如何制作和安装树脂粘合层叠垫片和固体填充物

HOW TO MAKE AND INSTALL RESIN BOND LAMINATED SHIMS AND SOLID FILLERS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5430. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自波音工艺规范 BAC5430。航空公司有一份波音工艺规范手册。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum requirements.

数据是通用的。它不适用于所有情况或特定安装。使用这些数据来帮助您编写最低要求。

C. Refer to SOPM 20-00-00 for a full list of all the vendor names and addresses.

供应商名称和地址的完整列表请参考 SOPM 20-00-00。

D. This subject tells how to make and install these BAC5430 types of shims and fillers:

本主题讲述了如何制作和安装这些 BAC5430 类型的垫片和填充物:

Type 1 — Metallic laminated shim stock, such as BAC1534, BACS18AJ, BACS40R, BACS40U, BMS 7-335 (Types 1 thru 5)

类型1——金属层压垫片,例如BAC1534、BACS18AJ、BACS40R、BACS40U、BMS 7-335(类型1至5)

Type 2 — Polyimide polymer laminated shim stock, such as BAC1535, BACS40V, BMS 7-335 (Type 6)

类型2——聚酰亚胺聚合物层压垫片,例如BAC1535、BACS40V、BMS 7-335(类型6)

Type 3 — Fiberglass laminated shim stock, such as BACS40X

类型3——玻璃纤维层压垫片,例如BACS40X

Type 4 — Metallic solid fillers, such as BACF3F, BACF3J, BACF3T, BACF3Y, BACF3AA

类型4——金属固体填充物,例如BACF3F、BACF3J、BACF3T、BACF3Y、BACF3AA

Type 5 — Metallic radius fillers, such as BACF3H, BACF3Z, BACF33C

类型5——金属半径填充物,例如BACF3H、BACF3Z、BACF33C

Type 6 — Fiberglass solid fillers, such as BACF3U, BACF3W, BACS40W

类型 6——玻璃纤维固体填充物,例如 BACF3U、BACF3W、BACS40W

Type 7 — Fiberglass radius fillers, such as BACF3V

类型 7——玻璃纤维半径填充物,例如 BACF3V

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

备注:可使用等效替代品。

A. Abrasive pads

研磨片

(1) Bear-Tex aluminum oxide, V06565

Bear-Tex 氧化铝,V06565

(2) Scotch-Brite Type A, V76381

Scotch-Brite A 型,V76381

B. Adhesives (Ref SOPM 20-50-12)

粘合剂(参考SOPM 20-50-12)

(1) Type 38

(2) Type 40

(3) Type 50

(4) Type 54

(5) Type 70

C. Polyimide film — BAC1535-29

聚酰亚胺薄膜——BAC1535-29

D. Primer — BMS 10-11, Type 1 (Ref SOPM 20-60-02)

底漆——BMS 10-11,类型1(参考SOPM 20-60-02)

E. Resin — BMS 8-139

树脂——BMS 8-139

F. Shim stock — BMS 7-335

垫片——BMS 7-335

G. Tape, adhesive transfer

胶带,粘合剂

(1) Scotch No. 464, 465, 468, 909, 924, Y953, 969, 976 or 9568, V76381

(2) BMS 5-91

H. Wipers — BMS 15-5, Class A or B

刷子——BMS 15-5,A类或B类

3. EQUIPMENT 设备

NOTE: Equivalent substitutes can be used.

注:可使用等效替代品。

A. Vacuum table

真空台

4. PREFIT PROCEDURES FOR TYPES 1,2,3,4 AND 6 SHIMS AND FILLERS 类型1、2、3、4和6垫片和填充物的预装程序

A. When the assembly was built at the factory, these procedures were used to make and install shims as necessary to fill gaps between mating parts or to adjust the relative position of the mating parts. Adjustment or replacement of these shims during overhaul is usually not necessary unless one or more of the mating parts is replaced. Then you can use these procedures to make a check of the gaps to see if you can use the old shims, or to make, adjust and install replacement shims.

当工厂组装时,这些程序用于根据需要制作和安装垫片,以填补配合零件之间的间隙或调整配合零件的相对位置。除非更换一个或多个配合零件,否则通常无需在大修期间调整或更换这些垫片。这时,您可以使用这些程序检查间隙,看看是否可以使用旧的垫片,或者制作、调整和安装替换垫片。

B. Put the parts together as a test without the shims or fillers, and before you drill full-size holes for fasteners. Use the assembly procedure and clamping forces specified by the overhaul instructions.

在钻出用于紧固件的全尺寸孔之前,在不使用垫片或填充物的情况下将零件组装在一起进行测试。使用大修说明中指定的组件程序和夹紧力。

C. If the overhaul instructions do not give the assembly procedure or the clamping force, put the parts together. Use a clamping force of 2 pounds maximum per linear foot if the parts are thinner than 0.045 inch thick. Use a clamping force of 5 pounds per linear foot if the parts are 0.045 inch or more thick.

如果大修说明中没有给出组装程序或夹紧力,则将零件组装在一起。如果零件厚度小于0.045英寸,则每线性英尺的最大夹紧力为2磅。如果零件厚度为0.045英寸或以上,则每线性英尺的夹紧力为5磅。

D. To make sure the clamping force is correct, measure it at each attachment point. If the attachment points are 12 inches apart, the force at each point will be the same as the specified value per linear foot. If the attachment points are closer together, the force at each point must be less, because the total per foot must be equal to the specified force per linear foot. For example, if the attachment points are 6 inches apart, the force at each point must be one-half of the specified force per foot. If the attachment points are 4 inches apart, the force at each point must be one-third of the specified force per foot. The total force for the assembly will be the force per foot times the total length in feet of the unit.

为确保夹紧力正确,请在每个连接点测量夹紧力。如果连接点相距12英寸,则每个连接点的夹紧力应与每线性英尺的指定值相同。如果连接点之间的距离更近,则每个连接点的夹紧力必须更小,因为每英尺的总夹紧力必须等于每线性英尺的指定夹紧力。例如,如果连接点之间的距离为6英寸,则每个连接点的力必须为每英尺指定力的二分之一。如果连接点之间的距离为4英寸,则每个连接点的力必须为每英尺指定力的三分之一。组件的总力等于每英尺力乘以组件的总长度(以英尺为单位)。

E. As an option to force applied at an attachment point, you can use a vacuum table. Apply a constant and continuous pressure along the surfaces of the parts. Use a minimum pressure of 0.014 psi for parts thinner than 0.045 inch. Use a minimum pressure of 0.035 psi for parts 0.045 inch or more thick. If the parts do not touch the table, start with a larger pressure to make the parts touch the table, then decrease the pressure.

作为施加在连接点上的力的一个选项,您可以使用真空台。沿零件表面施加恒定且连续的压力。对于厚度小于0.045英寸的零件,使用最小压力0.014 psi。对于厚度为0.045英寸或以上的零件,使用最小压力0.035 psi。如果零件不接触工作台,则先使用较大的压力使零件接触工作台,然后再减小压力。

F. After this test fit of the parts without shims, and before you drill full-size fastener holes, measure the gap dimension at each fastener location. Refer to the overhaul instructions for the maximum permitted gap dimension. If the overhaul instructions do not give a maximum gap dimension, use shims if the gap is larger than 0.010 inch in metal structure or is larger than 0.008 inch in composite structure of composite/metal structure. If the gap is less than these values or the gap given by the overhaul instructions, do not use shims.

在零件无垫片试装后,在钻全尺寸紧固件孔之前,测量每个紧固件位置的间隙尺寸。请参阅大修说明,了解最大允许间隙尺寸。如果大修说明未给出最大间隙尺寸,则当金属结构中的间隙大于0.010英寸或复合结构/金属结构中的间隙大于0.008英寸时,请使用垫片。如果间隙小于这些数值或检修说明给出的数值,则不要使用垫片。

G. Type 1 shims or solid fillers which will be permanently attached can be temporarily bonded in position with Scotch 465 adhesive transfer tape. But all tape and related adhesive must be removed before you install the fasteners.

类型1的垫片或永久性填充物可以用Scotch 465胶带临时粘在原位。但在安装紧固件前,必须将所有胶带和相关粘合剂清除干净。

H. When the overhaul instructions install the shim with permanent fasteners, Type 2 nonmetallic laminated shims and solid fibers can be held in position with Type 50, 54 or 70 adhesive per SOPM 20-50-12. But do not use the Type 50 adhesive to temporarily hold shims in position to machine them, because the adhesive will remove the finish if the shim must be removed before final assembly. Shims can be temporarily held in position with adhesive transfer tape, but all tape, film, or related adhesive must be removed before you install the fasteners.

当按照大修说明使用永久性紧固件安装垫片时,可使用50、54或70型粘合剂按照SOPM 20-50-12将2型非金属层压垫片和固体纤维固定在适当位置。但不要使用50型粘合剂临时固定垫片,因为如果在最终组装前必须拆下垫片,粘合剂会破坏表面涂层。垫片可以用粘合剂转移胶带临时固定,但在安装紧固件之前,必须将所有胶带、薄膜或相关粘合剂清除干净。

5. HOW TO INSTALL TYPES 1,2,3,4 AND 6 SHIMS AND FILLERS 如何安装类型1、2、3、4和6的垫片和填充物

A. Use the prefit procedures of Paragraph 4. to see if shims are necessary and how thick they must be.

使用第4段的预装程序,确定是否需要垫片以及垫片厚度。

B. If the old shim thickness is not best for the location, you can use shims of a different thickness, or no shim at all, to agree with the gaps you find.

如果旧垫片厚度不适合该位置,您可以使用不同厚度的垫片,或者完全不使用垫片,以满足发现的间隙。

C. Use the procedure of Paragraph 7. to make thinner laminated shims. You can use flat, tapered, or contoured solid fillers with or as an alternative to the laminated shims.

使用第7段中的步骤制作更薄的叠层垫片。您可以使用平的、锥形或波状的固体填充物,也可以使用叠层垫片或作为叠层垫片的替代品。

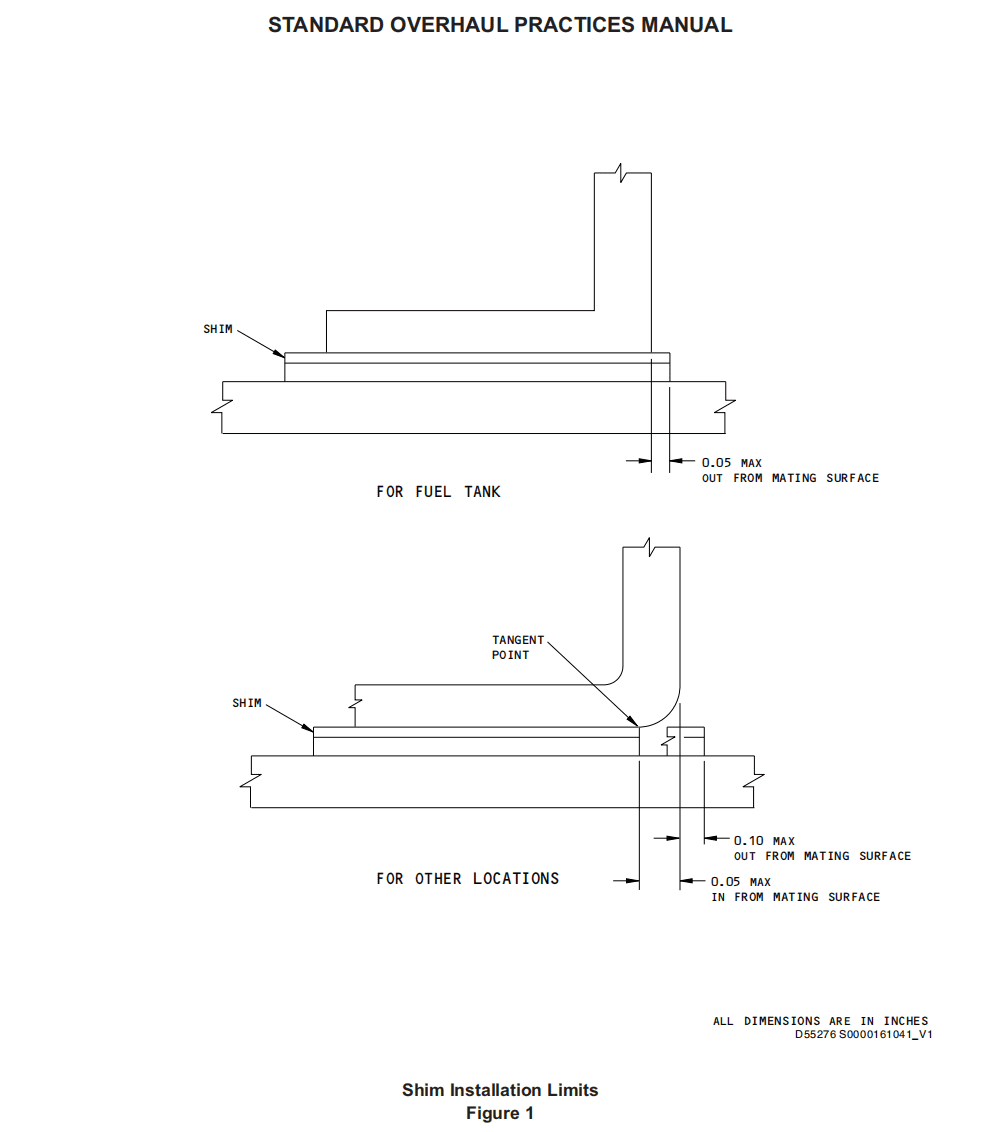

D. Machine or sand the solid part of the shim or solid filler to the necessary shape. Taper the shim or solid filler in more than one direction if necessary. The surface finish must be 250 microinches or smoother on these changed surfaces of the shims or solid fillers. Cut the outside edges of the shims and solid fillers to the tolerances shown in Figure 1. Break sharp edges of shim and fillers as specified in BAC5300. Machine titanium parts per SOPM 20-10-07. Machine CRES parts per SOPM 20-10-02.

利用机器或砂纸打磨垫片或固体填充物的固体部分,使其达到所需的形状。如有必要,可在多个方向上对垫片或固体填充物进行锥形处理。垫片或固体填充物这些改变的表面的表面光洁度必须达到250微英寸或更光滑。将垫片和固体填充物的外边缘切割成图1所示的公差。按照 BAC5300 的规定,修磨垫片和填充物的锋利边缘。按照 SOPM 20-10-07 加工钛零件。按照 SOPM 20-10-02 加工 CRES 零件。

E. Refinish the changed surfaces of the shims or solid fillers by these procedures, unless the overhaul instructions are different:

按照以下步骤修磨垫片或固体填充物的更改表面,除非大修说明另有规定:

(1) Aluminum — Chemical treat per BAC5719 (Ref SOPM 20-43-03). Apply BMS 10-11, Type 1 primer (F-20.02) but not on shims or fillers for fuel tanks.

铝——根据 BAC5719 进行化学处理(参考 SOPM 20-43-03)。使用 BMS 10-11,类型 1 底漆(F-20.02),但不要用于油箱垫片或填充物。

(2) Titanium — Use the overhaul instructions.

钛——使用大修说明。

(3) CRES — Clean with a dry abrasive blast (BAC5748 Type 2, Class 1). Then apply finish as specified in the overhaul instructions, but not on the bare surface of passivated shims.

CRES——用干磨料喷砂(BAC5748 类型 2,1 类)进行清洁。然后按照大修说明中的规定进行表面处理,但不要在钝化的垫片的裸露表面上进行。

(4) Type 2 or 3 shims — No finish is necessary.

类型 2 或 3 垫片——无需进行表面处理。

F. Drill full-size holes for the fasteners. Break sharp edges of the drilled holes as specified in BAC5300.

为紧固件钻全尺寸孔。按照 BAC5300 的规定,将钻孔的锋利边缘进行倒角。

G. If specified by the overhaul instructions, install the shim with a corrosion preventive finish, such as primer, sealant or adhesive.

如果大修说明有规定,则应在安装垫片时进行防腐处理,例如涂底漆、密封胶或粘合剂。

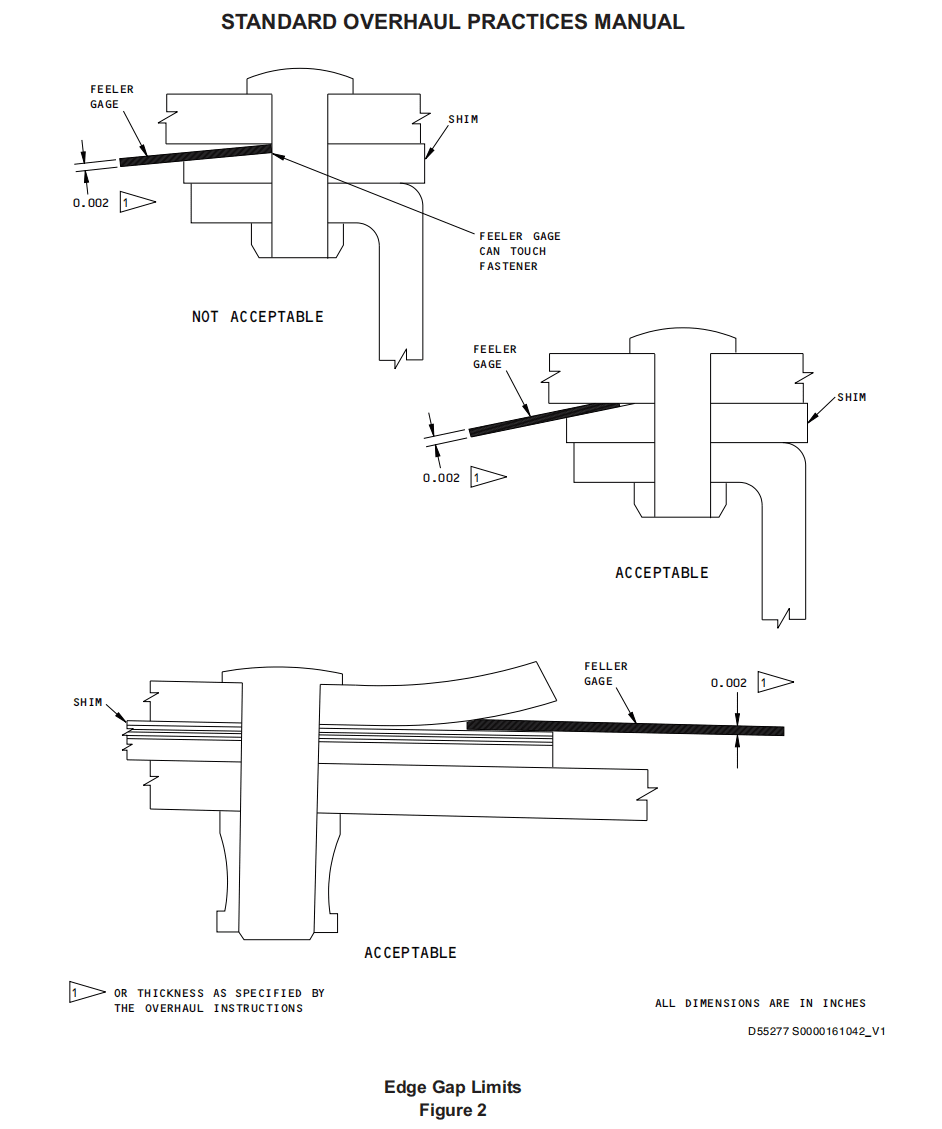

H. After you tighten the fasteners, gaps at the edges of the structure are acceptable if a shim or feeler gage 0.002 inch thick (or other specified thickness) cannot be put in to touch the fastener (Figure 2).

紧固紧固件后,如果垫片或塞尺(厚度为 0.002 英寸或指定厚度)无法接触到紧固件,则结构边缘的间隙是可以接受的(图 2)。

I. Do not use shims or solid fillers unless specified by the overhaul instructions.

除非大修说明有规定,否则不要使用垫片或固体填充物。

6. HOW TO INSTALL TYPES 5 AND 7 RADIUS FILLERS 如何安装类型 5 和 7 半径填充物

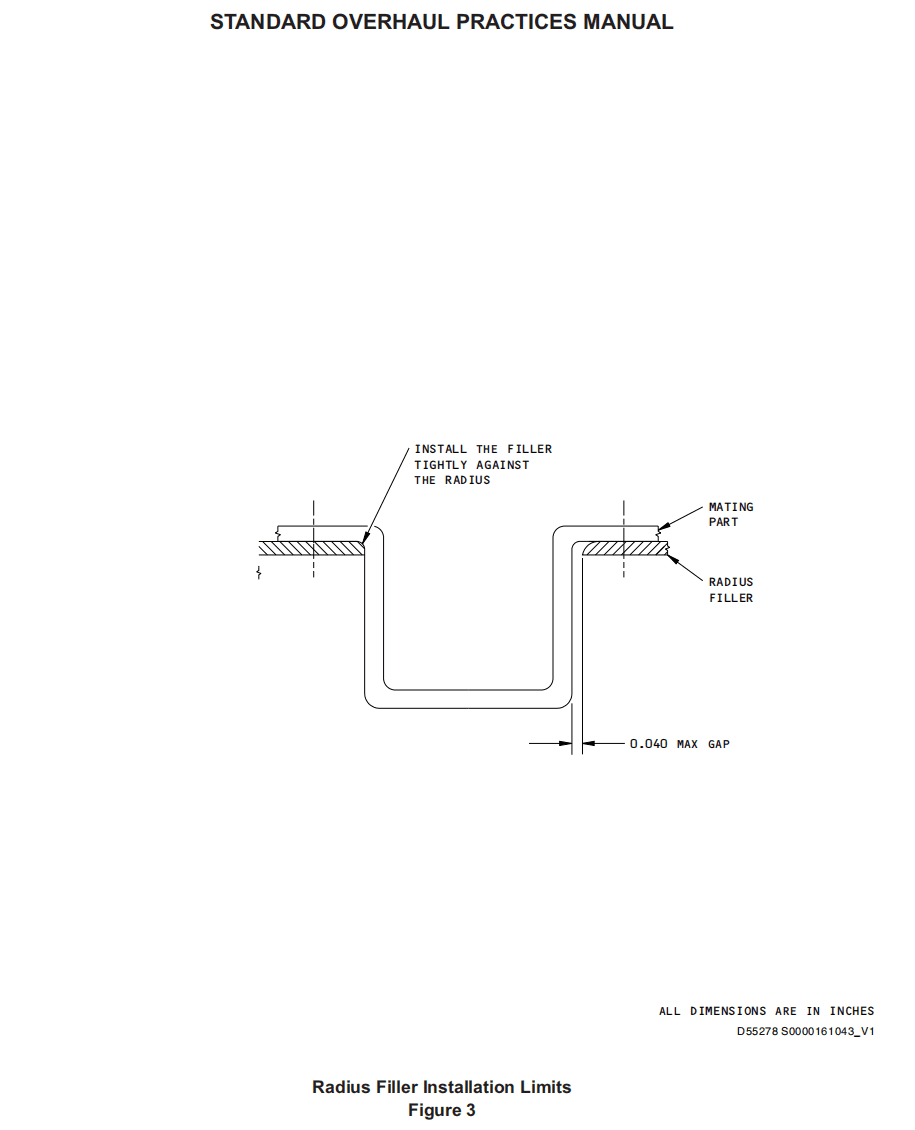

A. Unless specified differently by the overhaul instructions, install these radius fillers against the radius of the mating part, within the gap limits shown in Figure 3. No gap is permitted at the joints between the structure, shims, fillers or other parts unless shown by Figure 2.

除非大修说明有不同规定,否则应在图 3 所示间隙范围内,根据配合零件的半径安装这些半径填充物。除非图 2 所示,否则结构、垫片、填充物或其他零件之间的连接处不允许有间隙。

B. You can cut or machine these radius fillers to the necessary shape for gap adjustment, but you must refinish the shims per Paragraph 5.E. above.

您可以根据间隙调整的需要,对这些半径填充物进行切割或加工,但必须按照上文第5.E段所述重新打磨垫片。

7. HOW TO MAKE TYPES 1, 2, AND 3 SHIMS 如何制作类型1、2和3的垫片

A. If necessary, you can put together two shims, or a shim and a filler, or add plies of laminations to a shim. Use these procedures to bond them together with adhesive:

如有必要,您可以将两个垫片、一个垫片和一个填充物组合在一起,或者在垫片上添加叠片。使用以下步骤用粘合剂将它们粘合在一起:

(1) This procedure uses BMS 5-36 adhesive. Because this adhesive uses the moisture in the air to cure, keep the container closed, and open it only for the shortest possible time during this operation.

此步骤使用 BMS 5-36 粘合剂。由于这种粘合剂利用空气中的水分固化,因此请保持容器密闭,并在操作过程中尽可能缩短打开容器的时间。

(2) Lightly rub the mating surfaces with a clean abrasive pad. Wipe the surfaces clean.

用干净的研磨片轻轻擦拭配合表面。擦拭干净表面。

(3) Apply BMS 5-36 adhesive to one of the mating surfaces. Use Type 1 for metal-to-metal bonds. Use Type 2 when one or each of the mating surfaces is composite. If possible, apply the adhesive to make a layer.

在其中一个接合表面涂抹BMS 5-36粘合剂。金属与金属粘合时使用类型1。当其中一个或每个配合表面是复合材料时,使用类型2。如果可能,涂抹一层粘合剂。

(4) Put the mating surfaces together immediately. Final adjustment must be made within a few seconds, because the adhesive could cure that quickly. Apply pressure by hand, by clamps, or by something equivalent, to make the mating surfaces stay together tightly until the bond cures. The time for this is different for each material to be bonded. Usually it is a few seconds, but it could be as much as 3 to 5 minutes.

立即将配合表面贴合在一起。必须在几秒钟内完成最终调整,因为粘合剂可能很快固化。用手、夹具或类似工具施加压力,使配合表面紧密贴合,直到粘合剂固化。粘合时间因粘合材料而异。通常为几秒钟,但可能长达3到5分钟。

(5) Make sure the thickness of this assembly of shim parts is not more than the limit specified by the overhaul instructions.

确保此垫片组件的厚度不超过大修说明中规定的限制。

8. HOW TO MAKE TYPE 3 SHIMS FOR UNUSUAL CONTOURS 如何制作用于不规则轮廓的类型3垫片

A. Use this procedure when the overhaul instructions tell you to make a replacement shim for a location that has sudden bends or other unusual contours. You can bond a Type 2 laminated shim to a solid fiberglass filler which was specifically made for this location.

当大修说明要求为突然弯曲或其他异常轮廓的位置制作替换垫片时,请使用此程序。您可以将类型2叠层垫片粘接到专门为该位置制作的实心玻璃纤维填充物上。

B. Get the special fiberglass filler for this location, or make one by the procedures in the overhaul instructions. A typical fiberglass material is high-temperature resistant glass fabric prepreg BMS 8-139, Type 1581, Class 1, used per BAC5317 or BAC5317-3.

获取用于该位置的专用玻璃纤维填充物,或按照大修说明中的步骤自制。典型的玻璃纤维材料是耐高温玻璃纤维预浸料BMS 8-139,类型1581,等级1,根据BAC5317或BAC5317-3使用。

C. Cut the fiberglass filler to the necessary size. Break sharp edges as specified in BAC5300.

将玻璃纤维填充物切割成所需尺寸。根据BAC5300的规定,去除锋利的边缘。

D. Bond laminated polyimide BAC1535-29 to the fiberglass filler with adhesive BMS 5-36, Type 2, Grade 1. (This laminated material is 0.290 inch thick with 0.003 inch thick laminations).

用粘合剂BMS 5-36(类型2,等级1)将层压聚酰亚胺BAC1535-29粘合到玻璃纤维填充物上。(这种层压材料的厚度为0.290英寸,层压厚度为0.003英寸)。

E. Be sure to identify the solid fiberglass filler side of the shim with a rubber stamp.

确保用橡皮印章标记垫片的实心玻璃纤维填充物一侧。

F. Install the shim by the instructions in Paragraph 4. and Paragraph 5.

按照第4段和第5段的说明安装垫片。