复合材料结构中的紧固件安装FASTENER INSTALLATION IN COMPOSITE STRUCTURES

1. INTRODUCTION 介绍

A. The data in this subject comes from BAC 5063. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自 BAC 5063。航空公司有一份《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum requirements.

数据是通用的。它并不适用于所有情况或特定安装。使用这些数据来帮助您编写最低要求。

C. Refer to SOPM 20-00-00 for a full list of all the vendor names and addresses.

供应商名称和地址的完整列表请参阅 SOPM 20-00-00。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

注:可以使用等效替代品。

A. Lubricants

润滑剂

(1) Freon, oil-free

氟利昂、无油

(2) Cetyl alcohol

十六烷醇

(3) Freon TB-1

TB-1 氟利昂

(4) Microcut 26

B. Unidirectional tape

单向胶带

(1) BMS 8-212, Class 1

(2) BMS 8-256

(3) BMS 8-297

C. Sealant

密封剂

(1) BMS 5-95

3. EQUIPMENT 设备

NOTE: Equivalent substitutes can be used.

注:可使用等效替代品。

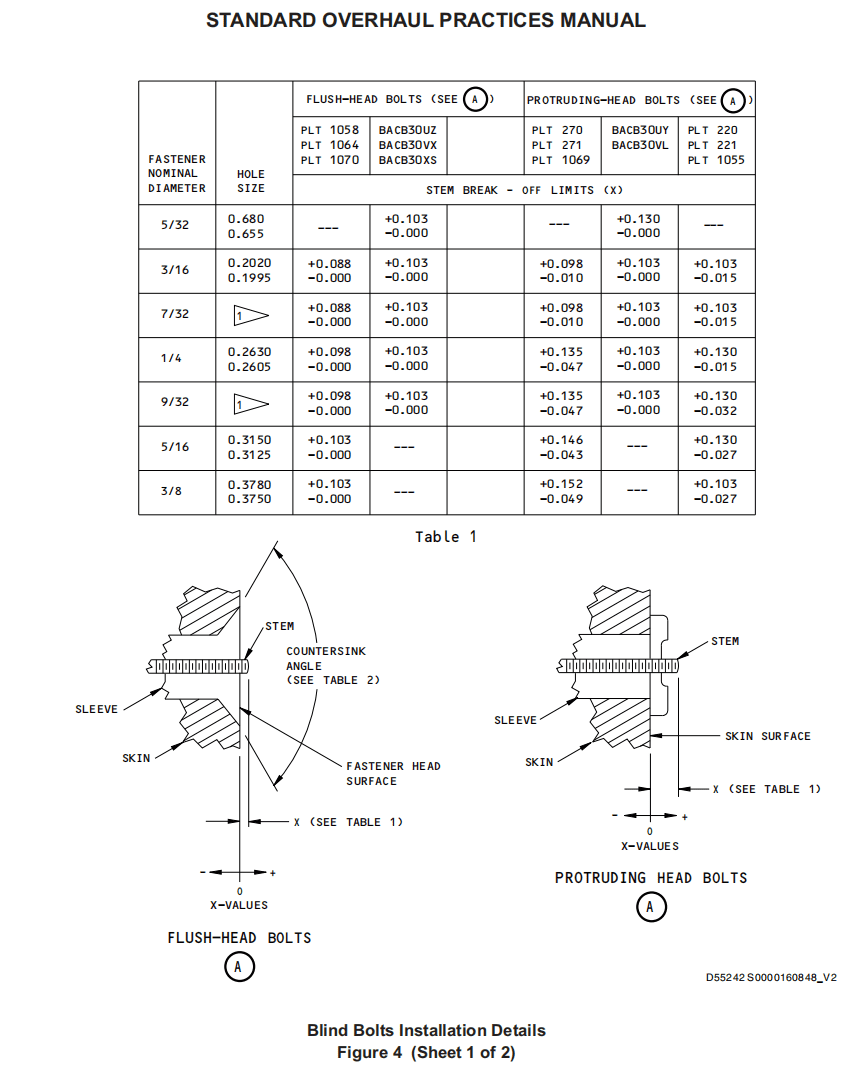

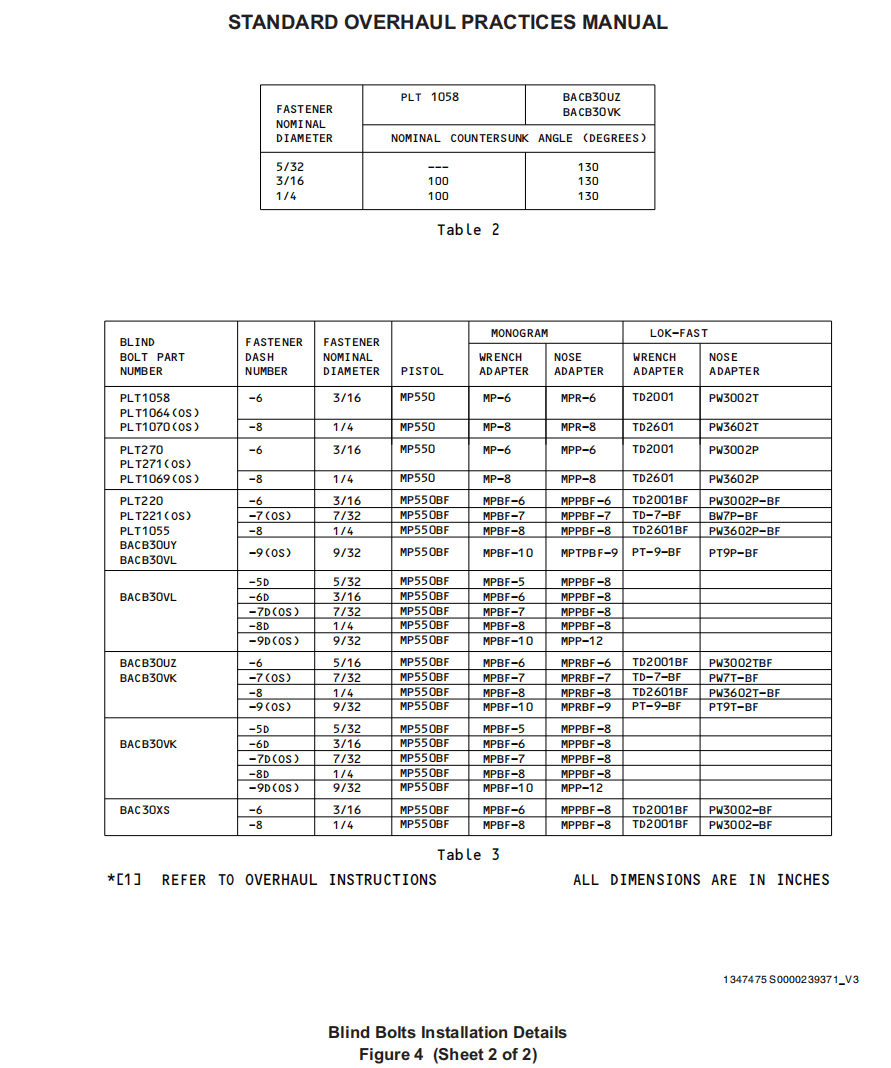

A. Blind bolts — See Figure 4.

盲螺栓——见图4。

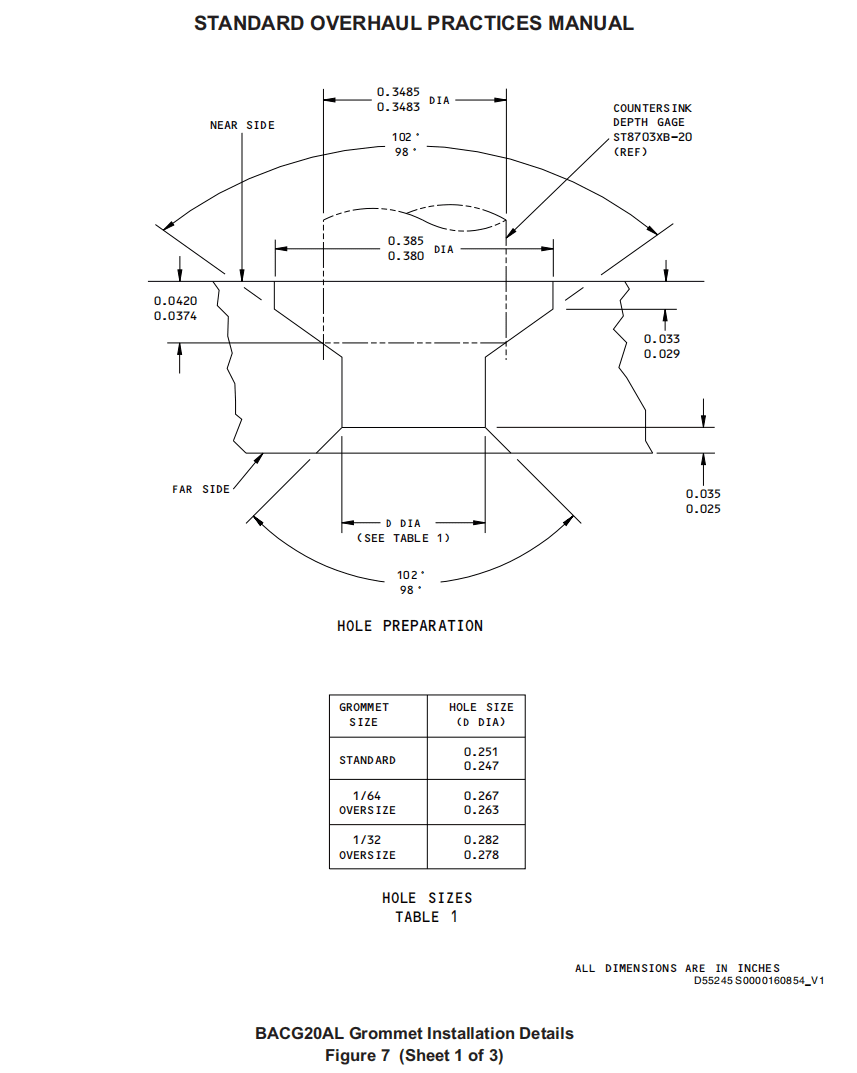

B. BACG20AL grommets:

BACG20AL 索环(扣眼)

(1) ST 1221C-CH countersink cutter

ST 1221C-CH埋头刀

(2) ST 8703XB-20 countersink depth gage

ST 8703XB-20埋头深度尺

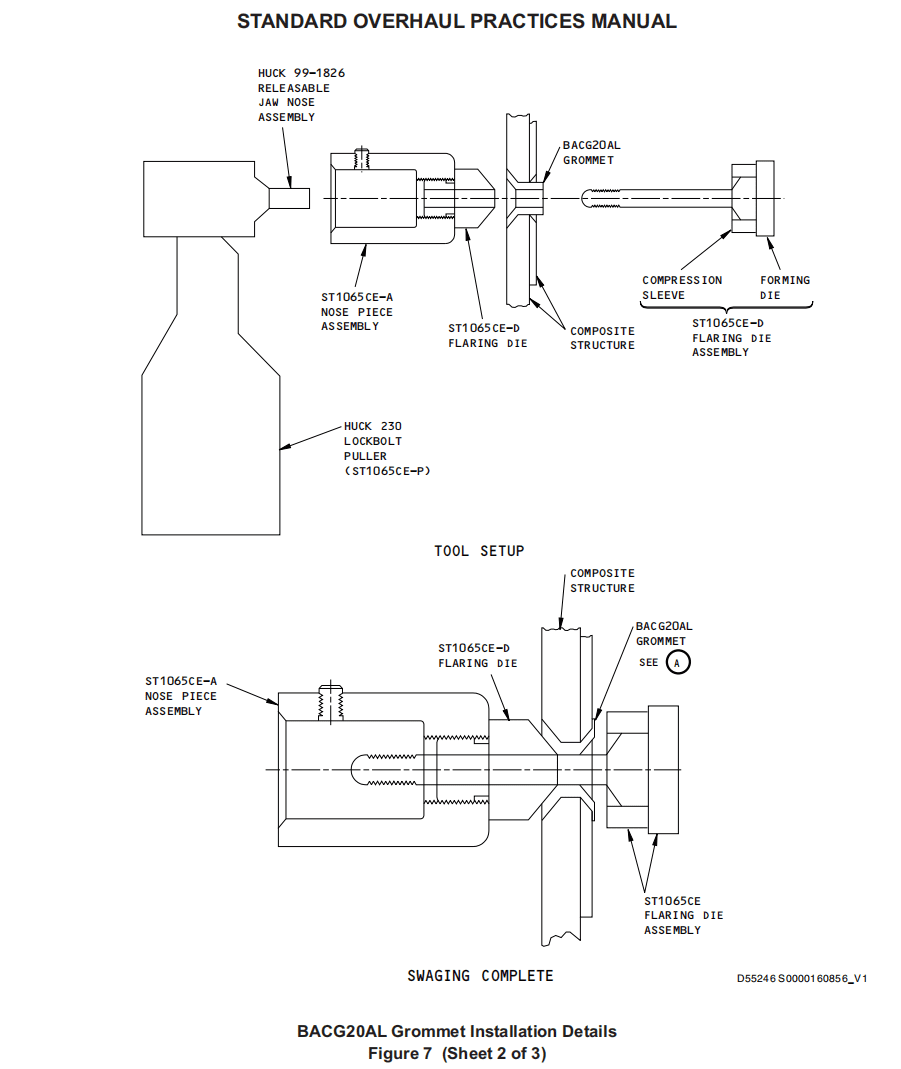

(3) Installation tools — See Figure 7

安装工具——见图7

(4) ST 1233H spotface cutter

ST 1233H平面铣刀

(5) ST 1257B drill

ST 1257B钻头

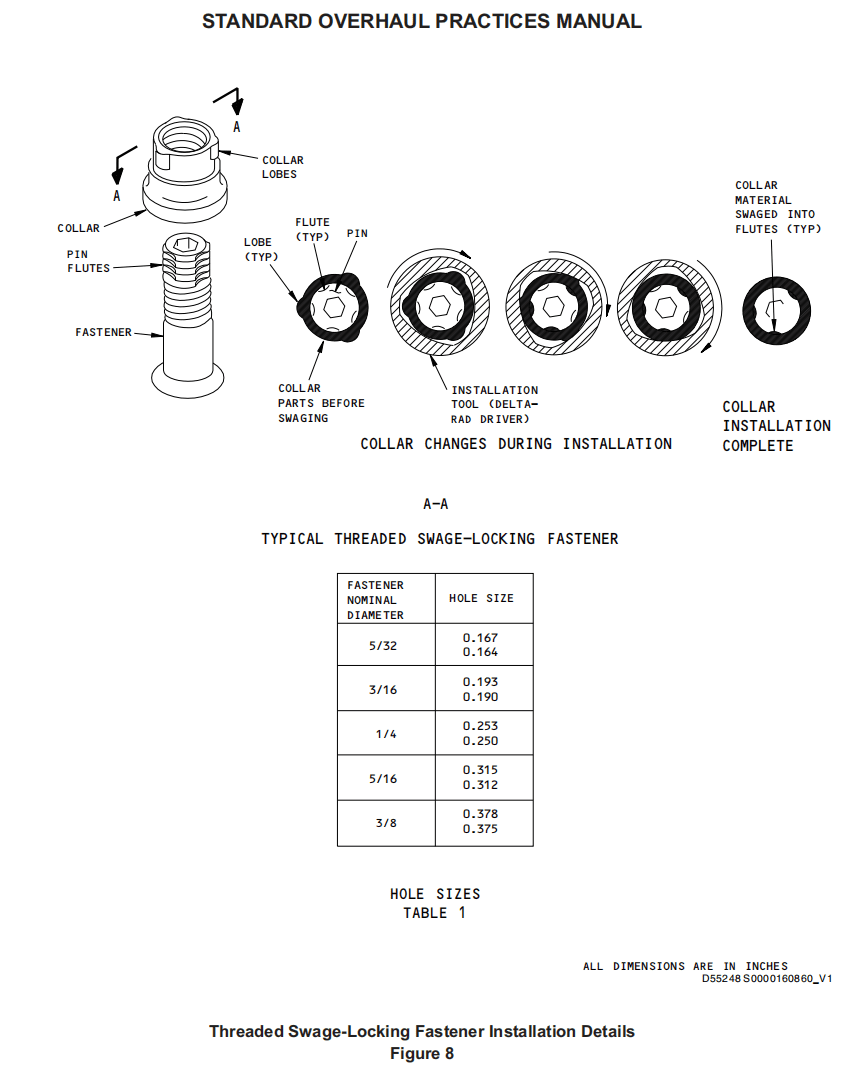

C. Threaded swage-locking fasteners — See Figure 8

螺纹压铆锁紧紧固件——见图8

4. GENERAL 通用

A. Clamp the components tightly together to prevent a gap between the components at the hole location while the hole is made.

在钻孔时,将部件紧密夹紧,防止部件在孔位置出现间隙。

B. Fastener holes must be perpendicular, within 2 degrees, to the surface against which the installed fastener will bear.

紧固件孔必须与紧固件安装表面垂直,且垂直度误差不得超过2度。

C. Fillet relief

圆角消除

(1) Fillet relief of fastener holes in composite structures is not permitted, unless the holes are for BACB30VG-series bolts installed with a decreased torque (usually in honeycomb structure):

复合结构中的紧固件孔不允许有圆角消除,除非孔用于以减小扭矩安装的BACB30VG系列螺栓(通常用于蜂窝结构):

(2) If the holes are for BACB30VG bolts, give the hole edges a radius or chamfer as shown in Figure 1.

如果孔用于BACB30VG螺栓,则如图1所示,在孔边缘加上半径或倒角。

(3) Fillet relief of holes for BACB30VG bolts must not cause fibers to break out of the external ply, unless within the limits specified in BAC 5063, Section 11.

BACB30VG螺栓孔的圆角消除不得导致纤维从外部层中断裂,除非在BAC 5063第11节规定的范围内。

(4) For fillet relief of holes for protruding-head fatigue-rated bolts, use countersunk washers per Table 4. A fatigue-rated bolt has an F in the class number, such as class number 200FC( ) for bolts BACB30LE or BACB30US.

对于突出头疲劳强度螺栓孔的圆角消除,请按照表4使用沉头垫圈。疲劳强度螺栓的等级编号中有一个F,例如,BACB30LE或BACB30US螺栓的等级编号为200FC( )。

(5) Where the fastener head bears against metal structure, use a fillet relief procedure or countersunk washer per BAC 5009(for bolts) or BAC 5004-2 (for hex drive fasteners and lockbolts) as necessary, for an acceptable gap between the fastener head and the surface of the part. Refer to BAC 5063, Section 11 for limits and other details.

当紧固件头部与金属结构接触时,根据需要使用圆角消除工艺或BAC 5009(适用于螺栓)或BAC 5004-2(适用于六角驱动紧固件和锁紧螺栓)规定的沉头垫圈,使紧固件头部与零件表面之间保持可接受的间隙。有关限制和其他详细信息,请参阅BAC 5063第11节。

D. Oil-free Freon, Boelube, cetyl alcohol or Freon TB-1 can be used as drill lubricants per BAC 5008 (SOPM 20-50-07). Microcut 26 can be used as a drill lubricant, but the drilled structure must be separated after the hole is made and all of the surfaces must be wiped dry with a cloth. Filtered air and carbon dioxide can be used as lubricants only when permitted by the overhaul instructions. Do not use other lubricants.

根据 BAC 5008(SOPM 20-50-07)的规定,无油氟利昂、Boelube、十六烷醇或氟利昂 TB-1 可作为钻孔润滑剂。Microcut 26 可作为钻孔润滑剂使用,但钻孔后必须将钻孔结构分开,并用布将所有表面擦干。只有在大修说明允许的情况下,过滤后的空气和二氧化碳才能作为润滑剂使用。请勿使用其他润滑剂。

E. If the drill exit will be on a surface which is BMS 8-218 Aramid 350°F cure, we recommend that unidirectional tape be applied to the surface to help prevent damage to the surface as the drill breaks through. Also, to decrease fiber breakout and increase hole quality, use backup material, controlled rates of feed and speed, and the correct drills.

如果钻孔出口位于BMS 8-218 Aramid 350°F固化表面,我们建议在表面贴上单向胶带,以防止钻孔时损坏表面。此外,为了减少纤维断裂和提高钻孔质量,请使用备用材料、控制进给率和速度,并使用正确的钻头。

F. Unless specified by the overhaul instructions, use the final hole sizes as given in this subject.

除非大修说明另有规定,否则请使用本主题中给出的最终孔尺寸。

G. Make sure all faying surfaces have no unwanted matter. Sealants or finishes are permitted as specified by the overhaul instructions.

确保所有接合表面没有多余物质。允许使用大修说明中指定的密封剂或饰面。

H. Be sure to vacuum or remove from the structure all carbon fiber particles that were made during hole preparation.

确保用真空吸尘器清理或从结构中清除孔准备过程中产生的所有碳纤维颗粒。

I. When the overhaul instructions specify a multiple-fastener installation without a tightening sequence, do not tighten the adjacent fasteners one after the other. A multiple-fastener installation is a row (5 or more fasteners in a line) or a pattern such as a circle, or multiple rows. For such installations, tighten opposite fasteners in an alternating pattern.

当大修说明中指定了多个紧固件的安装,且没有规定紧固顺序时,不要依次紧固相邻的紧固件。多个紧固件的安装是指一排(5个或更多紧固件排成一行)或一个图案,例如圆形或多排。对于此类安装,应交替紧固相对的紧固件。

J. Do not use aluminum fasteners in carbon fiber reinforced plastic (CFRP) composites, unless specified by the overhaul instructions.

除非大修说明有特别规定,否则不要在碳纤维增强塑料(CFRP)复合材料中使用铝制紧固件。

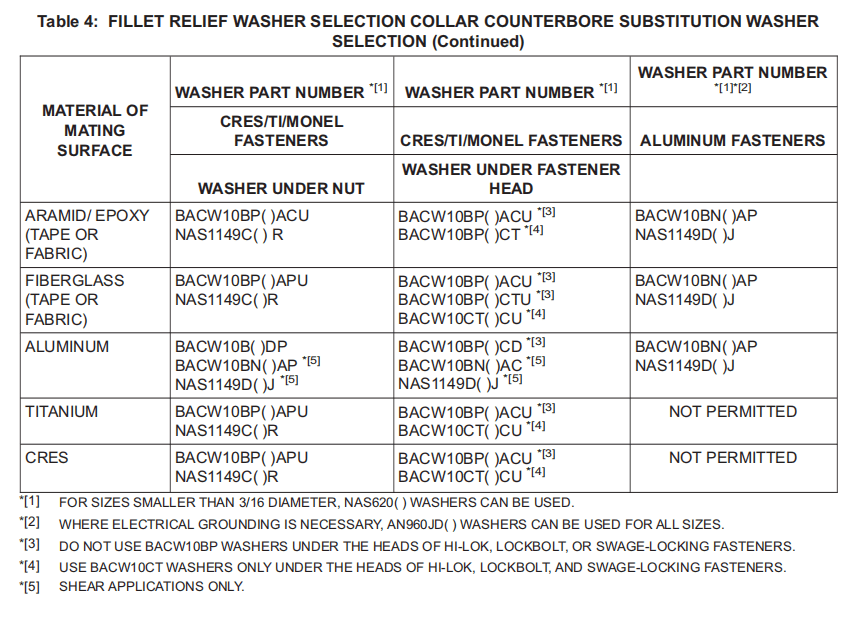

K. Do not install threaded swage-locking collars on hex drive pins. Do not install hex drive collars on threaded swage-locking pins. Although these combinations can make an installation which is apparently satisfactory, the collar will loosen and decrease the performance of the joint.

不要在六角驱动销子上安装螺纹压铆锁紧环。也不要将六角驱动锁紧环安装在螺纹压铆锁紧销子上。虽然这些组合可以完成看似令人满意的安装,但锁紧环会松动,降低连接性能。

L. When you install permanent fasteners in fay seal applications, be sure to clamp the joint to make the sealant correctly squeeze out. Use sufficient clamp pressure to prevent separation. Permanent fasteners can be installed after 10 minutes of clamp pressure for BMS 5-45 class B-1/2 or class B-2 sealants, or after 20 minutes for sealants with longer squeeze-out life. The fasteners must be installed during the sealant squeeze-out life.

在柔性密封(应该是胶类密封)应用中安装永久性紧固件时,请务必夹紧连接处,使密封胶正确挤出。使用足够的夹紧压力以防止分离。使用BMS 5-45 B-1/2级或B-2级密封胶时,在施加10分钟夹紧压力后即可安装永久性紧固件;使用挤出寿命更长的密封胶时,在施加20分钟夹紧压力后即可安装。紧固件必须在密封胶挤出寿命内安装。

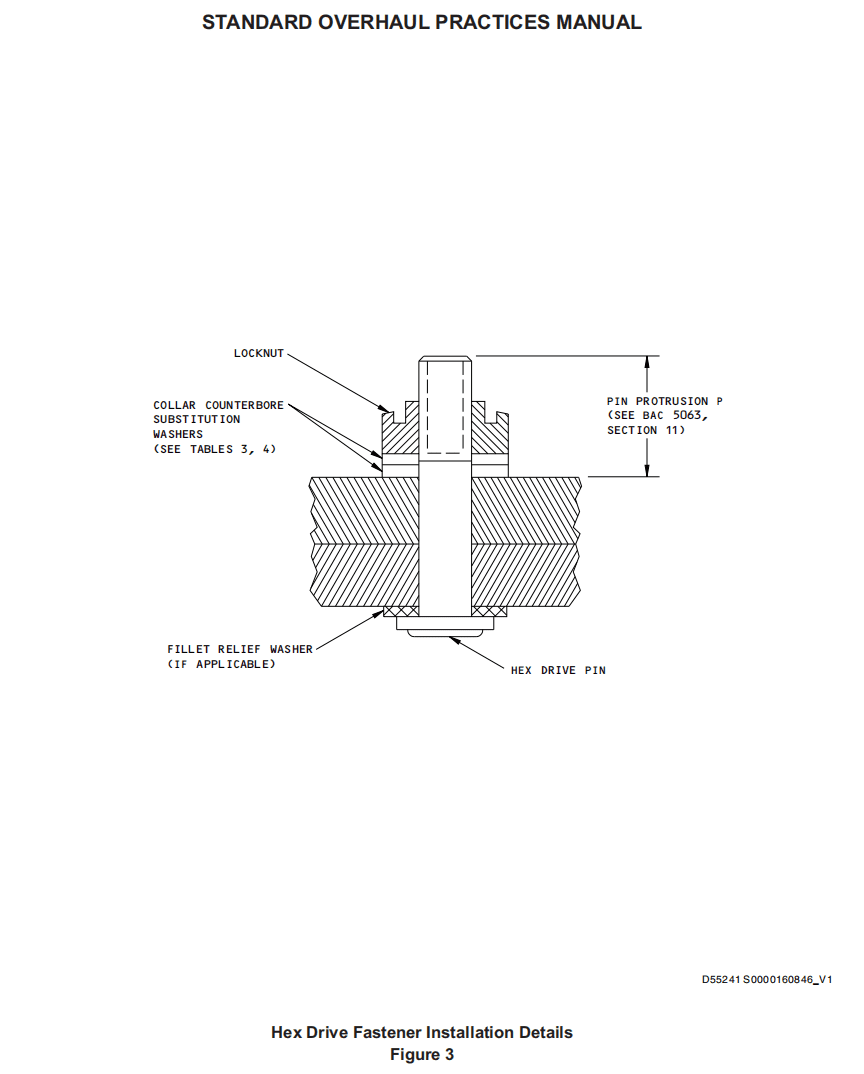

5. HEX DRIVE FASTENERS 六角驱动紧固件

(Figure 2, Figure 3)

(图2、图3)

A. A hex drive fastener has an internal hole for a hex drive wrench in the threaded end of the shank (see Figure 2).

六角驱动紧固件在柄端螺纹处有一个供六角驱动扳手使用的内孔(见图2)。

B. Unless the overhaul instructions are different, use the hole sizes shown in Table 1.

除非大修说明另有规定,否则请使用表1中所示的孔尺寸。

C. Pins or Bolts

销子或螺栓

(1) Use the pins or bolts specified by the overhaul instructions. If the length must be changed to get the pin protrusion requirements of BAC 5063, Section 11 because of changes in structural laminate thickness or shims, an adjustment of two grip lengths longer or shorter is permitted.

使用大修说明中指定的销子或螺栓。如果由于结构层压板厚度或垫片的变化,必须改变长度以满足 BAC 5063 第 11 节中规定的销子突出要求,则允许调整两个夹持长度,使其变长或变短。

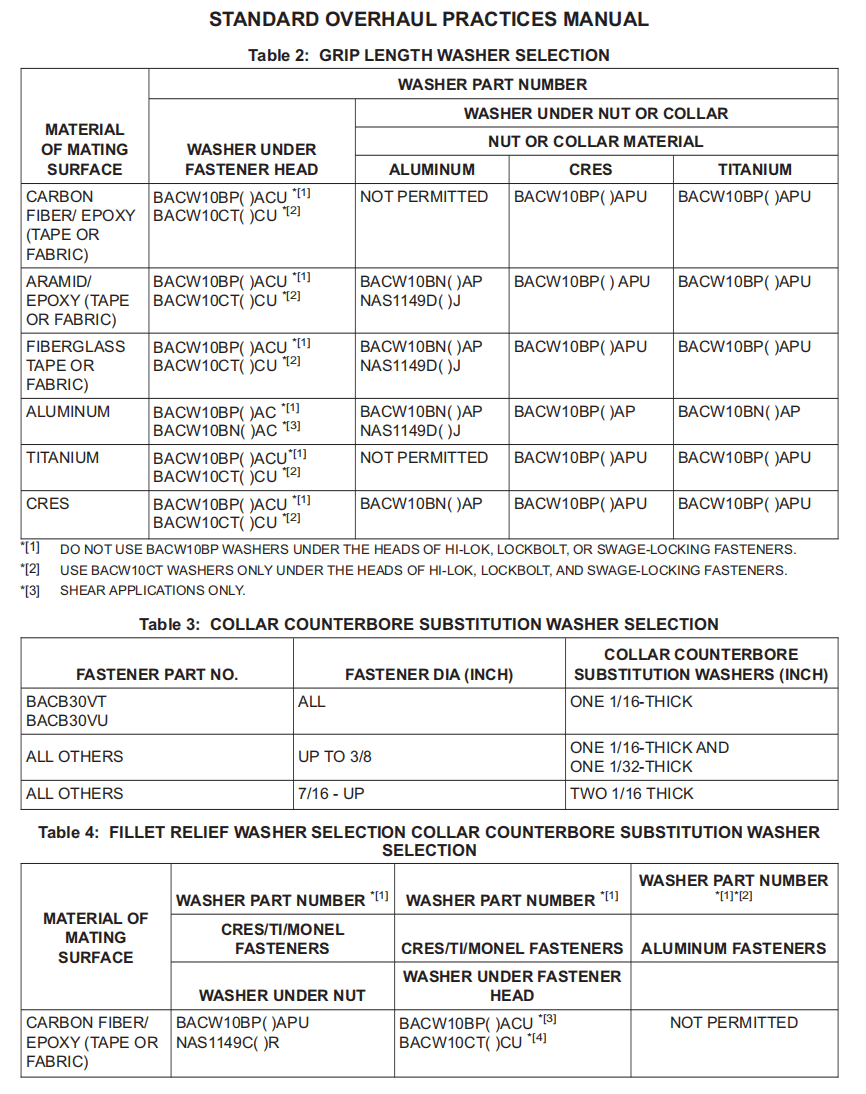

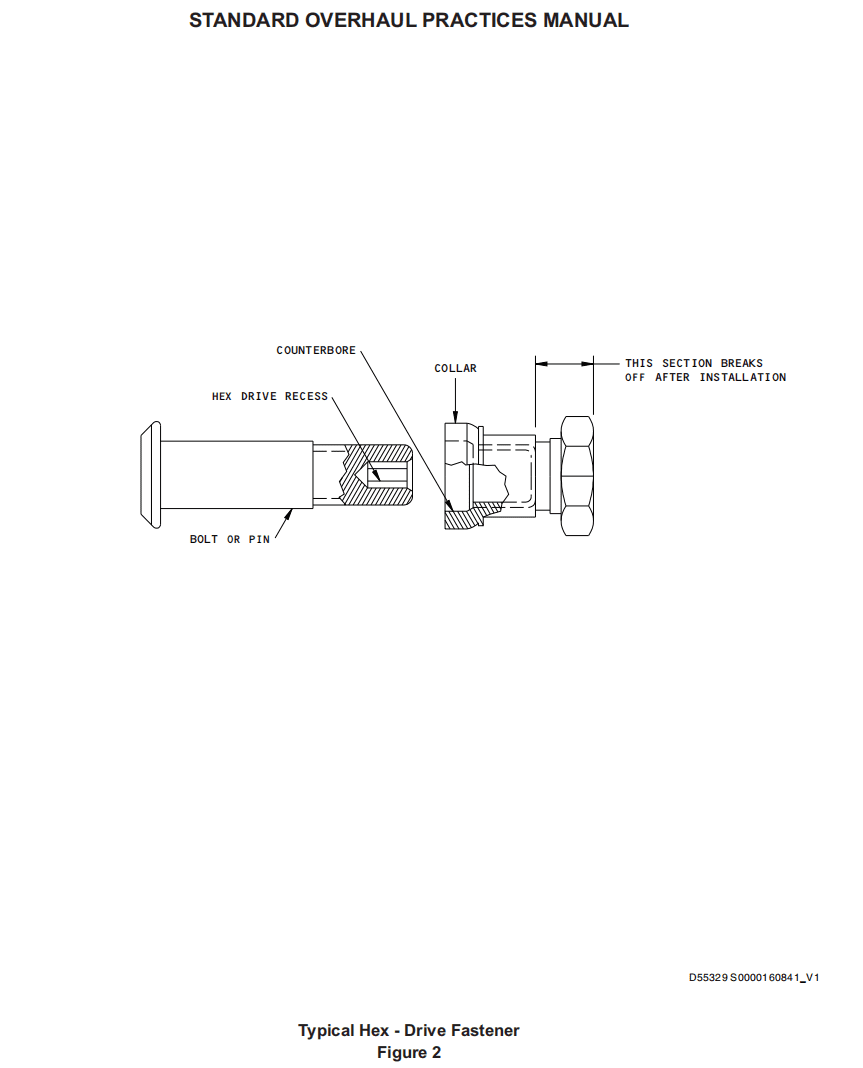

(2) If pins or bolts of the correct grip length are not available, you can use a longer grip length with washers. See Table 2 for washer selection. You can use a maximum of two washers under the head or collar, but no more than three washers on any one fastener.

如果找不到正确夹持长度的销子或螺栓,可以使用带垫圈的更长夹持长度。垫圈选择见表2。在螺钉头或轴环下最多可以使用两个垫圈,但任何一根紧固件上最多只能使用三个垫圈。

D. Collars

轴环

(1) The collars are supplied lubricated by the manufacturer. Do not degrease or apply more lubrication.

轴环由制造商润滑后提供。请勿脱脂或添加更多润滑剂。

(2) When collar replacement is necessary, do not use impact methods. Do not use the removed collars again.

需要更换轴环时,请勿使用冲击方法。请勿重复使用已拆卸的轴环。

E. Nuts

螺母

(1) When permitted by the overhaul instructions, locknuts can be used as an alternative to collars. Then washers must be added (Figure 3) because most nuts do not have the counterbore of the collar. See Table 3 and Table 4 for washer selection. See Table 1 to identify the nuts which have counterbores and thus can be used without counterbore substitution washers.

如果大修说明允许,可以用锁紧螺母替代轴环。但必须添加垫圈(图3),因为大多数螺母没有轴环的沉孔。垫圈的选择请参见表3和表4。请参见表1,确定螺母是否有沉孔,从而无需使用沉孔替代垫圈。

(2) Unless the overhaul instructions are different, tighten the locknuts to the torque shown in Table 1.

除非大修说明另有规定,否则请按照表1所示的扭矩拧紧锁紧螺母。

F. Tables

表

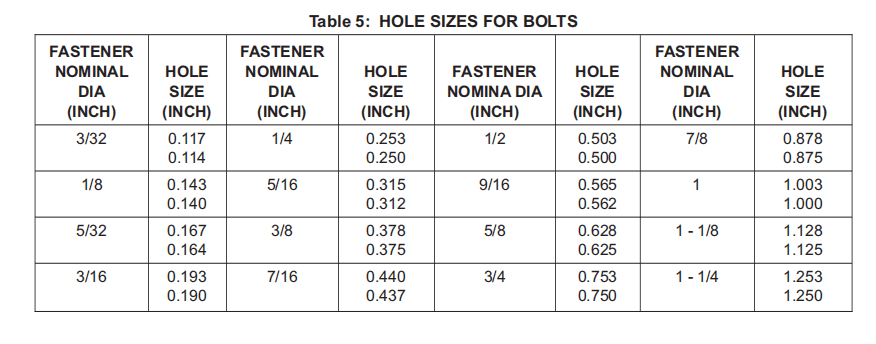

6. BOLTS AND NUTS 螺栓和螺母

A. Unless the overhaul instructions are different, use the hole sizes shown in Table 5.

除非大修说明另有规定,否则请使用表5所示的孔尺寸。

B. Fastener threads are not permitted against the walls of holes in composite material. Refer to SOPM 20-50-01 for data about fastener threads against the walls of holes in metal.

紧固件螺纹不允许紧贴复合材料孔壁。有关紧固件螺纹紧贴金属孔壁的数据,请参阅 SOPM 20-50-01。

C. Nuts must not engage the first incomplete thread next to the bolt shank.

螺母不得与螺栓柄旁的第一个不完整螺纹啮合。

D. All nut threads must be engaged. All of the chamfer on the end of the bolt must be out above the nut surface.

所有螺母螺纹必须啮合。螺栓端部的所有倒角必须超出螺母表面。

E. The nuts are supplied lubricated by the manufacturer. Do not degrease or apply more lubrication.

螺母由制造商润滑后提供。请勿脱脂或添加额外的润滑剂。

F. After a bolt is installed into the structure through a wet-sealed area, sealant removal from the bolt threads is not necessary if the nut is tightened during the sealant squeeze-out time, or if specified by the overhaul instructions.

螺栓通过湿密封区域安装到结构中后,如果在密封剂挤出期间拧紧螺母,或者按照大修说明进行操作,则无需从螺栓螺纹上清除密封剂。

G. Unless specified by the overhaul instructions, install bolts with their heads up or forward.

除非大修说明另有规定,否则螺栓的安装方向应为头部朝上或朝前。

H. Refer to Paragraph 4.I. for instructions about multiple-fastener installations.

有关多个紧固件的安装说明,请参阅第 4.I 段。

I. If the grip length must be changed because of changes in structural laminate thickness, an adjustment of two grip-length sizes longer or shorter is permitted.

如果因结构层压板厚度变化而必须改变夹持长度,则允许调整两个夹持长度尺寸,或长或短。

J. Unless the overhaul manual instructions are different, tighten the nuts to the torques shown in Table 6.

除非大修手册另有说明,否则请按照表6所示扭矩拧紧螺母。

(1) If the fasteners are in fay seal areas, complete the initial installation a minimum of 60 minutes before the end of the sealant squeeze-out life.

如果紧固件位于柔性密封区域,请在密封胶挤出寿命结束前至少60分钟完成初始安装。

(2) Retighten all fasteners in fay seal areas to 80-100% of the maximum torque value shown. If the sealant is BMS 5-45 class B-1/2 or B-2, wait 10 minutes or more before you retighten the fasteners. If the sealant has a longer squeeze-out life than BMS 5-45 class B-1/2 or B-2, wait 20 minutes or more before you retighten the fasteners. Make sure all fasteners are tightened before the end of the sealant squeeze-out life.

将密封区域的所有紧固件重新拧紧至所示最大扭矩值的80-100%。如果密封胶为BMS 5-45 B-1/2或B-2级,请在10分钟或更长时间后再次拧紧紧固件。如果密封胶的挤出寿命比BMS 5-45 B-1/2或B-2级更长,请在20分钟或更长时间后再次拧紧紧固件。确保在密封胶挤出寿命结束前拧紧所有紧固件。

K. For grip length adjustment or fillet relief, use a maximum of two washers under the bolt head or nut, but no more than three washers on any one fastener. Make your selection of washers per Table 2 or Table 4, as applicable.

如需调整夹持长度或圆角消除,螺栓头或螺母下最多使用两个垫圈,但任何紧固件上使用的垫圈不得超过三个。根据具体情况,按照表2或表4选择垫圈。

7. BLIND BOLTS 盲螺栓

(Figure 4)

(图4)

A. Use this procedure to install bolts, BACB30UY, BACB30UZ, BACB30VK, BACB30VL, BACB30XS, PLT 220, PLT 221, PLT 270, PLT 271, PLT 1055, PLT 1058, PLT 1064, PLT 1069, PLT 1070.

使用此程序安装螺栓,BACB30UY、BACB30UZ、BACB30VK、BACB30VL、BACB30XS、PLT 220、PLT 221、PL T 270、PLT 271、PLT 1055、PLT 1058、PLT 1064、PLT 1069、PLT 1070。

B. Unless the overhaul instructions are different, use the hole sizes shown in Figure 4, Table 1.

除非大修说明另有规定,否则请使用图4表1中所示的孔尺寸。

C. If the grip length must be changed because of changes in part thickness, an adjustment of one grip length size longer or shorter is permitted if the composite thickness is one inch or less, or two grip length sizes longer or shorter if the composite thickness is more than one inch.

如果因零件厚度变化而必须改变夹持长度,则允许调整一个夹持长度尺寸(长或短),前提是复合厚度为1英寸或更小;如果复合厚度超过1英寸,则允许调整两个夹持长度尺寸(长或短)。

D. See Figure 4 for data about tools, countersink requirements and lengths of the broken-off stem. The stem can be cut shorter if necessary, but the length must be within the Figure 4, Table 1 limits before you cut it. Do not remove material from the fastener head. Be careful not to damage the surface of the composite skin.

有关工具、沉头孔要求和断杆长度,请参见图4。如有必要,可将杆身截短,但长度必须在图4表1的限制范围内。请勿去除紧固件头部的材料。注意不要损坏复合材料表面的完整性。

E. Use a countersink tool whose pilot pin minimum diameter is 0.002 inch smaller than the drill used to make the hole.

使用埋头工具,其导向销的最小直径比用于钻孔的钻头小 0.002 英寸。

8. LOCK BOLTS 锁定螺栓

(Figure 5)

(图 5)

A. Lockbolts are permanent fasteners which include a pin with annular (circumferential) grooves and a collar which is swaged onto the installed pin.

锁定螺栓是永久性紧固件,包括一个带有环形(圆周)凹槽的销子和一个压装在已安装销子上的轴环。

B. Unless the overhaul instructions are different, use the hole sizes shown in Figure 5.

除非大修说明另有规定,否则请使用图5所示的孔尺寸。

C. If the grip length must be changed because of changes in part or shim thickness, an adjustment of two grip length sizes longer or shorter is permitted. Do not use washers to adjust the grip length.

如果因零件或垫片厚度变化而必须改变夹持长度,则允许调整两个夹持长度尺寸,即加长或缩短。请勿使用垫圈来调整夹持长度。

D. The collars are supplied lubricated by the manufacturer. Do not degrease or apply more lubrication.

轴环由制造商润滑后提供。请勿脱脂或添加额外的润滑剂。

E. Make sure you turn BACC30BN collars as shown, to put the flange against the structure surface. These collars can be installed on surfaces with a slope of up to 5 degrees, as shown.

确保按照所示方向转动BACC30BN轴环,使法兰与结构表面接触。这些轴环可以安装在倾斜度不超过5度的表面上,如图所示。

F. During installation keep the swaging die aligned with the lockbolt axis within 3 degrees.

在安装过程中,保持压模与锁紧螺栓轴线对齐,偏差不超过3度。

G. Do not use an impact method to swage the collars on composite structures.

不要使用冲击法将扣眼压入复合结构。

H. Unless the lockbolt has a sealant escape groove, remove sealant and other unwanted matter from the annular grooves before you install the collar. Visible signs of sealant are acceptable. On lockbolts with sealant escape grooves (H code in the part number), do not remove the sealant, and be sure to swage the collar within the sealant squeeze-out time.

除非锁紧螺栓有密封剂溢出槽,否则在安装轴环前,应清除环形槽中的密封剂和其他不需要的物质。可见的密封剂痕迹是可以接受的。在带有密封剂溢出槽(零件编号中的H代码)的锁紧螺栓上,不要清除密封剂,并确保在密封剂挤出时间内压装轴环。

9. OVERSIZE FASTENERS 超大紧固件(超尺寸紧固件)

A. Use these procedures to install fasteners in holes made larger during repair of the composite component.

使用这些程序在修理复合部件时在扩大的孔中安装紧固件。

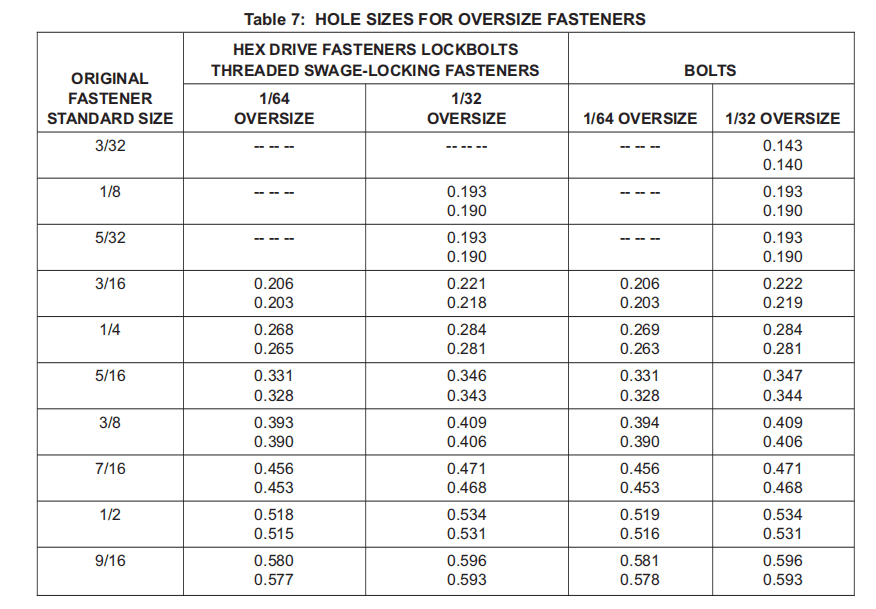

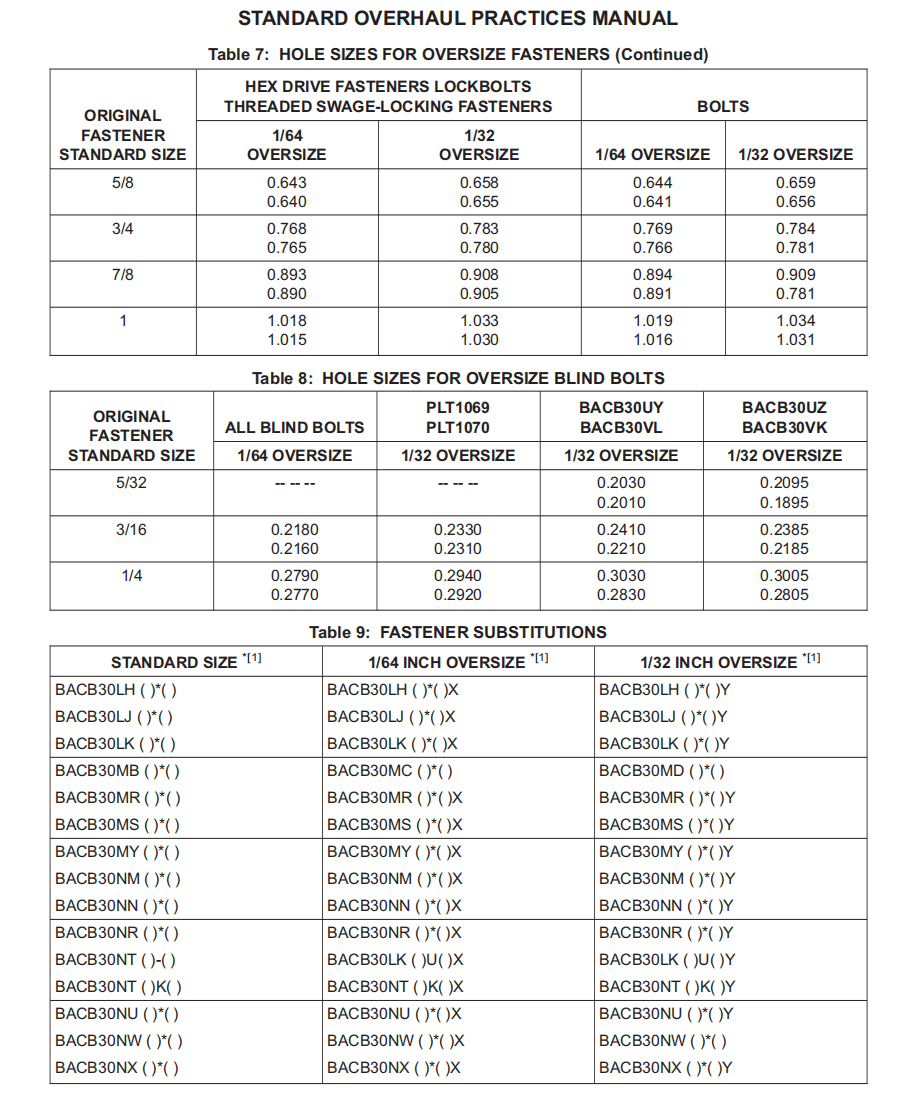

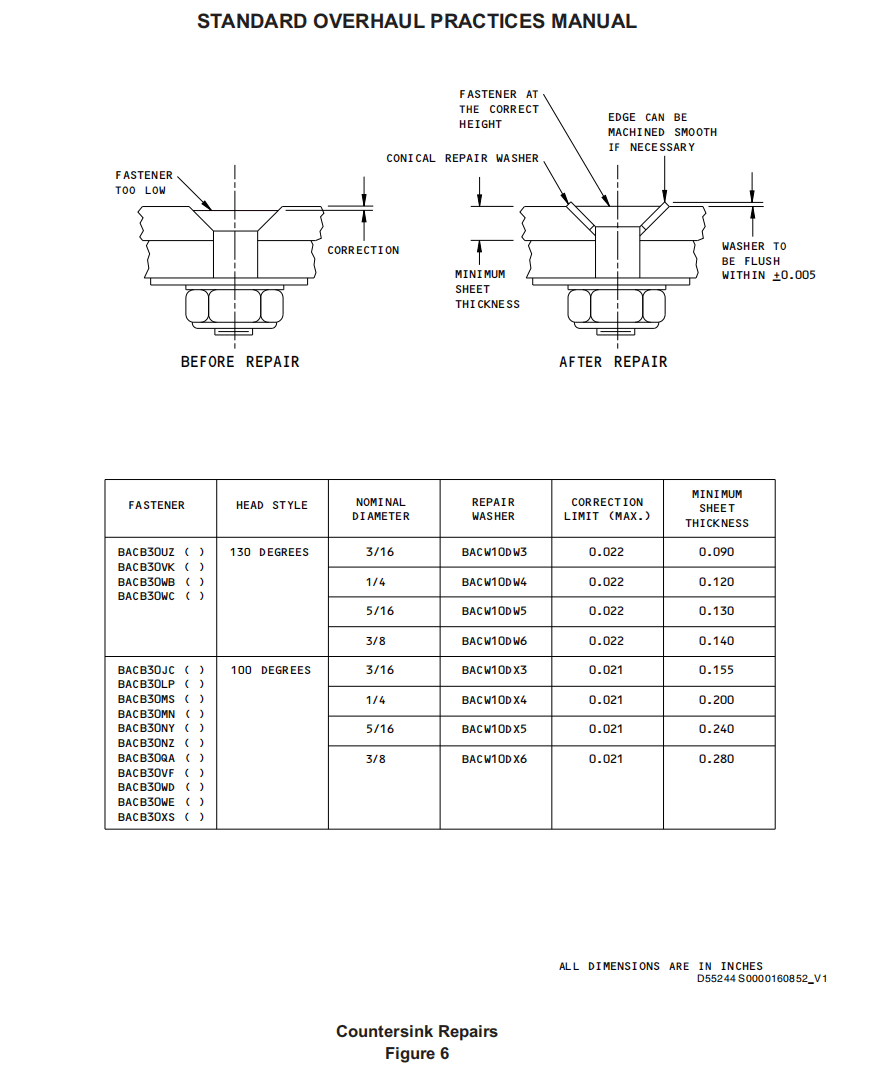

B. Unless the overhaul instructions are different, use the hole sizes and fastener substitutions shown in Table 7, Table 8, Table 9, and/or Table 10.

除非大修说明有所不同,否则请使用表7、表8、表9和/或表10中所示的孔尺寸和紧固件替代品。

C. If the grip length must be changed on these oversize fasteners, you can use a maximum of two washers under the nut or collar and a maximum of one washer under the fastener head. If washers are necessary to adjust the grip length or because the standard fastener used them, you can machine the bores of standard washers to the size necessary to fit the oversize fastener. If you use oversize washers, they must be of the same material as the standard or original washers. See Table 2 for grip length washer selections.

如果必须更换这些超大紧固件的夹持长度,则最多可在螺母或轴环下使用两个垫圈,在紧固件头部下使用一个垫圈。如果需要垫圈来调整夹持长度,或者因为使用的标准紧固件需要垫圈,您可以将标准垫圈的孔加工成适合超大紧固件的尺寸。如果使用超大垫圈,则其材质必须与标准垫圈或原装垫圈相同。夹持长度垫圈选择请参见表2。

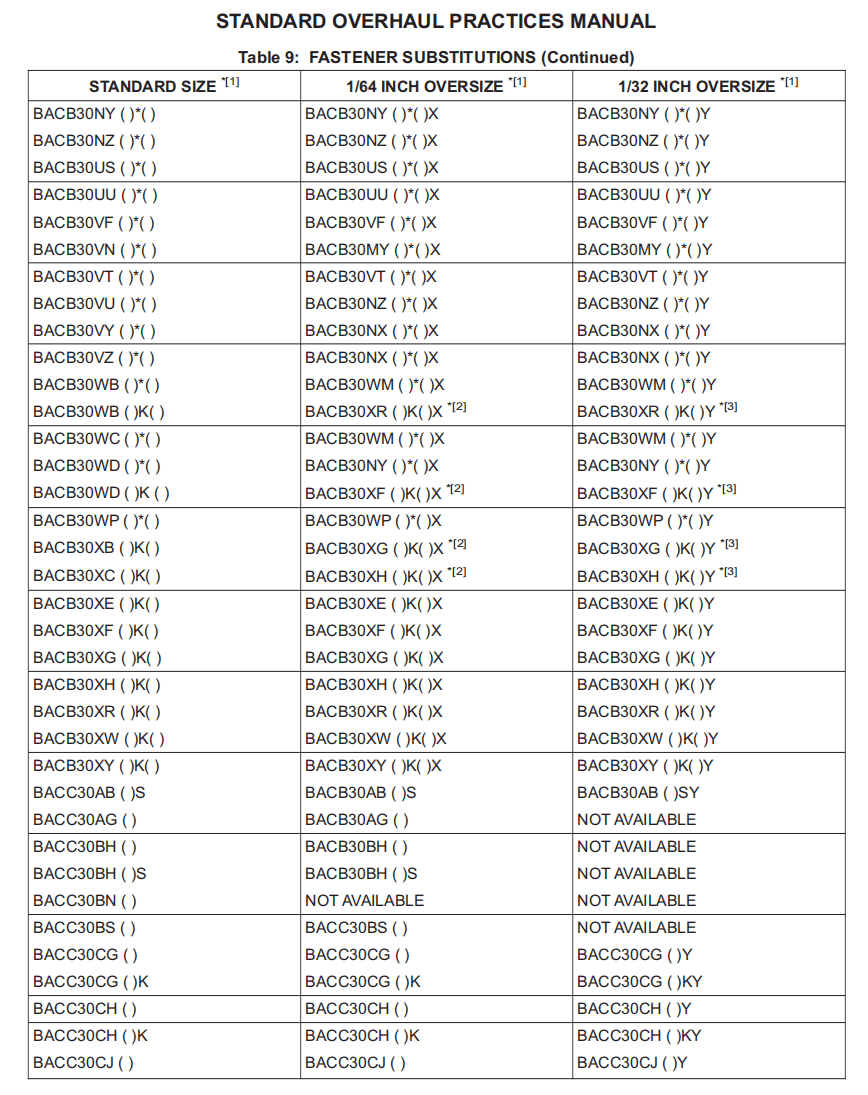

D. Countersink Repairs

埋头孔修复

(1) Oversize countersinks can be repaired with BACW10DW and BACW10DX conical washers as shown in Figure 6.

如图6所示,可使用BACW10DW和BACW10DX锥形垫圈修复超大型沉头孔。

(2) Install these washers with wet BMS 5-95 sealant. Push them down into the countersink to squeeze out the sealant. You can use your fingers. If this location is for a removable fastener, remove unwanted sealant from the installed washer before you install the fasteners.

使用湿BMS 5-95密封胶安装这些垫圈。将它们压入沉头孔,挤出密封胶。可以用手指操作。如果此处安装的是可拆卸紧固件,请在安装紧固件前清除已安装垫圈上多余的密封胶。

(3) Install the fastener within the squeeze-out time of the sealant.

在密封胶挤出时间内安装紧固件。

10. BACG20AL GROMMETS扣眼 BACG20AL

A. Use this procedure to install BACG20AL aluminum grommets in the composite structure (Figure 7).

使用此程序在复合结构中安装 BACG20AL 铝扣眼(图 7)。

B. Unless the overhaul instructions are different, use the hole sizes shown in Figure 7, Table 1.

除非大修说明不同,否则请使用图 7 表 1 中所示的孔尺寸。

C. Countersink the near side as shown with an ST1221C-CH cutter. You can measure the depth with an ST8703XB-20 countersink depth gage for BACR15FV rivets. The measured depth will be 0.0037-0.0083 inch deeper than the set zero with a -6 block.

用ST1221C-CH刀具在靠近一侧进行锪埋头孔。您可以使用ST8703XB-20锪孔深度量具测量BACR15FV铆钉的深度。测量深度应比-6块的设定零点深0.0037-0.0083英寸。

D. Countersink the far side as shown in Figure 7, (Sheet 1).

如图7(第1页)所示,在较远的一侧锪埋头孔。

E. Installation 安装

(1) Use the tool parts shown.

使用所示工具零件。

(2) Put the grommet into the panel.

将扣眼放入面板。

(3) Assemble the tool parts through the grommet as shown.

如图所示,通过扣眼组装工具零件。

(4) Connect the puller to the air supply. For nominal grommets, control the air pressure at 13-18 psi. For oversize grommets, control the air pressure to the minimum value at which the tool will operate, but no higher than 18 psi.

将连接器连接到供气装置上。对于标准扣眼,将气压控制在13-18 psi。对于超大扣眼,将气压控制在工具可操作的最低值,但不得高于18 psi。

(5) Operate the tool to swage the grommet material over the structure, as shown.

操作工具,将扣眼材料压入结构中,如图所示。

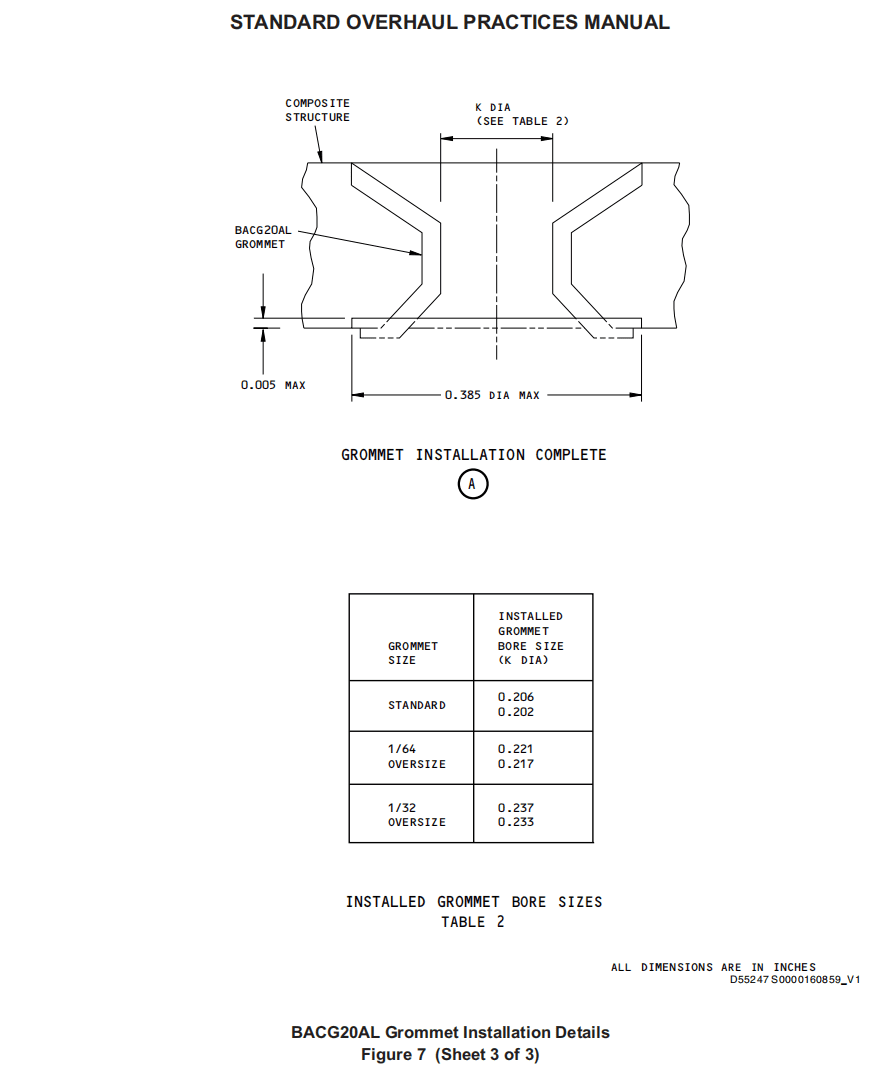

(6) Examine the swaged, flared end of the grommet without magnification. Cracks in the flared end of the grommet are acceptable if they do not go into the grommet material below the flush line.

不使用放大镜,检查扣眼扣压后的喇叭口。如果扣眼喇叭口处的裂纹未进入齐平线以下的扣眼材料,则可以接受。

(7) Machine the flared end of the grommet flush with the surface as shown, with an ST1233H spotface cutter.

使用ST1233H点面铣刀,如图所示,将扣眼的喇叭口与表面齐平。

(8) Examine the bore of the grommet for defects. If necessary, machine the bore to the size shown in Figure 7, Table 2.

检查扣眼孔是否有缺陷。如有必要,将孔加工成图7表2所示的尺寸。

F. Removal

拆卸

(1) Get an ST1257B drill with a diameter 0.002-inch smaller than the hole in the structure (Diameter D, Figure 7, Table 1).

准备一个直径比结构孔(图7表1中的直径D)小0.002英寸的ST1257B钻头。

(2) Align the drill with the center of the grommet.

将钻头对准扣眼中心。

(3) Drill through the grommet at a speed of 500 rpm or less.

以 500 rpm 或更低的转速钻透扣眼。

(4) Remove the grommet. Compare the hole size with the Figure 7, Table 1 values before you install a new grommet.

取下扣眼。在安装新的扣眼之前,请对比图 7、表 1 中的孔尺寸值。

11. THREADED SWAGE-LOCKING FASTENERS 螺纹压铆紧固件

A. A threaded swage-locking fastener has threads with five flutes (grooves) equally spaced around the circumference. The mating collar has three equally-spaced lobes which engage the installation tool. As the tool turns, it swages the lobes into the flutes to lock the collar tightly in position. The fastener has an internal hex-drive hole in the end to not let the fastener turn in the hole while the collar is installed (Figure 8).

螺纹压铆紧固件的螺纹有五个凹槽(沟槽),在圆周上等距分布。配合环有三个等距的凸缘,与安装工具啮合。当工具转动时,凸缘会嵌入凹槽,将环牢牢锁定在原位。紧固件末端有一个内六角驱动孔,以防止在安装轴环时紧固件在孔中转动(图8)。

B. Unless the overhaul instructions are different, use the hole sizes shown in Figure 8, Table 1.

除非大修说明另有规定,否则请使用图8、表1中所示的孔尺寸。

C. If the grip length must be changed because of changes in structural laminate thickness, an adjustment of two grip-length sizes longer or shorter is permitted.

如果因结构层压板厚度变化而必须改变夹持长度,允许调整两个夹持长度尺寸,即加长或缩短。

D. If fasteners of the correct grip length are not available, you can use longer fasteners with a maximum of two washers under the fastener head or collar, but no more than three washers on each fastener. See Table 2 for grip length washer selections.

如果无法获得正确夹持长度的紧固件,可以使用更长的紧固件,紧固件头或轴环下最多可放置两个垫圈,但每个紧固件上不得超过三个垫圈。有关加持长度垫圈的选择,请参阅表2。

E. The collars are supplied lubricated by the manufacturer. Do not degrease or apply more lubrication.

轴环由制造商润滑后提供。请勿去除润滑剂或添加额外的润滑剂。

F. When collar replacement is necessary, do not use impact methods. Do not use the removed collars or fasteners again.

需要更换轴环时,请勿使用冲击方法。请勿重复使用已拆除的轴环或紧固件。

G. Installation

安装

(1) Use the special Delta-Rad drivers to install the collars.

使用特殊的Delta-Rad驱动器安装轴环。

(2) Install the fastener in the structure, with the head against the structure surface.

将紧固件安装在结构中,使其头部紧贴结构表面。

(3) If the slope of the surface under the collar will be less than 1/2 degree, use the standard threaded swage-locking collars. If the slope is more than 1/2 degree, use a self-aligning collar or washer assembly.

如果轴环下方的表面坡度小于1/2度,请使用标准的螺纹锁紧轴环。如果坡度大于1/2度,请使用自调心轴环或垫圈组件。

(4) Unless you use an automatic feed or nut retention system, start the collar on the fastener by hand, and turn it a minimum of 3/4 turn before you use installation tools. Then put the installation tool tightly down on the collar. Make sure the hex key goes into the mating hex hole in the fastener. Make sure the tool engages the lobes on the collar. Then operate the tool. When its socket turns freely on the collar, the lobes are swaged into the thread flutes and the installation is complete.

除非使用自动进给或螺母固定系统,否则请手动启动紧固件上的轴环,并在使用安装工具前至少转动3/4圈。然后将安装工具紧紧压在轴环上。确保六角销子插入紧固件的六角孔中。确保工具与轴环上的凸缘啮合。然后操作工具。当其套筒在轴环上自由转动时,凸缘就压入螺纹凹槽中,安装完成。

(5) If you use an automatic feed or nut retention system, put the tool on the collar and operate the tool until the collar is tightly against the structure.

如果使用自动进给或螺母固定系统,请将工具放在轴环上,操作工具直到轴环紧贴结构。

(6) If the hole is a clearance fit with the fastener, make sure the hex key is engaged with the mating hex hole in the fastener, or the fastener will turn with the collar and cause damage to the structure or its finish.

如果孔与紧固件间隙配合,请确保六角销子与紧固件上的配合六角孔啮合,否则紧固件会随轴环转动,损坏结构或饰面。

(7) If the overhaul instructions specify installation with wet sealant, let the sealant stay on the threads and be sure to install the collar while the sealant is wet.

如果大修说明中指定使用湿密封剂进行安装,则让密封剂留在螺纹上,并确保在密封剂未干时安装轴环。

(8) Do not try to swage again an installed collar. If the collar is not completely swaged, remove the collar and its fastener and install a new fastener with a new collar.

不要试图再次压装已安装的轴环。如果轴环未完全压装,则拆下轴环及其紧固件,并安装新的紧固件和新的轴环。