防腐蚀粘合剂底漆的应用

APPLICATION OF CORROSION INHIBITING ADHESIVE PRIMER

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5514-589. Access to the Boeing Process Specifications is available.

本主题中的数据来自波音工艺规范 BAC5514-589。可访问波音工艺规范。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum standards.

数据为通用数据。不适用于所有情况或特定安装。使用这些数据来帮助您制定最低标准。

C. BMS 5-89 corrosion inhibiting adhesive primer is a solvent-based primer that gives a transparent but corrosion-resistant coating while it makes a good base for metal-to-metal adhesives. In a structural assembly where some surfaces are bonded together and others are not, this primer is applied to all surfaces. It then becomes the protection from corrosion for the complete structure, unless more protection is specified. Then a different primer, such as BMS 10-11 or BMS 10-79, can be applied on the BMS 5-89 layer.

BMS 5-89 防腐蚀粘合剂底漆是一种溶剂型底漆,可形成透明且耐腐蚀的涂层,同时为金属与金属粘合剂提供良好的基础。在结构组件中,有些表面粘合在一起,而有些表面没有粘合,这种底漆适用于所有表面。它将成为整个结构的防腐保护层,除非另有规定。然后,可以在BMS 5-89层上涂覆另一种底漆,例如BMS 10-11或BMS 10-79。

D. The BMS 5-89 primer comes in three types. Type 1 is a solvent-based, heat cured primer. Type 1 is divided into Grade A, a one- or two-part primer with low solids content and Grade B, a one- or two-part primer with high solids content. Type 2 is a one-part primer with zero volatile organic compound. Type 3 is a one-part primer with low volatile organic compound.

BMS 5-89 底漆有三种类型。类型 1 是一种溶剂型热固化底漆。类型 1 又分为 A 级(一种或两种组分的低固体含量底漆)和 B 级(一种或两种组分的高固体含量底漆)。类型 2 是一种零挥发性有机化合物的单组分底漆。类型 3 是一种低挥发性有机化合物的单组分底漆。

E. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

供应商名称和地址列表请参阅SOPM 20-00-00。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

备注:可使用等效替代品。

A. Corrosion inhibiting adhesive primer – BMS 5-89

防腐蚀粘合底漆——BMS 5-89

(1) Type 1, Grade A — sprayable

类型1,等级A——可喷涂

(2) Type 1, Grade B — roll coatable

类型1,等级B——可辊涂

(3) Type 2

类型2

(4) Type 3

类型3

B. Primer — BMS 10-11, Type 1, Color Y

底漆——BMS 10-11,类型1,颜色Y

C. Tape — Permacel P743, V99742

胶带——Permacel P743,V99742

D. Tape — CP 743, V4L0S0

胶带——CP 743,V4L0S0

E. Polyethylene film — carbon-black filled, 0.006-inch minimum thickness

聚乙烯薄膜——填充碳黑,最小厚度0.006英寸

F. Polyethylene film — 0.002-inch minimum thickness

聚乙烯薄膜——最小厚度0.002英寸

G. Mixture of 42 volume parts MEK with 58 volume parts sec-butyl alcohol

按体积比42份MEK与58份仲丁醇的混合物

H. Film, moisture resistant laminated opaque — Dry Pack No. 3600, V1E893

防潮层压不透明薄膜——Dry Pack No. 3600, V1E893

3. PREPARATION 准备

A. Preparation of the Surface

表面处理

(1) BMS 5-89 primer is usually applied only on surfaces phosphoric anodized per BAC5555. If the surfaces have defects or waited too long after they were anodized, they must be stripped and anodized again. Refer to BAC5555 for details.

BMS 5-89底漆通常仅用于根据BAC5555进行磷阳极氧化处理的表面。如果表面有缺陷或阳极氧化后等待时间过长,则必须将其剥离并重新阳极氧化。详情请参阅BAC5555。

(2) Chromic acid anodize is not permitted as a surface preparation before application of BMS 5-89 primer.

在涂覆BMS 5-89底漆之前,不允许使用铬酸阳极氧化作为表面处理。

B. Storage and Handling

储存和处理

(1) Store BMS 5-89 primer for these maximum times from date of shipment:

自发货之日起,BMS 5-89底漆的储存时间不得超过以下期限:

(a) Type 1, one-part primer: 9 months at 0°F maximum or 2 months at 40°F maximum.

类型1,单组份底漆:在0°F下最长可存放9个月,或在40°F下最长可存放2个月。

(b) Type 1, two-part primer: 9 months at 40°F maximum, or 6 months (Grade A), or 3 months (Grade B) at 90°F maximum.

类型1,双组份底漆:在40°F下最长可存放9个月,或在90°F下最长可存放6个月(A级)或3个月(B级)。

(c) Type 2, one-part primer: 12 months at 40°F maximum or 30 days at 90°F maximum.

类型2,单组份底漆:40°F时最长12个月,或90°F时最长30天。

(d) Type 3, one-part primer: 12 months at 40°F maximum or 7 days at 90°F maximum.

类型3,单组份底漆:40°F时最长12个月,或90°F时最长7天。

(e) For Types 2 and 3, the storage temperature is 35-55°F.

对于类型2和3,储存温度为35-55°F。

(2) Type 1, Grade A or unmixed Type 1, Grade B, or Type 2 or Type 3 material can be removed from refrigeration a maximum of 6 times.

类型1、A级或未混合的类型1、B级或类型2或类型3材料最多可从冷藏中取出6次。

(3) When you remove BMS 5-89 primer from refrigeration, let it get back to 65-90°F before you open the container to be sure moisture does not condense on the material. Close the container before you put it back in refrigeration.

当您从冷藏中取出BMS 5-89底漆时,请确保在打开容器前,温度恢复到65-90°F,以防止材料上凝结水汽。在重新放入冷藏前,请关闭容器。

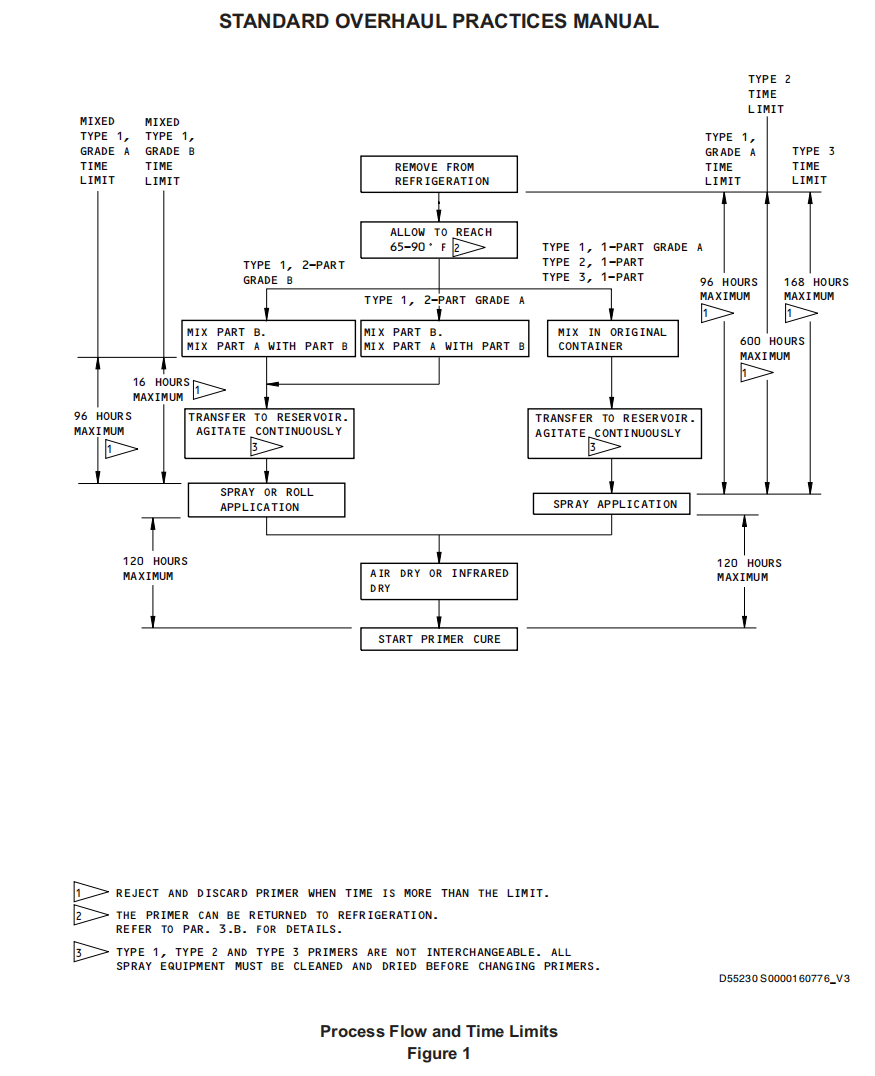

(4) See Figure 1 for time limits in the procedure for the application of the BMS 5-89 primer.

有关BMS 5-89底漆应用程序的时间限制,请参见图1。

C. Mixing

混合

WARNING :BMS 5-89 PRIMER IS VERY POISONOUS AND VERY FLAMMABLE. THE FLASH POINT IS VERY LOW (APPROXIMATELY 43°F (6°C). USE ONLY WITH ADEQUATE VENTILATION. DO NOT BREATHE THE MIST OR VAPOR. DO NOT LET THE PRIMER TOUCH EYES, SKIN, OR CLOTHING.

警告:BMS 5-89底漆毒性很强,极易燃。闪点很低(约43°F (6°C))。使用时请充分通风。不要吸入雾气或蒸汽。不要让底漆接触眼睛、皮肤或衣物。

(1) One-part primer

单组份底漆

(a) Immediately before you use it, fully mix each container on a vibrating paint mixer. Mix quart-size containers for a minimum of 5 minutes; mix gallon or larger containers for a minimum of 15 minutes.

使用前,在振动涂料混合器上充分混合每个容器。混合每夸脱容量的容器至少5分钟;混合加仑或更大容量的容器至少15分钟。

(b) Spray equipment must include continuous agitation in the container and recirculation in the hose during operation. If the agitation stops, the material must be mixed again for a minimum of 2 minutes before you continue.

喷涂设备在操作过程中必须包括容器内的持续搅拌和在软管内再循环。如果搅拌停止,则必须再次混合至少2分钟,然后才能继续。

(2) Two-part primer

双组份底漆

(a) Warm containers to 65-90°F. Shake the smaller volume container (Part B) on a paint mixer for 5 minutes minimum. Then add it to the larger volume component (Part A) within 5 minutes. Make sure that all solids in Part B were added to Part A.

将容器加热到65-90°F。在油漆搅拌机中摇晃较小容积的容器(B组份)至少5分钟。然后在5分钟内将其添加到较大容积的组分(A组份)中。确保将B组份中的所有固体都添加到A组份中。

(b) Shake the mixed parts A and B on a paint shaker for 15 more minutes minimum.

在油漆振动器中再摇晃混合后的A组份和B组份至少15分钟。

(c) Within 10 minutes after this mixing, put the mixed primer into the reservoir of the equipment and start agitation to prevent settling.

混合后10分钟内,将混合好的底漆倒入设备的容器中并开始搅拌,防止沉淀。

(d) Do not use material that has lumps or becomes a gel.

不要使用有结块或变成凝胶的材料。

4. APPLICATION 应用

A. With spray equipment

使用喷涂设备

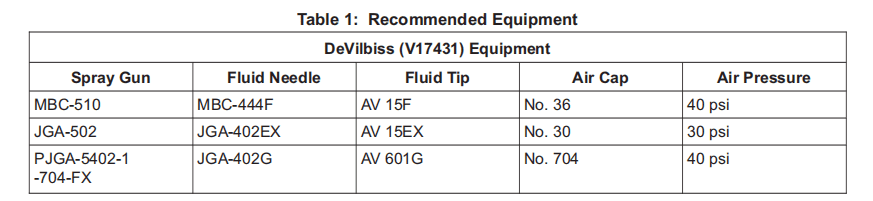

(1) Apply the BMS 5-89 primer to make a cured film thickness of 0.00015-0.00040 inch (0.15-0.40 mil). See Table 1 for recommended equipment. Primed surfaces that will not be bonded must have a coating of 0.00015 inch minimum. There is no maximum thickness limit but no runs are permitted.

喷涂BMS 5-89底漆,固化后的漆膜厚度为0.00015-0.00040英寸(0.15-0.40密耳)。推荐的设备见表1。未粘结的底漆表面必须至少涂0.00015英寸的涂层。没有最大厚度限制,但不允许出现流挂。

(a) Coating of edges is not necessary on parts with thicknesses up to 0.080 inch. Over-spray is permitted. Edges greater than 0.080-inch in thickness must be coated, unless these edges will be painted with BMS 10-11, Type 1 or BMS 10-79 primer.

厚度不超过 0.080 英寸的零件无需边缘涂层。允许过喷。厚度超过 0.080 英寸的边缘必须进行涂层,除非这些边缘将使用 BMS 10-11、类型 1 或 BMS 10-79 底漆进行喷涂。

(b) Coatings up to 0.0008-inch thick are permitted on areas within 1/4 inch of edges, 1/4 inch around holes, and 1/4 inch around areas touched by holding fixtures.

边缘1/4英寸范围内、孔洞周围1/4英寸范围内以及固定装置接触区域周围1/4英寸范围内的涂层厚度允许达到0.0008英寸。

(c) If the BMS 5-89 primer layer is thinner than the minimum thickness (0.00015 inch), you can apply a second layer to increase the BMS 5-89 primer thickness to the minimum value before baking. But the two layers must be cured within 120 hours after you apply the first layer.

如果BMS 5-89底漆层比最小厚度(0.00015英寸)薄,可以在烘烤前涂覆第二层,将BMS 5-89底漆厚度增加到最小值。但两层底漆必须在涂覆第一层后的120小时内固化。

(d) Bare spots caused by contact points of part clamps must not be more than 3/32-inch diameter in any dimension, except that one contact point at each clamp can be 1/8-inch diameter.

零件夹具接触点造成的裸露点,其直径不得超过 3/32 英寸,但每个夹具的一个接触点直径可为 1/8 英寸。

(2) Type 1, 2 or 3 primer can be cured in an oven outside the controlled contamination area, but the parts must have protection from airborne contamination and be outside the controlled area for no more than 30 minutes before they are put into the oven.

类型1、2或3的底漆可在受控污染区域外的烘箱中固化,但零件必须防止空气传播的污染,且在放入烘箱前在受控区域外的暴露时间不得超过30分钟。

(a) For Type 1 primer, air dry the primer a minimum of 30 minutes, or dry with infrared lamps until tack free at 200°F maximum coating temperature. Within 120 hours after coating, cure the primer at 240-260°F coating temperature for 30-120 minutes.

对于类型1底漆,在最高200°F的涂层温度下,至少风干30分钟,或用红外线灯烘干至不粘。在涂层后的120小时内,在240-260°F的涂层温度下固化底漆30-120分钟。

(b) For Type 2 primer, let the water flash off before curing the primer. Within 120 hours of coating, cure the primer at 240-260°F coating temperature for 30-120 minutes.

对于类型2底漆,在固化底漆前让水闪干(蒸发)。在涂覆后的120小时内,在240-260°F的涂覆温度下固化底漆30-120分钟。

NOTE: It is optional to heat stabilize the Type 2 primed surfaces before curing at a maximum temperature of 200°F for a maximum of 15 minutes before coating the reverse side.

注意:可选择在2型底漆表面固化前,在200°F下热稳定固化处理最多15分钟,然后涂覆背面。

(c) For Type 3 primer, let the water flash off before curing the primer. Air dry the primer at a minimum temperature of 70°F for at least 15 minutes before curing. Within 120 hours of coating, cure the primer at 250-270°F coating temperature for 30-120 minutes.

对于类型3底漆,在固化底漆前,让水闪干。在固化前,在最低70°F的温度下风干底漆至少15分钟。在涂覆后的120小时内,在250-270°F的涂覆温度下固化底漆30-120分钟。

(3) Coated and cured parts can be bonded as-is, if they were kept in the controlled contamination area for less than 30 days.

如果涂覆和固化后的零件在受控污染区域保存时间少于30天,则可以原样粘合。

(4) Parts with cured BMS 5-89 primer can be stored for 60 months maximum when they have the protection of one or more of these:

涂覆了固化后的BMS 5-89底漆的零件,如果受到以下一种或多种保护措施的保护,则最长可保存60个月:

(a) Wrapped individually or in groups with clean oil-free kraft paper, paper bags, cardboard, or black carbon-filled polyethylene (0.006-inch minimum). (Rubber or vinyl film is not approved.)

单独或成组地用干净的无油牛皮纸、纸袋、纸板或填充有黑色碳的聚乙烯(最小厚度为0.006英寸)包裹。(橡胶或乙烯薄膜不被批准使用。)

(b) Stacked with the top part covered if all surfaces to be bonded have protection.

如果所有待粘接的表面都有保护,则顶部覆盖堆放。

(c) Unstacked on covered shelves. The shelf covers must enclose the shelf and must be opaque to ultraviolet light.

堆叠在带盖的货架上。货架盖必须覆盖整个货架,且必须不透紫外线。

(d) With P743 or CP 743 tape on the bond surfaces.

在粘合表面使用 P743 或 CP 743 胶带。

(5) Parts with cured BMS 5-89 primer that were bonded, stored more than 30 days, or stored outside the controlled contamination area must be cleaned before they are bonded again. Vapor degrease the parts per SOPM 20-30-03 or wipe them with a Series 97 solvent (Ref SOPM 20-30-97), wipe dry, wipe again with a Series 97 solvent (Ref SOPM 20-30-97) and again wipe dry. Do not let the parts air dry.

经过固化 BMS 5-89 底漆处理的零件,如果粘合、存放超过 30 天,或存放在受控污染区域之外,则必须在再次粘合前进行清洁。按照SOPM 20-30-03对零件进行蒸汽脱脂,或用97系列溶剂擦拭(参考SOPM 20-30-97),擦干后再次用97系列溶剂擦拭(参考SOPM 20-30-97),再擦干。不要让零件风干。

(6) For surfaces with cured BMS 5-89 primer which are not bonded, give the parts protection during storage and shipment per SOPM 20-44-02.

对于涂有固化BMS 5-89底漆但未粘接的表面,在存放和运输过程中应按照SOPM 20-44-02进行保护。

(7) Parts with cured BMS 5-89 primer can be stored 20 years from application date when given the protection of laminated, opaque moisture-resistant film and then vacuum sealed. Be sure to put the primer application date on the outside of the wrapper.

涂有固化BMS 5-89底漆的零件,如果用不透光的防潮薄膜进行层压保护,然后真空密封,则自涂覆之日起可存放20年。请务必在包装外部注明底漆的涂覆日期。

B. With Roll Coating Equipment

使用辊涂设备

(1) The roll coating equipment used to apply Type 1, Grade B primer must include:

用于涂覆类型1、等级B底漆的辊涂设备必须包括:

(a) Continuous agitation of the primer reservoir.

底漆储罐的持续搅拌。

(b) Continuous circulation of primer between the rolls and the reservoir during coating.

涂覆过程中底漆在滚筒和储罐之间的持续循环。

(c) Continuous automatic viscosity control.

持续自动粘度控制。

(2) More primer can be added to the system to replace material used during a coating run. But no primer can stay in the system more than 18 hours after the first addition to the reservoir. At the end of this 18-hour time or at the end of the coating run, whichever occurs first, discard all remaining primer and fully clean the equipment.

可在系统中添加更多底漆,以替换涂层运行期间使用的材料。但任何底漆在首次添加到储罐后,在系统中的停留时间不得超过18小时。在这18小时结束时或涂层运行结束时(以先发生者为准),应丢弃所有剩余的底漆并彻底清洁设备。

(3) Fully clean the equipment before you change from one supplier’s material to another.

在更换供应商的材料之前,应彻底清洁设备。

(4) Drying, curing film thickness, storage, and handling requirements for roll coated primer are the same as for spray primer. To apply primer to two sides of a part, dry the first coated surface tack free before you coat the second surface. Do not oven cure before you coat the second side. The oven cure for the part must start within 120 hours after the first surface is coated.

辊涂底漆的干燥、固化膜厚度、储存和处理要求与喷涂底漆相同。若要在零件的两面涂底漆,则应在涂第二面之前使第一面干燥至无粘性。涂第二面之前不要进行烘箱固化。零件的烘箱固化必须在第一面涂漆后 120 小时内开始。

5. IN-PROCESS CORRECTION 过程中修正

A. Contamination before the primer cure

底漆固化前的污染

(1) Remove all of the primer with a Series 97 solvent (Ref SOPM 20-30-97).

用97系列溶剂(参考SOPM 20-30-97)清除所有底漆。

(2) Prepare the surface per Paragraph 3. and apply the primer again per Paragraph 4.

按照第3段所述准备表面,并按照第4段所述重新涂覆底漆。

B. Surface damage or shop dirt contamination of the cured primer layer

固化底漆层的表面损伤或车间污垢污染

(1) For dirt contamination or damage such as scratches in the coating that do not go through to the bare metal, wipe with a Series 97 solvent (Ref SOPM 20-30-97) and cheesecloth. Wipe dry. Wipe again with a Series 97 solvent (Ref SOPM 20-30-97). Wipe dry.

对于污垢污染或划痕等不深入金属的涂层损伤,请使用97系列溶剂(参考SOPM 20-30-97)和粗棉布擦拭。擦干。再用97系列溶剂(参考SOPM 20-30-97)擦拭。擦干。

(2) For surface damage in the primer layer that goes down to the bare metal:

对于底漆层中延伸到裸金属的表面损伤:

(a) Areas to be bonded which were phosphoric anodized per BAC5555:

按照 BAC5555 进行磷阳极氧化处理的待粘接区域:

1) Areas bare because of anodize clamps are acceptable as in Paragraph 4.A.(1)(d).

阳极氧化夹具导致的裸露区域可接受,如第 4.A.(1)(d) 段所述。

2) Areas of damage 0.25 square inch or less, not nearer than 0.15 inch from an exposed bonded edge: Clean the surface and apply a primer by the procedure for treating multistage assemblies in BAC5514. Only one correction per square foot of bonded area is permitted. If the bonded area is less than 1 square foot, one correction is permitted.

面积小于等于0.25平方英寸的损伤区域,且距离外露的粘接边缘不小于0.15英寸:按照BAC5514中处理多级组件的程序清洁表面并涂上底漆。每平方英尺的粘接区域只允许进行一次修正。如果粘接区域小于1平方英尺,则只允许进行一次修正。

3) Scratches and other defects on 0.3% of the total bonded area or less, not nearer than 0.15 inch from an exposed bonded edge: Wipe the damaged area two times with methyl ethyl ketone as in Paragraph 5.B.(1) above. Then touch up the area with a thin, manually-applied layer of BMS 5-89 primer. Let this air dry 30 minutes minimum. The touched-up area must not be more than 2% of the total area to be bonded.

划痕和其他缺陷占粘合总面积的0.3%或更少,且距离外露的粘合边缘不少于0.15英寸:用甲基乙基酮擦拭受损区域两次,如上文第5.B.(1)段所述。然后用手工涂抹一层薄薄的BMS 5-89底漆进行修补。至少晾干30分钟。修补面积不得超过待粘接总面积的2%。

(b) Unbonded areas — Colored chemical treat Type 2, Class A per SOPM 20-43-03. (This chemical treatment is optional on trimmed edges.) Then touch up with BMS 10-11, Type 1, Color Y per SOPM 20-41-02.

未粘接区域——根据SOPM 20-43-03进行2类A级有色化学处理。(该化学处理在边缘修整时可选。)然后根据SOPM 20-41-02进行1类Y色BMS 10-11修补。

6. QUALITY CONTROL 质量控制

A. Because of the aluminum alloy, surface condition, and the prebonding treatment, the color of a cured layer of BMS 5-89 primer can be from transparent to yellowish, or a light gold almost the same as Alodine 1200 chemical conversion coating. A correctly applied coating will be glossy.

由于铝合金、表面状况和预粘处理,固化后的BMS 5-89底漆颜色可能从透明到淡黄色,或与Alodine 1200化学转化涂层几乎相同的浅金色。正确涂覆的涂层应具有光泽。

B. BMS 5-89 primer coatings with scratches that go through to the bare metal in areas to be bonded are not acceptable.

BMS 5-89底漆涂层在需要粘合的区域有划痕,划痕直达裸金属,这种情况是不可接受的。

7. REMOVAL OF CURED LAYERS 固化涂层的去除

A. Remove cured BMS 5-89 primer per SOPM 20-30-02 by the same procedure as specified for BMS 10-11 primer.

按照SOPM 20-30-02的规定,使用与BMS 10-11底漆相同的程序去除固化后的BMS 5-89底漆。