粘合剂的应用APPLICATION OF ADHESIVES

1. INTRODUCTION 介绍

A. Other than the procedures in Paragraph 7. and Paragraph 8., the data in this subject comes from Boeing Process Specification BAC5010. Access to the Boeing Process Specifications is available.

除了第7段和第8段中的程序外,本主题中的数据来自波音工艺规范BAC5010。可访问波音工艺规范。

B. The procedure for application of adhesive film to vinyl placards in Paragraph 7. comes from Document D6-2862, Fabrication and Inspection Requirements for Adhesive Bonding of Decorative Interior Materials.

第7段中关于乙烯基标牌上粘贴胶膜的程序来自D6-2862号文件《内饰装饰材料粘合的制造和检验要求》。

C. The procedure for application of retaining compounds in Paragraph 8. comes from Boeing Process Specification BAC5011, Application of Retaining Compounds.

第8段中关于固定剂的应用程序来自波音工艺规范BAC5011,固定剂的应用。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

供应商名称和地址列表请参考SOPM 20-00-00。

2. EQUIPMENT 设备

A. You can use any equipment to mix the adhesive if it will make a smooth, mixture without lumps or air pockets.

如果它能混合均匀,没有结块或气泡,可以使用任何设备来混合粘合剂。

B. Use containers of metal, glass, polyethylene, Teflon, or polyethylene-lined paper or cardboard for blended adhesive. Do not use waxed or porous paper containers.

使用金属、玻璃、聚乙烯、特氟龙或聚乙烯衬里的纸或纸板容器来混合粘合剂。不要使用蜡纸或多孔纸容器。

C. Use only containers and mixing equipment which are clean and dry. Clean the equipment at least daily, and when the application procedure is stopped for a long time, when you are done with the task, and when you change adhesives. Dry all equipment before you use it. When continuous-operation equipment is used, remove the mixed adhesive from the blending head at least once every 8 hours and at the end of intermittent periods of operation. To clean the head, you can put one of the adhesive components through it, or disassemble the head and solvent clean it. When you use all of the supply of a batch of adhesive, you can add a new supply of the adhesive materials to the supply tanks without removal of the remaining quantity of the adhesive, but the new materials must be of the same specification and from the same supplier as that of the old materials.

仅使用干净、干燥的容器和混合设备。至少每天清洁设备,当操作程序长时间停止时、任务完成后以及更换粘合剂时,也应清洁设备。使用前,应确保所有设备干燥。当使用连续操作设备时,至少每8小时一次,以及在间歇操作结束时,应从混合头中取出混合好的粘合剂。要清洁混合头,可将其中一种粘合剂组分穿过混合头,或分解混合头并用溶剂清洗。当您用完一批粘合剂的供应量时,可以在供应罐中添加新的粘合剂材料,而无需清除剩余的粘合剂,但新材料必须与旧材料具有相同的规格,且来自相同的供应商。

D. If the containers and equipment were used for silicone adhesives, do not use them for nonsilicone adhesives. These adhesives are silicone: Types 60, 62, 68, 74, 77, 79, 80, 84, 98, 109 and 119.

如果容器和设备用于硅酮胶,则不得用于非硅酮胶。这些胶属于硅酮胶:类型60、62、68、74、77、79、80、84、98、109和119。

E. Silicone and nonsilicone materials in their original unopened containers can be stored together. Opened containers of each material must not be stored in the same cabinet.

硅酮和非硅酮材料可以一起存放在未开封的原装容器中。已开封的每种材料不得存放在同一柜子中。

F. Equipment used to weigh or measure by volume must have an accuracy of ± 2.5%.

用于称重或体积测量的设备必须精确到±2.5%。

3. PREPARATION OF ADHESIVES 粘合剂的制备

WARNING :THE ADHESIVES, PRIMERS, SURFACE TREATMENT MATERIALS, AND SOLVENTS CONTAIN POISONOUS, FLAMMABLE COMPONENTS. DO NOT BREATHE VAPORS, MIST, OR DUST. MIX AND APPLY ADHESIVES AND PRIMERS IN AN AREA WITH A GOOD FLOW OF AIR. KEEP LIQUID ADHESIVES AND PRIMERS AWAY FROM SKIN AND EYES. USE APPROVED RESPIRATORS WHEN YOU USE THESE MATERIALS IN CONFINED AREAS. USE PROTECTIVE CLOTHING AND GLOVES AS NECESSARY. KEEP LIQUID ADHESIVES, PRIMERS, AND SOLVENTS AWAY FROM SOURCES OF IGNITION. OBEY THE SPECIFIC PRECAUTIONS IN THE INDIVIDUAL APPLICATION PROCEDURES.

警告:粘合剂、底漆、表面处理材料和溶剂含有有毒易燃组分。请勿吸入蒸汽、雾气或粉尘。请在空气流通良好的区域混合并使用粘合剂和底漆。请勿让液体粘合剂和底漆接触皮肤和眼睛。在密闭区域使用这些材料时,请佩戴经批准的呼吸器。必要时使用防护服和手套。请将液态粘合剂、底漆和溶剂远离火源。遵守各个应用程序中的具体预防措施。

A. If the adhesives or individual components were in storage at a temperature below 65°F, let them warm to room temperature (65°F minimum) in the unopened containers before you mix, weigh, or use them. Wipe all visible moisture from external surfaces of the containers before you open them.

如果粘合剂或单个组件在低于65°F的温度下储存,请在混合、称重或使用前,将其放在未开封的容器中,使其升温至室温(最低65°F)。在打开容器前,请擦去容器外表面所有可见的水分。

B. Use the ingredients and procedures as specified to mix and apply the materials. Do not use different ingredients or procedures. Do not use thinner in adhesives or in components unless specified. Weigh components to an accuracy of ± 2.5%.

按照规定的配料和程序混合并使用材料。不要使用不同的配料或程序。除非另有说明,否则不要在粘合剂或组件中使用稀释剂。配料称量精度为±2.5%。

C. When you use thinner, do not stir quickly, beat or shake the adhesives, which could cause foam. When there is air in mixed adhesive, give sufficient time for it to be released. Deaeration is recommended for the high viscosity adhesives.

使用稀释剂时,请勿快速搅拌、敲打或摇晃粘合剂,否则可能会产生泡沫。如果混合后的粘合剂中有空气,请留出足够的时间使其释放。建议对高粘度粘合剂进行脱气处理。

D. Do not use undated or expired materials.

请勿使用未注明日期或过期的材料。

E. Identify containers of mixed adhesive with this data:

混合粘合剂的容器应标明以下数据:

(1) BAC5010 Type number, or manufacturer’s designation, and BMS number if applicable

BAC5010 型号或制造商名称,以及 BMS 编号(如适用)

(2) Date and time that the mixture will be expired

混合物过期日期和时间

(3) Identification of the person that made the mixture

混合物的制作者身份

WARNING :MAKE SURE YOU INCLUDE THE REQUIRED SAFETY PRECAUTIONS WHEN YOU MAKE THE NEW LABELS.

警告:制作新标签时,请务必包含必要的安全预防措施。

F. When you put adhesives into smaller containers, give the same information on the smaller container labels as on the original. Before you move the contents between the containers, mix it until it is smooth.

将粘合剂装入较小的容器时,应在较小的容器标签上注明与原标签相同的信息。在容器之间转移内容物之前,应充分混合。

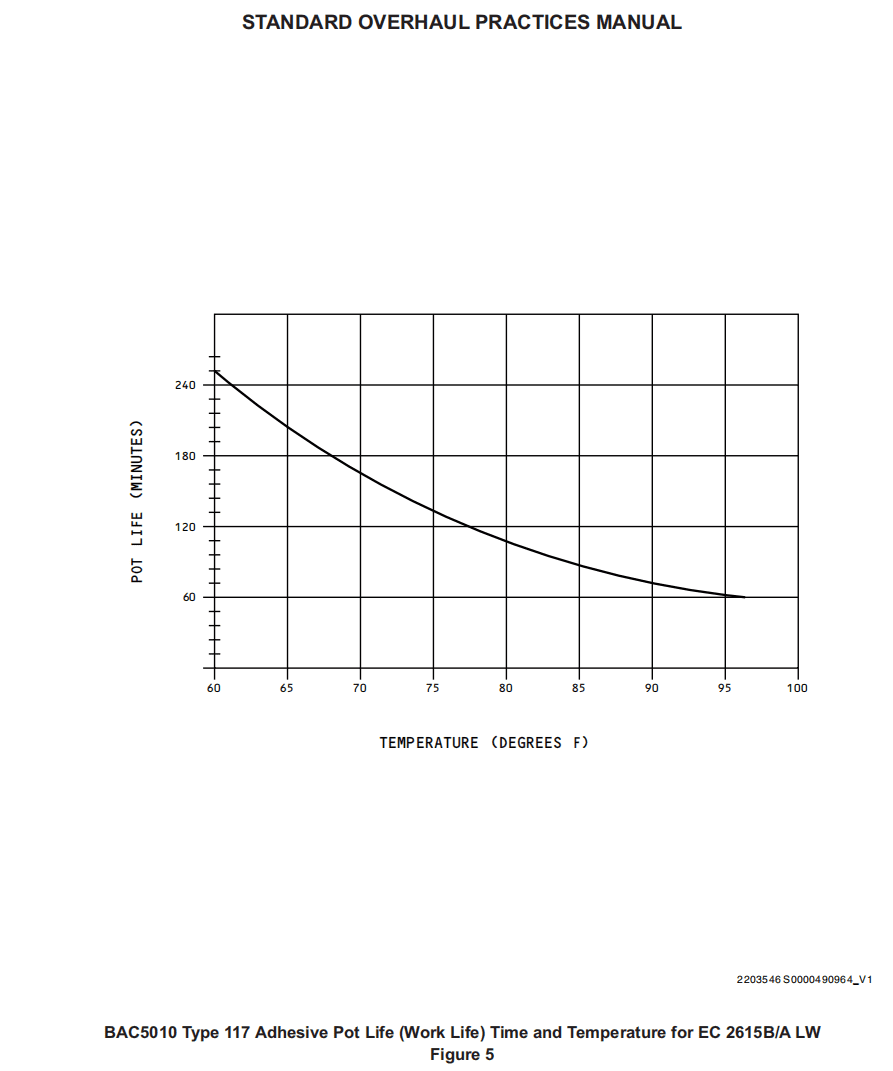

G. High temperature and humidity or a large quantity of adhesive will decrease pot life. Low temperature or a small quantity of adhesive will increase pot life. If possible, mix only the necessary quantity of adhesive immediately before you use it.

高温高湿或粘合剂用量过多会缩短使用期。低温或粘合剂用量过少会延长使用期。如果可能,请在即将使用前才混合所需数量的粘合剂。

H. Mix the adhesives or primers in their original containers or in containers of clean metal, glass, Teflon, polyethylene or polyethylene-lined. Do not use waxed or porous paper containers. When you mix by hand, use only clean stirrers such as metal spatulas. Do not use metal containers that have rust on the inside.

在原装容器或干净金属、玻璃、特氟龙、聚乙烯或聚乙烯衬里的容器中混合粘合剂或底漆。请勿使用蜡纸或多孔纸容器。用手搅拌时,仅使用干净的搅拌工具,如金属刮刀。请勿使用内部生锈的金属容器。

I. Unless the procedure specifies differently, mix or shake each component by itself first. This will make sure its ingredients are mixed smoothly together. Then mix the components together as specified.

除非程序另有规定,否则应先将各组分单独混合或摇匀。这样可以确保各组分充分混合。然后按照规定的顺序将各组分混合在一起。

4. PREPARATION OF SURFACES 表面处理

A. Make sure the mating surfaces are a good fit. Make sure only light pressure (1-2 psi) is necessary for the mating surfaces to fully touch.

确保配合表面完全贴合。确保配合表面只需轻微压力(1-2 psi)即可完全贴合。

B. Clean surfaces are necessary to make strong adhesive bonds. All unwanted materials such as oils, greases, waxes, or powders must be removed before the adhesive is applied.

清洁的表面是形成牢固粘合力的必要条件。在涂粘合剂前,必须清除所有不需要的材料,如油、油脂、蜡或粉末。

C. Unless shown differently, solvent clean all mating surfaces by the General Cleaning and Final Cleaning procedures of SOPM 20-30-03. Use BMS 15-5 wipers and the solvents as specified.

除非另有说明,否则按照SOPM 20-30-03的通用清洁和最终清洁程序用溶剂清洁所有配合表面。使用BMS 15-5刷子和规定的溶剂。

D. Apply the primers or adhesives immediately after you prepare the mating surfaces. Be very careful to keep dust and unwanted materials off the surfaces. Do not touch the cleaned or primed surfaces unless you use clean gloves.

在准备配合表面后立即涂上底漆或粘合剂。务必小心,防止灰尘和多余材料进入表面。除非使用干净的手套,否则不要触摸清洁或涂底漆的表面。

E. When you bond adjacent to decorative areas, use masking materials as specified in BAC5034 (SOPM 20-44-02) as necessary to keep adhesive from those areas.

当您在装饰区域附近粘合时,请根据需要使用BAC5034(SOPM 20-44-02)中规定的遮蔽材料,以防止粘合剂进入这些区域。

F. On nondecorative parts, clean (and apply the primer, if applicable) on an area larger than that which will be bonded or touch the adhesive.

在非装饰性零件上,清洁(并涂底漆,如果适用)的区域应大于粘合或接触粘合剂的区域。

G. Fabrics

织物

(1) Try the solvent on a small piece before you clean a large area. If the solvent damages the fabric, refer to the manufacturer for more instructions.

在清洁大面积区域前,先在一小块织物上试用溶剂。如果溶剂损坏了织物,请咨询制造商以获取更多说明。

(2) Fabric newly removed from a roll or pack can be used without more cleaning.

从卷筒或包装中刚取出的织物无需进一步清洁即可使用。

(3) Clean dirty fabric by the solvent clean procedure of SOPM 20-30-03. Dry fabric until the odor of solvent is gone.

按照SOPM 20-30-03的溶剂清洁程序清洁脏污织物。将织物晾干,直至溶剂气味消失。

H. Coated Fabrics

涂层织物

(1) Clean as specified in Paragraph 4.I. and Paragraph 4.K. unless it is waterproof coated nylon cloth as specified in MIL-C-20696, used to cover insulation blankets.

按照第4.I.和第4.K.段的规定进行清洁,除非是用于覆盖绝缘毯的MIL-C-20696规定的防水涂层尼龙布。

(2) If there is a parting agent on the vinyl surface, be sure to remove it before you bond.

如果乙烯基表面有分离剂,在粘合前一定要将其清除。

I. Calendered, Extruded, or Molded Rubber Parts

压延、挤压或模压橡胶零件

(1) The parting agent on such parts is usually embedded in the rubber. Sand the parts to remove the parting agent. Solvent clean to remove the sanding debris.

此类零件上的分离剂通常嵌入橡胶中。 打磨零件以清除分离剂。 用溶剂清洗以清除打磨碎屑。

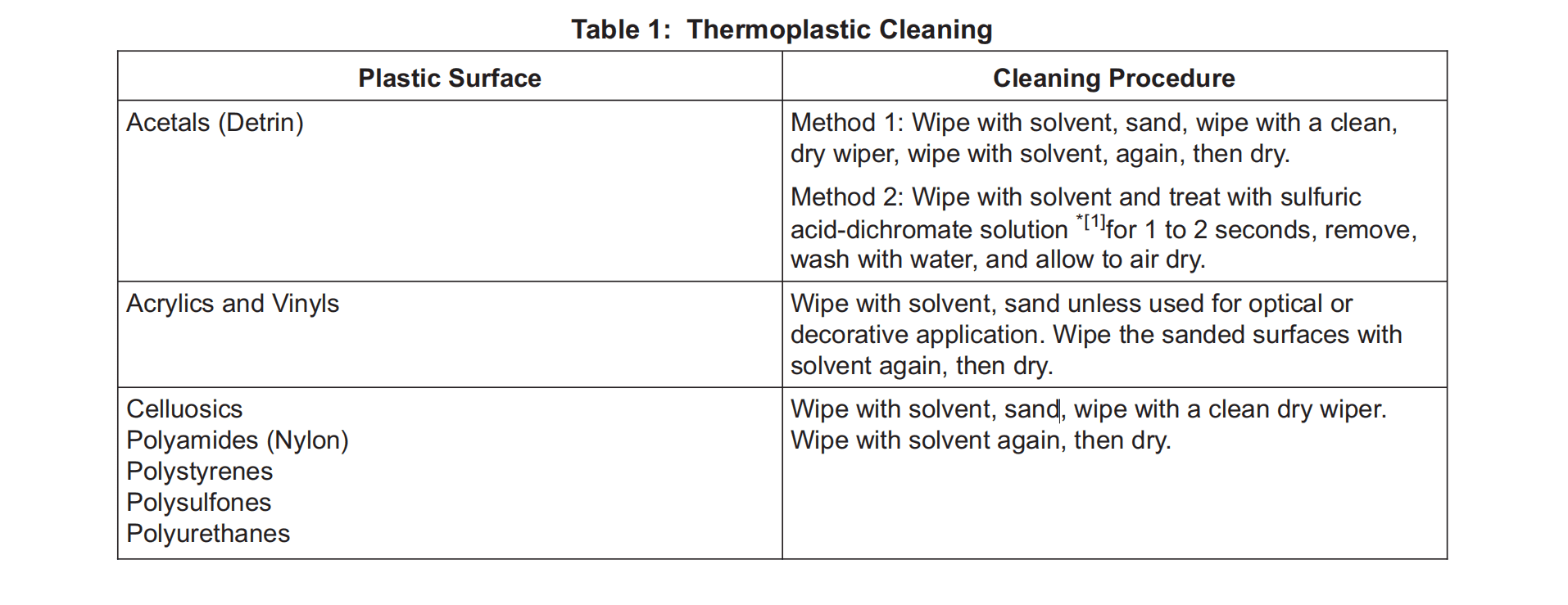

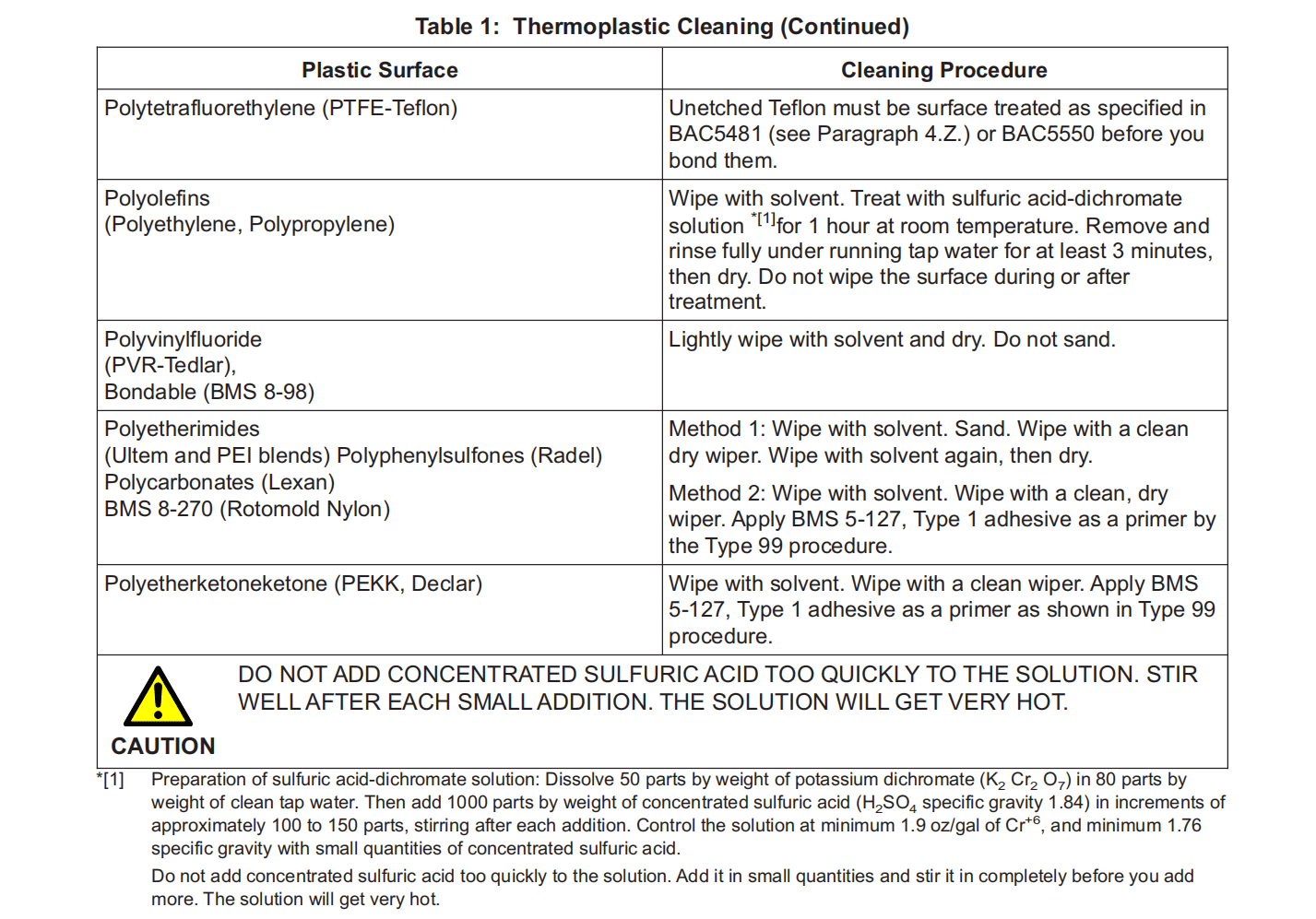

(2) Wipe ethylene-propylene rubber with solvent as specified in SOPM 20-30-03 and dry. Treat with sulfuric acid-dichromate solution as specified in Table 1 for 10-15 minutes at room temperature. Remove and rinse under running water for at least 3 minutes, then dry.

用SOPM 20-30-03规定的溶剂擦拭乙丙橡胶并使其干燥。在室温下用表1规定的硫酸-重铬酸钾溶液处理10-15分钟。取出并在流水下冲洗至少3分钟,然后晾干。

J. Thermosetting Plastics

热固性塑料

(1) General procedure for all bonding surfaces.

所有粘接表面的通用程序。

(a) Lightly sand the surface to remove the gloss, unless this is a polyester or epoxy laminate or panel (such as BMS 4-20 or BMS 4-23) with a peel ply which is removed before you bond.

轻轻打磨表面,去除光泽,除非是聚酯或环氧树脂层压板或面板(如BMS 4-20或BMS 4-23),其剥离层在粘合前已去除。

(b) Solvent clean by the Final Cleaning procedures of SOPM 20-30-03.

根据SOPM 20-30-03的最终清洁程序进行溶剂清洁。

(2) Optional procedure for local cleaning of bonding surfaces.

粘合表面局部清洁的可选程序。

(a) Solvent clean by the Final Cleaning procedures of SOPM 20-30-02.

按照SOPM 20-30-02的最终清洁程序进行溶剂清洁。

(b) Lightly sand the surface with 180 grit or finer abrasive paper until the gloss and contamination is removed. Use only clean abrasive paper. Wipe clean with a dry wiper.

用180目或更细的砂纸轻轻打磨表面,直到光泽和污垢被去除。 仅使用干净的砂纸。 用干燥的刷子子擦拭干净。

K. Thermoplastic Surfaces — See Table 1.

热塑性表面——见表1。

L. TT-P-1757 Zinc Chromate Primed Surfaces

TT-P-1757 铬酸锌底漆表面

(1) Remove the zinc chromate primer before you bond to the surface, unless parts are held in position at all times by something other than the adhesive, unless batts, lining materials, paper, or felt are to be bonded to the primed surface, or unless adhesive is used only to make assembly easier.

在粘合表面前,应去除铬酸锌底漆,除非零件始终由粘合剂以外的其他东西固定,除非将填充物、衬里材料、纸张或毡布粘合到底漆表面,或者除非仅使用粘合剂是为了使组装容易。

(2) Before you bond, clean the surface by the Final Cleaning procedure of SOPM 20-30-03.

在粘合之前,请按照SOPM 20-30-03的最终清洁程序清洁表面。

(3) Zinc chromate primer must be sufficiently cured before it can be used as an adhesive bond surface. To see if it is cured, wipe with a clean cloth wet with methyl ethyl ketone. Cure is sufficient when many wipes are necessary for removal. If the primer is easily removed with methyl ethyl ketone, remove all of the primer before you bond to the surface.

锌铬酸盐底漆必须充分固化后才能用作粘合表面。 要检查是否固化,请用蘸有甲基乙基酮的干净布擦拭。如果需要多次擦拭才能去除,则表明已经充分固化。如果底漆很容易用甲基乙基酮去除,则在粘合表面前应去除所有底漆。

(4) Cured zinc chromate primer can be removed with paint and lacquer remover TT-R-248. Apply the remover with a brush only to the area which will be bonded. When primer is wrinkled or softened, remove it with a clean wiper. After removal of primer, solvent clean by the Final Cleaning procedure of SOPM 20-30-03. Make sure all of this area gets the protection of the adhesive. Or apply more primer after the bond procedure. Make sure there are no bare magnesium surfaces.

固化后的锌铬酸盐底漆可用油漆和清漆去除剂 TT-R-248 去除。用刷子将去除剂涂在需要粘合的区域。当底漆起皱或变软时,用干净的刷子将其清除。清除底漆后,按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。确保该区域的所有部分都得到粘合剂的防护。或者在粘合后涂上更多的底漆。确保没有裸露的镁表面。

M. BMS 10-11, Type 1 Primed Surfaces

BMS 10-11,类型1 涂底漆的表面

(1) This primer can stay on the surfaces. But the primer must be permitted to dry as follows before you bond to it.

此底漆可以留在表面上。但在粘合之前,必须按照以下方法让底漆干燥。

(a) For adhesive Types 38, 52, 54, 70 and 71, make sure this primer dried for one of these periods:

对于38、52、54、70和71类型粘合剂,请确保底漆在以下时间干燥:

1) 7 hours minimum at 50°F minimum,

最低50°F下至少7小时,

2) 4 hours minimum at 75°F minimum,

最低75°F下至少4小时,

3) 15 minutes minimum at 140-160°F, or

在140-160°F下至少15分钟,或

4) 5 minutes minimum at 190-210°F.

在190-210°F下至少5分钟。

(b) Type 93 adhesive can be applied over primer after the primer dried for a minimum of one hour at 130-150°F, or a minimum of 4 hours at 65°F minimum.

93型粘合剂可在底漆在130-150°F下至少干燥一小时后,或在65°F下至少干燥四小时后涂抹在底漆上。

(c) For all adhesive other types, make sure this primer dried a minimum of 24 hours at approximately 75°F.

对于所有其他类型的粘合剂,请确保底漆在约75°F的温度下至少干燥24小时。

(2) Clean these surfaces, before you bond to them, by the Final Cleaning procedure of SOPM 20-30-03.

在粘合前,请按照SOPM 20-30-03的最终清洁程序清洁这些表面。

N. Aluminum without surface treatment

未进行表面处理的铝

(1) Solvent clean by the General Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的通用清洁程序进行溶剂清洁。

(2) Sand the surface with aluminum wool or aluminum oxide or silicon carbide abrasive.

用铝棉、氧化铝或碳化硅砂纸打磨表面。

(3) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

O. Aluminum with Surface Treatment (Alodine, Anodize, etc.)

经过表面处理(阿洛丁、阳极氧化等)的铝

(1) Do not sand the surface.

不要打磨表面。

(2) Solvent clean the surface by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序用溶剂清洁表面。

P. Steel without plating

未电镀的钢

(1) Solvent clean by the General Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的通用清洁程序用溶剂清洁。

(2) Sand the surface with 180 grit or finer abrasive.

用180目或更细的砂纸打磨表面。

(3) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

Q. Steel (such as zinc or cadmium).

钢(如锌或镉)。

(1) Do not sand the surface.

不要打磨表面。

(2) Solvent clean the surface by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

R. Titanium

钛

CAUTION :TO PREVENT HYDROGEN EMBRITTLEMENT, DO NOT USE CHLORINATED SOLVENTS ON TITANIUM WHICH WILL BE IN TEMPERATURES ABOVE 600°F (316°C) ON THE AIRPLANE OR IN SUBSEQUENT PROCEDURES SUCH AS STRESS RELIEVING, ANNEALING, OR WELDING

注意:为防止氢脆,在飞机上或随后的应力消除、退火或焊接等程序中,请勿在温度超过600°F(316°C)的钛上使用含氯溶剂

(1) Solvent clean by the General Cleaning procedure of SOPM 20-30-03. Do not use chlorinated solvents.

按照SOPM 20-30-03的通用清洁程序进行溶剂清洁。请勿使用含氯溶剂。

(2) Sand the surface with 180 grit or finer abrasive.

用180目或更细的砂纸打磨表面。

(3) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

S. BMS 10-11, Type 2, BMS 10-60, BMS 10-83, and MIL-C-83286 Polyurethane Enamels

BMS 10-11、类型 2、BMS 10-60、BMS 10-83 和 MIL-C-83286 聚氨酯瓷漆

(1) Abrade or lightly sand the cured enamel surfaces to remove all surface gloss.

打磨或轻轻打磨固化后的瓷漆表面,去除所有表面光泽。

(2) Solvent clean the surface by the Final Cleaning procedure of SOPM 20-30-03.

按照 SOPM 20-30-03 的最终清洁程序用溶剂清洁表面。

T. Paper, Felt, Cork, Leather — Remove dust and surface contamination with a clean wiper.

纸、毡、软木、皮革——用干净的刷子清除灰尘和表面污染物。

U. Tin and Lead Plated Surfaces

镀锡和镀铅表面

(1) Solvent clean by the General Cleaning procedure of SOPM 20-30-03. Do not use chlorinated solvents.

按照SOPM 20-30-03的通用清洁程序进行溶剂清洁。不要使用含氯溶剂。

(2) Sand the surface with abrasive fabric or pads.

用砂布或砂垫打磨表面。

(3) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

V. BMS 5-89, BMS 5-137 and MIL-P-23377 Epoxy Primers

BMS 5-89、BMS 5-137和MIL-P-23377环氧底漆

(1) Do not sand the cured primer surface.

不要打磨固化底漆表面。

(2) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

W. Chemglaze II A276 or Chemglaze Z306 Polyurethane Enamels

Chemglaze II A276或Chemglaze Z306聚氨酯瓷漆

(1) Lightly sand the area with 320-grit or finer aluminum oxide or silicon carbide sandpaper, to remove surface gloss. Do not go through the enamel layer.

用320目或更细的氧化铝或碳化硅砂纸轻轻打磨,去除表面光泽。不要打磨瓷漆层。

(2) Remove the sand and dust with a clean wiper wet with solvent. Immediately wipe dry with a clean, dry wiper.

用蘸有溶剂的干净刷子清除砂砾和灰尘。立即用干净的干刷子擦干。

X. Wood

木材

(1) Sand along the grain to fully clean the faying surfaces. This is not necessary on a clean cut surface.

沿纹理打磨,以充分清洁接合表面。对于切割整齐的表面,则无需打磨。

(2) Remove sand and dust with a clean wiper, a clean, soft-bristled brush, or a vacuum cleaner.

用干净的刷子、干净的软毛刷或真空吸尘器清除沙子和灰尘。

Y. Alkyd Enamel, Acrylic Enamel, Vinyl Paint, Nitrocellulose Lacquers

醇酸磁漆、丙烯酸磁漆、乙烯基漆、硝基漆

(1) You must not bond to surfaces that have these finishes. Remove them as specified in SOPM 20-30-02 from the area which will get the adhesive.

不得粘附在这些饰面的表面上。按照SOPM 20-30-02的规定,从将要粘接的区域将其清除。

(2) If the removal process damages the primer layers, remove all of the primer also.

如果清除过程损坏了底漆层,则也要清除所有的底漆。

Z. BMS 10-20 Coating

BMS 10-20涂层

(1) Lightly sand the surface to remove the gloss.

轻轻打磨表面以去除光泽。

(2) Solvent clean by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁。

(3) If you must repair the coating, use the procedures of BAC5793 with an elevated temperature cure.

如果必须修复涂层,请按照BAC5793的程序进行高温固化。

AA. Unetched polytetrafluoroethylene (TFE) (Teflon) (Ref BAC5481):

未腐蚀的聚四氟乙烯(TFE)(特氟龙)(参考BAC5481):

(1) Clean with a Series 98 solvent (SOPM 20-30-98) and dry with a clean wiper.

用98系列溶剂(SOPM 20-30-98)清洗并用干净的刷子擦干。

(2) Lightly make the surface rough with Scotch-Brite, or aluminum oxide sandpaper or cloth, 250 grit or finer.

用250目或更细的Scotch-Brite或氧化铝砂纸或砂布轻轻打磨表面使其粗糙。

(3) Clean again as specified in Paragraph 4.AA.(1).

按照第4.AA.(1)段的规定再次清洗。

(4) With masking tape, mask off the surfaces not to be bonded.

用遮蔽胶带遮住不需要粘合的表面。

(5) Clean again if necessary as specified in Paragraph 4.AA.(1).

如有必要,请按照第4.AA.(1)段的规定再次清洁。

(6) Put the part in a TFE etchant for 15-60 seconds until the surface becomes brown. The time will increase with the age of the solution. It is not possible to etch too much. The brown color is applicable only to materials without pigment. If the parts are not etched after 60 seconds, the etchant is worn out and must be replaced.

将零件放入TFE蚀刻剂中15-60秒,直到表面变成棕色。时间会随着溶液的老化而增加。蚀刻时间不能过长。棕色仅适用于不含色素的材料。如果零件在60秒后仍未蚀刻,则表明蚀刻剂已耗尽,必须更换。

(7) Wash immediately in n-butyl alcohol to remove remaining etchant.

立即用正丁醇清洗,以去除残留的蚀刻剂。

(8) Rise in hot water until you get a water break free surface. You can add a liquid detergent to the rinse water to help clean the surface.

放入热水中加热,直到出现不无断水表面(直到表面不再有水汽)。您可以在冲洗水中加入液体洗涤剂,以帮助清洁表面。

(9) Let the parts dry and remove all maskants. Do not touch the etched surfaces.

让零件干燥并去除所有掩膜剂。不要触摸蚀刻表面。

(10) If the parts will not be bonded within 48 hours, give the parts protection from sunlight. The etched surface will be good to bond to for 6 months if given protection from abrasion and light.

如果零件在48小时内无法粘合,请避免阳光照射。如果避免磨损和光照,蚀刻表面在6个月内仍可粘合。

AB. BMS 10-103, Type 1 Primer

BMS 10-103,类型1底漆

(1) Removal of the primer is not necessary. Make sure the primer dried for the Minimum Time Prior to Handling as specified in BAC5325.

无需去除底漆。确保底漆按照BAC5325的规定,在处理前的干燥最短时间。

(2) Solvent clean the primed surfaces by the Final Cleaning Method (SOPM 20-30-03).

按照最终清洁方法(SOPM 20-30-03)用溶剂清洁涂有底漆的表面。

AC. Inspection after Cleaning

清洁后的检查

(1) Wipe the surface with a clean, lint-free cloth. Clean the surface again if you see contamination or discoloration on the cloth.

用干净的无绒布擦拭表面。如果看到布上有污渍或变色,请再次清洁表面。

(2) Examine the surface with reflected light across the cleaned area. Clean the surface again if you find dirt, corrosion, oil, grease, or other contamination.

用反射光检查清洁区域的表面。如果发现污垢、腐蚀、油、油脂或其他污染物,请再次清洁表面。

(3) Examine adjacent surfaces and crevices for contamination by dirt removed from the bond area or by solvent. Clean these areas as necessary.

检查相邻表面和缝隙,看是否有从粘接区域清除的污垢或溶剂残留。必要时清洁这些区域。

5. QUALITY CONTROL 质量控制

A. Make sure the parts are correctly aligned. Reject bonds if the bond strength is reduced, as when the parts were aligned after they were put together.

确保零件对齐正确。如果粘接强度降低,则应拒绝粘接,例如在零件组装后对齐时。

B. A serviceable bond will be continuous along the edges of all mating surfaces. Reject bonds with loose edges or corners or if adjacent laminations come apart.

合格的粘合剂应沿所有接合表面的边缘连续延伸。边缘或角落松动或相邻叠片分离的粘合剂应予以剔除。

C. Reject bonds if you find gaps, blisters, or cracks along the bond line.

沿粘合线出现缝隙、气泡或裂纹的粘合剂应予以剔除。

D. Adhesives that cure, as compared to adhesives that become tacky as their solvents dry, come out as a bead when the parts are put together. Make sure this bead is continuous along all edges and at the corners.

固化型粘合剂与溶剂干燥(挥发)后变粘的粘合剂相比,在将零件组装在一起时会出现一条粘胶。确保这条粘胶沿所有边缘和角落连续延伸。

E. Do not try to pull apart the bonded parts as a test of the bond unless this is a specimen in a test procedure.

除非这是测试程序中的样本,否则不要试图将粘合的零件拉开作为粘合测试。

F. Look for unwanted adhesive that comes out of the joint, or contamination of adjacent areas by adhesive. Nonsolvent-curing adhesive can have a fillet, if this does not cause a problem with appearance or the fit of subsequent mating parts.

检查粘合处是否有多余的粘合剂溢出,或相邻区域是否被粘合剂污染。非溶剂固化粘合剂可能会出现圆角,只要不影响外观或后续配合零件的配合即可。

G. If you removed primer to apply the adhesive, make sure this surface has the protection of the adhesive. If it does not, then apply primer on the area that does not have protection.

如果为了涂覆粘合剂而去除底漆,请确保该表面有粘合剂的保护。如果没有,请在没有保护的区域涂覆底漆。

H. During the adhesive cure, keep the bonding pressure on the parts as constant and continuous as possible over the bond line or area.

在粘合剂固化期间,应尽可能保持粘合线或粘合区域上零件的持续恒定压力。

I. The cure time specified for the individual adhesive types is the minimum time necessary at the specified temperature for sufficient bond strength to let you move the parts. But the bond could possibly not get to full strength until 7 days at 65°F. If stress could be put in the new bond because of the part size, shape, or subsequent assembly operations, give the bond more time to cure than specified.

为单独粘合剂类型规定的固化时间是其在规定温度下达到足够粘接强度以移动零件所需的最短时间。但在65°F下,粘合剂可能需要7天才能达到完全强度。如果由于零件尺寸、形状或后续组件操作而给新粘合处施加应力,则应延长固化时间。

J. Make sure the temperature of the part stays above 65°F during the adhesive cure. If the part becomes colder than 65°F, increase the part temperature to a minimum of 65°F to continue the cure. The time that the part is colder than 65°F cannot be included in the cure time. If you use an elevated temperature cure, the cure time starts when the bondline gets to the specified temperature range.

确保在粘合剂固化期间,零件温度保持在65°F以上。如果零件温度低于65°F,则将零件温度至少提高到65°F,以继续固化。零件温度低于65°F的时间不能计入固化时间。如果使用高温固化,则固化时间从粘合线达到固定温度范围时开始计算。

K. If the adhesive components come in a unit which has two syringes operated together, put the unit into an applicator gun and attach a mixing nozzle. When you start to operate the gun to apply the adhesive, make sure the two syringes flow equally and freely. Before you apply the adhesive to the parts, release and discard a bead of adhesive approximately equal to the length and diameter of the mixing nozzle.

如果粘合剂组件是一个同时操作两个注射器的单元,请将该单元放入涂胶枪并连接混合喷嘴。当您开始操作喷枪涂胶时,请确保两个注射器流量均匀且顺畅。在将粘合剂涂覆到零件上之前,释放并丢弃大约与混合喷嘴长度和直径相等的粘合剂。

6. APPLICATION PROCEDURES 应用程序

NOTE: Refer to Paragraph 9. for the list of materials and vendors.

注意:请参阅第9段,查看材料和供应商列表。

A. Type 5 (Deleted) (Superseded by Type 58)

类型5(已删除)(由类型58取代)

B. Type 9 (Deleted)

类型9(已删除)

C. Type 12

类型12

(1) Material — BMS 5-55 Adhesive

材料——BMS 5-55粘合剂

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(3) BMS 5-55 adhesive will settle and must be mixed fully before you use it, and at intervals while you use it.

BMS 5-55 粘合剂在使用前会沉淀,必须充分混合,在使用过程中也要定期混合。

CAUTION :UNLESS KEPT IN AIRTIGHT CONTAINERS AND CONTINUOUSLY SHAKEN, THINNED ADHESIVE MUST BE USED WITHIN 4 HOURS.

注意:稀释的粘合剂必须在4小时内使用,除非保存在密闭容器中并持续摇晃。

(4) No thinner is necessary to apply BMS 5-55 with a brush. To spray the adhesive, use one part of BMS 5-55 with up to 3 parts by volume of aliphatic naphtha.

使用刷子涂抹BMS 5-55时无需稀释剂。要喷涂粘合剂,请使用一份BMS 5-55和最多三份体积的脂肪族石脑油。

(5) For nonporous surfaces, apply a continuous brush layer or three to four spray layers, one after the other to each surface. On porous surfaces, apply two brush layers or four to five spray layers one after the other. Let each layer dry 20 to 30 minutes. Let 10 to 20 minutes for the last coat of adhesive to become tacky, but not to get on your knuckle when touched lightly.

对于无孔表面,应连续刷涂一层或喷涂三至四层,每层之间间隔一段时间。对于多孔表面,应连续刷涂两层或喷涂四至五层,每层之间间隔一段时间。每层应干燥20至30分钟。最后一层粘合剂应干燥10至20分钟,使其变粘,但轻轻触碰不会粘在指关节上。

(6) When the bonding area is large, let the last coat of adhesive dry tack-free. Then lightly wipe one surface with clean cheesecloth wet with aliphatic naphtha.

当粘接面积较大时,让最后一层粘合剂干燥,使其不粘手。然后用蘸有脂肪烃石脑油的干净粗棉布轻轻擦拭一个表面。

(7) Push or roll the parts together. Apply sufficient pressure to make the surfaces touch completely. Do not make air pockets.

将零件推到一起或滚动到一起。施加足够的压力,使表面完全接触。不要形成气穴。

(8) Do not heat cure BMS 5-55 adhesive above 125°F. Assemblies can be moved immediately.

不要在超过125°F的温度下加热固化BMS 5-55粘合剂。组件可以立即移动。

(9) Clean equipment with aliphatic naphtha.

用脂肪族石脑油清洁设备。

D. Type 17 (Deleted)

类型17(已删除)

E. Type 19

类型19

(1) Materials

材料

WARNING :BECAUSE THIS ADHESIVE CONTAINS FORMALDEHYDE, IT COULD CAUSE SKIN IRRITATION. USE PROTECTIVE CREAMS AND FREQUENTLY WASH WITH SOAP AND HOT WATER TO HELP PREVENT SKIN IRRITATION.

警告:由于这种粘合剂含有甲醛,可能会刺激皮肤。请使用防护霜,并经常用肥皂和热水清洗,以防止皮肤受到刺激。

(a) Adhesive — MMM-A-181, Type 1, Grade B

粘合剂——MMM-A-181,类型1,等级B

(b) Primer — Bostik L1007M

底漆——Bostik L1007M

(2) Method 1 — Wood Flyaway Application

方法 1——木制飞行材料应用

(a) Make a check of the wood parts to be bonded for a good mechanical fit. Smoothly machine or sand the surfaces in the direction of the grain within one day before you bond them.

检查待粘接的木制零件,确保机械配合良好。在粘接前的一天之内,沿纹理方向对表面进行平滑加工或打磨。

(b) The moisture content of the wood must be between 8 and 12%. Control the temperature and humidity of the work rooms to keep the moisture content of the wood in this range. Keep continuous inspection records of temperature and humidity. Calculate the moisture content of the wood as follows:

木材的含水量必须在8%到12%之间。控制工作间的温度和湿度,使木材的含水量保持在上述范围内。持续记录温度和湿度。计算木材的含水量,方法如下:

1) Make test specimens of the material to be bonded. Make the length of the test specimen approximately 1 inch in the direction of the grain. The specimen must include the full cross section of the piece. Cut the specimens at least 12 inches from the end to be sure that the moisture content is not of a dried end.

制作待粘合材料的测试样本。测试样本的长度应与纹理方向大致一致,约为1英寸。样本必须包括整个横截面。从末端至少切下12英寸的样本,以确保含水量不是干燥末端。

2) Remove all loose splinters. Weigh the test specimen immediately after you cut it before the moisture content changes.

清除所有松散的碎片。在切割后立即称量测试样本,以免含水量发生变化。

3) Put the specimens in a drying oven and dry at 212° to 221°F until the weight becomes constant. This will occur after approximately 24 hours. Put specimens in the oven to let each piece have free access to the hot air.

将样本放入干燥箱,在212°至221°F的温度下干燥,直到重量稳定。这将会发生在24小时之后(大约24小时后,重量会稳定下来)。将试样放入干燥箱,让每块试样都能接触到热空气。

4) Weigh the test specimen immediately after removal from the oven.

从干燥箱中取出测试样本后立即称重。

5) Calculate the moisture content:

计算含水量:

Percent moisture content = W-D/W X 100

含水量百分比 = W-D/W X 100

where

其中

W = original weight (before drying)

W = 原始重量(干燥前)

D = oven-dry weight

D = 烘箱干燥重量

(c) Fully mix the individual ingredients. Mix the catalyst with the base resin in a ratio of 25 parts catalyst per 100 parts resin by weight. If the adhesive was refrigerated, let it warm to room temperature, not below 65°F, before you mix it. Do not use a thinner.

充分混合各组分。按重量比 25 份催化剂对 100 份树脂的比例将催化剂与基料树脂混合。如果粘合剂是冷藏的,请在混合前将其加热到室温,不低于 65°F。请勿使用稀释剂。

(d) The pot life of the mixed adhesive is approximately 2 hours below 100°F.

混合后的粘合剂在 100°F 下的可使用时间约为 2 小时。

(e) Make sure the temperature of the adhesive and the parts is not lower than 65°F.

确保粘合剂和零件的温度不低于65°F。

(f) With a brush, apply the adhesive to each surface. Put on not less than 0.5 ounce per square foot on each surface.

用刷子将粘合剂涂在每个表面上。在每个表面每平方英尺至少涂0.5盎司。

(g) Wait for this interval after you apply the adhesive and before you apply pressure:

在涂上粘合剂后,在施加压力前,请等待以下时间间隔:

1) Open assembly (surfaces glued but not assembled): 5-15 minutes.

开放式组件(表面已粘接但未组装):5-15分钟。

2) Closed assembly (surface glued and immediately assembled but no pressure applied): 15-60 minutes.

封闭式组件(表面已粘接并立即组装,但未施加压力):15-60分钟。

3) Open-closed assembly (surface glued, not assembled for an interval, and then assembled): 15 minutes minimum; maximum period can be calculated as follows:

开放-封闭式组件(表面已粘接,未组装一段时间,然后组装):最短15分钟;最长时间可按下式计算:

For each minute of open assembly, decrease the closed assembly period maximum (60 minutes) by 4 minutes.

开放式组件每增加一分钟,封闭式组件的最长时间(60分钟)减少4分钟。

4) For each 5-degree increase in temperature above 70°F, decrease the permitted open assembly time by 1 minute, and the closed assembly time by 2-1/2 minutes.

温度每升高5度(超过70华氏度),开放式组件的时间减少1分钟,封闭式组件的时间减少2.5分钟。

(h) Use these pressures, if permitted by the shape and nature of the part:

如果零件的形状和性质允许,请使用以下压力:

200-250 psi on birch, maple, hickory, oak

桦木、枫木、山核桃木、橡木 200-250 psi

150-200 psi on Douglas fir, walnut, mahogany

花旗松、胡桃木、桃花心木 150-200 psi

100-150 psi on spruce, cedar and other low density woods

云杉、雪松和其他低密度木材 100-150 psi

(i) Keep the pressure on for 8 hours at 65°F minimum. If the glue line is stressed, keep the pressure on for a minimum of 12 hours. Heat can be used to make the cure faster. The pressure and heat can be removed after 2 hours at 100°-120°F or after 1 hour at 130°-150°F.

在最低65°F的温度下保持压力8小时。如果胶线受力,则保持压力至少12小时。加热可以加快固化速度。在100°-120°F的温度下2小时后,或在130°-150°F的温度下1小时后,可移除压力和加热。

(j) Let the assembly cure a minimum of 24 hours before you apply more stress or machine on it.

在对组件施加更大压力或使用机器之前,应使其固化至少24小时。

(k) Do not use a thinner with this adhesive. Equipment can be cleaned with denatured alcohol or water before the adhesive is cured.

此粘合剂请勿使用稀释剂稀释。在粘合剂固化之前,可用变性酒精或水清洗设备。

(3) Method 2 – Bonding Wood and Buna-N Rubber to Metals

方法2——将木材和丁腈橡胶与金属粘合

(a) Fully mix the individual components. Then mix together the catalyst with the base resin in a ratio of 25 parts catalyst per 100 parts resin. If the adhesive was refrigerated, let it warm to 65-80°F before you mix it. Do not use a thinner.

充分混合各组分。然后按照25份催化剂与100份树脂的比例将催化剂与基料树脂混合。如果粘合剂是冷藏的,请在混合前将其加热到65-80°F。不要使用稀释剂。

(b) Clean the mating surfaces as specified in Paragraph 4..

按照第4段的规定清洁配合表面。

(c) With a brush, apply one layer of Bostik L1007M primer to metal surfaces. Let this dry for a minimum of 30 minutes. Mix the Bostik L1007M until smooth. Do not use a thinner.

用刷子在金属表面涂一层Bostik L1007M底漆。至少干燥30分钟。将Bostik L1007M混合至光滑。不要使用稀释剂。

(d) With a brush, apply a layer of the mixed adhesive to the mating surfaces. Air dry at least 10 minutes before assembly, but do not let the adhesive to dry until tack-free.

用刷子在接合表面涂一层混合好的粘合剂。在组装前至少风干10分钟,但不要让粘合剂完全干燥,直到不粘手。

(e) Press the parts together and hold sufficient pressure to make sure all of the mating surfaces touch. Cure under pressure for a minimum of 8 hours at 65-80°F, 2 hours at 90-110°F or to 1 hour at 120-140°F.

将零件压在一起并保持足够的压力,以确保所有配合表面接触。在65-80°F的压力下固化至少8小时,在90-110°F下固化2小时,或在120-140°F下固化1小时。

(f) Let the assembly cure for a minimum of 24 hours at room temperature before you apply stress to the bonds.

在对粘结处施加压力之前,应先在室温下放置至少24小时。

(g) Equipment can be cleaned with denatured alcohol before the adhesive is cured.

在粘合剂固化之前,可用变性酒精清洁设备。

F. Type 30

类型30

(1) Material — Duco Cement

材料——Duco水泥

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段所述清洁配合表面。

(3) Nonporous materials – Apply one layer of the adhesive on each surface and clamp together until dry (approximately 4 hours).

无孔材料——在每个表面涂一层粘合剂,然后夹紧直至干燥(约4小时)。

(4) Porous materials such as wood and textiles — Two layers are necessary. The first coat must be a complete seal and must be dry before you apply the second layer. After you apply the second layer, clamp the parts together until dry (approximately 4 hours).

多孔材料,如木材和纺织品——需要涂两层。第一层必须完全密封,且在涂第二层前必须干燥。涂完第二层后,将零件夹紧直至干燥(约4小时)。

(5) When the area covered is large, you can reactivate the adhesive. Lightly wipe one surface with clean cheesecloth wet with methyl ethyl ketone.

当覆盖区域较大时,可以重新活化粘合剂。用蘸有甲基乙基酮的干净粗棉布轻轻擦拭一个表面。

G. Type 34 (Deleted)

类型 34(已删除)

H. Type 38

类型 38

(1) Materials

材料

(a) Adhesives

粘合剂

NOTE: BMS 5-29 was superseded by BMS 5-126.

注:BMS 5-29 被 BMS 5-126 取代。

1) BMS 5-126, Type 2, Class 1 — A liquid, two-part, natural-colored adhesive

BMS 5-126,类型 2,等级 1——一种由两部分组成的天然色液体粘合剂

2) BMS 5-126, Type 3, Class 1 — A liquid, two-part, natural-colored adhesive thickened with 6 percent Cab-O-Sil

BMS 5-126,类型3,等级1——一种由两部分组成的天然色液体粘合剂,添加了6%的Cab-O-Sil

3) BMS 5-126, Type 4, Class 1 — A two-part, flame-retardant paste adhesive with 10 15 minute pot life

BMS 5-126,类型4,等级1——一种由两部分组成的阻燃膏状粘合剂,可使用10-15分钟

4) BMS 5-126, Type 4, Class 1 or 4 — A two-part, flame-retardant paste adhesive with 20 30 minute pot life. Class 4 material is resistant to ultraviolet light.

BMS 5-126,类型4,等级1或4——一种双组分阻燃膏状粘合剂,可使用时间为20-30分钟。等级4材料可抵抗紫外线。

(b) Primers — EC776 or MIL-S-4383

底漆——EC776或MIL-S-4383

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4款的规定清洁配合表面。

(3) Prepare the adhesive as follows:

按如下方法准备粘合剂:

NOTE: The pot life of the BMS 5-126, Type 2 and 3 adhesives is approximately 1.5 hours if below 100°F. But small batches of mixed adhesive (not more than 60 grams) can be used a maximum of 20 days later if refrigerated, below -40°F, immediately after they are mixed. After you thaw this adhesive, do not refrigerate it again. Keep these batches in sealed moisture-proof containers marked as specified in par. Paragraph 3.E.

注意:如果温度低于100°F,BMS 5-126、2型和3型粘合剂的使用时间约为1.5小时。但如果在混合后立即冷藏在-40°F以下,小批量混合的粘合剂(不超过60克)最多可在20天后使用。在您解冻粘合剂后,请勿再次冷藏。将粘合剂分装在密封的防潮容器中,并按照第3.E.

(a) Immediately before you use them, fully mix each individual component. Then fully mix the components together as shown below.

在使用前,立即充分混合各组分。然后按照以下步骤将各组分充分混合。

(b) BMS 5-126, Type 2, Class 1 — Mix equal parts by weight of component A with component B.

BMS 5-126,类型2,等级1——将A组分和B组分按重量比等份混合。

(c) BMS 5-126, Type 3, Class 1 — Mix equal parts by weight of modified component A with component B.

BMS 5-126,类型3,1类——按重量比将改良的组分A与组分B等份混合。

(d) BMS 5-126, Type 4, Class 1 or 4 — Mix the components by the vendor’s instructions.

BMS 5-126,类型4,1类或4类——按供应商的说明混合组分。

(4) Apply adhesive as follows:

按照以下方法涂抹粘合剂:

(a) Standard Method (to be used when Type 38 is specified without modification)

标准方法(在指定使用38型且未作修改时使用)

1) Apply a thin, continuous smooth layer of the mixed adhesive to each mating surface. As an alternative, you can apply the adhesive to only one of the surfaces if the surface is smooth, the mating surfaces fit with a maximum gap of 0.010 inch, and sufficient adhesive is applied to make sure the other surface will be completely touched by the adhesive.

在每个配合表面涂上一层薄薄的、连续的、光滑的混合粘合剂。作为替代方案,如果表面光滑,配合表面最大间隙为0.010英寸,并且涂上足够的粘合剂以确保另一表面完全被粘合剂覆盖,则可以只在一个表面上涂粘合剂。

2) Assemble the parts and apply continuous pressure to make sure the surfaces touch completely. Remove unwanted adhesive, before it cures, with a clean cloth wet with solvent. Do not let solvent flow into the bond line.

组装零件并持续加压,确保表面完全接触。在粘合剂固化前,用蘸有溶剂的干净布清除多余的粘合剂。不要让溶剂流入粘合线。

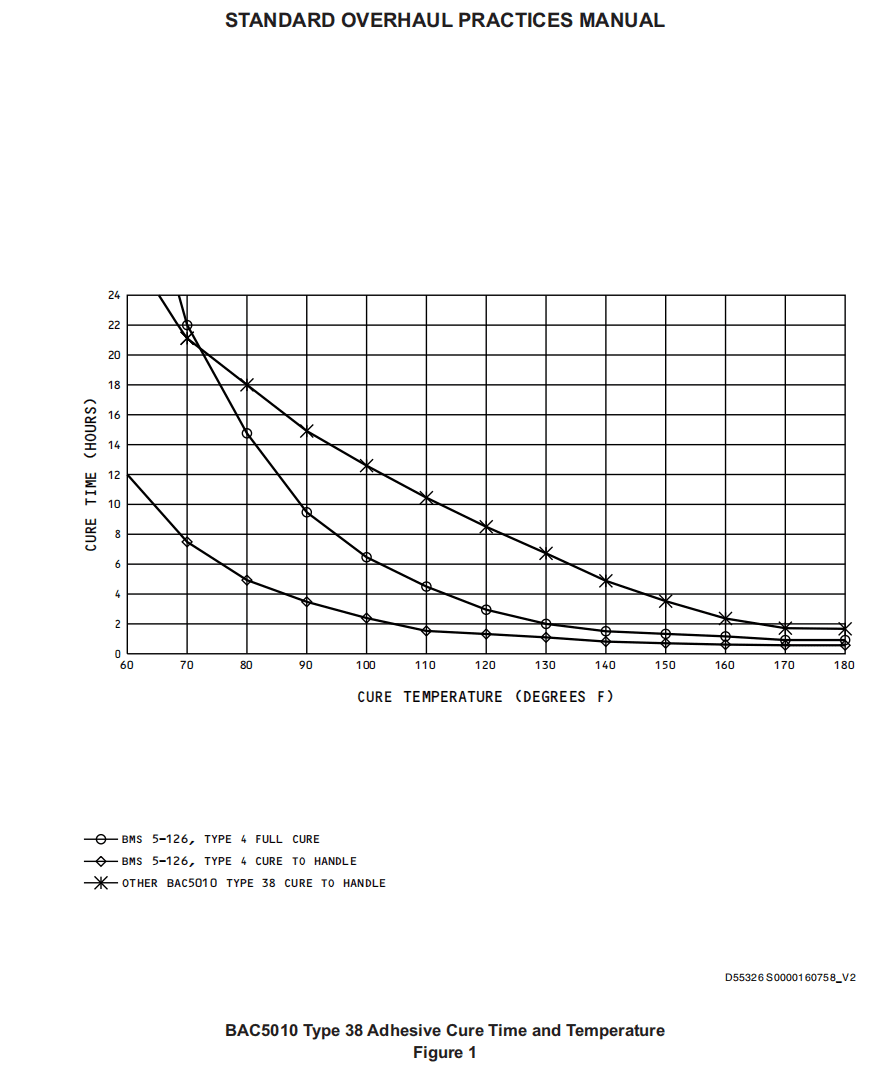

3) Cure under pressure at a time and temperature as specified in Figure 1. After the adhesive is cured, let the parts cool below 100°F before you remove pressure. Parts bonded with BMS 5-126, Type 4, Class 2 or 4 adhesive can be moved after you cure them a minimum of 45 minutes at a minimum bondline temperature of 130°F and then cooled below 100°F before removal of pressure.

在图1中规定的压力和时间、温度下固化。粘合剂固化后,待零件冷却至100°F以下再释放压力。使用BMS 5-126、类型4、2或4级粘合剂粘合的零件,在粘合线温度至少达到130°F并固化至少45分钟后,即可移动,然后冷却至100°F以下,再移除压力。

(b) Special Method l — Bonds to Metal Surfaces

特殊方法 l ——与金属表面的粘接

1) Apply a thin, continuous smooth layer of one of the Type 38 primers to the metal faying surfaces. Dry not less than 3 hours at 60-70°F, 2 hours at 70-80°F, or 1 hour at 80-90°F.

在金属接合表面涂上一层薄薄的、连续的、光滑的38型底漆。在60-70°F下干燥至少3小时,在70-80°F下干燥至少2小时,或在80-90°F下干燥至少1小时 。

2) Do the procedure of the Standard Method.

执行标准方法步骤。

(c) Special Method II — Nonstructural Metal-to-Metal Bonds With Glass Scrim

特殊方法 II——非结构性金属与金属粘接,使用玻璃纤维网布

1) Apply a thin, continuous smooth layer of one of the Type 38 primers to each metal mating surface. Dry not less than 3 hours at 60-70°F, 2 hours at 70-80°F, or 1 hour at 80-90°F.

在每个金属接合面上涂上一层薄薄的、连续的、光滑的 38 类型底漆。在 60-70°F 下干燥至少 3 小时,在 70-80°F 下干燥至少 2 小时,或在 80-90°F 下干燥至少 1 小时。

2) Cut glass scrim to the applicable dimensions.

将玻璃薄纱裁剪成合适的尺寸。

3) Apply a continuous smooth layer of the adhesive to one of the mating surfaces. Push the glass scrim down into the adhesive.

在其中一个配合面上涂上一层连续光滑的粘合剂。将玻璃薄纱压入粘合剂中。

4) Apply a continuous smooth layer of the adhesive to the remaining metal surface.

在剩余的金属表面上涂上一层连续光滑的粘合剂。

5) Assemble the parts and apply sufficient pressure to make the mating surfaces touch the scrim cloth and to push out the unwanted adhesive.

组装零件并施加足够的压力,使配合面接触薄纱布并挤出多余的粘合剂。

6) Remove the unwanted adhesive before it is cured, with a clean cloth wet with solvent. Do not let the solvent flow into the bond line.

在多余粘合剂固化前,用蘸有溶剂的干净布将其清除。不要让溶剂流入粘合线。

7) Cure at a time and temperature as specified in Figure 1. Then cool the parts to below 100°F before you remove the pressure.

按图1中规定的时间和温度固化。然后冷却零件至100°F以下,再卸压。

(d) Optional Method II — Bonds of Scrim Cloth to Adhesive Primer by Heat Reactivation

可选方法二——通过热活化将纱布与粘合剂底漆粘合

1) Apply a thin, smooth layer of one of the Type 38 primers to the mating surfaces. Dry a minimum of 3 hours at 60-70°F, 2 hours at 70-80°F, or 1 hour at 80-90°F. Parts with primed surfaces can be kept in storage as long as 1 week if they are given protection from contamination.

在配合表面涂上一层薄薄的、光滑的38型底漆。在60-70°F的温度下干燥至少3小时,在70-80°F的温度下干燥2小时,或在80-90°F的温度下干燥1小时。如果涂有底漆的零件表面得到保护,防止污染,则可以存放长达1周。

2) Cut the scrim cloth to the applicable dimension.

将薄纱布裁剪成合适的尺寸。

WARNING :THE IRON IS NOT A VAPOR-TIGHT UNIT AND COULD BE AN IGNITION SOURCE FOR SOLVENTS, ADHESIVES AND PRIMER. USE ONLY AN APPROVED IRON.

警告:烙铁不是气密装置,可能会点燃溶剂、粘合剂和底漆。请仅使用经认可的烙铁。

3) Put the scrim cloth on the primed surface and tack it in position with pressure from a hot iron (such as a heat sealing iron, or an ordinary household electric iron).

将薄纱布放在已涂底漆的表面上,并用热熨斗(如热封熨斗或普通家用电熨斗)按压将其固定。

NOTE: Surface temperature of the iron must be 300-425°F. Less than 10 seconds of pressure time is necessary if you push down sufficiently. A longer contact time will make the faying surface too hot. Use a clean iron to prevent contamination of the fabric. The complete fabric area, or as small an area as is necessary, can be heat-reactivated. Parts with scrim cloth attached may also be kept in storage as long as 1 week if given protection from contamination.

注意:熨斗表面温度必须为300-425°F。如果向下按压足够充分,则按压时间需少于10秒。接触时间过长会使贴合表面过热。使用干净的熨斗,防止织物被污染。整个织物区域或必要的销区域都可以重新热活化。只要做好防污染措施,带有薄纱布的零件也可以存放长达一周。

4) Do the procedure of the Standard Method.

按照标准方法进行操作。

(e) Special Method III — Bonds to Metal or Nonmetal Surfaces With Glass Scrim

特殊方法 III——与玻璃薄纱布的金属或非金属表面的粘合

1) Clean all aluminum mating surfaces as specified below. Clean all other mating surfaces as specified in Paragraph 4.

按照以下规定清洁所有铝制配合表面。按照第 4 段规定清洁所有其他配合表面。

a) Solvent clean by the General Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的通用清洁程序进行溶剂清洁。

b) Abrasive grit blast (aluminum oxide 180 grit or finer) as specified in SOPM 20-30-03. Use only new clean grit.

按照SOPM 20-30-03的规定进行喷砂处理(氧化铝180目或更细)。仅使用新的干净砂砾。

c) Solvent clean to remove the grit and contamination by the Final Cleaning procedures of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序进行溶剂清洁,以去除砂砾和污染物。

2) Cut the glass scrim to the approximate applicable dimensions, but larger to let you adjust its size after assembly.

将玻璃纤维网切割成大致合适的尺寸,但尺寸应稍大,以便在组装后调整其大小。

3) Prepare the adhesive as specified in Paragraph 6.H.(3)

按照第 6.H.(3) 款的规定准备粘合剂

4) Apply a continuous smooth layer of the adhesive to one of the cleaned mating surfaces. Push the glass scrim down into the adhesive.

在已清洁的配合面之一上涂上一层连续光滑的粘合剂。将玻璃纤维网向下推入粘合剂中。

5) Apply a continuous smooth layer of the adhesive to the remaining mating surface.

在剩余的配合面上涂上一层连续光滑的粘合剂。

6) Assemble the parts. Apply and keep a sufficient pressure to make the surfaces touch the glass scrim and push out the unwanted adhesive. Be sure to keep the pressure on. If you let the pressure be decreased or released after you start, you must disassemble the parts and start all over again.

组装零件。施加并保持足够的压力,使表面与玻璃纤维布接触,并挤出多余的粘合剂。确保持续施加压力。如果开始后压力减小或释放,则必须分解零件并重新开始。

7) Cut the edges of the glass scrim to align them with the edges of the bond line.

切割玻璃纤维布边缘,使其与粘合线的边缘对齐。

8) Wipe off the unwanted adhesive before it cures, with a clean cloth wet with methyl ethyl ketone, methyl propyl ketone, isopropyl alcohol or denatured alcohol. Do not let the solvent flow into the adhesive bond line.

在粘合剂固化前,用蘸有甲基乙基酮、甲基丙基酮、异丙醇或变性酒精的干净布将其擦去。不要让溶剂流入粘合剂粘合线。

9) Keep the pressure on and cure with a time and temperature as specified in Figure 1. Then cool the part below 100°F before you remove the pressure.

保持压力,按照图1中规定的时间和温度固化。然后冷却零件,使其温度低于100°F,然后再卸压。

I. Type 40

类型 40

(1) Material — BMS 5-14 adhesive

材料——BMS 5-14 粘合剂

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第 4 段的规定清洁配合表面

(3) Mix the adhesive fully before you use it. Do not use adhesive which is too thick or became a gel. When you use a thinner, as for spray application, use up to 3 parts by volume of methyl ethyl ketone with one part adhesive. Use this thinned adhesive within 4 hours unless you keep it in airtight containers and continuously shaken.

使用前充分混合粘合剂。请勿使用过稠或呈凝胶状的粘合剂。如果使用稀释剂,例如喷涂,则按体积计算,最多可将3份甲基乙基酮与1份粘合剂混合。稀释后的粘合剂应在4小时内使用,除非将其保存在密闭容器中并持续摇晃。

(4) On nonporous surfaces, apply a layer by brush or three or four spray layers, one after the other, of the adhesive to each mating surface.

在无孔表面,用刷子或喷枪将一层粘合剂涂在每个配合表面,然后依次涂上三到四层。

(5) On porous surfaces such as textiles and soft woods, seal the surfaces with two adhesive layers by brush or four to five spray adhesive layers, one after the other. The first brush layer must fully seal the surface and be dried for 20-30 minutes before you apply the second layer.

在多孔表面(如纺织品和软木),用刷子或喷枪将两层粘合剂涂在表面,然后依次涂上四到五层。第一层刷涂必须完全密封表面,并在涂第二层前干燥20-30分钟。

(6) Let the final layer of adhesive dry until it is tacky, but will not get on your knuckle, when you lightly touch it. This will be after 10-20 minutes at approximately 70°F.

让最后一层粘合剂干燥,直到它变得粘稠,但轻轻触摸时不会粘到指关节上。大约70°F下,10-20分钟后即可。

(7) When the adhesive area is large, or if the mating surfaces have no pores, caught solvent becomes a problem. Then let the surfaces dry until they are not tacky. Then lightly wipe one surface with clean cheesecloth wet with methyl ethyl ketone to reactivate the adhesive.

当粘合面积较大,或者配合表面没有孔时,残留溶剂就会成为问题。这时,让表面干燥,直到不粘手。然后用蘸有甲基乙基酮的干净粗棉布轻轻擦拭一个表面,以重新活化粘合剂。

(8) Put the mating surfaces together while the adhesive is tacky. Apply sufficient pressure to make sure the surfaces fully touch.

在粘合剂变粘时,将配合表面放在一起。施加足够的压力,确保表面完全接触。

(9) The assembly can be moved immediately.

组件可以立即移动。

(10) Remove unwanted adhesive with solvent. Do not let the solvent flow into the bond line.

用溶剂去除多余的粘合剂。不要让溶剂流入粘合线。

(11) For a faster cure and better bond strength, cure at a maximum of 200°F for 1-6 hours. Let the heat cured bonds cool to 70-80°F before you apply stress.

为了加快固化速度并提高粘接强度,请在最高200°F的温度下固化1-6小时。 在施加应力之前,让热固化的粘接冷却至70-80°F。

J. Type 44

类型44

(1) Material:

材料:

(a) You can use any of these materials.

您可以使用任何这些材料。

1) BMS 5-44, Class B

2) BMS 5-45, Class B

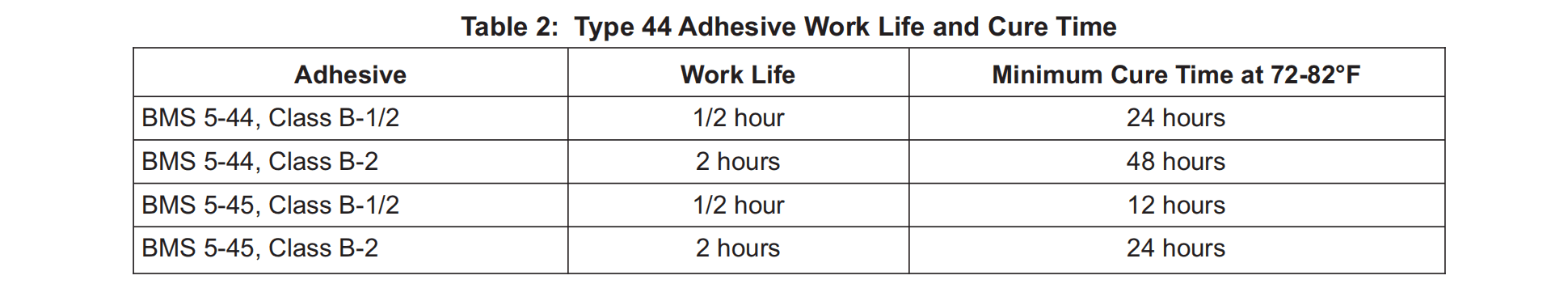

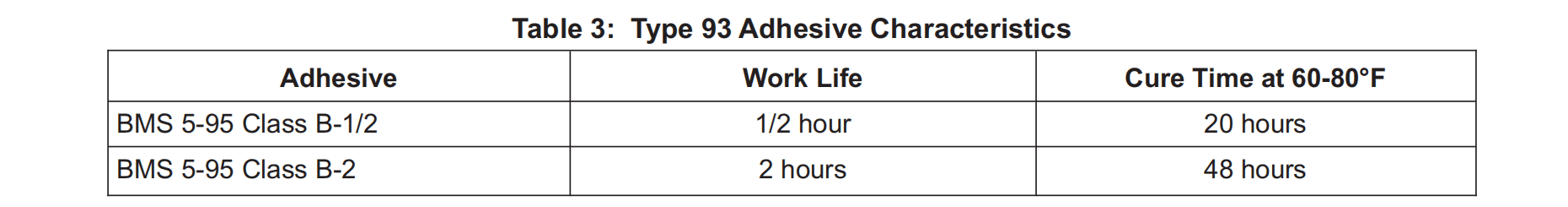

(b) Use the adhesive with a work life which is best for the task (Table 2). The dash number of the class letter is the same as the work life in hours, at temperatures below 100°F.

使用工作寿命最适合任务的粘合剂(表2)。在低于100°F的温度下,等级字母的破折号数字与工作寿命(小时)相同。

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(3) Before you use them, fully mix the individual components. Then mix the base compound with its activator by the manufacturer’s instructions. Do not use a thinner.

使用前,将各组分充分混合。然后按照制造商的说明将基料化合物与激活剂混合。请勿使用稀释剂。

(4) Apply a thin, continuous, smooth layer of the mixed adhesive to the mating surfaces. As an alternative, you can apply the adhesive to only one of the surfaces if the surface is smooth, the mating surfaces fit with a maximum gap of 0.010 inch, and sufficient adhesive is applied to make sure the other surface will be completely touched by the adhesive. On large surfaces, you can use a phenolic spreader approximately 4 inches wide with one edge beveled and notched approximately every 1/8 inch with notches approximately 1/32 inch wide.

在配合面上涂上一层薄而连续的平滑混合胶。作为等效,如果表面光滑,配合面最大间隙为0.010英寸,并且涂有足够的胶以确保另一面完全被胶粘住,则也可以只在一面上涂胶。在较大的表面上,可以使用约4英寸宽的酚醛涂抹器,其一侧边缘呈斜面,每隔1/8英寸开一个约1/32英寸宽的凹口。

(5) Put the mating surfaces together immediately, and apply sufficient pressure to make sure the parts fully touch. Make sure there is a continuous bead of pushed out adhesive.

立即将配合表面贴合在一起,并施加足够的压力以确保零件完全接触。确保挤出粘合剂形成连续的胶条。

(6) Before you move the unit, cure until the squeezed-out adhesive cannot be removed when it is rubbed with a Pink Pearl eraser (or equivalent). A reading of 30 on a Rex Model A Durometer (preferred) or a reading of 20 on a Shore A Durometer will also tell you the bond is sufficiently strong to let you move the unit.

在移动装置前,应使其固化,直到用粉红珍珠橡皮(或类似材料)擦拭时挤出的粘合剂无法去除。在Rex A型硬度计上读数为30(首选)或在Shore A型硬度计上读数为20,也表明粘合强度足以允许移动装置。

(7) For a faster cure, you can apply heat to get a maximum bond line temperature of 140°F. In general, the cure time will decrease approximately 50% for each 20°F increase in temperature. But a cure at temperatures below 75°F will be much slower than shown in Table 2.

为了加快固化速度,您可以加热,使粘合线的最高温度达到140°F。一般来说,温度每升高20°F,固化时间将缩短约50%。但是,在低于75°F的温度下固化,速度会比表2中显示的要慢得多。

K. Type 45 (Superseded by Type 68)

类型45(已被类型68取代)

L. Type 46 (Superseded by Type 77)

类型46(被类型77取代)

M. Type 47 (Deleted)

类型47(已删除)

N. Type 48

类型48

NOTE: Detailed procedures for bonding Velcro Tape and Duracote Corporation EF foam to anodized aluminum grills are contained in Boeing Process Document D6-2862.

注:将维可牢尼龙搭扣和Duracote公司EF泡沫粘合到阳极氧化铝格栅上的详细步骤包含在波音工艺文件D6-2862中。

(1) Material — BMS 5-30 adhesive

材料——BMS 5-30粘合剂

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(3) Mix the adhesive fully before you use it. Do not use adhesive which is too thick or became a gel. When you use a thinner, as for spray application, use up to 3 parts by volume of methyl ethyl ketone or methyl propyl ketone with one part adhesive. For brush application, use up to 1 part by volume methyl ethyl ketone or methyl propyl ketone with one part adhesive. Use this thinned adhesive within 4 hours unless you keep it in airtight containers and continuously shaken.

使用前充分混合粘合剂。请勿使用太稠或呈凝胶状的粘合剂。使用稀释剂时,如采用喷涂方式,最多可将3份体积的甲基乙基酮或甲基丙基酮与1份粘合剂混合。刷涂时,最多使用1份体积的甲基乙基酮或甲基丙基酮与1份粘合剂。稀释后的粘合剂应在4小时内使用,除非将其保存在持续摇晃的密闭容器中。

(4) On nonporous surfaces, apply to each mating surface a medium to heavy smooth layer of the adhesive with a brush, or three to four spray layers, one after the other.

在无孔表面上,用刷子在每个配合表面涂上一层中等到厚的光滑粘合剂,或依次喷涂三到四层。

(5) On porous surfaces, such as textiles and soft woods, apply two layers of adhesive by brush, or spray on four to five layers of adhesive, one after the other. The first brush layer must fully seal the surface and be dried for 20 to 30 minutes before you apply the second layer. (As an option, and only when you bond foam, felt, or honeycomb to metal, apply one layer of adhesive to the metal and let it dry until tacky. Then apply one more layer of adhesive to the metal and apply the felt, foam or honeycomb while the adhesive layer is wet.)

在多孔表面(如纺织品和软木)上,用刷子涂两层粘合剂,或依次喷涂四至五层粘合剂。第一层刷涂的粘合剂必须完全密封表面,并在涂第二层前干燥20至30分钟。(作为选项,且仅当您将泡沫、毡或蜂窝状物粘接到金属上时,在金属上涂一层粘合剂,让其干燥至有粘性。然后在粘合剂层湿润时,在金属上再涂一层粘合剂,并贴上毡、泡沫或蜂窝状物。)

(6) Let the final layer of adhesive dry until it is tacky but will not get on your knuckle when you touch it lightly. This will be after 10-20 minutes at approximately 70°F.

让最后一层粘合剂干燥,直到有粘性,但轻轻触碰时不会粘到指关节上。大约70°F下,10-20分钟后即可。

(7) When the adhesive area is large, or if the mating surfaces have no pores, caught solvent becomes a problem. Then let the surfaces dry until they are not tacky. Then lightly wipe one surface with a clean wiper wet with methyl ethyl ketone or methyl propyl ketone to reactivate the adhesive.

如果粘合面积较大,或者配合表面没有孔隙,残留溶剂就会成为问题。这时,让表面干燥,直到不粘。然后用蘸有甲基乙基酮或甲基丙基酮的干净刷子轻轻擦拭一个表面,以重新活化粘合剂。

(8) Put the mating surfaces together while the adhesive is tacky, or immediately after you wiped with methyl ethyl ketone or methyl propyl ketone. Apply sufficient pressure to make sure the parts fully touch. Do not make air pockets.

在粘合剂变粘时,或用甲基乙基酮或甲基丙基酮擦拭后立即将配合表面贴合在一起。施加足够的压力,确保零件完全接触。不要形成气穴。

(9) Parts can be moved immediately, but do not put stress on the bond for 24 hours. Maximum strength comes in 5 to 7 days at 65 to 80°F.

零件可以立即移动,但24小时内不要对粘合处施加压力。在65至80°F的温度下,5至7天后强度达到最大。

(10) Remove unwanted adhesive with solvent, such as the solvent used for Paragraph 6.N.(2). Do not let the solvent flow into the bond line.

用溶剂去除不需要的粘合剂,例如第6.N.(2)段中使用的溶剂。不要让溶剂流入粘合线。

O. Type 49 (Superseded by Type 38.)

类型49(已被类型38取代)

P. Type 50

类型50

WARNING :BE VERY CAREFUL WHEN YOU USE BMS 5-36 ADHESIVE. THIS ADHESIVE MAKES AN ALMOST IMMEDIATE, VERY STRONG BOND. APPLY IT ONLY TO SURFACES TO BE BONDED. THIS ADHESIVE IS AN EYE IRRITANT AND BONDS SKIN IN SECONDS. USE GOGGLES OR SAFETY GLASSES AND POLYETHYLENE GLOVES. DO NOT USE RUBBER OR CLOTH GLOVES. RUBBER WILL BOND WHEN IT TOUCHES THIS ADHESIVE. CLOTH WILL SOAK UP THE ADHESIVE AND THEN BOND TO THE SKIN. IF THIS ADHESIVE GETS IN THE EYES OR INTERNALLY, GET MEDICAL ATTENTION. IF THIS ADHESIVE GETS ON THE SKIN, FLUSH THE SKIN WITH WATER IMMEDIATELY.

警告:使用BMS 5-36粘合剂时务必小心。这种粘合剂几乎可以立即产生非常牢固的粘合力。仅将其涂在需要粘合的表面上。这种粘合剂会刺激眼睛,并在数秒内粘住皮肤。请佩戴护目镜或安全眼镜和聚乙烯手套。请勿使用橡胶或布手套。橡胶手套接触本粘合剂后会粘上。布手套会吸收粘合剂,然后粘在皮肤上。如果本粘合剂进入眼睛或体内,请就医。如果本粘合剂沾到皮肤上,请立即用水冲洗。

CAUTION :THIS ADHESIVE SOAKS UP WATER VERY EASILY AND CURES WITH MOISTURE. BECAUSE OF THIS, THE ADHESIVE MUST BE KEPT IN SEALED CONTAINERS. OPEN THE CONTAINER ONLY FOR THE SHORTEST POSSIBLE TIME. TO HELP PREVENT CONTAMINATION BY APPLICATORS AND TO DECREASE THE RISK OF CONTAMINATION, ONLY THE SMALL TUBES OR SMALL POLYETHYLENE CONTAINER-APPLICATOR COMBINATIONS ARE RECOMMENDED.

注意:这种粘合剂极易吸水,遇湿固化。因此,粘合剂必须保存在密封容器中。打开容器的时间应尽可能短。为防止涂抹器污染并降低污染风险,建议仅使用小管或小聚乙烯容器-涂抹器组合。

(1) Material — BMS 5-36 adhesive

材料——BMS 5-36 粘合剂

(2) Method I — General Applications

方法 I——通用应用

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第 4 段的规定清洁配合表面。

(b) Apply the BMS 5-36 adhesive to one mating surface. Apply the adhesive directly from the container with a medicine dropper or directly from the container-applicator. Apply the adhesive in as thin a layer as possible with a glass rod or equivalent tool.

在一个配合表面涂上 BMS 5-36 粘合剂。用药物滴管直接从容器中或直接从容器-涂抹器中涂抹粘合剂。用玻璃棒或类似工具尽可能薄地涂抹粘合剂。

(c) Assemble the parts immediately. Final adjustment must be made within seconds after the parts touch, because the adhesive cures that quickly. Apply some pressure by had, by clamps, or by something equivalent to make sure the mating surfaces stay together tightly until the bond cures. The time for this is different for each material to be bonded. Usually it is some seconds, but it could be as much as 3 to 5 minutes.

立即组装零件。由于粘合剂固化速度很快,必须在零件接触后的几秒钟内进行最终调整。用手、夹具或等效工具施加一定的压力,确保配合表面紧密贴合,直到粘合剂固化。粘合时间因粘合材料而异。通常为几秒钟,但最长可达3至5分钟。

(d) The parts can be moved after the 1 hour cure at 65-100°F.

在 65-100°F 下固化 1 小时后,零件即可移动。

(3) Method II — Primer Application Only

方法 II——仅使用底漆

NOTE: This procedure is used to bond thin rubber gaskets, parts with unusual properties or details, and when one surface has much plastic in or on it.

注意:此程序用于粘合薄橡胶垫圈、具有特殊性质或细节的零件,以及一个表面有大量塑料或塑料附着在表面的情况。

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第 4 段的规定清洁配合表面。

(b) Apply a thin, continuous, smooth layer of the adhesive to the surface that has the plastic. Refer to Paragraph 6.P.(2)(b) above for details.

在有塑料的表面上涂上一层薄而连续的平滑粘合剂。详情请参阅上文第6.P.(2)(b)段。

(c) Air dry for a minimum of 5 minutes or until the adhesive is dry to the touch.

风干至少5分钟,或直到粘合剂摸起来变干。

(d) Bond the parts together with BMS 5-14 adhesive by the Type 40 procedure.

按40型程序用BMS 5-14粘合剂将零件粘在一起。

(4) Cleanup of Spilled Adhesive

清理溢出的粘合剂

(a) If you spill large quantities of adhesive, immediately flood the area with water. This will cure the adhesive which can then be scraped from the surface.

如果大量粘合剂溢出,应立即用水冲洗。粘合剂会固化,然后从表面刮除。

(b) Do not use rags or tissues to wipe up spills. The fabric will cause a chemical reaction, and the adhesive will make heat during the cure, with smoke and strong, irritating vapors.

不要用抹布或纸巾擦拭溢出的粘合剂。织物会引起化学反应,粘合剂在固化过程中会发热,产生烟雾和刺激性很强的蒸汽。

Q. Type 51

类型51

(1) Material — BMS 5-31 adhesive, which includes base and accelerator.

材料——BMS 5-31粘合剂,包括基料和促进剂。

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(3) Fully mix each component in its container before you mix them together. Immediately before you use it, mix 30 parts by weight of accelerator with 100 parts by weight of base resin. Pot life of the mixture is approximately 20 minutes below 100°F. Do not use a thinner.

在混合前,将每个零件充分混合在容器中。在使用前,将30份促进剂与100份基料树脂按重量比立即混合。在100°F以下,混合物的可使用时间约为20分钟。请勿使用稀释剂。

(4) Apply a thin, smooth layer of the mixed adhesive to the mating surfaces. As an alternative, you can apply the adhesive to only one of the surfaces if the surface is smooth, the mating surfaces fit with a maximum gap of 0.010 inch, and sufficient adhesive is applied to make sure the other surface will be completely touched by the adhesive.

在配合表面涂上一层薄薄的、光滑的混合粘合剂。作为等效,如果表面光滑,配合表面最大间隙为0.010英寸,并且涂有足够的粘合剂以确保另一表面完全被粘合剂覆盖,则也可以只在一面上涂粘合剂。

(5) Put the surfaces together and apply sufficient pressure to make sure the surfaces fully touch and the unwanted adhesive comes out. Use only sufficient pressure to hold the parts together.

将两个表面贴合在一起,并施加足够的压力,确保两个表面完全接触,多余粘合剂流出。仅使用足够的压力将零件固定在一起。

(6) Remove the unwanted adhesive before it cures, with a clean cloth wet with solvent. Do not let the solvent flow into the bond line.

在多余粘合剂固化之前,用蘸有溶剂的干净布将其清除。不要让溶剂流入粘合线。

(7) Cure at one of these minimum times before you move or use the part. The bond will get to full strength after 48 hours.

在移动或使用零件前,在这些最短时间内固化。粘合剂将在48小时后达到完全强度。

(a) 10.5 hours at 55-64°F

10.5小时,55-64°F

(b) 8.5 hours at 65-72°F

8.5小时,65-72°F

(c) 6.5 hours at 73-84°F

6.5小时,73-84°F

(d) 4.5 hours at 85-90°F

4.5小时,85-90°F

R. Type 52

类型 52

(1) Material — BMS 5-60 adhesive, which has two components, a base and a hardener

材料——BMS 5-60粘合剂,该粘合剂由两部分组成,即基料和固化剂

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面

(3) Fully mix the individual components. Then mix the two components of BMS 5-60 in the ratio of 25 parts by weight of hardener to 100 parts by weight of base resin.

充分混合各组分。然后按照25份固化剂与100份基料树脂的重量比混合BMS 5-60的两种组分

(4) The pot life of the mixed adhesive is 45 minutes below 100°F. But the mixed adhesive can be kept in refrigerated storage at -20°F or colder for 7 days, or -40°F or colder for 10 days. If you do this, be sure to put a label on the container which gives the name of the adhesive, the date it was mixed, and the date it will expire.

混合后的粘合剂的使用时间为45分钟(低于100°F)。但混合后的粘合剂可在-20°F或更低的温度下冷藏保存7天,或在-40°F或更低的温度下冷藏保存10天。如果这样做,请务必在容器上贴上标签,注明粘合剂的名称、混合日期和过期日期。

(5) Apply the adhesive to the mating surfaces.

将粘合剂涂在配合面上。

(6) Assemble the parts, and apply only sufficient pressure to make sure the mating surfaces fully touch.

组装零件,仅施加足够的压力以确保配合面完全接触。

(7) Wipe off the unwanted adhesive, before it cures, with a clean cloth wet with solvent. Do not let the solvent flow into the bond line.

在粘合剂固化前,用蘸有溶剂的干净布将其擦去。不要让溶剂流入粘合线。

(8) Cure under constant pressure for 12 hours at 65-80°F, a minimum of 2 hours at 115-135°F, or 55-65 minutes at 190-210°F. This adhesive will not cure satisfactorily below 65°F.

在65-80°F的温度下持续加压固化12小时,在115-135°F的温度下至少固化2小时,或在190-210°F的温度下固化55-65分钟。此粘合剂在低于65°F的温度下无法达到理想的固化效果。

S. Type 53 (Superseded by Type 58, BMS 5-7, Type 2)

类型53(已被类型58、BMS 5-7、2型取代)

T. Type 54

类型 54

(1) Materials

材料

(a) BMS 5-25, Type 2, Grade 1

BMS 5-25,类型 2,等级 1

(b) Thickening agent — Cab-O-Sil, Type M-5 or HS-5

增稠剂——Cab-O-Sil,M-5 或 HS-5 类型

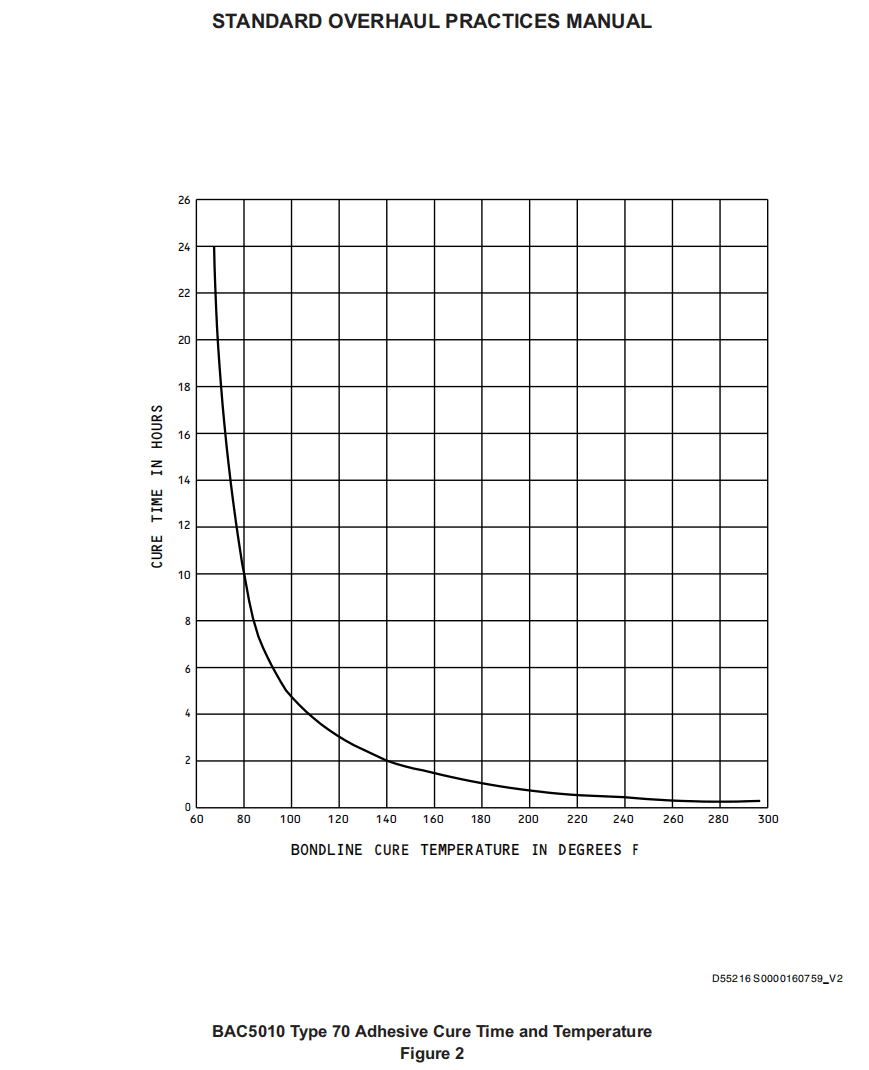

NOTE: This adhesive is usually cured at 60-80°F, but a faster cure can be used as indicated below.

注:这种粘合剂通常在 60-80°F 下固化,但也可以使用以下方法加快固化速度。

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第4段所述清洁配合表面。

(3) Fully mix each component. Then mix the components together by the vendor’s instructions. The pot life of the mixed adhesive is approximately 1 hour. Do not use a thinner. For a cure at higher temperatures, you can add a maximum of 1 part by weight of thickening agent to 49 parts adhesive.

充分混合各组分。然后按照供应商的说明将各组分混合在一起。混合后的粘合剂的使用时间约为1小时。请勿使用稀释剂。如需在更高温度下固化,可在49份粘合剂中加入最多1份重量(按重量计)的增稠剂。

(4) Apply a thin layer of the mixed adhesive to each faying surface.

在每个配合表面涂上一层薄薄的混合粘合剂。

(5) Assemble the parts and apply sufficient pressure to make sure all of the surfaces touch completely. A continuous bead of adhesive that comes out usually indicates that the surfaces touched completely.

组装零件并施加足够的压力,确保所有表面完全接触。 通常,连续的粘合剂流出来表明表面完全接触。

(6) Remove unwanted adhesive before it cures. Use a clean cloth wet with solvent. Do not let the solvent get into the bond line.

在粘合剂固化之前,用溶剂浸湿的干净布将其清除。 不要让溶剂进入粘合线。

(7) Cure under constant pressure, for a minimum of 12 hours at 65-100°F, or 2 hours minimum at 115-135°F, or 55-65 minutes at 190-210°F. This adhesive will not cure satisfactorily below 65°F.

在恒定压力下固化,在65-100°F下至少12小时,或在115-135°F下至少2小时,或在190-210°F下至少55-65分钟。此粘合剂在65°F以下无法达到理想的固化效果。

U. Type 55

类型 55

(1) Material — Chemlock 220 adhesive

材料——Chemlock 220 粘合剂

(2) Make the metal mating surfaces rough with sandpaper or sandblast them.

用砂纸打磨或喷砂处理金属配合表面,使其粗糙。

(3) Clean the metal mating surfaces as specified in Paragraph 4.

按照第 4 段所述清洁金属配合表面。

(4) Fully mix the adhesive until smooth and continuous.

充分混合粘合剂,直至光滑、连续。

(5) Apply the adhesive to the metal faying surfaces and let it air dry for 30 minutes at 65-100°F.

将粘合剂涂在金属配合表面,并在 65-100°F 下风干 30 分钟。

(6) Put the uncured Butyl rubber in position on the cleaned metal part(s) and apply sufficient pressure to form the rubber. Mechanical and/or vacuum pressure can be used.

将未固化的丁基橡胶放置在清洁的金属零件上,并施加足够的压力以形成橡胶。可以使用机械和/或真空压力。

(7) Use the same cure time and temperature as that of the Butyl rubber used. A typical cure time and temperature for Butyl rubber is 45 minutes at 290-310°F.

使用与丁基橡胶相同的固化时间和温度。丁基橡胶的典型固化时间和温度为45分钟,温度为290-310°F。

V. Type 56

类型56

(1) Materials

材料

(a) Adhesive — Epon 828

粘合剂——Epon 828

(b) Catalyst — Pyromellitic dianhydride (PMDA) or 946 Hardener

催化剂——均苯四甲酸二酐(PMDA)或946硬化剂

(2) Clean the mating surfaces as specified in Paragraph 4. If the surfaces are unetched Teflon, be sure to etch them as specified in Paragraph 4.AA.

按照第4段的规定清洁配合表面。如果表面是未蚀刻的特氟龙,请务必按照第4.AA段的规定进行蚀刻。

(3) Before you use them, thoroughly mix the individual components. Then mix 100 parts by weight of Epon 828 with 40 parts by weight of PMDA or 20 parts by weight of 946 hardener. Pot life below 100°F is approximately 24 hours for the mixture with PMDA, or 10-15 minutes for the mixture with 946 hardener.

使用前,将各组分充分混合。然后,将100份Epon 828与40份PMDA或20份946固化剂按重量比混合。在100°F以下,PMDA混合物的使用时间约为24小时,946固化剂混合物的使用时间约为10-15分钟。

(4) Apply a thin, continuous, smooth layer of adhesive to each mating surface and assemble the components.

在每个配合表面涂上一层薄而连续的平滑粘合剂,然后组装组件。

(5) Remove unwanted adhesive before it cures. Use a clean cloth wet with solvent. Do not let the solvent get into the bond line.

在粘合剂固化前将其清除。使用蘸有溶剂的干净布。不要让溶剂进入粘合线。

(6) Cure under pressure of 5-15 psi for 25-30 minutes at 340-360°F. Cure time starts when the bond line reaches the specified temperature.

在 5-15 psi 的压力下,在 340-360°F 的温度下固化 25-30 分钟。固化时间从粘合线达到指定温度时开始。

(7) If the overhaul instructions specify a primer layer of Type 56 to bond Teflon, apply a thin layer of this adhesive to treated Teflon surfaces and cure without pressure for 25-35 minutes at 340-360°F as above.

如果大修说明指定使用 56 型底漆层粘接特氟龙,则在处理过的特氟龙表面涂上一层薄薄的这种粘合剂,并在 340-360°F(如上)固化25-35分钟。

(8) Parts can be used immediately after the cure.

零件可在固化后立即使用。

W. Type 58

类型58

(1) Material — BMS 5-7, Type 1 or Type 2 adhesive

材料——BMS 5-7,1型或2型粘合剂

NOTE: When the BMS 5-7 type is not specified, use Type 1.

注意:如果没有指定BMS 5-7类型,请使用1型。

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(b) Mix the adhesive fully before you use it. Do not use adhesive which is too thick, or became a gel. Do not use a thinner with this adhesive.

使用前充分混合粘合剂。请勿使用过稠或已凝胶化的粘合剂。请勿使用稀释剂稀释粘合剂。

(c) Apply two thin, continuous, smooth layers by brush or spray to each mating surface. On porous surfaces, two or more layers of adhesive could be necessary to fully seal the surface. Let each layer dry at 65-100°F.

用刷子或喷雾器在每个配合表面涂上两层薄而连续的平滑涂层。在多孔表面上,可能需要涂两层或更多层粘合剂才能完全密封表面。让每层在65-100°F下干燥。

(d) Let the last coat adhesive dry until it is tacky, but will not get on your knuckle when you touch it lightly.

让最后一层粘合剂干燥,直到有粘性,但轻轻触摸时不会粘在指关节上。

(e) As an alternative to Paragraph 6.W.(1)(d), let the adhesive dry tack free and, to reactivate, lightly wipe one surface with clean wiper wet with methyl ethyl ketone or naphtha. This is a good alternative when the adhesive area is large or the mating surfaces have no pores to let caught solvent get out.

作为第 6.W.(1)(d) 段的替代方案,让粘合剂干燥至无粘性,然后用蘸有甲基乙基酮或石脑油的干净刷子轻轻擦拭一个表面,使其恢复活性。当粘合面积较大或配合表面没有孔隙让残留的溶剂流出时,这是一个很好的替代方案。

(f) Put the mating surfaces together while the adhesive is tacky, and apply sufficient pressure to make sure the parts fully touch. Do not make air pockets.

在粘合剂变粘时,将配合表面放在一起,并施加足够的压力,确保零件完全接触。不要形成气穴。

(g) The assembly can be moved immediately.

组件可以立即移动。

(h) Remove unwanted adhesive with the solvent you used to prepare the surface as specified in Paragraph 4. Do not let the solvent get into the bond line.

用第4段中规定的用于准备表面的溶剂去除不需要的粘合剂。不要让溶剂进入粘合线。

X. Type 59 (Superseded by Type 70)

类型59(已被类型70取代)

Y. Type 60

类型 60

(1) Adhesives

粘合剂

(a) Grade 1 (white) — RTV 102, IS 802

1 级(白色)——RTV 102、IS 802

(b) Grade 2 (translucent) — RTV 108

2 级(半透明)——RTV 108

(c) Grade 3 (gray) — RTV 157

3 级(灰色)——RTV 157

(d) Grade 4 (beige) — CRTV 9405

4 级(米色)——CRTV 9405

(e) Grade 5 (white) — RTV 108

5级(白色)——RTV 108

(2) Primer — PR-1200 (red or clear) or PR-1204

底漆——PR-1200(红色或透明)或PR-1204

(3) Standard Method. Use this method to bond parts or when the overhaul instructions do not fill gaps or spaces with this adhesive.

标准方法。使用此方法粘接零件,或当大修说明未要求使用此粘合剂填充间隙或空隙时。

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(b) When adhesive primer is specified, apply a thin layer of Type 60 primer to all surfaces to be bonded unless they are silicone rubber. Apply a thin layer of this primer by brush or spray. Do not use a thinner with this primer. Use this primer as supplied. Do not use primer which is cloudy or milky. Let this primer dry 30 minutes to 4 hours at 65-100°F.

如果指定使用粘合剂底漆,则应在所有待粘合表面(硅橡胶表面除外)涂上一层薄薄的60型底漆。用刷子或喷雾器涂上一层薄薄的底漆。请勿使用稀释剂稀释底漆。请使用原配底漆。请勿使用浑浊或乳白色的底漆。在65-100°F的温度下,让底漆干燥30分钟至4小时。

(c) If the overhaul instructions specify Type 60 without a grade, you can use any grade, to agree with the color of the surfaces.

如果大修说明中指定了60型但没有等级,您可以使用任何等级,以符合表面的颜色。

(d) Apply a smooth layer of the adhesive on one or each surface to be bonded. Be very careful not to apply the adhesive outside of the bond area if the surfaces will be subsequently finished.

在一个或每个要粘合的表面上涂上一层光滑的粘合剂。 如果表面随后要进行表面处理,请格外小心,不要在粘合区域外涂上粘合剂。

(e) Put the surfaces together as quickly as possible after you apply the adhesive, because after a few minutes the adhesive layer will get a skin which will prevent a good bond.

涂上粘合剂后,应尽快将表面粘合在一起,因为几分钟后粘合剂表面会结皮,影响粘合效果。

(f) Apply sufficient pressure to make sure the surfaces fully touch, but not to squeeze out too much adhesive. A bond line thickness of 0.015-0.030 inch (10-30 mils) gives best results.

施加足够的压力,确保表面完全接触,但不要挤出过多的粘合剂。 粘合线厚度为0.015-0.030英寸(10-30密耳)时效果最佳。

(g) To cure, this adhesive must absorb moisture from the air. Thus the bondline must be open to the air. No location in the bond can be more than 0.50 inch from an outer edge unless the material of the parts has pores.

为了固化,这种粘合剂必须吸收空气中的水分。因此,粘合线必须暴露在空气中。除非零件材料有孔,否则粘合线中的任何位置都不能距离外边缘超过0.50英寸。

(h) Cure under pressure for a minimum of 24 hours at 65-100°F and a minimum of 20% relative humidity. There will be an odor of acetic acid until the cure is complete. For a faster cure, cure the parts at 6 hours minimum at 100°F minimum, with a minimum of 60% relative humidity inside the oven.

在65-100°F的温度和至少20%的相对湿度下,在压力下固化至少24小时。在固化完成之前,会有醋酸气味。为了加快固化速度,零件在100°F下至少固化6小时,烤箱内相对湿度至少为60%。

(4) Gap-Filling Method. Use this method when the overhaul instructions fill gaps with this adhesive.

间隙填充法。当大修说明要求使用这种粘合剂填充间隙时,请使用此方法。

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

(b) Apply sufficient adhesive to fully fill the gap. Remove unwanted adhesive. Do not let too much adhesive get on adjacent surfaces because removal will be necessary if the surfaces will be refinished. If the overhaul instructions do not specify the color, you can use any grade to agree with the color of the part.

涂上足够的粘合剂以完全填满缝隙。清除多余的粘合剂。不要让过多的粘合剂沾到相邻的表面上,因为如果需要重新对这些表面做表面处理,就需要清除这些粘合剂。如果大修说明没有指定颜色,您可以使用任何与零件颜色匹配的等级。

(c) Before you touch or move the parts, let the adhesive make a skin that is tack-free. Do not touch the adhesive until it is fully cured. The adhesives will become tack free in these approximate times at 50% relative humidity:

在接触或移动零件之前,让粘合剂形成无粘性的表面。在粘合剂完全固化之前不要触摸。在50%的相对湿度下,粘合剂将在以下大致时间后形成无粘性表面:

1) RTV 102, RTV 108: 20 minutes

RTV 102, RTV 108: 20 分钟

2) RTV 157: 45 minutes

RTV 157:45分钟

3) CRTV 9405: 60 minutes

CRTV 9405:60分钟

Z. Type 61

类型61

(1) Materials

材料

(a) Adhesive — PR-1710

粘合剂——PR-1710

(b) Catalyst — PR-1710 Accelerator

催化剂——PR-1710 促进剂

(c) Primer — PR-1711

底漆——PR-1711

(2) Standard Method

标准方法

NOTE: This method is to be used when the overhaul instructions specify Type 61 without a method.

注:当大修说明中指定了61类型但没有指定方法时,应使用此方法。

(a) Clean the mating surfaces as specified in Paragraph 4.

按照第4段的规定清洁配合表面。

CAUTION :PR-1711 PRIMER WILL ABSORB WATER AND MUST BE KEPT AWAY FROM MOISTURE. WHEN PR-1711 BECOMES CLOUDY, IT MUST BE DISCARDED

注意:PR-1711底漆会吸收水分,必须远离潮湿环境。当PR-1711底漆变得浑浊时,必须丢弃

(b) Brush one continuous layer of PR-1711 primer on nonrubber surfaces to be bonded. Allow to air dry for 30 minutes at 65 to 100°F.

在需要粘合的非橡胶表面上连续刷一层PR-1711底漆。在65至100°F的温度下风干30分钟。

(c) Fully mix the individual components. Then mix 20 parts by weight of PR-1710 base with 1 part of accelerator. Pot life of the mixed adhesive is approximately 24 hours below 100°F if kept in a sealed container.

充分混合各组分。然后按重量比例将20份PR-1710基料与1份促进剂混合。如果密封保存,混合后的粘合剂在100°F以下可保持24小时左右。

(d) Bond the parts.

粘合零件。

1) To bond a rubber surface to a nonrubber surface, apply a thin, continuous layer of mixed PR-1710 adhesive on the rubber surface with a brush or other method that will fully cover it. Let this air dry for 30 minutes to 1 hour. Apply a equivalent layer on the primed nonrubber surfaces. Let this air dry until tacky. Then put the surfaces together with sufficient pressure to make sure they fully touch.

若要将橡胶表面与非橡胶表面粘合,请用刷子或其他方法在橡胶表面涂上一层薄薄的、连续的混合PR-1710粘合剂,使其完全覆盖橡胶表面。让其风干30分钟至1小时。在涂有底漆的非橡胶表面涂上等量的粘合剂。让其风干至有粘性。然后将两个表面压在一起,确保它们完全接触。

2) To bond rubber to rubber, apply a thin, continuous layer of mixed PR-1710 adhesive to each surfaces with a brush or other method that will fully cover the surfaces. Let these layers air dry for 30 minutes to 1 hour. Then apply one more layer of adhesive to one of the surfaces. Let this layer air dry until tacky. Then put the surfaces together with sufficient pressure to make sure they fully touch.

若要将橡胶与橡胶粘合,请用刷子或其他方法在每个表面涂上一层薄薄的、连续的混合 PR-1710 粘合剂,使其完全覆盖表面。让这些层风干 30 分钟至 1 小时。然后在其中一个表面再涂一层粘合剂。让这一层风干,直到变粘。然后将表面充分压紧,确保它们完全接触。

CAUTION :KEEP SOLVENTS AWAY FROM MATERIALS OR SURFACES ON WHICH IT WILL CAUSE DETERIORATION.

注意:溶剂应远离会导致材料或表面损坏的材料或表面。

3) Optional Method:

可选方法:

a) With a brush, apply a continuous layer of mixed PR-1710 adhesive to each of the prepared surfaces. Let this air dry 30 minutes to 1 hour.

用刷子在每个准备好的表面上连续涂上一层混合的PR-1710粘合剂。让其风干30分钟到1小时。

b) Put the adhesive surfaces at an angle, then quickly apply methyl ethyl ketone from a clean squirt bottle onto the adhesive surfaces.

将粘合剂表面倾斜放置,然后用干净的喷雾瓶快速将甲基乙基酮喷到粘合剂表面。

c) Carefully put the wet surfaces together, in the exact position they must be. Do not try to align the surfaces after they touch.

小心地将湿润的表面放在正确的位置。不要在表面接触后再对齐。

d) Immediately apply sufficient pressure to make sure the surfaces fully touch. Shot bags are recommended to apply pressure on large parts. Weights or clamps can be used on small parts.

立即施加足够的压力,确保表面完全接触。建议使用射袋对大型零件施加压力。小型零件可使用砝码或夹具。

e) Seal the edges of the bond lines with a continuous layer of the adhesive, applied with a brush.

用刷子将一层连续的粘合剂密封粘合线的边缘。

(e) For all of these methods, let the adhesive cure under pressure for 16 hours minimum at 65-100°F before you move the assembly.

对于所有这些方法,在移动组件之前,请至少在65-100°F的压力下固化粘合剂16小时。

(3) Special Method 1

特殊方法1

(a) Clean nonmetal surfaces as specified in Paragraph 4. Dry abrasive clean metal surfaces, then solvent them by the Final Cleaning method of SOPM 20-30-03.

按照第4段的规定清洁非金属表面。用干磨料清洁金属表面,然后用SOPM 20-30-03的最终清洁方法进行溶剂清洁。

(b) Do steps (b) thru (e) of the standard method.

执行标准方法的步骤 (b) 至 (e)。

AA. Type 62

类型 62

(1) Materials

材料

(a) Adhesive — Q4-2817

粘合剂——Q4-2817

(b) Primer — PR-1200, red or clear

底漆——PR-1200,红色或透明

(2) Clean the mating surfaces as specified in Paragraph 4.

按照第 4 款的规定清洁配合表面。

CAUTION :KEEP SOLVENTS AWAY FROM MATERIALS OR SURFACES ON WHICH IT WILL CAUSE DETERIORATION.

注意:溶剂应远离会导致材料或表面损坏的材料或表面。

(3) Apply a thin layer of Type 62 primer to all bonding surfaces unless they are fluorosilicone rubber. Use a brush or spray. Do not thin the primer. Do not use primer if it becomes cloudy or milky. Air dry for 30 minutes minimum and 4 hours maximum at 65 to 100°F.

在所有粘接表面(氟硅橡胶除外)涂上一层薄薄的62型底漆。使用刷子或喷雾器。不要稀释底漆。如果底漆变得浑浊或呈乳白色,请勿使用。在65至100°F的温度下,至少风干30分钟,最多风干4小时。

(4) Apply a smooth layer of the adhesive on each surface to be bonded. Be very careful not to apply the adhesive outside of the bond area if the surfaces will be subsequently finished.

在每个需要粘合的表面涂上一层光滑的粘合剂。如果表面随后要进行表面处理,则要非常小心,不要在粘合区域外涂上粘合剂。

(5) Put the surfaces together as quickly as possible after you apply the adhesive, because after a few minutes the adhesive layer will get a skin which will prevent a good bond.

在涂上粘合剂后,尽快将表面粘合在一起,因为几分钟后,粘合剂层会结皮,从而影响粘合效果。

(6) Apply sufficient pressure to make sure the surfaces fully touch, but not to squeeze out too much adhesive. A bondline thickness of 0.010-0.030 inch (10-30 mils) gives best results.

施加足够的压力,确保表面完全接触,但不要挤出过多的粘合剂。粘合线厚度为0.010-0.030英寸(10-30密耳)时效果最佳。

(7) To cure, this adhesive must absorb moisture from the air. Thus the bondline must be open to the air. No location in the bond can be more than 0.50 inch from an outer edge unless the material of the parts has pores.

为了固化,这种粘合剂必须吸收空气中的水分。因此,粘合线必须暴露在空气中。除非零件材料有孔,否则粘合线中任何位置与外缘的距离不得超过0.50英寸。

(8) Cure under pressure for 4 days minimum at 65-100°F and a minimum of 20% relative humidity.

在65-100°F的温度和至少20%的相对湿度下,在压力下固化至少4天。

AB. Type 63 (Superseded by Type 82)

类型 63(已被类型 82 取代)

AC. Type 65 (Deleted)

类型 65(已删除)

AD. Type 66

类型 66

(1) Materials

材料

(a) Adhesive — Part A of S-1005, S-1006, or S-1009

粘合剂——S-1005、S-1006 或 S-1009 的 A 部分

(b) Catalyst — Part B of S-1005, S-1006, or S-1009

催化剂——S-1005、S-1006或S-1009的B部分

(2) Sand the bonding surfaces of the heat-shrinkable parts lightly with 240-grit aluminum oxide cloth. (This is not necessary on the internal surfaces of heat-shrinkable sleeving, boots, or transitions with ID less than 0.25 inch.) Clean the sanded surfaces with a wiper with solvent and wipe dry immediately with a clean wiper. Be careful not to put contamination on cleaned areas.

用240目氧化铝布轻轻打磨热缩零件的粘接表面。(热缩套管、套管或内径小于0.25英寸的过渡件的内部表面无需打磨。) 用溶剂蘸湿的刷子清洁打磨表面,并立即用干净的刷子擦干。注意不要将污染物弄到已清洁的区域。

(a) Prepare inner bonding surfaces of heat-shrinkable boots and transitions before you shrink them.

在收缩热缩套管和过渡段之前,先准备好其内粘结表面。

(b) Prepare outer bonding surfaces of heat-shrinkable sleeves after you shrink them. The sanded area must be larger than the bond area by 0.25 inch minimum.

在收缩热缩套管之后,准备好其外粘结表面。打磨区域必须比粘结区域至少大0.25英寸。

(3) Clean the bonding surfaces of connectors with a wiper wet with solvent and wipe dry immediately with a clean wiper. Be careful not to put contamination on cleaned areas.

用蘸有溶剂的刷子清洁连接器的粘接表面,并立即用干净的刷子将其擦干。注意不要将污染物弄到清洁的区域。

(4) Mix these adhesive components together for approximately 3 minutes.

将这些粘合剂组分混合约3分钟。

(a) S-1005 or S-1006: Mix 33-37 parts by weight of Component A with 62-68 parts by weight of Component B.

S-1005或S-1006:按重量比,将33-37份A组份与62-68份B组份混合。

(b) S-1009: Mix 48-52 parts by weight of Component A with 48-52 parts by weight of Component B.

S-1009:按重量比,将48-52份A组份与48-52份B组份混合。

(5) The pot life of the mixed adhesive is approximately 1 hour at 60-80°F. But small quantities of the mixed adhesive, not more than 25 grams each, can be kept up to a maximum of 20 days in refrigerated storage, colder than -40°F, immediately after they are mixed. If you do this, be sure to put a label on each container which gives the data of Paragraph 3.E. When you thaw such units, do not put them back into refrigerated storage again.

混合后的粘合剂在60-80°F的温度下可使用约1小时。但少量混合后的粘合剂(每份不超过25克)可在混合后立即冷藏保存,最长可保存20天,但温度不得低于-40°F。如果这样做,请务必在每个容器上贴上标签,标明第3.E段中的数据。当您解冻这些单元时,不要再次将其放入冷藏室。

(6) Apply a thin, continuous layer of adhesive to all surfaces to be bonded.

在所有需要粘合的表面上涂上一层薄薄的连续粘合剂。

(7) Put boots and transitions in position and shrink them as specified in BAC5155 (SOPM 20-11-03 or SOPM 20-12-01).

将套管和过渡件放置到位,并按照 BAC5155(SOPM 20-11-03 或 SOPM 20-12-01)的规定进行收缩。

(8) Immediately after you shrink the boots and transitions, wipe off the unwanted adhesive at the joints with a wiper wet with naphtha or BMS 11-7 solvent. Do not let fillets of adhesive be at joints.

在收缩套管和过渡件后,立即用蘸有石脑油或 BMS 11-7 溶剂的刷子清除接头处多余的粘合剂。 不要让粘合剂在接头处形成圆角。

(9) Do not bend or stress the bonded joints during the cure. Cure the adhesives as follows:

在固化过程中,不要弯曲或挤压粘合的接缝。粘合剂的固化方法如下:

(a) Cure adhesives S-1005 and S-1006 for 1 hour minimum at 180°F or for 24 hours minimum at 65-100°F.

粘合剂 S-1005 和 S-1006 至少在 180°F 下固化 1 小时,或在 65-100°F 下固化 24 小时。

(b) Cure adhesive S-1009 for 1 hour minimum at 250°F, 2 hours minimum at 200°F, or 4 days at 60-100°F.

固化粘合剂S-1009在250°F下至少固化1小时,在200°F下至少固化2小时,或在60-100°F下固化4天。

AE. Type 67 (Deleted)

类型67(已删除)

AF. Type 68

类型68

(1) Materials

材料

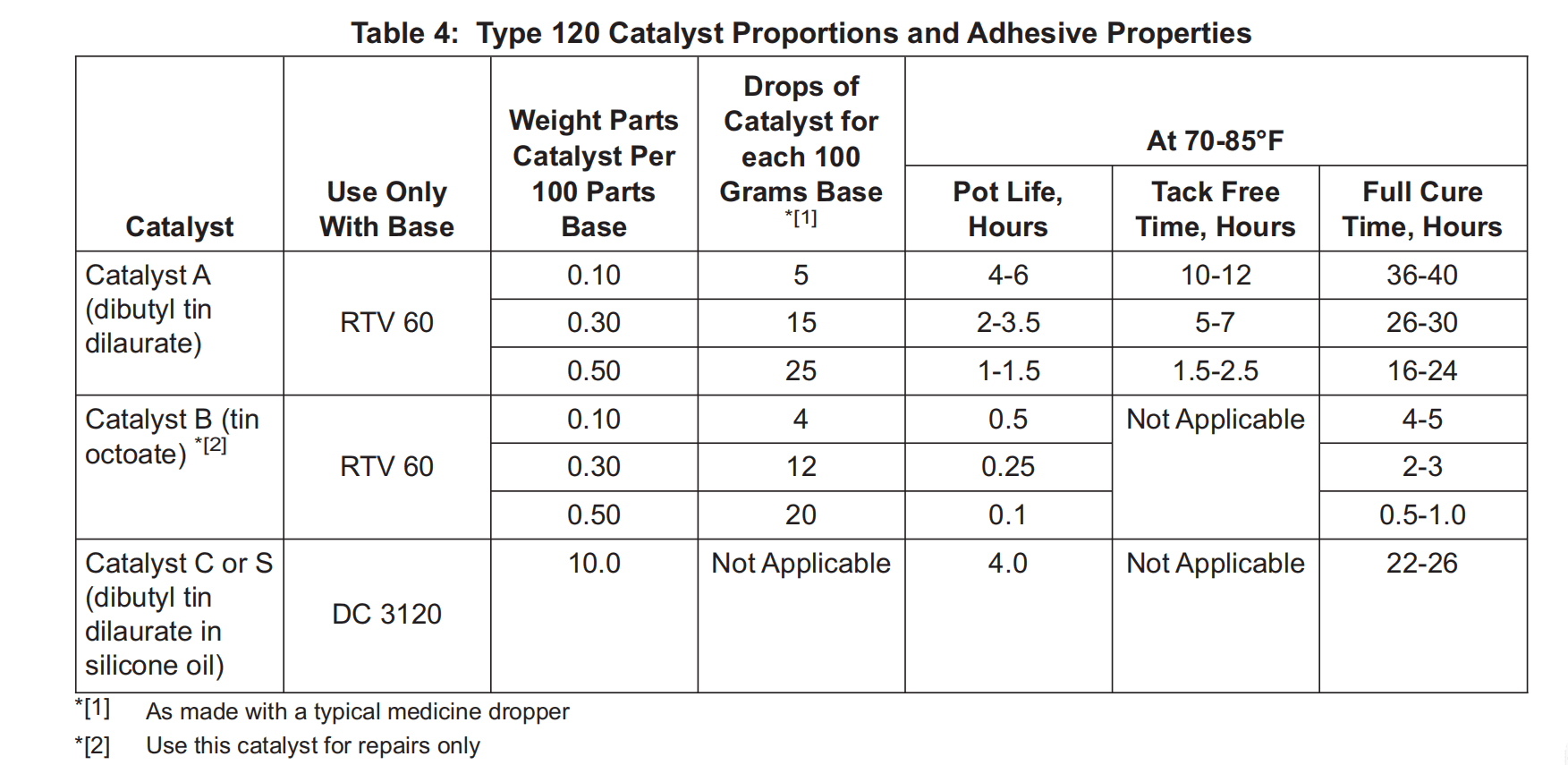

(a) 93-076 Adhesive

93-076粘合剂

1) 93-076 Base

93-076 基料

2) 93-076-2 Catalyst

93-076-2 催化剂

3) PR-1204 Primer

PR-1204 底漆

4) Fascat 4202 Primer

Fascat 4202 底漆

(b) RTV 430 Adhesive

RTV 430 粘合剂

1) RTV 430 Base

RTV 430 基料

2) Beta 5 or Beta 11-D1 Catalyst

Beta 5 或 Beta 11-D1 催化剂

3) SS4155 Primer

SS4155 底漆

(2) Clean the mating surfaces as specified in Paragraph 4. Lightly sand silicone rubber surfaces first, then clean them as specified in Paragraph 4.

按照第4段规定清洁配合表面。首先轻轻打磨硅橡胶表面,然后按照第4段规定进行清洁。

(3) Apply a thin, continuous layer of primer to the surfaces to be bonded. Use a brush, spray, or wipe the primer on.

在待粘合的表面涂上一层薄薄的连续底漆。使用刷子、喷雾器或抹布涂抹底漆。