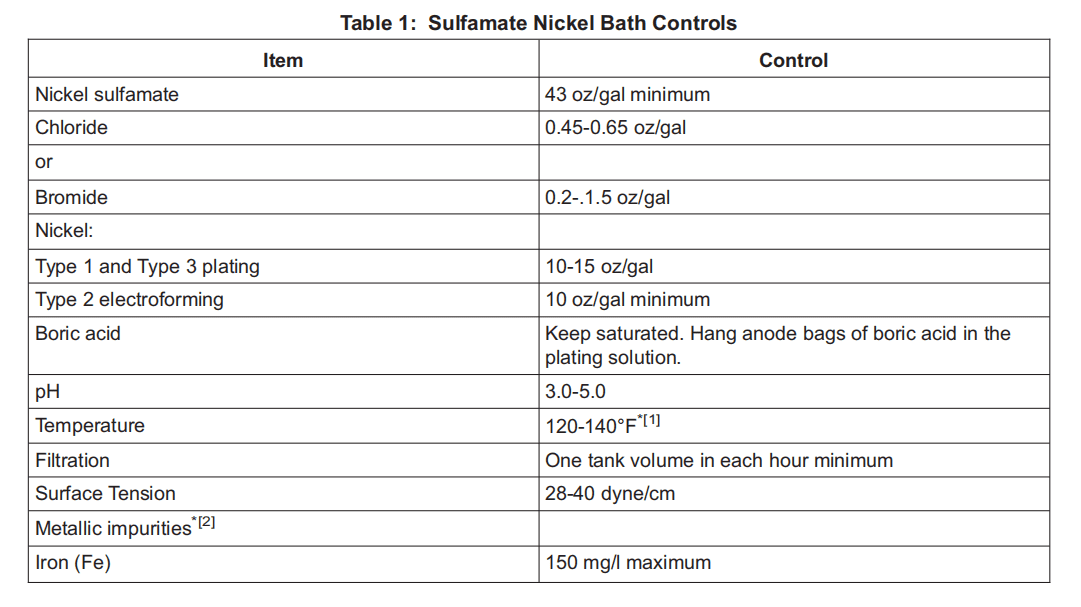

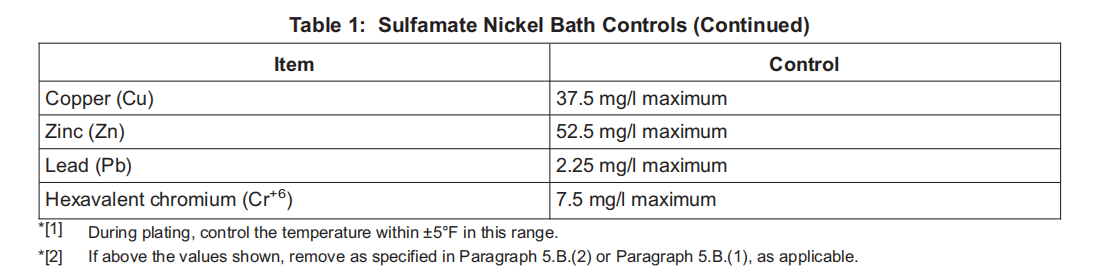

(7) Control the solution at the values shown in Table 1.

将溶液控制在表 1 所示的数值。

(8) Use nickel anodes with anode bags. Use the bagged titanium anode basket with sulfur depolarized nickel chips.

使用带阳极袋的镍阳极。使用装有硫去极化镍屑的袋装钛阳极篮。

(9) For water additions to adjust for evaporation, use deionized or distilled water.

为调节蒸发而加水时,应使用去离子水或蒸馏水。

(10) If you use the sulfamate solution for localized cup plating (BAC5746 Class 2), you can use these alternatives:

如果使用氨基磺酸盐溶液进行局部电镀杯(BAC5746 2 级),可以使用这些替代方法:

(a) It is optional to use chlorides, bromides and wetting agents.

可选择使用氯化物、溴化物和润湿剂。

(b) It is optional to send the solution through a filter.

可以选择将溶液通过过滤器送入。

(c) Solution analysis is not necessary if:

如果出现以下情况,则无需进行溶液分析

1) The solution was within the limits of Table 1 before plating (based on make-up or analysis) and

电镀前溶液在表 1 的限制范围内(根据修补或分析),且

2) The solution is discarded after 10 amp-hr/gal of plating.

溶液在电镀 10 安培-小时/加仑后报废。

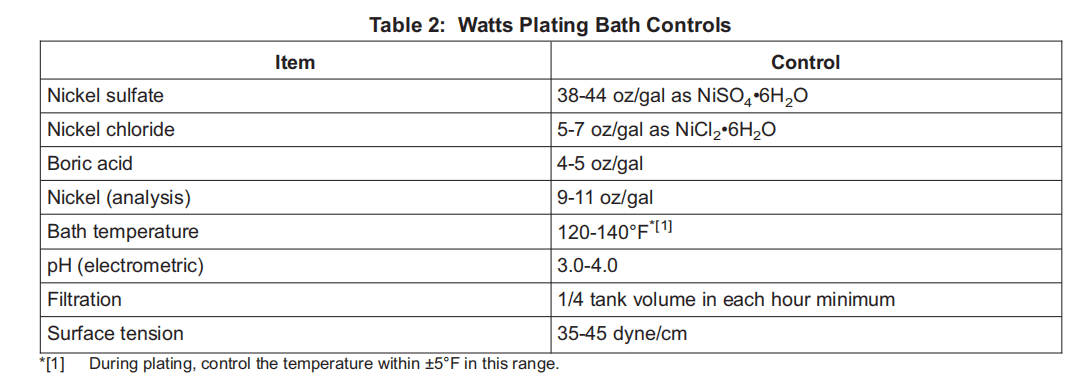

B. Watts Nickel Plating Bath or Solution (for plating parts below 220 ksi)

瓦特镍电镀槽或溶液(用于电镀 220 ksi 以下的零件)

(1) Clean the tank fully and fill it to the half level with warm (120-140°F) deionized or distilled water.

充分清洁槽,并注入温的(120-140 °F)去离子水或蒸馏水至半水位。

(2) Add 40.0 ounces nickel sulfate for each gallon of final solution and stir until the chemical is dissolved.

每加仑最终溶液加入 40.0 盎司硫酸镍,搅拌直至化学品溶解。

(3) Add 6.0 ounces nickel chloride for each gallon of final solution and stir until the chemical is dissolved.

每加仑最终溶液加入 6.0 盎司氯化镍,搅拌直至化学品溶解。

(4) Dissolve 5.0 ounces boric acid for each gallon of final solution in warm water, add to Watts solution, and stir to mix.

每加仑最终溶液用温水溶解 5.0 盎司硼酸,加入Watts溶液并搅拌混合。

(5) Add water to fill the tank to the operating level.

加水将槽注满至操作水平面。

(6) Adjust the pH of the solution as follows:

按以下方法调节溶液的 pH 值:

(a) Decrease the pH with a solution of sulfuric acid and water.

用硫酸和水的溶液降低 pH 值。

(b) Increase the pH with nickel carbonate, added through the filter.

通过过滤器加入碳酸镍,提高 pH 值。

(c) Add the chemicals carefully, and let the solution come back to equilibrium before you add more chemicals. If you added nickel carbonate, keep the solution at 120-140°F for a minimum of 2 hours before you plate with it.

小心添加化学品,待溶液恢复平衡后再添加更多化学品。如果添加了碳酸镍,请将溶液保持在 120-140°F 的温度下至少 2 小时后再电镀。

(7) Add wetting agent powder, 0.05 oz/gal, or liquid, 0.1 oz/gal.

加入润湿剂粉末 0.05 oz/gal,或液体 0.1 oz/gal。

(8) Control the solution at the values shown in Table 2.

将溶液控制在表 2 所示的数值。

(9) Use nickel anodes with anode bags. Use the bagged titanium anode basket with sulfur depolarized nickel chips.

使用带阳极袋的镍阳极。使用装有硫去极化镍屑的袋装钛阳极篮。

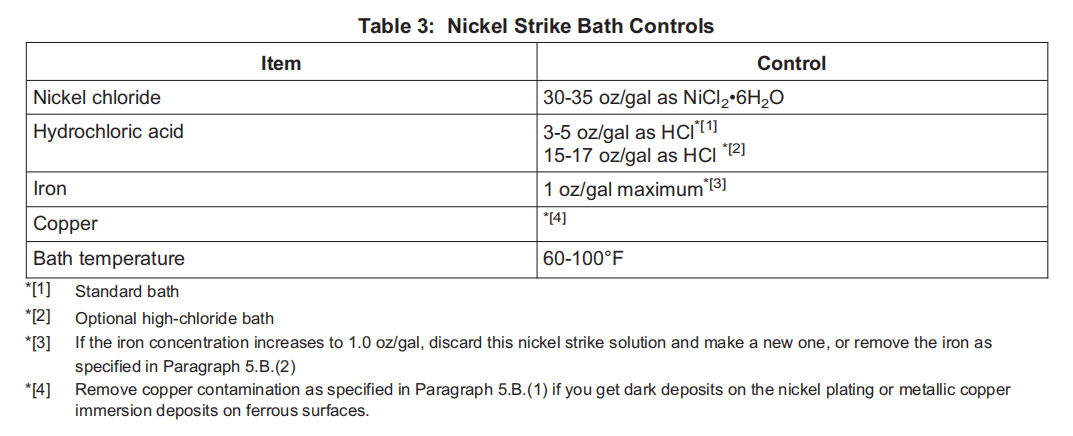

C. Nickel Strike Bath or Solution

击镍槽或溶液

(1) Clean the tank fully and fill to the half level with water.

将槽完全清洗干净,加水至半水位。

(2) Add 32 ounces nickel chloride powder (or 0.33 gallon of a nickel chloride liquid that has 6 pounds nickel chloride hexahydrate in each gallon) for each gallon of final solution and stir until the chemical is dissolved.

每加仑最终溶液加入 32 盎司氯化镍粉(或 0.33 加仑氯化镍液,每加仑含 6 磅六水氯化镍),搅拌至化学品溶解。

(3) Add 10 fluid ounces hydrochloric acid for each gallon of final solution, or 44 fluid ounces for each gallon for the optional high-chloride bath.

每加仑最终溶液加入 10 液盎司盐酸,或每加仑可选高盐浴槽加入 44 液盎司盐酸。

(4) Fill the tank to the operating level with water.

将水注入槽至操作水平。

(5) Control the solution at the values shown in Table 3.

将溶液控制在表 3 所示的数值。

(6) Remove the anodes when you will not use the tank for a long period of time.

长时间不使用槽时,应卸下阳极。

(7) Use nickel anodes with anode bags. Use the bagged titanium anode basket with sulfur depolarized nickel chips.

使用带阳极袋的镍阳极。使用装有硫磺去极化镍片的袋装钛阳极篮。

D. Fluoboric Acid Activation Solution (for copper surfaces only)

氟硼酸活化溶液(仅用于铜表面)

(1) Fill the tank to the 9/10 level with water.

在槽中加水至 9/10 水位。

(2) Add a quantity of fluoboric acid equal to 2.5 percent of the final tank volume.

加入相当于槽最终容积 2.5%的氟硼酸。

(3) Fill the tank to the operating level with water.

将水槽注满水至操作(工作)水位。

(4) Control the fluoboric acid at 1.25-2.50 oz/gal HBF4 . Control the solution temperature at 60-90°F.

将氟硼酸控制在 1.25-2.50 oz/gal HBF4 。将溶液温度控制在 60-90 °F。

E. Sulfamic Acid Bath

氨基磺酸浴槽

(1) Make this solution with 13-15 ounces sulfamic acid for each gallon (97-112 grams for each liter) of final solution in water.

以每加仑最终溶液加入 13-15 盎司氨基磺酸(每升 97-112 克)的水配制此溶液。

(2) Use the solution at room temperature.

溶液在室温下使用。

F. Inhibited Hydrochloric Acid. Make and operate one of these solutions:

抑制盐酸。配制并使用其中一种溶液:

(1) BAC5625 Solution 1

BAC5625 溶液 1

(2) BAC5632 dilute hydrochloric acid solution

BAC5632 稀盐酸溶液

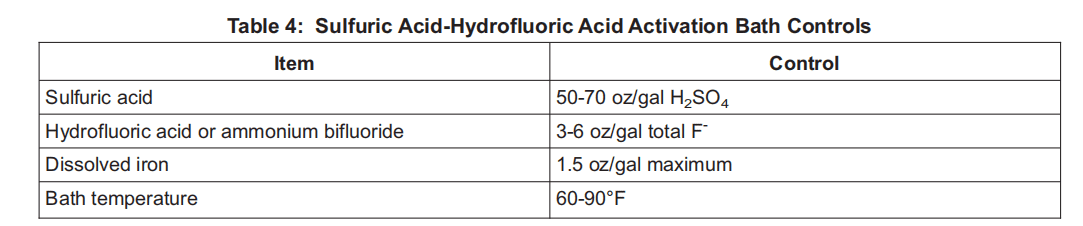

G. Sulfuric Acid – Hydrofluoric Acid Activation Solution

硫酸 – 氢氟酸活化溶液

NOTE: The quantities of hydrofluoric acid in this recipe are for 70% HF. If you use a different concentration of hydrofluoric acid, be sure to adjust the quantities of this acid.

注: 本配方中的氢氟酸用量为 70% HF。如果使用不同浓度的氢氟酸,请务必调整该酸的用量。

(1) Clean the tank fully and fill it to the half level with water.

将槽完全清洗干净,并加水至一半高度。

(2) Slowly add concentrated sulfuric acid in the quantity of 25 percent of the final tank volume. Mix continuously while you add it in.

缓慢加入浓硫酸,加入量为槽最终容积的 25%。加入时要不断搅拌。

(3) Let the solution cool below 90°F, then add 4 gallons of hydrofluoric acid, or 25 pounds of ammonium bifluoride, for each 100 gallons of final solution.

让溶液冷却到 90°F 以下,然后每 100 加仑最终溶液加入 4 加仑氢氟酸或 25 磅氟化氢铵。

(4) Fill the tank with cold water (below 90°F) to the operating level. Mix continuously while you add the water.

向槽中注入冷水(低于 90°F)至操作水位。加水时要不断搅拌。

(5) Control the solution at the values shown in Table 4.

将溶液控制在表 4 所示的数值。

(6) Use acid resistant carbon electrodes or lead (Pb-7Sn) electrodes.

使用耐酸碳电极或铅(Pb-7Sn)电极。

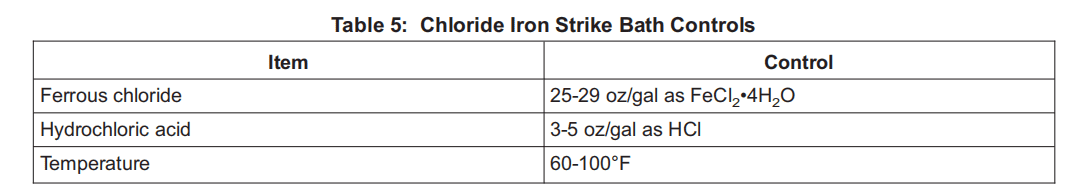

H. Chloride Iron Strike Bath

氯化物击铁槽

(1) Clean the tank and fill it to the half level with water.

清洗槽并加水至一半高度。

(2) Add approximately 27 ounces ferrous chloride for each gallon of final solution and mix until dissolved.

每加仑最终溶液加入约 27 盎司氯化亚铁,搅拌至溶解。

(3) Add approximately 10 ounces hydrochloric acid for each gallon of final solution.

每加仑最终溶液加入约 10 盎司盐酸。

(4) Fill the tank to the operating level with water.

将水注入槽至操作水平。

(5) Control the solution at the values shown in Table 5.

将溶液控制在表 5 所示的数值。

(6) Remove the anodes when you will not use the tank for a long period of time.

长时间不使用槽时,应取下阳极。

I. Sulfate-Citric Acid Iron Strike Bath

硫酸-柠檬酸铁击槽

(1) Clean the tank and fill it to the half level with water.

清洗槽并加水至一半水平位置。

(2) Add approximately 19 ounces ferrous sulfate for each gallon of final solution and mix until dissolved.

每加仑最终溶液加入约 19 盎司硫酸亚铁,搅拌至溶解。

(3) Add approximately 13 ounces citric acid for each gallon of final solution and mix until dissolved.

每加仑最终溶液加入约 13 盎司柠檬酸,搅拌至溶解。

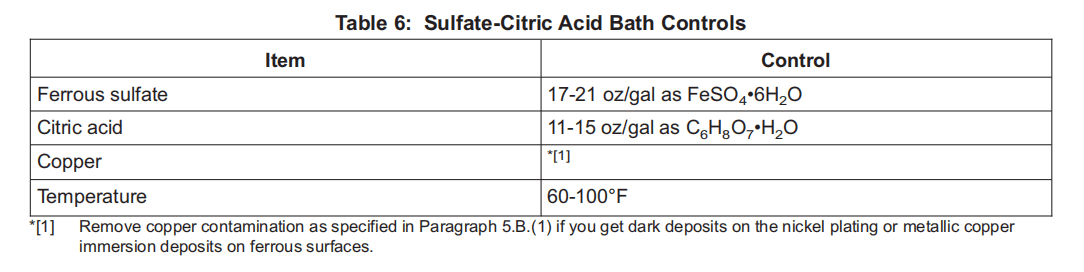

(4) Control the solution at the values shown in Table 6

将溶液控制在表 6 所示的值

(5) Remove the anodes when you will not use the tank for a long period of time.

长时间不使用槽时,应卸下阳极。

J. Uninhibited Hydrochloric Acid Solution: Make and operate BAC5625 Solution 19.

无抑制盐酸溶液: 制作并操作 BAC5625 溶液 19。

5. NICKEL PLATING SOLUTION PURIFICATION 电镀镍溶液净化

A. Removal of Organic Contamination

清除有机污染物

(1) Move the dirty solution to a different tank to permit removal of the contamination.

把脏溶液移到另一个槽,以便清除污染。

(2) Adjust the pH to 2.0-2.5 with careful additions of these chemicals:

加入以下化学品,调节 pH 值至 2.0-2.5:

(a) For sulfamate solution, add sulfamic acid.

对于氨基磺酸盐溶液,加入氨基磺酸。

(b) For Watts solution, add sulfuric acid.

对于瓦特溶液,加入硫酸。

(c) For the nickel strike solution, add hydrochloric acid.

对于镍击溶液,加入盐酸。

(3) Add 1.0 pint hydrogen peroxide for each 100 gallons of solution. Mix the solution for 2-4 hours.

每 100 加仑溶液加入 1.0 品脱过氧化氢。搅拌溶液 2-4 小时。

CAUTION :DO NOT HEAT THE SOLUTION ABOVE 150°F, BECAUSE THE CHEMICALS WILL DECOMPOSE AT APPROXIMATELY 155°F.

注意:不要将溶液加热到 150°F 以上,因为化学品会在大约 155°F 时分解。

(4) Heat the solution to 140-150°F. Add 5-7 pounds activated charcoal for each 100 gallons of solution and mix for 3-4 hours, or let the heated solution flow through an activated charcoal filter.

将溶液加热至 140-150°F。每 100 加仑溶液加入 5-7 磅活性炭,混合 3-4 小时,或让加热后的溶液流经活性炭过滤器。

(5) Let the solution settle for a minimum of 8 hours.

让溶液沉淀至少 8 小时。

(6) Prepare a filter cake with 2 ounces of filter aid (as a 1 pound per gallon slurry) for each square foot of filtering area. Let the solution flow through the filter until it comes out transparent.

按每平方英尺的过滤面积用 2 盎司助滤剂(每加仑 1 磅的泥浆)制备滤饼。让溶液流经过滤器,直到流出透明为止。

(7) Rinse the filter with clean water.

用清水冲洗过滤器。

(8) Increase the solution pH to 5.5-5.8 with a slurry of nickel carbonate.

用碳酸镍浆将溶液 pH 值提高到 5.5-5.8。

(9) Clean the plating tank fully. Heat the solution to 120-140°F and send the solution through the filter, back to the plating tank.

充分清洗电镀槽。将溶液加热至 120-140°F,然后将溶液通过过滤器,送回电镀槽。

(10) Keep the solution at 120-140°F for a minimum of 2 hours before you use it.

将溶液保持在 120-140°F 至少 2 小时后再使用。

(11) Adjust the temperature, pH and surface tension of the solution to the original operating values as specified in the controls for the applicable bath.

将溶液的温度、pH 值和表面张力调整到相应镀槽控制装置规定的原始操作值。

B. Removal of Metallic Contamination

清除金属污染物

(1) Copper, lead, iron, zinc:

铜、铅、铁、锌:

(a) Adjust the solution to the controls and temperature as specified by Table 1, Table 3 or Table 6, as applicable.

视情况将溶液调节到表 1、表 3 或表 6 规定的控制值和温度。

(b) Start to agitate the solution.

开始搅拌溶液。

(c) With corrugated steel cathodes, fill the tank with as large a cathode area as possible.

使用波纹钢阴极时,尽可能将阴极面积填满槽。

(d) Plate something at 3.5-4.5 asf for 4-5 ampere hours for each gallon of solution.

每加仑溶液电镀 4-5 安培小时,电镀量为 3.5-4.5 安培。

(2) Iron and chromium:

铁和铬:

NOTE: This procedure could remove some of the organic material.

注: 此程序可去除部分有机物。

(a) Move the solution to a different tank.

将溶液移到不同的槽中。

(b) Heat the solution to 120-140°F.

将溶液加热至 120-140°F。

(c) Add 1.0 pint hydrogen peroxide for each 100 gallons of solution.

每 100 加仑溶液加入 1.0 品脱过氧化氢。

(d) Increase the solution pH to 5.5-5.8 with a slurry of nickel carbonate.

用碳酸镍浆将溶液 pH 值提高到 5.5-5.8。

(e) Add 4.0 pounds activated charcoal for each 100 gallons of solution and agitate the solution for 3-4 hours, or let the heated solution flow through an activated charcoal filter.

每 100 加仑溶液加入 4.0 磅活性炭,搅拌溶液 3-4 小时,或让加热后的溶液流经活性炭过滤器。

(f) Let the solution stand at 130-140°F for a minimum of 8 hours.

让溶液在 130-140°F 下放置至少 8 小时。

(g) Prepare a filter cake with 2 ounces of filter aid (as a 1 pound per gallon slurry) for each square foot of filtering area.

每平方英尺的过滤面积用 2 盎司助滤剂(每加仑 1 磅的浆液)制作滤饼。

(h) Clean the plating tank fully. Then send the solution, through the filter, back to the plating tank.

充分清洗电镀槽。然后通过过滤器将溶液送回电镀槽。

(i) Adjust the solution to the controls and temperature as specified in Table 1, Table 3 or Table 6, as applicable.

视情况将溶液调整到表 1、表 3 或表 6 规定的控制和温度。

6. PREPLATE STRESS RELIEF 镀前应力消除

A. Unless the overhaul instructions are different, or as permitted by Paragraph 6.B., before plating, stress relieve all parts 180-200 ksi (160-180 ksi for threaded parts) or higher if they were ground, machined, straightened or proof loaded after heat treatment.

除非大修说明不同,或在第 6.B 段允许的情况下,否则在电镀前,对所有零件进行 180-200 ksi(螺纹零件为 160-180 ksi)或更高的应力消除,如果这些零件在热处理后经过磨削、机加工、矫直或加载。

(1) If the preplate stress relief is necessary, do it by SOPM 20-10-02 Fig. 1, or by these specifications:

如果必须进行镀前应力消除,则应按照 SOPM 20-10-02 图 1 或这些规范进行:

(a) Alloy steel parts: BAC5617 unless specified by BAC5620, BAC5640 or BAC5641.

合金钢零件: BAC5617 除非有 BAC5620、BAC5640 或 BAC5641 的规定。

(b) CRES parts: BAC5617 unless specified by BAC5620, BAC5640 or BAC5641

CRES 零件: BAC5617 除非由 BAC5620、BAC5640 或 BAC5641 规定。

(c) Induction hardened parts: BAC5620

感应淬火零件: BAC5620

(d) Nitrided parts: BAC5640

氮化零件: BAC5640

(e) Carburized parts: BAC5641

渗碳零件: BAC5641

(2) Stress relieve after you grind, machine, straighten, form or proof load.

在磨削、机加工、矫直、成形或加载后消除应力。

(3) Stress relieve before you shot peen, roll threads, cold work the holes or roll the head to shank radii.

在喷丸、滚压螺纹、冷加工孔或滚压头部至柄部半径之前消除应力。

B. Unless otherwise specified, preplate stress relief is not necessary for these alloys and conditions:

除另有规定外,这些合金和条件无需进行镀前消除应力处理:

(1) Non-threaded parts heat treated below 180 ksi

热处理低于 180 ksi 的非螺纹零件

(2) Threaded parts heat treated 150-170 ksi, and below.

150-170 ksi 及以下热处理的螺纹零件。

(3) Parts that were only honed, lapped, shot peened, thread rolled or head to shank radii rolled.

只经过珩磨、研磨、喷丸、螺纹滚压或头部至柄部半径滚压的零件。

(4) 300-series CRES and A286 CRES.

300 系列 CRES 和 A286 CRES。

7. CLEANING BEFORE MASKING 遮蔽前的清洁

A. If necessary, clean the parts before you apply masks to them, by these procedures as applicable:

如有必要,在对零件应用遮蔽物之前,应根据情况按以下程序进行清洁:

(1) Vapor degrease (BAC5408)

蒸汽脱脂 (BAC5408)

(2) Emulsion clean or aqueous degrease (BAC5763)

乳化液清洗或水性脱脂 (BAC5763)

(3) Solvent clean (BAC5750)

溶剂清洗(BAC5750)

(4) Manual clean (BAC5744)

手工清洗(BAC5744)

(5) Alkaline clean (BAC5749)

碱性清洗(BAC5749)

(6) Acid pickle (BAC5751, Type 1 or BAC5625, Method 1)

酸洗(BAC5751,类型 1 或 BAC5625,方法 1)

B. Do not electrolytic alkaline clean or acid clean or pickle steels heat treated above 220 ksi (Type 3).

不得对热处理超过 220 ksi(类型 3)的钢材进行电解碱性清洗或酸洗。

8. MASKING AND RACKING 遮蔽和装架

A. Type 1 and Type 3 plating

1 类和 3 类电镀

(1) You can use any maskant that is inert to the solutions and which gives acceptable line definitions.

您可以使用任何对溶液具有惰性并能提供可接受的线条定义的遮蔽剂。

(2) Apply the maskant to the part surfaces not to be plated. Plug holes not to be plated. You can apply the maskant to the full part surface and then remove it from the areas to be plated. You can use templates to lay out guidelines.

将遮蔽剂应用在不电镀的零件表面。堵塞不电镀的孔。可以在整个零件表面应用掩蔽剂,然后从要电镀的区域去除。您可以使用样板制定准则。

(3) Apply maskant to surfaces of the rack that will be touched by the plating solution. Do not apply maskant to the points of the rack that will touch the parts to be plated.

在电镀溶液将接触到的机架表面应用遮蔽剂。不要将遮蔽剂应用在电镀机架上与待镀零件接触的点上。

(4) Put the parts on the rack to prevent caught gases and to help solutions drain.

将零件放在机架上,以防止夹带气体并帮助溶液排出。

(5) Make good electrical connections to help prevent arcs. The points where the racks touch the parts can be seen after the plating, and must be outside the important surfaces of the parts. Locations in masked areas are recommended.

做好电气连接以防止电弧。电镀后可以看到电镀架与零件的接触点,这些点必须位于零件重要表面之外。建议位于遮蔽区域内。

(6) Use auxiliary (internal) anodes as necessary to apply plating of the specified thickness.

必要时使用辅助(内部)阳极,以镀上规定厚度的电镀层。

(7) To monitor the plating thickness as it is deposited, you can attach a thickness reference coupon (control coupon) on the rack. Make the coupon 1 inch by 4 inches by 0.040 inch thick. Put the coupon on the rack in a location for easy access and control.

为了在电镀过程中监测电镀厚度,可以在架子上安装厚度参考迭片(控制迭片)。参考样板的尺寸为 1 英寸 x 4 英寸 x 0.040 英寸厚。将参考样板放在镀架上便于取用和控制的位置。

B. Type 2 Electroforming

类型 2 电铸

(1) Put maskant on the mandrels used in the procedure.

在程序中使用的心轴上涂上遮蔽剂。

9. CLEANING AND ACTIVATION BEFORE PLATING 电镀前的清洁和活化

A. Cleaning and Activation Before Type 1 Plating

第 1 类电镀前的清洁和活化

(1) Low alloy steels heat treated below 220 ksi

低于 220 ksi 热处理的低合金钢

(a) If necessary, remove scale and oxide with one of these procedures:

如有必要,采用以下程序之一去除氧化皮和氧化物:

1) Procedure 1

程序 1

a) Abrasive clean as specified in BAC5748, Type 1 with glass beads or aluminum oxide abrasives.

用玻璃珠或氧化铝磨料进行 BAC5748 规定的 1 类磨料清洁。

b) Alkaline clean 10-12 minutes as specified in BAC5749.

按 BAC5749 规定进行 10-12 分钟碱性清洗。

c) Warm water rinse for 5 minutes minimum.

温水冲洗至少 5 分钟。

d) Start to activate the part within one minute (Paragraph 9.A.(1)(b)).

在一分钟内开始激活零件(第 9.A.(1)(b)段)。

2) Procedure 2

程序 2

a) Etch as specified in BAC5751, Type 1 or BAC5625, Method 1.

按照 BAC5751 类型 1 或 BAC5625 方法 1 的规定进行蚀刻。

b) Rinse with water.

用清水冲洗。

c) Start to activate the part within one minute (Paragraph 9.A.(1)(b)).

在一分钟内开始激活零件(第 9.A.(1)(b)段)。

3) Procedure 3 (only for low alloy steels heat treated to 180 ksi or below)

程序 3(仅适用于热处理至 180 ksi 或以下的低合金钢)

a) Periodic reverse clean to remove scale for 10-20 minutes at 120-140°F and 100-250 asf as specified in BAC5749, Method 3.

按照 BAC5749 方法 3 的规定,在 120-140°F 和 100-250 asf 下定期反向清洁 10-20 分钟,以去除水垢。

b) Rinse with water and examine to make sure the surfaces are clean.

用清水冲洗并检查,确保表面清洁。

c) Start to activate the part within one minute (Paragraph 9.A.(1)(b)).

在一分钟内开始激活零件(第 9.A.(1)(b)段)。

4) Procedure 4 (only for low alloy steels heat treated to 180 ksi or below)

程序 4(仅适用于热处理至 180 ksi 或以下的低合金钢)

a) Periodic reverse clean in Enprep 214 solution as specified in BAC5749, Method 3.

按照 BAC5749 方法 3 的规定,定期在 Enprep 214 溶液中进行反向清洁。

b) Rinse with water and examine to make sure the surfaces are clean.

用清水冲洗并检查,确保表面清洁。

c) Start to activate the part within one minute (Paragraph 9.A.(1)(b)).

在一分钟内开始激活零件(第 9.A.(1)(b)段)。

(b) Use one of these procedures to activate the part surface.

使用以下程序之一活化零件表面。

1) TPSG (Preferred option for low alloy steels heat treated to 180 ksi or below)

TPSG(热处理至 180 ksi 或以下的低合金钢的首选方案)

a) Periodic reverse electroactivate in TPSG solution as specified in BAC5749. End on the anodic cycle.

按照 BAC5749 的规定,在 TPSG 溶液中进行周期性反向电活化。阳极循环结束。

b) Rinse for 2-3 minutes.

冲洗 2-3 分钟。

c) Put the part in sulfamic acid solution for 30-90 seconds.

将零件放入氨基磺酸溶液中 30-90 秒。

d) Do not rinse. Start to nickel plate the part within one minute.

不要冲洗。一分钟内开始对零件进行电镀镍。

2) Enprep 214

a) Cathodic clean in Enprep 214 solution at 50 asf for 1.5-2.0 minutes.

在 50 asf 的 Enprep 214 溶液中阴极清洗 1.5-2.0 分钟。

b) Rinse in warm water for 2-3 minutes.

用温水冲洗 2-3 分钟。

c) Put the part in sulfamic acid solution for 30-60 seconds.

将零件放入氨基磺酸溶液中 30-60 秒。

d) Rinse in warm water for 2-3 minutes.

用温水冲洗 2-3 分钟。

e) Cathodic clean in Enprep 214 solution again, at 50 asf for 1.5-2.0 minutes.

再次在 Enprep 214 溶液中进行阴极清洗,在50 asf下1.5-2.0 分钟。

f) Rinse in warm water for 2-3 minutes. Then rinse in cold water for 30-60 seconds.

在温水中冲洗 2-3 分钟。然后在冷水中冲洗 30-60 秒。

g) Put the part in sulfamic acid solution for 30-60 seconds.

将零件放入氨基磺酸溶液中 30-60 秒。

h) Do not rinse. Start to nickel plate the part within one minute.

不要冲洗。一分钟内开始对零件进行电镀镍。

3) Inhibited Hydrochloric Acid

抑制盐酸

a) Alkaline clean as specified in BAC5749.

按照 BAC5749 的规定进行碱性清洗。

b) Rinse in cold water.

用冷水冲洗。

c) Put the part in inhibited hydrochloric acid for 15 seconds maximum (parts cleaned with glass beads) or 10 seconds maximum (parts cleaned with aluminum oxide).

将零件放入抑制盐酸中最多 15 秒(用玻璃珠清洗的零件)或最多 10 秒(用氧化铝清洗的零件)。

d) Rinse in cold water. Start to nickel plate the part within 30 seconds.

用冷水冲洗。在 30 秒内开始对零件进行电镀镍。

(2) Nickel, Cobalt and Chromium Alloys; PH, 300 and 400-series CRES

镍、钴和铬合金;PH、300 和 400 系列 CRES

(a) Clean and activate with the nickel strike or iron strike procedures. Use the iron strike procedure only for cadmium as specified in BAC5701 or zinc-nickel as specified in BAC5637.

使用镍击或铁击程序进行清洁和活化。仅对 BAC5701 规定的镉或 BAC5637 规定的锌-镍使用铁击程序。

(b) Nickel strike (Optional for PH CRES)

镍击 (PH CRES 可选)

NOTE: For the preferred nickel strike for PH CRES, see Paragraph 9.A.(2)(c).

注: PH CRES 的首选镍击,见第 9.A.(2)(c)段。

1) Electrolytic clean in Enprep 214 solution or TPSG solution as specified in BAC5749, Method 3, or abrasive clean as specified in BAC5748, Type 2, Class 1 or 2.

按照 BAC5749 方法 3 的规定,在 Enprep 214 溶液或 TPSG 溶液中进行电解清洁,或按照 BAC5748 类型 2、1 级或 2 级的规定进行研磨清洁。

2) Rinse in cold water for a minimum of 5 minutes.

在冷水中冲洗至少 5 分钟。

3) Make electrical connections and put the part in the nickel strike bath with the power on. Use a current density of 25-35 asf for both the anodic and cathodic strikes. Apply anodic current for a maximum of 3 minutes, then switch to cathodic for 4-5 minutes. The anodic cycle can be removed from this procedure if:

接通电源,将零件放入镍击槽中。阳极和阴极电击的电流密度均为 25-35 asf。阳极电流最多持续 3 分钟,然后转为阴极电流 4-5 分钟。如果出现以下情况,可从该程序中取消阳极循环:

a) Smut or bad bonds occur

出现污点或粘结不良

b) You cleaned 15-5PH CRES with glass beads as specified in BAC5748, Type 2.

您按照 BAC5748 类型 2 的规定用玻璃珠清洁了 15-5PH CRES。

4) Rinse for 30-90 seconds. Immediately move the parts to the nickel plating bath or another subsequent plating bath. Do not let the parts dry during the move.

冲洗 30-90 秒。立即将零件移至镀镍槽或另一个后续电镀槽。在移动过程中不要让零件干燥。

(c) Nickel strike (Preferred for plating on PH CRES)

镍镀层(电镀 PH CRES 的首选方法)

1) Alkaline clean as specified in BAC5749, Method 1 or 3, or abrasive clean as specified in BAC5748, Type 2, Class 1 or 2.

按 BAC5749 方法 1 或 3 规定进行碱性清洗,或按 BAC5748 方法 2 类型 1 或 2 级规定进行研磨清洗。

2) Rinse in cold water.

用冷水冲洗。

3) Put the parts in inhibited hydrochloric acid or uninhibited hydrochloric acid for 30-60 seconds.

将零件放入抑制盐酸或未抑制盐酸中 30-60 秒。

4) Rinse in cold water.

用冷水冲洗。

a) Optional: Put the parts in Enprep 214 bath (make and control as specified in BAC5749), cyanide hold (BAC5625, Solution 11) or alkaline cleaner (BAC5749). Then rinse in cold water.

可选: 将零件放入 Enprep 214 浴(按 BAC5749 中的规定制造和控制)、氰化保持剂 (BAC5625,溶液 11)或碱性清洁剂(BAC5749)中。然后用冷水冲洗。

CAUTION :SEQUENCE IS ANODIC FOLLOWED BY CATHODIC. DO NOT USE CATHODIC FOLLOWED BY ANODIC.

注意 :顺序是先阳极后阴极。切勿先阴极后阳极。

5) Make electrical connections. Put the parts in the nickel strike bath (Paragraph 9.A.(2)(c)). Use a current density of 20-25 asf at 3-7 volts for both the anodic and cathodic strikes. Apply anodic current for 3.0-3.5 minutes, then switch to cathodic for 4-5 minutes. If you find that the anodic cycle causes smut or bad bonds on PH CRES, then do not do the anodic strike. Do only the cathodic strike for 4-5 minutes.

进行电气连接。将零件放入镀镍槽中(第 9.A.(2)(c)段)。阳极和阴极电击的电流密度均为 20-25 asf,电压为 3-7 伏。阳极电流持续 3.0-3.5 分钟,然后转为阴极电流持续 4-5 分钟。如果发现阳极循环会导致 PH CRES 上出现污点或粘结不良,则不要进行阳极击穿。只进行 4-5 分钟的阴极电击。

6) Fully rinse for 30-90 seconds. Immediately move the parts to the nickel plating bath or another subsequent plating bath. Do not let the parts dry during the move.

充分冲洗 30-90 秒。立即将零件移至镀镍槽或另一个后续电镀槽。在移动过程中不要让零件干燥。

(d) Iron strike (Use only for cadmium as specified in BAC5701, or zinc-nickel as specified in BAC5637)

铁击(仅用于 BAC5701 规定的镉镀层或 BAC5637 规定的锌镍镀层)

1) Abrasive clean as specified in BAC5748, Type 1 with aluminum oxide abrasive.

按 BAC5748 规定的 1 类氧化铝研磨剂进行研磨清洁。

2) Cold water rinse. Do not dry.

冷水冲洗。不要干燥。

3) Put the parts in sulfuric acid-hydrofluoric acid solution with the current off.

将零件放入硫酸-氢氟酸溶液中,关闭电流。

4) Activate anodically for 60-70 seconds at 60-100 asf.

在 60-100 asf 下阳极活化 60-70 秒。

5) Rinse for 30-90 seconds.

冲洗 30-90 秒。

6) Put the parts in the iron strike solution within 1 minute.

在 1 分钟内将零件放入铁击溶液中。

7) Make electrical connections and put the parts in the iron strike solution with the power on. Apply cathodic current for 4.5-5.5 minutes at a current density of 30-40 asf.

接通电源,将零件放入铁击溶液中。以 30-40 asf的电流密度施加阴极电流 4.5-5.5 分钟。

8) Rinse for 30-40 seconds. Immediately move the parts to the nickel plating bath or another subsequent plating bath. Do not let the parts dry during the move.

冲洗 30-40 秒。立即将零件移至镀镍槽或另一个后续电镀槽。在移动过程中不要让零件干燥。

(3) Aluminum Alloys

铝合金

(a) Prepare aluminum alloys for plating as specified in BAC5714.

按照 BAC5714 的规定准备电镀铝合金。

(4) Copper Alloys (but not circuit boards)

铜合金(但不包括电路板)

(a) Prepare copper alloys for plating as specified in BAC5770.

按照 BAC5770 的规定制备电镀用铜合金。

(b) Activate in the fluoboric acid bath for 2-6 minutes.

在氟硼酸浴中活化 2-6 分钟。

(c) Rinse in cold water for 30-45 seconds. Move the parts to the nickel plating bath within one minute.

在冷水中冲洗 30-45 秒。在一分钟内将零件移至电镀镍槽。

B. Cleaning Before Type 2 Plating (Electroforming)

第二类电镀(电铸)前的清洗

(1) Alkaline clean and rinse as specified in BAC5749.

按 BAC5749 规定进行碱性清洁和冲洗。

(2) Apply DuPont 8535 Conductive Silver Composition where necessary.

必要时使用DuPont 8535 导电银粉。

(3) Electroform as specified in BAC5746 Section 8.5.

按 BAC5746 第 8.5 节规定进行电铸。

C. Cleaning and Activation Before Type 3, Class 1 Plating (Optional for low alloy steels below 220 ksi)

第 3 类第 1 级电镀前的清洁与活化(220 ksi 以下的低合金钢可选):

(1) Dry abrasive blast the parts as specified in BAC5748, Type 1. If there are areas for localized cup plating (Class 2), clean them with Scotch-Brite pads.

按 BAC5748 第 1 类规定对零件进行干喷砂处理。如果有局部电镀杯(第 2 类)的区域,则使用 Scotch-Brite 电镀盘进行清洁。

(2) Rinse in cold water.

用冷水冲洗。

(3) To activate the surface, put the part in sulfuric acid-hydrofluoric acid solution for 15-25 seconds, then anodically etch for 60-90 seconds at 3-6 amps per square inch. Optional: Enclosed anode configurations can be etched for 30-180 seconds at 1.0-2.0 amps per square inch to prevent too much etching.

为活化表面,将零件放入硫酸-氢氟酸溶液中 15-25 秒,然后以每平方英寸 3-6 安培的电流阳极腐蚀 60-90 秒。可选: 封闭式阳极配置可在每平方英寸 1.0-2.0 安培的条件下进行 30-180 秒的阳极蚀刻,以防止过多的蚀刻。

(4) Rinse in cold water within 30 seconds after you stop the anodic current.

阳极电流停止后 30 秒内用冷水冲洗。

(5) Clean the parts again, from Paragraph 9.C.(1), if one or more of these conditions occur:

如果出现以下一种或多种情况,则应根据第 9.C.(1)段再次清洗零件:

(a) The sulfuric-HF etched surface does not have a layer of dark gray or black smut.

硫酸-氢氟酸蚀刻表面没有一层深灰色或黑色污垢。

(b) The parts waited more than 5 minutes between the sulfuric-HF solution and the plating solution.

零件在硫酸-氢氟酸溶液和电镀溶液之间的等待时间超过 5 分钟。

(c) The parts were not kept wet with water, but were permitted to dry.

零件没有用水浸湿,而是让其干燥。

(6) Put the parts in the plating solution and start to plate them.

将零件放入电镀液中并开始电镀。

10. NICKEL PLATING PROCEDURES 电镀镍程序

A. General

通用

(1) The nickel plating solutions must be purified as specified in Paragraph 5. when one or more of these conditions occur:

当出现以下一种或多种情况时,必须按照第 5.段的规定净化电镀镍溶液:

(a) The nickel plating you get is mirror-bright or rough, or has cracks, flakes or streaks or bad colors after all solution controls are within the specified limits.

在所有溶液控制在规定范围内后,得到的电镀镍呈镜面光泽或粗糙,或有裂纹、片状或条纹或颜色不好。

(b) Organic contamination, such as solvent, lacquer, paint, oil, or grease, came into the solution. Cured masking materials on parts are not contamination if the plating results are satisfactory.

溶液中进入有机污染物,如溶剂、漆、油漆、油或油脂。如果电镀结果令人满意,则零件上的固化遮蔽材料不属于污染。

(c) Metallic contamination is more than the limits specified for the plating solution.

金属污染超过电镀溶液规定的限值。

(d) The sulfamate nickel plating stress, when tested as specified in BAC5746 Section 12.4, is outside of these ranges:

按 BAC5746 第 12.4 节规定进行测试时,氨基磺酸镍电镀应力超出这些范围:

1) Types 2 and 3: 0 to +9 ksi (tensile)

类型 2 和 3:0 至 +9 ksi (拉伸)

2) Type 1: -1 ksi (compressive) to +15 ksi (tensile)

类型 1:-1 ksi(压缩)至 +15 ksi(拉伸)

(2) Surfaces must be water-break-free after they are put in any processing solution or rinse, unless after vapor degreasing, solvent cleaning, or emulsion cleaning. A water-break-free surface is a surface which keeps a continuous water film for 30 seconds minimum after spray or immersion in clean water at temperatures less than 100°F. Clean the parts again if their surfaces are not water-break-free.

除非经过蒸气脱脂、溶剂清洗或乳液清洗,否则表面在放入任何加工溶液或冲洗后必须无断水。无断水表面是指在温度低于 100 °F 的情况下,喷洒或浸泡在清洁的水中后,能保持连续水膜至少 30 秒钟的表面。如果零件表面无断水,则再次清洗。

(3) Unless the overhaul instructions are different, the part surface must not be rougher than 125 microinches.

除非大修说明不同,否则零件表面粗糙度不得超过 125 微英寸。

B. BAC5746 Class 1 (Tank) Nickel Plating

BAC5746 1 级(槽)电镀镍

(1) Make sure all parts in a load to be plated are of the same alloy.

确保装载的所有待电镀零件均为相同合金。

(2) Mask and rack the parts as necessary for good electrical contact.

根据需要对零件进行遮蔽和上架,以保持良好的电气接触。

(3) Put the parts into the plating bath as follows:

按以下步骤将零件放入电镀槽:

(a) Type 1 or Type 2 parts

1 类或 2 类零件

1) Use either the sulfamate bath or the Watts bath.

使用氨基磺酸盐镀液或Watts镀液。

2) Make electrical connections from the cathode bus bar (or other cathodic leads from the rectifier) to the parts before you put them in the plating tank.

在将零件放入电镀槽之前,将阴极母线(或整流器的其他阴极引线)与零件进行电气连接。

3) Set the voltage at 0.25-0.50 volt to let the current start as the parts go into the bath.

将电压设置在 0.25-0.50 伏,以便在零件进入镀槽时启动电流。

4) Lower the parts into the bath.

将零件放入镀槽。

5) Keep this voltage until the parts get to the bath temperature.

保持此电压直到零件达到镀槽温度。

(b) Type 3 parts

第 3 类零件

1) Use the sulfamate bath.

使用氨基磺酸盐浴槽。

2) Lower the parts into the bath.

将零件放入浴槽。

3) Within 3 minutes, strike plate the parts at 60-100 asf for 1-3 minutes.

在 3 分钟内,在 60-100 asf 下电镀零件 1-3 分钟。

4) Decrease the current density to 20-30 asf until the parts get to the bath temperature.

将电流密度降至 20-30 安培,直到零件达到浴槽温度。

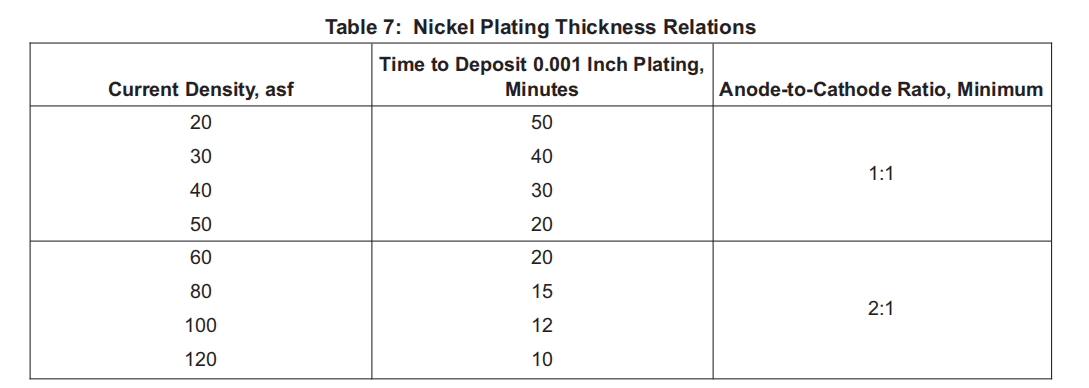

(4) After the parts get to the solution temperature, adjust the voltage upwards until the current density comes to the specified range. You can use Table 7 as a guide for current density versus time relationships, but do not use it as an alternative to the actual thickness measurements specified in Paragraph 10.B.(7).

待零件达到溶液温度后,上调电压,直至电流密度达到规定范围。您可以使用表 7 作为电流密度与时间关系的指南,但不要用它来替代第 10.B.(7)段规定的实际厚度测量。

NOTE: Plating at a current density of 70-100 asf is recommended. Plating at a higher current density causes more edge buildup, and the plating can get contamination such as fingerprints more easily.

注: 建议在 70-100 asf 的电流密度下电镀。电镀电流密度越大,边缘堆积越多,电镀层越容易沾上指纹等污染物。

(5) Use solution, part and/or anode agitation to prevent gas pitting. Strong agitation is recommended, and is necessary for localized cup plating.

使用溶液、零件和/或阳极搅拌来防止气体点蚀。建议使用强力搅拌,这对于局部杯状电镀是必要的。

(6) If the current is stopped, reactivate Type 1 or Type 2 parts as specified in Paragraph 9.A.(2). Reactivate Type 3 parts as specified in Paragraph 9.C.

如果电流停止,按照第 9.A.(2)段的规定重新激活 1 类或 2 类零件。按第 9.C 段规定重新激活第 3 类零件。

(7) Plate to the thickness specified in Paragraph 13.B., based on the measurement of the test coupons (thickness reference coupons) or on control with an amp-hour meter.

根据测试脆片(厚度参考脆片)的测量结果或安培小时计的控制结果,电镀至第 13.B 段规定的厚度。

(8) Remove the parts from the tank. Rinse them fully in cold water. Then hot water rinse as necessary to help them dry.

将零件从槽中取出。用冷水充分冲洗。然后根据需要用热水冲洗以帮助干燥。

(9) Remove the parts from the rack. Remove masks if applied.

将零件从架子上取下。如果有面罩,取下面罩。

(10) Dry the parts. Make a check of the plating thickness on electroformed parts. Mechanically remove nodules which could be a problem with subsequent plating.

擦干零件。检查电镀零件的电镀厚度。用机械方法清除可能影响后续电镀的结节。

(11) Do not flex springs or other parts before the hydrogen embrittlement bake.

在氢脆烘烤之前,不要弯曲弹簧或其他零件。

(12) If the necessary plating time to get the specified thickness come near to or becomes more than 24 hours, use the procedures of Paragraph 11.A. to stop the plating cycle and do intermediate hydrogen embrittlement bake cycles as necessary.

如果达到规定厚度所需的电镀时间接近或超过 24 小时,则应按照第 11.A. 段的程序停止电镀循环,并在必要时进行中间氢脆烘烤循环。

C. BAC5746 Class 2 (Localized Cup) Nickel Plating

BAC5746 第 2 级(局部杯状)电镀镍

(1) See BAC5746 PSD 6-42 or 6-43, as applicable, for details.

详见 BAC5746 PSD 6-42 或 6-43。

11. HYDROGEN EMBRITTLEMENT BAKE 氢脆烘烤

A. Unless the overhaul instructions are different, start to bake the parts as necessary within 10 hours after plating or less than 24 hours after the current was first applied to the part, whichever is first. One bake can be used for long or multiple plating cycles if the bake starts within 24 hours after the current was first applied to the part. More than one bake is necessary for longer cycles. Reactivate parts before you start more plating cycles.

除非大修说明有所不同,否则应在电镀后 10 小时内或电流首次作用于零件后 24 小时内(以先到者为准)开始对零件进行必要的烘烤。如果在首次对零件施加电流后 24 小时内开始烘烤,则可以对长电镀周期或多次电镀周期使用一次烘烤。对于较长的电镀周期,需要进行一次以上的烘烤。在开始更多电镀循环之前,重新激活零件。

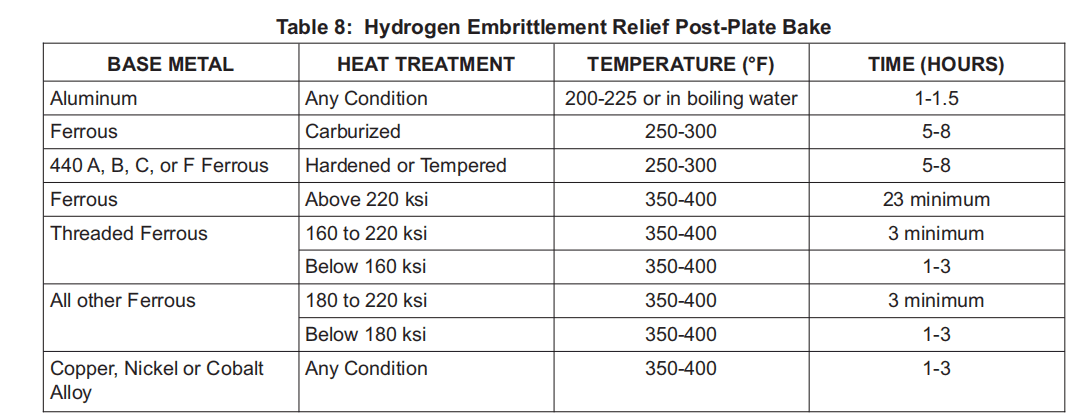

B. Bake Type 1 and Type 3 plated parts as specified in Table 8 unless specified by the overhaul instructions. Set the control at the temperature specified. For Type 3 plated parts with a hydrogen diffusion path longer than 1.0 inch, increase the bake time 8 hours for each 0.5 inch (or fraction of 0.5 inch) that the diffusion path of the part is longer than 1.0 inch. The maximum hydrogen diffusion path length must not be longer than 2.0 inches.

按照表 8 的规定烘烤 1 类和 3 类电镀零件,除非大修说明有规定。将控制器设定在规定的温度。对于氢扩散路径长于 1.0 英寸的 3 类电镀零件,零件扩散路径每长于 1.0 英寸 0.5 英寸(或 0.5 英寸的分数),烘烤时间增加 8 小时。最大氢扩散路径长度不得超过 2.0 英寸。

C. For Type 2 (electroformed) parts, a post-plate bake is not necessary unless specified by the overhaul instructions.

对于 2 类(电镀)零件,除非大修说明有规定,否则无需进行电镀后烘烤。

D. Unless specified, the bake is not necessary for these alloys:

除非有规定,这些合金无需进行烘烤:

(1) 300-Series CRES, A-286, nickel alloys 625 and 718

300 系列 CRES、A-286、镍合金 625 和 718

(2) Nonthreaded alloy and PH steels below 180 ksi

低于 180 ksi 的非螺纹合金钢和 PH 钢

(3) Threaded alloy and PH steels below 160 ksi

低于 160 ksi 的螺纹合金钢和 PH 钢

(4) 17-7PH in the CH-900 condition.

CH-900 条件下的 17-7PH。

12. NICKEL PLATE RUNOUT 镍电镀跳动

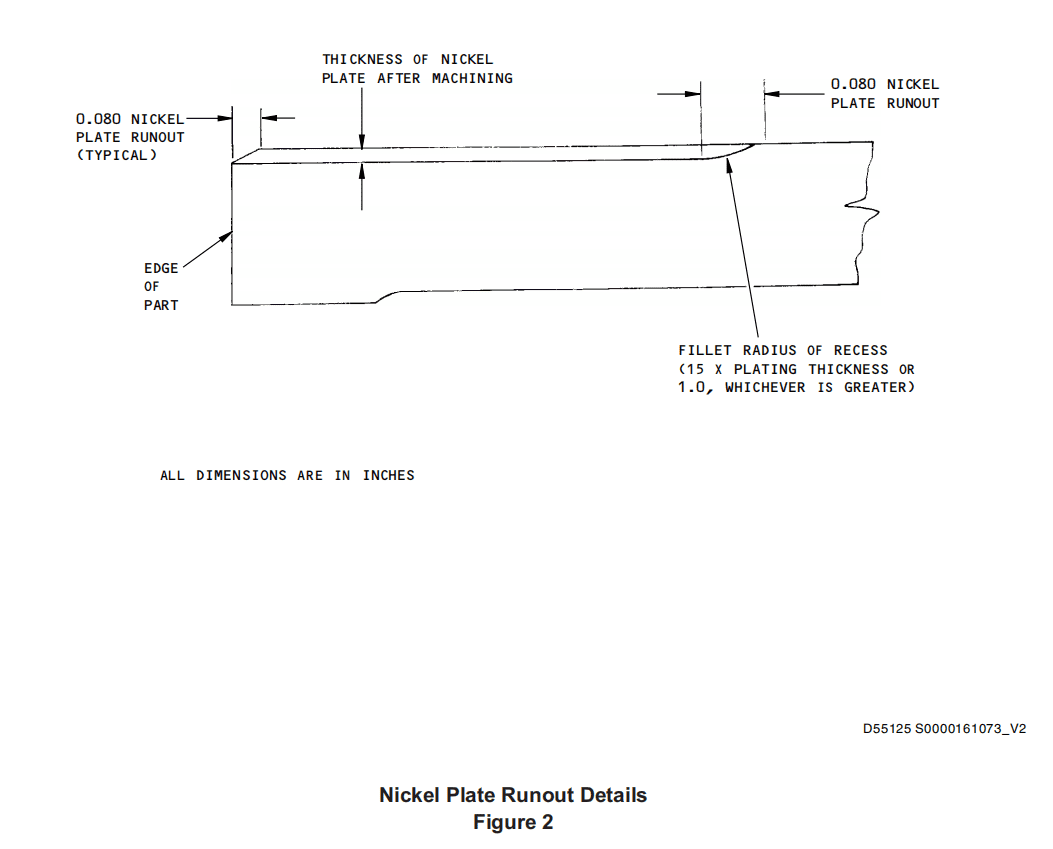

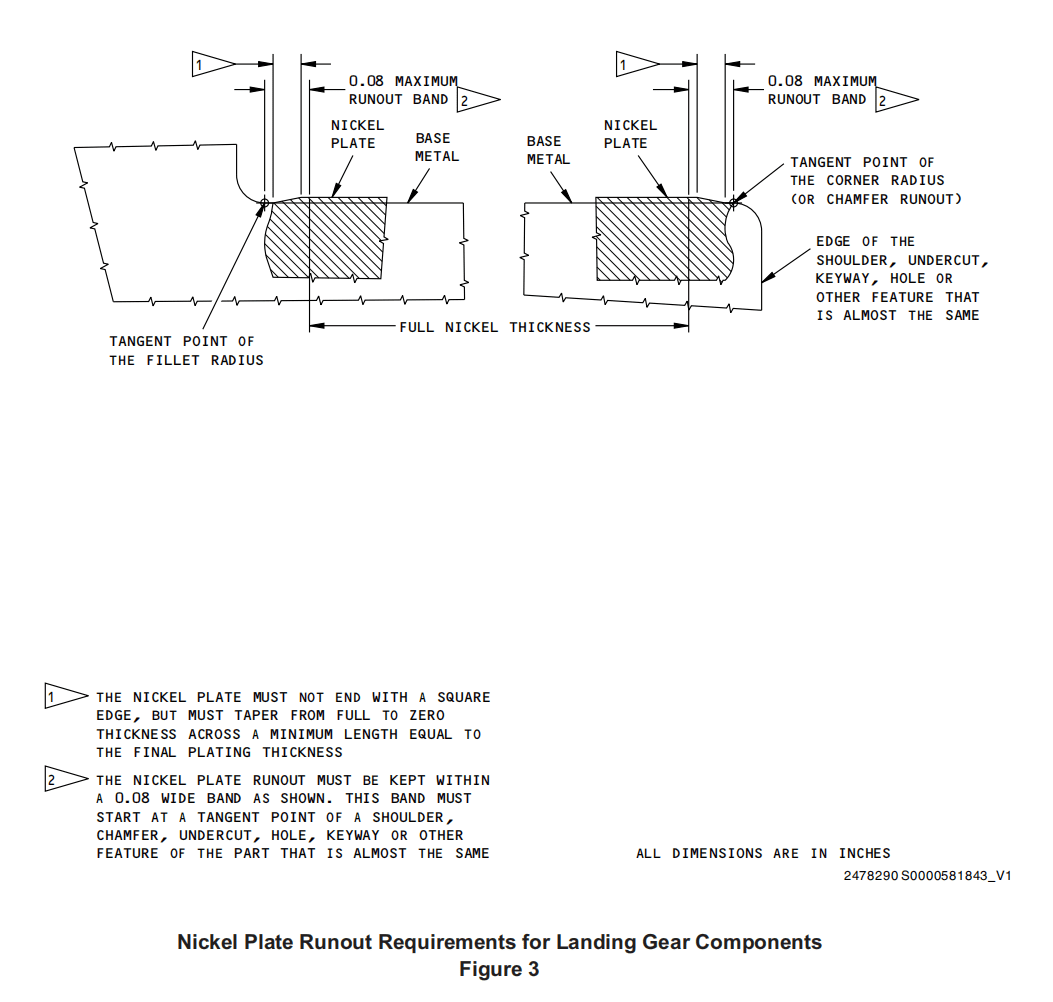

A. The nickel plate runout area is that area of the nickel plated surfaces where the nickel plating thickness changes from the specified thickness to zero. The specified runout is necessary to be sure the plating area is correct and to give clearance for machining (where applicable) and masking materials.

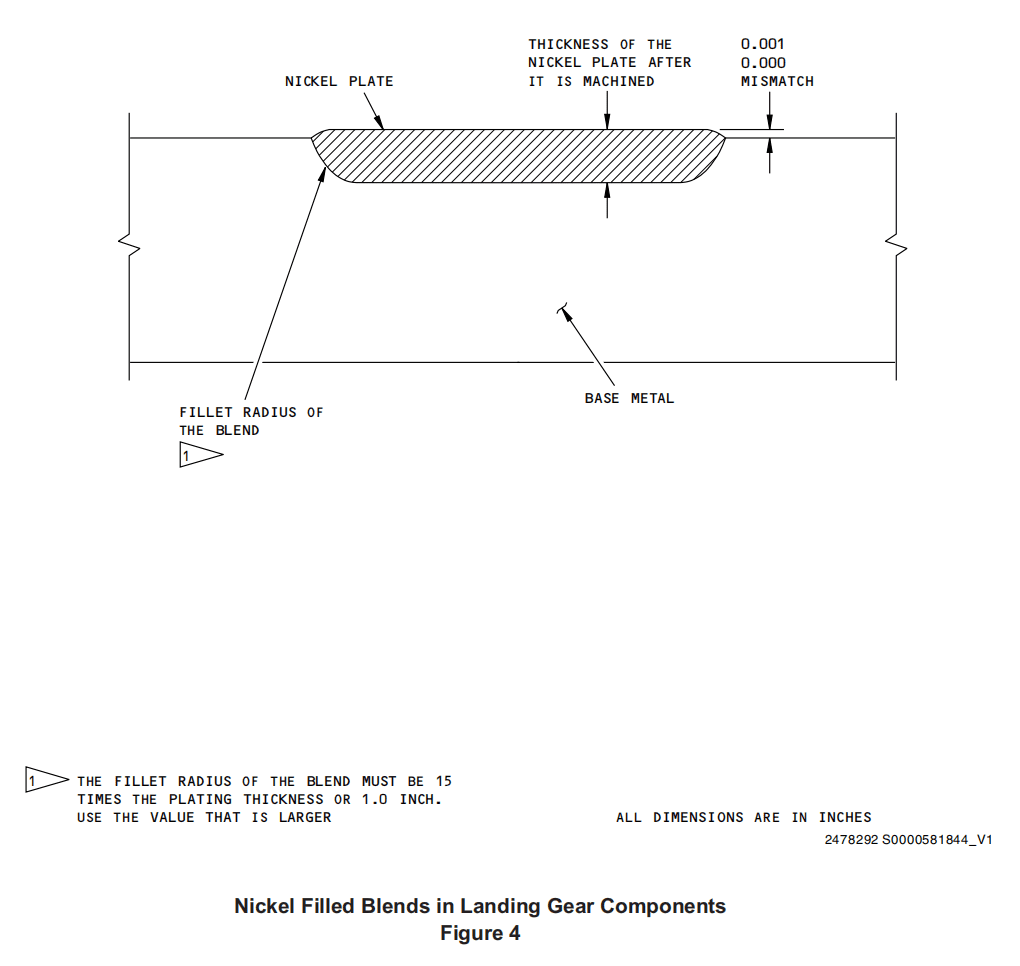

电镀镍板跳动区域是镀镍表面上镀镍厚度从规定厚度变为零的区域。规定的跳动是必要的,以确保电镀区域正确,并为机加工(如适用)和遮蔽材料留出间隙。

B. Unless specified by the applicable overhaul instructions, make the nickel plating runout within a 0.080 inch wide band at the edges of the plated area, as shown in Figure 2 and Figure 3. See Figure 4 for data about nickel filled blends in landing gear components.

如图 2 和图 3 所示,除非适用的大修说明有规定,否则应在电镀区域边缘 0.080 英寸宽的范围内进行电镀镍跳动。有关起落架部件中镍填充混合物的数据,请参见图 4。

13. QUALITY CONTROL 质量控制

A. The nickel plating must be smooth, fine grained, well bonded, and have no blisters, pits, nodules, porosity, burns or other defects when visually examined without magnification. Small color differences because of bakes are acceptable. The unplated surfaces must have no pits, burns, or etch marks when examined without magnification.

电镀镍层必须光滑、纹理清晰、结合良好,且在不用放大镜的情况下目视检查时没有起泡、凹坑、结节、气孔、烧伤或其他缺陷。因烘烤而产生的微小色差是可以接受的。在不用放大镜的情况下检查未镀层表面,不得有凹坑、烧伤或蚀刻痕迹。

B. Plating Thickness

电镀厚度

(1) When the nickel plating thickness is not specified by the overhaul instructions, it must be 0.003 inch minimum on alloy steels and 0.0015 inch minimum on other metals.

如大修说明未规定电镀镍的厚度,则合金钢的电镀镍厚度不得小于 0.003 英寸,其他金属的电镀镍厚度不得小于 0.0015 英寸。

(2) Unless specified by overhaul instructions, the thickness requirements apply only to surfaces that can be touched by a ball 0.75 inch in diameter. All other visible surfaces open to the plating current must be completely covered by the plating, except in recessed areas where the depth is more than twice the width or diameter.

除非大修说明有规定,厚度要求仅适用于直径 0.75 英寸的球可触及的表面。除深度超过宽度或直径两倍的凹陷区域外,所有其他向电镀电流开放的可见表面必须完全被电镀覆盖。

(3) These thickness requirements apply to nickel plating after all necessary metal finishing operations. Do not include the thickness of other plating under the nickel when you measure the thickness of the nickel plating.

这些厚度要求适用于所有必要的金属表面处理操作后的电镀镍。在测量镀镍层厚度时,不要将镀镍层下其他电镀层的厚度计算在内。

(4) When the overhaul instructions specify QQ-N-290 or AMS-QQ-N-290 nickel plating without a thickness, make the plating thickness as shown in Table 9.

当大修说明书规定使用 QQ-N-290 或 AMS-QQ-N-290 电镀镍而未规定厚度时,应按表 9 所示确定电镀厚度。

C. Do tests on the strength of the bond and the stress in the layer of nickel plating. Refer to BAC5746 for details.

做结合强度和镀镍层应力的测试。详情请参阅 BAC5746。

D. Do tests on samples at regular intervals to be sure of the plating quality. If the interval is not specified by this procedure or in BAC5746, use an interval that agrees with standard industry practices, your experience with the procedure, and to make sure you can find parts that could have bad plating. If BAC5746 gives a formula to calculate the interval, use it for your basic quality control plan.

定期对样品进行测试,以确保电镀质量。如果本程序或 BAC5746 没有规定间隔时间,则使用符合标准行业惯例、您的程序经验的间隔时间,并确保您能找到可能存在不良电镀的零件。如果 BAC5746 提供了计算间隔时间的公式,请将其用于基本质量控制计划。