铝的化学转化涂层CHEMICAL CONVERSION COATINGS FOR ALUMINUM

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5719. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自波音工艺规范 BAC5719。航空公司有一本《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并不涉及所有情况或特定安装。请将此数据作为指南,帮助您编写最低标准。

C. If the instructions in the finish code refers to BAC5719, use only this procedure. If the instructions refer to MIL-DTL-5541, you can use procedures that agree with MIL-DTL-5541.

如果饰面代码中的说明指的是 BAC5719,则只能使用此程序。如果说明中提到 MIL-DTL-5541,则可以使用与 MIL-DTL-5541 一致的程序。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

请参阅 SOPM 20-00-00,了解所有供应商的名称和地址。

2. SCOPE 范围

A. This chemical conversion coating is used on aluminum to increase corrosion resistance, to be a paint base, and to give an electrically conductive finish.

本化学转化涂层用于铝材,以增加其耐腐蚀性、作为涂料基底并提供导电表面。

B. The coatings applied by these procedures agree with the requirements of MIL-DTL-5541. But the paint adhesion tests of MIL-DTL-5541 are not included. For parts to be painted, use the paint adhesion tests of the applicable paint application specification.

按这些程序涂装的涂层符合 MIL-DTL-5541 的要求。但不包括 MIL-DTL-5541 的涂料附着力测试。对于要涂漆的零件,应使用适用的涂漆应用规范的涂漆附着力测试。

3. CLASSIFICATION 分类

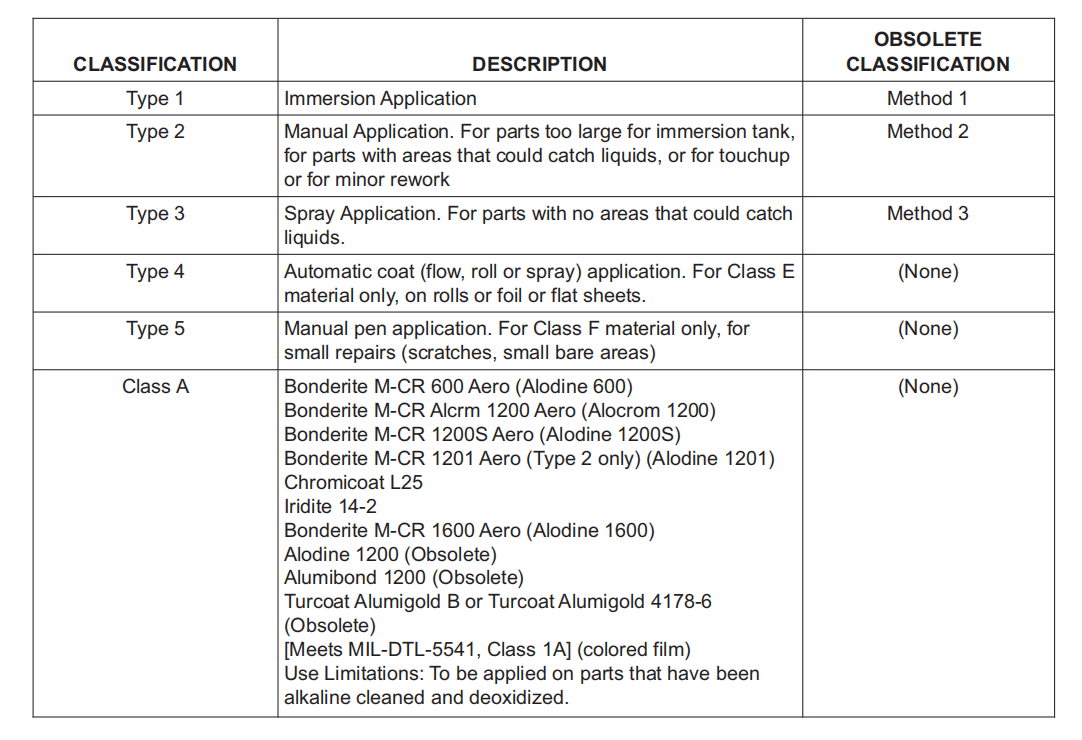

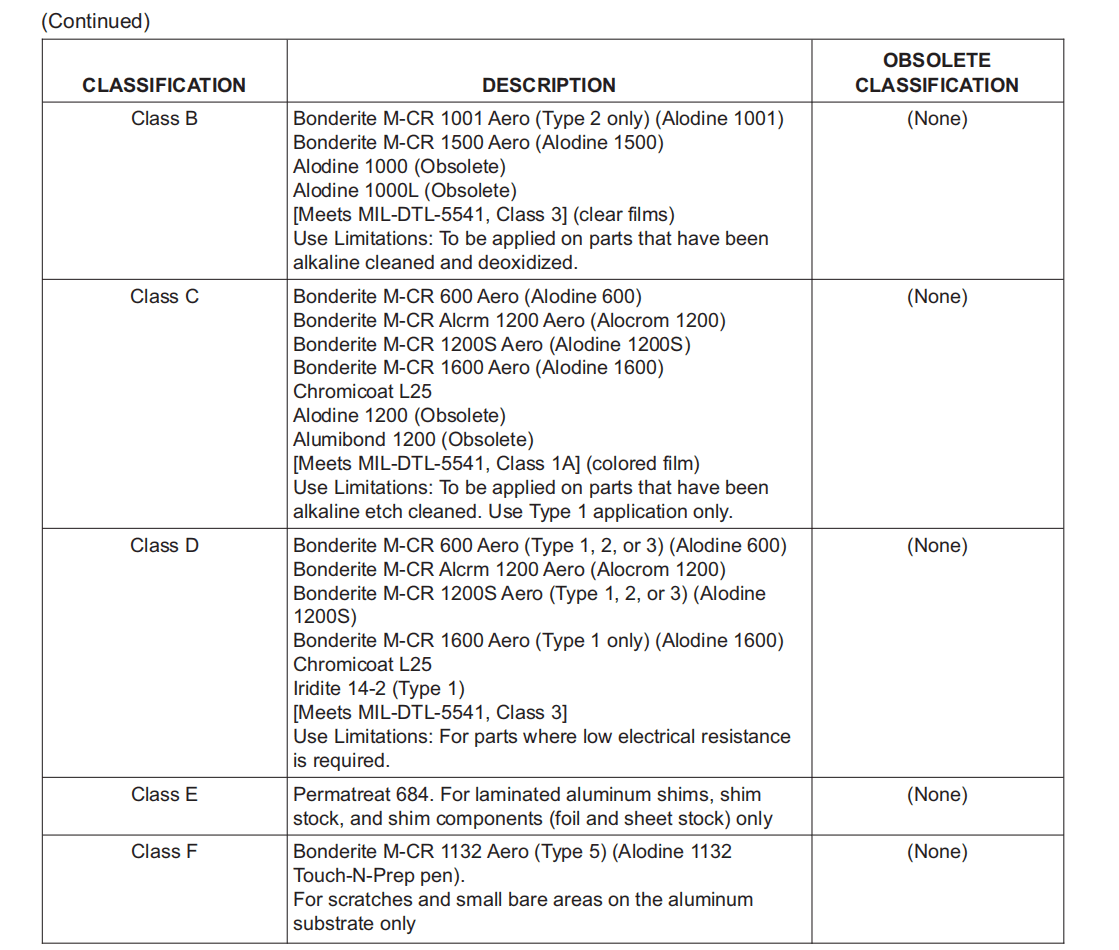

A. This procedure has these types and classes:

本程序有以下类型和等级:

B. If the overhaul instructions do not give the type or method and the parts have no areas that could catch solutions, use Type 1, 2, 3 or 4. If the parts do have areas that could catch solutions, use Type 2.

如果大修说明中没有给出类型或方法,且零件没有可以吸附溶液的区域,则使用类型 1、2、3 或 4。如果零件有可以吸附溶液的区域,则使用类型 2。

C. If the overhaul instructions do not give the class or color, use Class A or C. If the overhaul instructions specify Class A, you can use Class C as an alternative. For bare (non-clad) detail parts, use Class C only. On shim stock or components, use Class E. If the overhaul instructions specify colorless or clear coating, use Class B.

如果大修说明没有给出等级或颜色,则使用 A 级或 C 级。如果大修说明指定了A级,则可以使用C级作为替代方案。对于裸露(无包覆)的细节零件,只能使用 C 级。如果大修说明规定使用无色或透明涂层,则使用 B 级。

D. If the parts have BMS 10-20 primer, use only Bonderite M-CR 600 Aero. Other coating materials such as Bonderite M-CR Alcrm 1200 Aero, Bonderite M-CR 1200S Aero, or Bonderite M-CR 1132 can cause a powdery coating if applied on cured BMS 10-20 primer.

如果零件有 BMS 10-20 底漆,则只能使用 Bonderite M-CR 600 Aero。其他涂层材料,如 Bonderite M-CR Alcrm 1200 Aero、Bonderite M-CR 1200S Aero 或 Bonderite M-CR 1132,如涂在已固化的 BMS 10-20 底漆上,会产生粉状涂层。

E. Do not use the Bonderite M-CR 1132 Aero pen on surfaces to be sealed with BMS 5-45 sealant.

不要将 Bonderite M-CR 1132 Aero 笔用于将用 BMS 5-45 密封胶密封的表面。

4. MATERIALS 材料

A. Bonderite M-CR Alcrm 1200 Aero, VK0008

B. Bonderite M-CR 600 Aero, V84063

C. Bonderite M-CR 1132 Aero, V84063

D. Bonderite M-CR 1200S Aero, V84063

E. Bonderite M-CR 1201 Aero, V84063

F. Bonderite M-CR 1500 Aero, V84063

G. Bonderite M-CR 1600 Aero, V84063

H. Bonderite M-AD 1660 Aero, V84063

I. Chromicoat L25, V44389

J. Chromicoat T3, V44389

K. Iridite 14-2, V0PX54

L. Permatreat 684, V24774

M. Bonderite M-AD 22 Toner Aero, V84063

N. Ammonium Hydroxide, 28%, technical grade

O. Nitric Acid — Technical, A-A-59105 (Replaces O-E-350) or JIS-K-1308, 40 or 42° Baume’

P. Hydrofluoric Acid — 70% recommended; other concentrations are acceptable

Q. Sodium hydroxide, 50% liquid, ASTM E 1098

R. Sandpaper — aluminum or garnet abrasive, 600 grit

S. Brush — fiber or nylon

T. Sponge — cellulose

U. Wipers — cheesecloth, gauze, or new laundered rags

V. Mop — cotton

W. Maskants (Ref SOPM 20-44-02)

X. Gloves — cotton, nylon, or equivalent

Y. Betz Kleen 147, V24774

Z. Abrasive Pads — Scotch-Brite aluminum oxide, Type A, very fine, V76381 or non-metallic abrasive fiber pads

AA. Bonderite M-CR 600RTU Aero, V84063

AB. Bonderite M-CR Alcrm 1200BR Aero, V84063

AC. Bonderite M-CR 1001 Aero, V84063

AD. Bonderite M-CR 1200SRTU Aero, V84063

5. APPLICATION PROCEDURE 应用程序

A. General

通用

WARNING :SOME OF THESE MATERIALS ARE FLAMMABLE AND TOXIC. CHEMICAL CONVERSION COATING POWDERS THAT TOUCH ORGANIC SOLVENT CAN CAUSE A FIRE.

警告 :这些材料中有些是易燃和有毒的。化学转化涂料粉末接触有机溶剂会引起火灾。

(1) Class A, C, D, E or F coatings have an easy-to-see color that could be from light golden iridescent to gold-brown. Class B coatings have no color. You can use the color to help identify the coating, but clad parts with a Bonderite M-CR 600 Aero coating could have little or no color.

A 级、C 级、D 级、E 级或 F 级涂料具有易于观察的颜色,可从浅金色彩虹色到金棕色。B 级涂料没有颜色。您可以用颜色来帮助识别涂层,但使用 Bonderite M-CR 600 Aero 涂层的包覆零件很少或没有颜色。

(2) For tubing to get a complete, smooth coating on the interior surface, we recommend this forced-solution-movement procedure:

对于要在内表面获得完整、光滑涂层的管材,我们建议采用这种强力溶液移动程序:

(a) Pump the chemical conversion coating at a rate of up to 60 feet/minute to fill the tubes.

以高达 60 英尺/分钟的速度泵送化学转换涂层,使其充满管道。

(b) Stop the pump and keep the tubes below the surface of the solution in the tank for 85-95 seconds before removal.

停止泵送,使管道低于槽中溶液表面 85-95 秒后再移除。

(c) Pump cold water at a rate of up to 60 feet/minute to fill the tubes.

以最高每分钟 60 英尺的速度泵送冷水以填充管道。

(d) Stop the pump and keep the tubes below the surface of the water in the rinse tank for a minimum of 4 minutes.

停止泵,使管道保持在冲洗槽内水面以下至少 4 分钟。

(e) Pump water through the tubes again, for 25-35 more seconds, before removal.

在移除之前,再次用泵将水流过管道,时间为 25-35 秒钟。

(3) For straight tubing smaller than 0.75-inch OD, use the forced-solution-movement procedure or as an alternative, this multiple-immersion procedure.

对于外径小于 0.75 英寸的直管,可采用强力溶液移动程序,或采用多次浸泡程序。

(a) Do a minimum of four immersions in each procedure step, but not in the chemical conversion coating solution. More than four immersions in the chemical conversion coating solution could cause powdery coatings.

每个程序步骤至少浸泡四次,但不浸泡在化学转换涂层溶液中。在化学转化涂层溶液中浸泡四次以上可能会导致涂层粉化。

(b) During each immersion, let the tubing completely fill with the treatment liquid before you remove it. Then let the liquid drain from the tubing. Do not put the tubing back into the liquid until the continuous flow from the tube becomes intermittent.

在每次浸泡过程中,要让管子完全充满处理液后再取出。然后让液体从管子中排出。直到管子中的持续流动变得断断续续,才可将管子放回液体中。

B. Type 1 (Immersion Application), Class A, B and C.

类型 1(浸入式应用),A 级、B 级和 C 级。

(1) Alkaline clean and rinse per BAC5749 (Ref SOPM 20-30-03) to get a water-break-free surface, unless the parts:

按照 BAC5749(参考 SOPM 20-30-03)进行碱性清洁和冲洗,以获得无断水的表面,除非零件:

(a) have a thermal spray coating.

有热喷涂涂层。

(b) are heat treated aluminum with heavy scale. Then you can alkaline etch per BAC5786, Type 2.

经过热处理的铝材有严重的结垢。然后可以按照 BAC5786 第 2 类进行碱性蚀刻。

(c) could catch solutions, as by open faying surfaces, swaged anodized fittings on tubes or ducts, or spot welded joints. Then use this procedure to get a water-break-free surface:

可能吸附溶液,如开放的焊接表面、管子或管道上的阳极氧化接头或点焊接头。然后使用本程序获得无断水表面:

NOTE: Check for water-break-free by flushing the cleaned surface with water. If the surface is clean (free of oils), water will make an unbroken layer and sheet off. If the surface is not clean, water will bead on the surface (droplets) or appear as patchy and non-uniform. The cleaned surface is considered water-break-free if the water is continuous for approximately 30 seconds.

注: 用水冲洗清洁表面,检查是否无断水。如果表面清洁(无油污),水会形成一层无破损的薄层并从表面脱落。如果表面不清洁,水会在表面上形成水珠(水滴),或呈斑片状和不均匀。如果连续出水约 30 秒,则认为清洁后的表面无断水。

1) Rinse in cold water for 2 minutes minimum and examine for water breaks.

用冷水冲洗至少 2 分钟,检查是否有断水现象。

2) If there are water breaks, do one of these three steps until there are no water breaks:

如果有断水,请执行以下三个步骤之一,直到没有断水为止:

a) Manually clean per BAC5765, Method 3, or

按照 BAC5765 方法 3 手动清洗,或

b) Abrasive clean the surface with very fine Scotch-Brite pads and water. Rub only to scratch the surface. Be careful not to remove the clad surface, if the part has it. Then wipe with clean wipers or sponges wet with water. Wipe the area a minimum of two times until all sand and unwanted matter is gone.

使用极细的 Scotch-Brite 研磨片和水对表面进行研磨清洁。擦拭时仅划伤表面。如果零件有包层,小心不要擦掉包层表面。然后用干净的抹布或海绵沾水擦拭。至少擦拭两遍,直到沙子和杂质全部清除。

c) Manually clean per BAC5744 or manually deoxidize per BAC5765 with Solutions 16, 20, 42, or 43. Wipe or spray rinse to remove all cleaning or deoxidizing solutions, especially from areas that could catch solutions. Use only Solution 43 on BMS 8-289 aluminum foil.

按照 BAC5744 进行手工清洁,或按照 BAC5765 使用溶液 16、20、42 或 43 进行手工脱氧。擦拭或喷淋冲洗以清除所有清洁或脱氧溶液,尤其是可能吸附溶液的区域。在 BMS 8-289 铝箔上只能使用溶液 43。

(d) are Class C parts. Then alkaline etch per BAC5786.

属于 C 级零件。然后按照 BAC5786 进行碱性蚀刻。

(e) are tubing. Then as an alternative, alkaline etch per BAC5786 Type 2 with TEA etchant, pumped through the tubing at a maximum flow rate of 60 feet per minute.

为管道。作为替代方法,按照 BAC5786 类型 2 使用 TEA 蚀刻液进行碱性蚀刻,以每分钟 60 英尺的最大流速泵入管路。

(2) Deoxidize and rinse per BAC5765, Method 1, unless the parts:

按照 BAC5765 方法 1 进行脱氧和冲洗,除非零件:

(a) are Class B parts.

属于 B 级零件。

(b) have thermal spray coating. Then abrasive clean the oxide from the aluminum surfaces per BAC5748, Type 2 Class 1. Do not use wet methods to remove the grit and unwanted matter. Use a vacuum or blow the parts clean with clean compressed air.

有热喷涂涂层。然后按照 BAC5748,2 类 1 级的方法,用磨料清理铝表面的氧化物。不要使用湿法清除砂粒和杂质。使用真空吸尘器或清洁的压缩空气将零件吹干净。

(c) are aluminum tubing that was alkaline etch cleaned per BAC5876. Then deoxidize per BAC5786 for 10 minutes minimum, with the solution pumped through the tubing at a maximum flow rate of 60 feet per minute.

铝管按照 BAC5876 进行碱性蚀刻清洁。然后按照 BAC5786 将溶液以每分钟 60 英尺的最大流速泵入铝管,脱氧至少 10 分钟。

(d) are cast or welded parts. Then deoxidize per BAC5765 with Solutions 27A, 37, 38, or 39. Immediately rinse in water.

是铸造或焊接零件。然后用溶液 27A、37、38 或 39 按照 BAC5765 进行脱氧。立即用水冲洗。

(3) Put the parts in the applicable chemical conversion treatment solution for the time necessary to get a satisfactory coating. For tubing, use the forced-solution-movement or multiple-immersion procedures, as applicable. If air pockets cannot be prevented, turn parts only as necessary. Drain the parts up to 1 minute over the tank to minimize carry-over.

将零件放入适用的化学转换处理溶液中,浸泡必要的时间,以获得满意的涂层。对于管材,可酌情使用强力溶液移动程序或多次浸泡程序。如果无法防止气穴,只在必要时转动零件。在槽上方最多 1 分钟内排空零件,以尽量减少残留。

CAUTION :TOO STRONG A WATER SPRAY COULD DAMAGE THE SOFT COATING.

注意 :过强的水雾可能会损坏软涂层。

(4) Rinse with cold water for 2-5 minutes. As an alternative for Bonderite M-CR 1200S Aero or Bonderite M-CR Alcrm 1200 Aero coatings, you can use a warm water rinse at 130°F maximum for 1-3 minutes.

用冷水冲洗 2-5 分钟。作为 Bonderite M-CR 1200S Aero 或 Bonderite M-CR Alcrm 1200 Aero 涂层的替代方法,可使用最高温度为 130°F 的温水冲洗 1-3 分钟。

(5) Air dry fully at room temperature to 130°F maximum. For better corrosion resistance, air dry fully at 110-130°F for 20-35 minutes.

在室温至最高 130°F 下充分晾干。为获得更好的耐腐蚀性,可在 110-130°F 温度下充分晾干 20-35 分钟。

(6) Touch parts only with clean gloves. The coating is soft and easily damaged. Give it protection from abrasion, damage, and contamination.

只能用干净的手套接触零件。涂层很软,容易损坏。要防止磨损、损坏和污染。

(7) If applicable, apply primer and other coating per overhaul instructions.

如果适用,按照大修说明涂刷底漆和其他涂层。

C. Type 2 (Manual Application) – Classes A, B, C, D.

第 2 类(手工涂装)–A、B、C、D 级。

(1) Manual clean-deoxidize per BAC5765, Method 3, or use an alternate procedure from step (2), unless the parts:

按照 BAC5765 方法 3 进行手工清洁-脱氧,或使用步骤 (2) 的替代程序,除非零件:

(a) are made of bonded pieces, unsealed or only partially sealed, and thus could catch solutions. Then alkaline clean per BAC5744, without the step that deoxides.

由未密封或仅部分密封的粘合件制成,因此可能吸附溶液。然后按照 BAC5744 进行碱性清洗,但不进行脱氧步骤。

(b) are fiberglass with aluminum thermal coating. Then, after removal of the parting agent, alkaline clean per BAC5744, then abrasive clean with very fine Scotch-Brite pads and water. Make sure the surfaces are water-break-free.

是带有铝热涂层的玻璃纤维。去除零件剂后,按照 BAC5744 进行碱性清洗,然后用非常细的 Scotch-Brite 研磨片和水进行研磨清洗。确保表面无断水。

(c) were deoxidized, and with new material removal or abraded surfaces. Then clean them per BAC5744 Method 2 without the steps that deoxidize.

已脱氧、去除新材料或磨损的表面。那就按照 BAC5744 方法 2 进行清洁,而不采取脱氧步骤。

(d) have polished, skin-quality surfaces to get a Class B chemical coating. Then solvent clean them per BAC5750, or manual clean them per BAC5744, Method 1. Make sure the surfaces are water-break-free.

表面经过抛光,达到表皮质量,可获得 B 级化学涂层。然后按照 BAC5750 进行溶剂清洗,或按照 BAC5744 方法 1 进行手工清洗。确保表面无断水。

(e) were trimmed, sanded, drilled or machined in the last 2 hours. Then solvent clean them per BAC5750 or BAC5744 Method 2. It is not necessary to clean the surfaces with Scoth-Brite or abrasives.

在过去 2 小时内进行过修剪、打磨、钻孔或机加工。然后按照 BAC5750 或 BAC5744 方法 2 进行溶剂清洗。无需使用 Scoth-Brite 或研磨剂清洁表面。

(2) Alternate surface preparation procedures

其他表面处理程序

(a) Abrasive clean with Scotch-Bride pads

使用Scotch-Bride磨片进行研磨清洁

1) Abrasive clean the area to be chemical conversion coated with very fine Scotch Brite abrasive pads and water. Abrade only enough to scuff the surface. Use care to minimize removal of cladding, if present.

用极细的Scotch Brite磨片和水对要进行化学转化涂层的区域进行研磨清洁。打磨的程度仅够擦伤表面。如果有包层,应小心尽量减少包层的去除。

2) Rinse thoroughly by flushing or, if parts have the possibility of entrapping water, rinse by swabbing with clean wipers or sponges soaked with water. Swab the area a minimum of two times until all sanding residue has been removed. Check to ensure a water-break-free surface is present or do step Paragraph 5.C.(2)(a) again.

用冲水彻底冲洗,如果零件可能积水,则用干净的抹布或海绵蘸水擦拭冲洗。至少拭擦该区域两次,直至去除所有打磨残留物。检查以确保表面无断水,或再次执行步骤 5.C.(2)(a)。

NOTE: Check for water-break-free by flushing the cleaned surface with water. If the surface is clean (free of oils), water will make an unbroken layer and sheet off. If the surface is not clean, water will bead on the surface (droplets) or appear as patchy and non-uniform. The cleaned surface is considered water-break-free if the water is continuous for approximately 30 seconds.

注: 用水冲洗清洁表面,检查是否无断水。如果表面清洁(不含油),水会形成不间断的水层并被冲掉。如果表面不清洁,水会在表面上形成水珠(水滴),或呈斑片状和不均匀的现象。如果连续出水约 30 秒,则可认为清洁后的表面无断水。

(b) Removal of shot-peen contamination from assemblies only

仅清除组件上的喷丸污染

1) Method 1 — Scotch-Brite pads and deionized water

方法 1 — Scotch Brite磨片和去离子水

a) Solvent wipe per BAC5750.

按 BAC5750 进行溶剂擦拭。

b) Manually alkaline clean per BAC5744.

根据 BAC5744 进行手动碱性清洁。

c) Abrasive clean with fine-grit Scotch-Brite pads and deionized water per BAC5748. Do this three more times with a new Scotch-Brite pad each time.

按照 BAC5748,用细粒度的Scotch Brite磨片和去离子水进行研磨清洁。多做三次,每次换一块新的Scotch Brite磨片。

d) Rinse with water or, if the parts could catch water, wipe them with clean wipers or sponges wet with water. Wipe the area a minimum of two times until all sand and unwanted matter is gone. Make sure the surfaces are water-breakfree or do step 1) again.

用清水冲洗,如果零件可能进水,则用干净的抹布或海绵沾水擦拭。至少擦拭两遍,直到沙子和杂质全部清除。确保表面不断水,否则再执行步骤 1)。

2) Method 2 — Aluminum oxide blast

方法 2 — 氧化铝喷砂

a) Abrasive clean per BAC5748, Type II Class 1 with clean aluminum oxide grit.

按照 BAC5748,类型 II Class 1,用干净的氧化铝砂粒进行研磨清洁。

b) Rinse with water or, if the parts could catch water, wipe them with clean wipers or sponges wet with water. Wipe the area a minimum of two times until all sand and unwanted matter is gone. Make sure the surfaces are water-breakfree, or do step 2) again.

用清水冲洗,如果零件可能进水,则用干净的抹布或海绵沾水擦拭。至少擦拭两遍,直到沙子和杂质全部清除。确保表面不断水,否则再次执行步骤 2)。

(c) For Class E parts, prepare the surface per BAC5744 Method I, or solvent clean them per BAC5750.

对于 E 级零件,按照 BAC5744 方法 I 准备表面,或按照 BAC5750 进行溶剂清洗。

(d) For Class F parts, solvent clean them per BAC5750.

对于 F 级零件,按照 BAC5750 进行溶剂清洗。

CAUTION :DO NOT LET ITEMS WET WITH COATING SOLUTION DRY WITH SOLUTION IN THEM, BECAUSE SPONTANEOUS COMBUSTION COULD OCCUR. FULLY WASH ALL SOLUTION-WET CLOTHS, OR WRING THEM OUT AND PUT THEM IN A FIREPROOF CONTAINER.

注意 :不要让被溶液浸湿的物品带着溶液晾干,因为可能发生自燃。彻底清洗所有溶液湿布,或将其拧干并放入防火容器中。

(3) For Class A, C, and D coatings, apply the solution to the part with a cloth, brush, cellulose sponge or mop, or spray it on. Keep the surface wet until you can see color. The color will come in 2-3 minutes. If the color does not come, if the solution breaks up into beads, or if a powdery layer occurs, lightly sand area with 600-grit paper or Scotch-Brite abrasive pads or equivalent, rinse and reapply the chemical conversion treatment solution.

对于 A 级、C 级和 D 级涂料,用布、刷子、纤维素海绵或拖把将溶液涂抹到零件上,或喷洒上去。保持表面湿润,直至看到颜色。颜色会在 2-3 分钟内显现。如果不着色、溶液碎成珠子或出现粉末层,则用 600 号砂纸或 Scotch-Brite 研磨片或类似材料轻轻打磨该区域,冲洗后重新涂抹化学转化处理溶液。

(4) For Class B coatings, apply the solution on the part with cloth, brush, cellulose sponge or mop or spray it on. Keep the surface wet for 30 seconds less than the time necessary to cause color. If the coating solution breaks up into beads, or if a powdery coating occurs, lightly sand the area with 600-grit paper or Scotch-Brite abrasive pads or equivalent, rinse and reapply the chemical conversion treatment solution. Do not apply this coating in direct sunlight.

对于 B 级涂层,用布、刷子、纤维素海绵或拖把将溶液涂抹在零件上,或喷洒上去。保持表面湿润的时间应少于产生颜色所需的时间 30 秒。如果涂层溶液破裂成珠状,或出现粉末状涂层,可用 600 砂纸或 Scotch-Brite 研磨片或类似材料轻轻打磨该区域,冲洗后重新涂抹化学转化处理溶液。请勿在阳光直射下使用该涂层。

(5) If the parts have surfaces with primer BMS 10-11, BMS 10-20, or BMS 10-79, and the bare metal surfaces have no water breaks, you can let the chemical conversion treatment solution touch the primer. If the primer is BMS 10-20, use only Bonderite M-CR 600 Aero as the chemical conversion treatment solution.

如果零件表面的底漆是 BMS 10-11、BMS 10-20 或 BMS 10-79,且裸金属表面没有断水,可以让化学转化处理溶液接触底漆。如果底漆是 BMS 10-20,则只能使用 Bonderite M-CR 600 Aero 作为化学转换处理溶液。

(6) Flush with water, or, if parts could catch water, use a cloth or sponge wet with water. Be careful, because the coating is soft and easily damaged.

用清水冲洗,如果零件可能进水,则用布或海绵沾水冲洗。要小心,因为涂层很软,很容易损坏。

(7) Air dry at room temperature to 130°F maximum. For better corrosion resistance, air dry fully at 110-130°F for 20-35 minutes.

在室温下晾干至最高 130°F。为了获得更好的耐腐蚀性,请在 110-130°F 温度下充分晾干 20-35 分钟。

(8) Touch parts only with clean gloves. The coating is soft. Give it protection from abrasion, handling damage, and contamination.

只能用干净的手套接触零件。涂层很软。要防止磨损、操作损坏和污染。

(9) If applicable, apply primer and other coating per overhaul instructions.

如果适用,按照大修说明涂刷底漆和其他涂层。

(10) For Class E coatings, apply the solution with clean wipers, brush, cellulose sponge or mop, or spray it on. Then dry the coating sufficiently to evaporate the water. Do not let the metal get hotter than 200°F.

对于 E 级涂层,用干净的抹布、刷子、纤维素海绵或拖把涂抹溶液,或喷洒。然后充分干燥涂层以蒸发水分。不要让金属温度超过200°F。

D. Type 3 (Spray Application) – Classes A and B

类型 3(喷涂)–A 级和 B 级

NOTE: This procedure must not be used for conveyorized flow coat priming. For chemical conversion treatment flow coat operations, use only the Type 4 procedure per Paragraph 5.E.

注: 此程序不得用于输送式流动涂层打底。对于化学转化处理流动涂层作业,只能使用第 5.E 段中的第 4 类程序。

(1) Mask off metal inserts of different metal, unless the inserts are CRES or titanium, or are plated with chromium, nickel, or cobalt.

遮盖不同金属的金属钢丝螺套,除非钢丝螺套为 CRES 或钛,或镀有铬、镍或钴。

(2) Spray alkaline clean per BAC5749 (Ref SOPM 20-30-03).

按 BAC5749喷碱性清洁剂(参考 SOPM 20-30-03)。

(3) Spray deoxidize 30-60 seconds with one of BAC5765 solutions 1 thru 5. Use solutions at room temperatures up to 110°F. This step is optional if parts have no scale or corrosion.

用 BAC5765 溶液 1 至 5 之一喷洒脱氧溶液 30-60 秒。在室温至 110 °F 下使用溶液。如果零件没有结垢或腐蚀,则可选择此步骤。

(4) Spray water rinse for 30-60 seconds at 90°F maximum.

在最高 90°F 温度下喷水冲洗 30-60 秒。

(5) Apply the coating solution.

涂抹溶液。

(a) For Class A coating, spray the Class A solution 25-35 seconds at 75-95°F.

对于 A 级涂层,在 75-95°F 温度下喷洒 A 级溶液 25-35 秒。

(b) For Class B coating, spray the Class B solution 30-90 seconds at 140-160°F.

对于 B 级涂层,在 140-160°F 温度下喷涂 B 级溶液 30-90 秒。

(6) Spray water rinse for 30-60 seconds at 130°F maximum.

在最高温度 130°F 下喷水冲洗 30-60 秒。

(7) Dry with clean air at a maximum temperature of 130°F for 3-6 minutes. There is no time limit for long drying periods below 100°F. Use a sufficient volume and flow of air for complete removal of water from the parts.

用清洁空气在最高温度 130°F 下干燥 3-6 分钟。低于 100°F 的长时间干燥没有时间限制。使用足够的空气量和流量,以完全去除零件上的水分。

(8) If applicable, apply primer and other coatings per overhaul instructions.

如适用,按大修说明涂上底漆和其他涂层。

E. Type 4 (Automatic Coat Application) – Class E

类型 4(自动涂层应用)–E 级

(1) Spray alkaline clean with Betz Kleen 147, or clean per BAC5749.

使用 Betz Kleen 147 喷碱性清洁剂,或按照 BAC5749 进行清洁。

(2) Spray deoxidize 30-60 seconds with one of the BAC5765 solutions 1 thru 5. Use the solutions at room temperatures up to 110°F. This step is optional if the parts have no scale or corrosion.

用 BAC5765 溶液 1 至 5 之一喷洒脱氧溶液 30-60 秒。溶液在室温至 110 °F 下使用。如果零件没有结垢或腐蚀,则可选择此步骤。

(3) Spray water rinse for 30-60 seconds at 140°F maximum.

在最高 140°F 温度下喷水冲洗 30-60 秒。

(4) Apply a smooth layer on all of the surface.

在整个表面涂上一层光滑的涂层。

(5) Dry the layer with a heat source will make the material sufficiently warm to evaporate the water. A metal temperature of 120°F is preferred. Do not let the metal become hotter than 200°F.

用热源烘干涂层,使材料温度足以蒸发水分。金属温度以 120°F 为佳。不要让金属温度超过 200°F.

F. Type 5 (Bonderite M-CR 1132 Aero Application)

类型 5(Bonderite M-CR 1132 航空应用)

(1) Prepare substrate in accordance with Paragraph 5.C.(2)(a).

按照第 5.C.(2)(a)段准备基材。

(2) Verify water-break-free surface condition. Repeat cleaning procedures as necessary.

确认表面无断水状况。必要时重复清洁程序。

(3) Blot the surface with a clean cloth to remove excess water. Inspect cloth for any residue. Repeat the cleaning or deoxidixing process if any residue is on the cloth.

用干净布擦拭表面,去除多余水分。检查布上是否有残留物。如果布上有任何残留物,则重复清洁或脱氧过程。

(4) Remove cap of the pen and hold the pen with applicator tip downwards.

取下笔帽,握住笔,笔尖朝下。

(5) Activate pen by pressing tip against a firm surface. This will open the valve allowing the chemical conversion solution to reach the applicator tip. A new unit should charge in 30 to 45 seconds. When the solution wets the tip, release pressure. Unit is ready for use.

将笔尖按在坚硬的表面上,以激活笔。这将打开活门,使化学转换溶液到达涂抹器尖端。新装置应在 30 至 45 秒内充电。当溶液润湿笔尖时,释放压力。设备即可使用。

CAUTION :MAKE SURE THAT YOU DO NOT CAUSE PUDDLES. IT WILL INCREASE THE TIME NECESSARY TO DRY. THICK AND UNEVEN AREAS IN THE LAYER CAN CAUSE A PERFORMANCE FAILURE.

注意 :确保不要造成积水。这会增加干燥所需的时间。如果涂层过厚或不均匀,会导致性能故障。

(6) Apply the chemical conversion coating to the part surface in smooth even strokes. Fifty percent overlap of strokes usually gives proper coating weight. Do not allow the solution to puddle.

在零件表面平滑均匀地涂抹化学转化涂层。通常,50% 的涂抹重叠可获得适当的涂层重量。不要让溶液积聚。

(7) Wait until the coating dries and repeat Paragraph 5.F.(6) in a cross hatch pattern. Do not water rinse.

待涂层干透后,以十字形图案重复第 5.F.(6)段。不要用水冲洗。

(8) Ambient air dry or force air dry coating at 130°F maximum.

在最高温度 130°F 的环境中风干或强制风干涂层。

6. SOLUTION MAKEUP AND CONTROL 溶液修补和控制

A. For all solutions, use stainless steel tanks or tanks lined with acid-resistant plastic or rubber.

所有溶液均应使用不锈钢槽或内衬耐酸塑料或橡胶的槽。

B. Make sure the tank is clean. Then fill it half-full with makeup water. Sprinkle the powder chemicals smoothly over the surface, or pour the liquid chemicals along the length of the tank. Stir the solution until the chemicals are completely dissolved or the liquids are completely mixed, then add water to volume.

确保槽是干净的。然后注入半满的修补水。将粉末状化学品平稳地洒在表面,或将液体化学品沿槽的长度方向倒入。搅拌溶液,直到化学品完全溶解或液体完全混合,然后加水至满。

C. For large, long tanks, longitudinal agitation is recommended to keep solution concentrations uniform.

对于大而长的槽,建议进行纵向搅拌,以保持溶液浓度均匀。

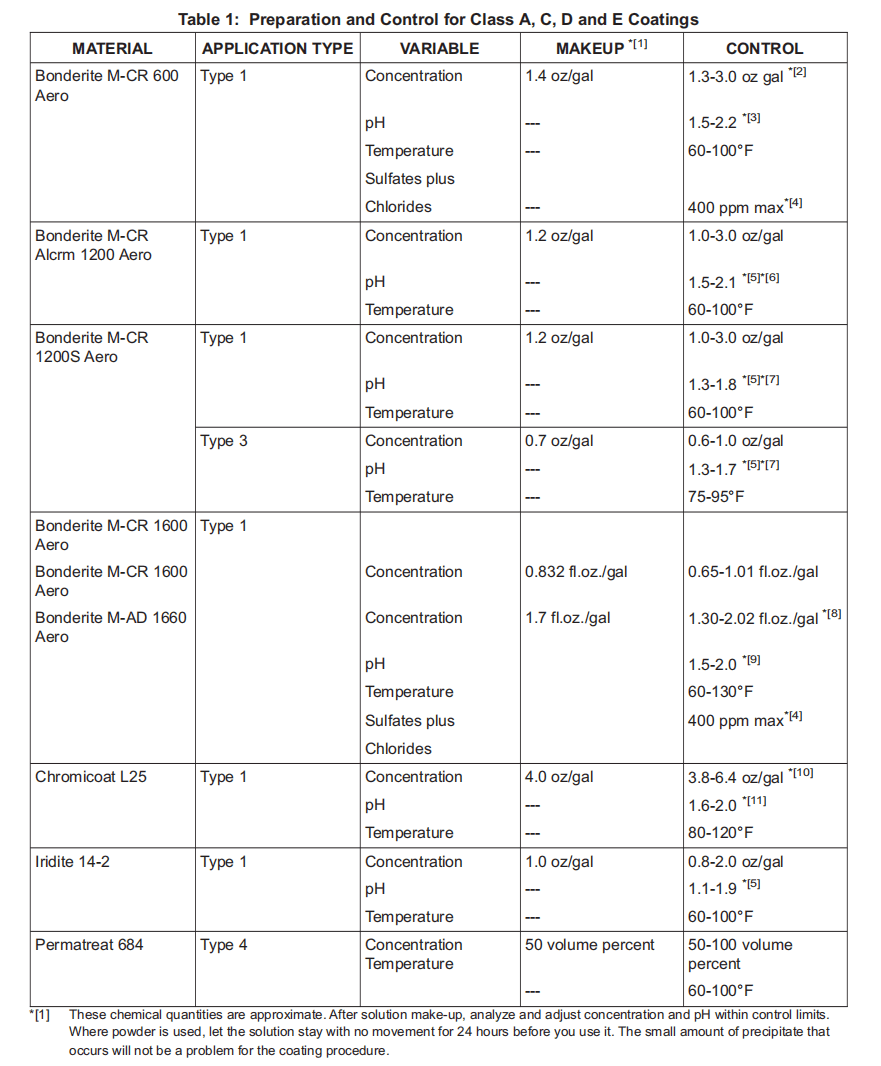

D. For Types 1, 3, 4 coatings (Class A, C, D and E solutions), prepare and control the solutions per Table 1.

对于 1、3、4 类涂料(A、C、D 和 E 级溶液),按表 1 配制和控制溶液。

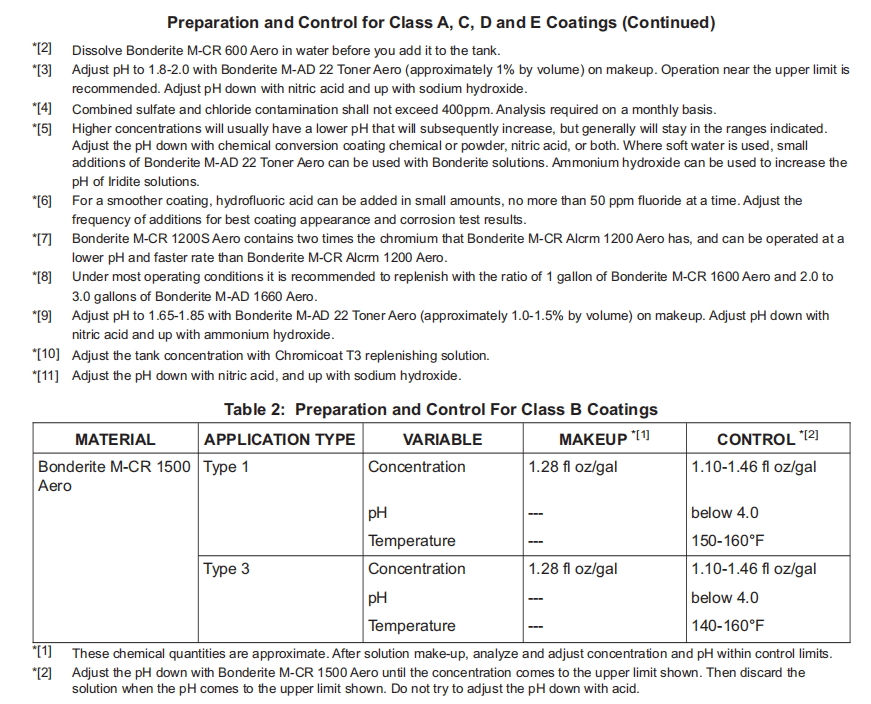

E. For Type 1 and Type 3 coatings (Class B solutions), prepare and control the solutions per Table 2.

对于 1 类和 3 类涂料(B 级溶液),按表 2 配制和控制溶液。

F. Immersion Application (Type 1) solutions collect sludge. Do not let the sludge rise to a level where it touches the work. Remove the sludge as necessary to keep it away from the parts.

浸入式喷涂(类型 1)溶液会收集沉淀物。不要让沉淀物上升到接触工件的程度。必要时清除沉淀物,使其远离零件。

G. Manual Application (Type 2) Solutions

手工涂抹(第 2 类)溶液

(1) Prepare and use solutions only in containers of stainless steel or acid-resistant plastic or rubber (polyethylene preferred). Put covers on containers will be put into storage.

只能用不锈钢或耐酸塑料或橡胶(最好是聚乙烯)容器配制和使用溶液。在将要存放的容器上盖上盖子。

NOTE: Use approximately the quantity of solution necessary for the work on hand. Discard the solution after you use it; if a brush, sponge, or wiper was put into it; or if contaminants get into the solution.

注意: 使用的溶液量大约为手头工作所需的量。使用溶液后,如果有刷子、海绵或擦拭布放入溶液中,或溶液中混入污染物,请将溶液报废。

(2) Bonderite M-CR 600 Aero: Add 3 ounces of powder to water for each gallon of final solution. Stir until the powder is dissolved. Then add up to 2% by volume of Bonderite M-AD 22 Toner Aero or ammonium hydroxide and stir to adjust the pH to 1.5-2.0. Ignore small quantities of material that do not dissolve. Let the solution stand at least 1 hour before you use it.

Bonderite M-CR 600 Aero: 每加仑最终溶液在水中加入 3 盎司粉末。搅拌直至粉末溶解。然后按体积加入不超过 2%的 Bonderite M-AD 22 Toner Aero 或氢氧化铵,并搅拌以调节 pH 值至 1.5-2.0。忽略少量未溶解的材料。将溶液放置至少 1 小时后再使用。

(3) Bonderite M-CR 1201 Aero: This is a pre-mixed liquid. Make-up is not applicable.

Bonderite M-CR 1201 Aero: 这是一种预混液体。制备不适用。

(4) Bonderite M-CR 1001 Aero: This is a pre-mixed liquid. Make-up is not applicable.

Bonderite M-CR 1001 Aero: 这是一种预混液体。制备不适用。

(5) Bonderite M-CR 1132 Aero: This is a pre-mixed liquid comes in a pen. Make-up is not applicable.

Bonderite M-CR 1132 Aero: 这是一种笔装预混合液体。制备不适用。

(6) Bonderite M-CR Alcrm 1200 Aero: Add 3 ounces of powder to water for each gallon of final solution. Stir until the powder is dissolved. Ignore small quantities of material that do not dissolve. Let the solution stand at least 1 hour before you use it. Keep the pH in the range of 1.50-1.90. Use nitric acid or ammonium hydroxide to decrease the pH.

Bonderite M-CR Alcrm 1200 Aero: 每加仑最终溶液在水中加入 3 盎司粉末。搅拌直至粉末溶解。忽略少量未溶解的材料。溶液放置至少 1 小时后再使用。保持 pH 值在 1.50-1.90 之间。使用硝酸或氢氧化铵降低 pH 值。

(7) Bonderite M-CR 1200S Aero: Add 1.9-2.1 ounces of powder to water for each gallon of final solution. Stir until the powder is dissolved. Ignore small quantities of material that do not dissolve. Let the solution stand at least 1 hour before you use it.

Bonderite M-CR 1200S Aero: 每加仑最终溶液在水中加入 1.9-2.1 盎司粉末。搅拌直至粉末溶解。忽略少量未溶解的材料。溶液放置至少 1 小时后再使用。

(8) Bonderite M-CR 1500 Aero: Add 8 fluid ounces of Bonderite M-CR 1500 Aero to water for each gallon of final solution. Stir to completely mix.

Bonderite M-CR 1500 Aero: 在每加仑最终溶液中加入 8 液量盎司的 Bonderite M-CR 1500 Aero 水。搅拌使其完全混合。

(9) Permatreat 684: See Table 1.

Permatreat 684:见表 1。

(10) Use approximately the quantity of solution necessary for the work on hand. Discard the solution after you use it; if a brush, sponge, or wiper was put into it; or if contaminants get into the solution.

使用手头工作所需的大致溶液量。如果溶液中混入了刷子、海绵或擦拭布,或溶液中混入了污染物,请在使用后报废溶液。

(11) Chromicoat L25: Add nitric acid to adjust water to a pH range of 5.0-5.5. Add 6.2-6.6 fluid ounces of Chromicoat L25 to water for each gallon of the final solution. Stir for a constant mixture. Use Sodium Hydroxide to increase the pH.

Chromicoat L25:加入硝酸调节水的 pH 值至 5.0-5.5。每加仑最终溶液在水中加入 6.2-6.6 液量盎司的 Chromicoat L25。搅拌均匀。使用氢氧化钠提高 pH 值。

(12) Bonderite M-CR 1600 Aero: Add 0.8 fluid ounce of Bonderite M-CR 1600 Aero, 2.6 fluid ounces of Bonderite M-AD 1660 Aero additive for each gallon of final solution. Stir well for a constant mixture. Then add up to 2 percent by volume of Bonderite M-AD 22 Toner Aero as necessary to adjust the pH to between 1.5 and 2.0.

Bonderite M-CR 1600 Aero: 每加仑最终溶液加入 0.8 液量盎司的 Bonderite M-CR 1600 Aero 和 2.6 液量盎司的 Bonderite M-AD 1660 Aero 添加剂。充分搅拌,使混合均匀。然后按需要加入不超过 2%(体积)的 Bonderite M-AD 22 Toner Aero,以将 pH 值调整到 1.5 至 2.0 之间。

(13) Bonderite M-CR Alcrm 1200BR Aero: Mix equal volumes of Part A and Part B. Stir to mix fully.

Bonderite M-CR Alcrm 1200BR Aero: 混合等体积的 A 部分和 B 部分,搅拌使其充分混合。

(14) Bonderite M-CR 600RTU Aero: This is a pre-mixed liquid, with a final concentration of 2.8-3.2 ounces of Bonderite M-CR 600 Aero powder for each gallon of solution. Make-up is not applicable.

Bonderite M-CR 600RTU Aero: 这是一种预混合液,其最终浓度为每加仑溶液含 2.8-3.2 盎司 Bonderite M-CR 600 Aero 粉末。制备不适用。

(15) Bonderite M-CR 1200SRTU Aero: This is a pre-mixed liquid, with a final concentration of 1.9-2.1 ounces of Bonderite M-CR 1200S Aero powder for each gallon of solution. Make-up is not applicable.

Bonderite M-CR 1200SRTU Aero: 这是一种预混合液,每加仑溶液的最终浓度为 1.9-2.1 盎司 Bonderite M-CR 1200S Aero 粉末。制备不适用。

7. QUALITY CONTROL 质量控制

A. Appearance

外观

(1) When examined without magnification, coatings must have no streaks, and must be continuous and have no powder or loose areas. The coating must have no breaks or scratches go through to the base metal, or other defects will make the part less serviceable. The size and number of contact marks must be kept to a minimum that agrees with good practice. Touchup of bare spots that occur at contact points is not necessary if the longest dimension of each spot is 0.1 inch or less. One bare spot can be up to 0.125 inch.

在不使用放大镜的情况下,涂层不得有条纹,必须连续,不得有粉末或松散区域。涂层不得有破损或划痕,否则会影响零件的使用性能。接触痕迹的大小和数量必须保持在符合良好操作规范的最低限度。如果每个接触点的最长尺寸为 0.1 英寸或更小,则无需对接触点上的裸斑进行修整。一个裸斑的最大尺寸可达 0.125 英寸。

(2) Color differences can occur because of the base metal, how it is examined and with different conditions of light. Differences in color on a part, or between different batches, are satisfactory.

由于基体金属、检查方式和光线条件的不同,可能会出现色差。一个零件上或不同批次之间的颜色差异是令人满意的。

(3) Class B: When examined without magnification, coatings must be without color.

B 级:在不使用放大镜的情况下,涂层必须无色。

(4) Class D: The coating color can be between a light golden iridescent to a gold brown, but must not be dark brown. Clad parts with Bonderite M-CR 600 Aero coating could possibly have no color, is satisfactory.

D 级: 涂层颜色可从浅金色到金棕色,但不得为深棕色。覆有 Bonderite M-CR 600 Aero 涂层的零件可能没有颜色,但也是令人满意的。

B. All classes of unpainted chemical coating on aluminum and aluminum alloy parts must give the base metal protection from corrosion when given the 5% salt spray test specified in BAC5719.

铝及铝合金零件上所有等级的未涂漆化学涂层,在进行 BAC5719 规定的 5%盐雾试验时,必须能保护基体金属免受腐蚀。

C. Use only Bonderite M-CR 600 Aero for touchup and rework of parts or assemblies painted with BMS 10-20 primer. Other coating materials such as Bonderite M-CR Alcrm 1200 Aero, Bonderite M-CR 1200S Aero or Bonderite M-CR 1132 Aero can cause a powdery coating if used on BMS 10-20 primer.

对于涂有 BMS 10-20 底漆的零件或组件,只能使用 Bonderite M-CR 600 Aero 进行修补和返修。如果在 BMS 10-20 底漆上使用其他涂层材料,如 Bonderite M-CR Alcrm 1200 Aero、Bonderite M-CR 1200S Aero 或 Bonderite M-CR 1132 Aero,可能会导致涂层粉化。

D. Do not use the Bonderite M-CR 1132 Aero pen on surfaces that will get BMS 5-45 sealant.

请勿将 Bonderite M-CR 1132 Aero 笔用于涂有 BMS 5-45 密封胶的表面。