垫片、填充物的粘合辅助和详情BONDING AID FOR SHIMS, FILLERS AND DETAILS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specification BAC5444. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自波音工艺规范 BAC5444。航空公司有一份波音工艺规范手册。

B. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum requirements.

数据是通用的。它不适用于所有情况或特定安装。使用这些数据来帮助您编写最低要求。

C. Refer to SOPM 20-00-00 for a full list of all the vendor names and addresses.

供应商名称和地址的完整列表请参考 SOPM 20-00-00。

2. MATERIALS 材料

NOTE: Equivalent substitutes can be used.

注意:可以使用等效替代品。

A. Method 2

方法 2

(1) Adhesive transfer tape, width optional

胶带,宽度可选

(a) Scotch 464, 465, 468, 909, 924, Y926, Y953, 969, 973, 9568 (SOPM 20-60-04)

(b) BMS 5-91

B. Method 4

方法 4

(1) Adhesives

粘合剂

(a) BMS 5-14

(b) EC-776, V76381

(c) EC-1357, V76381

(d) BMS 5-36 (for optional method)

(e) BMS 5-92 (for optional method)

C. Method 5

方法 5

(1) Adhesive

粘合剂

(a) BMS 5-25, Type 2, Grade 1

(b) BMS 5-92 (for optional method)

D. Method 6

方法 6

(1) Adhesive — BMS 5-25, Type 2, Grade 1

粘合剂——BMS 5-25,类型 2,等级 1

(2) Fabric — Style 1620 fiberglass

织物——1620 型玻璃纤维

E. Method 8

方法 8

(1) Adhesive — Super 77 Spray Adhesive, V76381

粘合剂——Super 77 喷雾粘合剂,V76381

3. GENERAL 通用

A. This procedure is only for shims, fillers and other such parts, which will be subsequently attached with permanent fasteners. Permanent fasteners do not include threaded bolts or equivalent fasteners that can be removed nondestructively. Do not use this procedure when the shims, fillers, or details are installed with wet primer or wet sealant, or when the parts can become hotter than 250 degrees F. during service.

本程序仅适用于垫片、填充物和其他此类零件,这些零件随后将用永久性紧固件固定。永久性紧固件不包括可无损拆卸的螺纹螺栓或类似紧固件。当垫片、填充物或零件安装有湿底漆或湿密封胶,或零件在使用期间温度可能超过250℉时,请勿使用本程序。

B. This procedure has these methods:

此程序有以下几种方法:

(1) Method 1 — Obsolete

方法 1——已过时

(2) Method 2 — Bonds with pressure sensitive adhesive tapes and films

方法 2——用压敏胶带和薄膜粘接

(3) Method 3 — Obsolete

方法 3——已过时

(4) Method 4 — Bonds with contact adhesives or cyanoacrylates (“super glue”)

方法 4——用接触型粘合剂或氰基丙烯酸酯(“强力胶”)粘接

(5) Method 5 — Bonds with epoxy resins

方法 5——用环氧树脂粘接

(6) Method 6 — Bond with epoxy resins with an added scrim

方法 6——使用环氧树脂粘合,并添加无纺布

(7) Method 7 — Obsolete

方法 7——已过时

(8) Method 8 — Bonds with spray adhesives

方法 8——使用喷胶粘合

C. If the overhaul instructions do not specify the method, you can use Methods 2, 4, 5, or 6.

如果大修说明未指定方法,则可以使用方法 2、4、5 或 6。

D. Mix ratios are nominal unless shown differently.

除非另有说明,否则混合比例均为标称值。

4. SURFACE PREPARATION 表面准备

A. Clean the surfaces by the Final Cleaning procedure of SOPM 20-30-03.

按照SOPM 20-30-03的最终清洁程序清洁表面。

5. APPLICATION OF ADHESIVES 粘合剂的应用

A. Method 2

方法2

(1) You can cut the tape to size before or after application.

可在使用前或使用后裁剪胶带。

(2) Apply the tape to one of the surfaces to be bonded and press or roll with good pressure. Parts can be put in storage with paper-backed tape for approximately 2 months.

将胶带粘贴到待粘合的表面之一,然后用力按压或滚动。用纸背胶带包裹的零件可存放约2个月。

(3) Use only one layer of adhesive film.

仅使用一层粘合膜。

(4) Peel the paper backing from the adhesive film and press or roll with pressure to make sure the bond is good.

剥离粘合膜的纸背,然后按压或滚动以确保粘合牢固。

(5) Parts can be used immediately.

零件可立即使用。

B. Method 4

方法 4

(1) Preferred procedure

首选方法

(a) You can thin BMS 5-14 material up to 50 percent with methyl ethyl ketone. For EC-776 and EC-1357 no thinner is necessary.

您可以用甲基乙基酮稀释BMS 5-14材料,稀释比例最高可达50%。EC-776和EC-1357无需稀释。

(b) Apply a thin, smooth layer of adhesive to the two mating surfaces. The layer must not be thicker than 0.014 inch.

在两个接合表面涂上一层薄而光滑的粘合剂。粘合剂层厚度不得超过0.014英寸。

(c) Let the adhesive dry 10 minutes, or until the surface is tacky but does not get on your knuckles if touched.

让粘合剂干燥10分钟,或直到表面有粘性,但触摸时不会粘到指关节。

(d) Assembly the parts and apply pressure. For small parts and thin shims, hand pressure is sufficient. For rigid sheet that does not easily bend under hand pressure, apply approximately 5 psi pressure by any method.

组装零件并施加压力。对于小零件和薄垫片,用手压即可。对于在手动压力下不易弯曲的刚性薄板,请通过任何方法施加约5磅/平方英寸的压力。

(e) Remove unwanted adhesive with solvent per BAC5750 (SOPM 20-30-03). Do not let solvent flow into the bond line.

使用符合 BAC5750(SOPM 20-30-03)标准的溶剂去除多余的粘合剂。不要让溶剂流入粘接线。

(f) Parts with dried adhesive layers can be bonded by heat activation. Apply pressure to the assembled parts and heat with a heat source not hotter than 260 degrees F. until bonded.

带有干燥粘合剂的零件可通过热激活进行粘接。对组装好的零件施加压力,并用温度不超过 260 ℉的热源加热,直到粘接。

(2) Optional procedure with BMS 5-36

BMS 5-36 的可选程序

(a) Apply BMS 5-36 adhesive to one of the mating surfaces. Apply it from the container with a medicine dropper or with the applicator that comes with the container. Make a layer as thin as possible with a glass rod or equivalent tool.

在其中一个接合面上涂抹BMS 5-36粘合剂。用滴管或容器附带的涂抹器从容器中取出粘合剂。用玻璃棒或类似工具涂抹尽可能薄的粘合剂。

(b) Assemble the parts immediately. Make final adjustment within seconds after the parts touch. Apply sufficient pressure by hand, with clamps or equivalent devices to make sure the parts fully touch until the bond sets. The time could be seconds or up to 3-5 minutes.

立即组装零件。在零件接触后的几秒钟内进行最终调整。用手、夹具或类似装置施加足够的压力,确保零件完全接触,直到粘合剂固化。时间可能是几秒钟,也可能长达3-5分钟。

(c) Most bonds are sufficiently cured after 1 hour at 70-80 degrees F.

大多数粘合剂在70-80℉下1小时后即可充分固化。

(d) If you spill large quantities of the liquid adhesive, flood the area with water. This will make the liquid cyanoacrylate cure. Then you can scrape it from the surface. Do not try to wipe up the spilled liquid adhesive with rags or tissues, because the fabric will cause polymerization. Large quantities of adhesive will generate heat as they cure, and make smoke and strong, irritating vapors.

如果大量液体粘合剂溢出,请用水冲洗该区域。这将使液态氰基丙烯酸酯固化。然后,您可以将其从表面刮掉。不要试图用抹布或纸巾擦拭溢出的液体粘合剂,因为织物会导致聚合。大量粘合剂在固化时会发热,并产生烟雾和刺激性很强的蒸汽。

(3) Optional procedure with BMS 5-92

BMS 5-92的可选程序

(a) Clean the mating surfaces by the Precleaning and Final Cleaning procedures of BAC5750 (SOPM 20-30-03).

按照BAC5750(SOPM 20-30-03)的预清洁和最终清洁程序清洁配合表面。

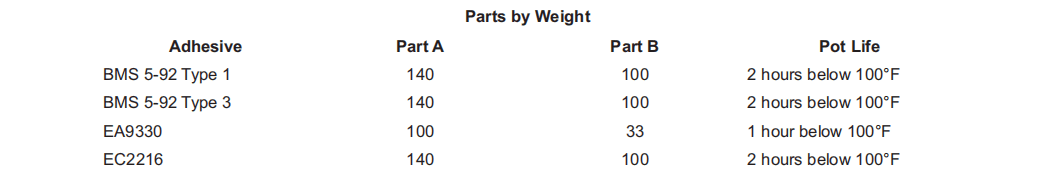

(b) Mix the individual components of the adhesive as follows:

按如下方式混合粘合剂的各个成分:

(c) Apply a thin, continuous layer of the mixed adhesive to each mating surface. A one-surface application can be made on smooth mating surfaces of less than 12 square inches if the surfaces fit tightly and there are no voids in the bond area. A one-surface application can also be made on long, narrow surfaces if they are not wider than 1 inch and the adhesive will squeeze out at the edges.

在每个配合表面涂上一层薄薄的、连续的混合粘合剂。如果表面紧密贴合且粘合区域没有空隙,则可在小于12平方英寸的平滑配合表面进行单面涂覆。如果长而窄的表面不超过1英寸且粘合剂会从边缘挤出,则也可以进行单面涂覆。

(d) Put the parts together and apply steady pressure to make sure the surfaces fully touch. The bondline must be continuous and the pressure must be good for a good bond and for good control of the shim thickness.

将零件组装在一起,并施加稳定压力,确保表面完全接触。粘结线必须连续,压力必须良好,以确保粘结牢固,并控制垫片厚度。

(e) Wipe off unwanted adhesive, before it cures, with a clean wiper or cotton swab wet with the same solvent you used to clean the surfaces in Paragraph 5.B.(3)(a).

在粘合剂固化之前,用干净的刷子或棉签将其擦去,棉签应蘸取与第5.B.(3)(a)段中用于清洁表面的溶剂相同的溶剂。

(f) Keep the pressure on, and cure at 65-100°F. for a minimum of 24 hours, or at 240-260°F. for 120-140 minutes or at 110-130°F. for 170-190 minutes.

保持压力,在65-100°F下固化至少24小时,或在240-260°F下固化120-140分钟,或在110-130°F下固化170-190分钟。

C. Method 5

方法5

(1) Epibond 1539A/B-10

(a) Mix 113 parts of Epibond 1539 Part A with 100 parts by weight Part B. The pot life of the mixture is approximately 1 hour at 75°F. Do not thin the Epibond 1539.

按重量比将113份Epibond 1539 A部分与100份B部分混合。在75°F时,混合物的可使用时间约为1小时。请勿稀释Epibond 1539。

(b) Mix the adhesive until smooth.

混合粘合剂直至光滑。

(c) Apply a layer of mixed adhesive, not more than 0.005 inch thick, to each mating surface.

在每个配合表面涂上一层混合胶,厚度不超过0.005英寸。

(d) Put the parts together and apply 2-6 psi pressure to make sure the surfaces fully touch. A continuous bead of adhesive at the edges is usually a good sign of sufficient contact.

将零件放在一起,并施加2-6磅的压力,以确保表面完全接触。边缘出现连续的胶条通常是充分接触的良好迹象。

(e) Wipe off unwanted adhesive, before it cures, with a clean wiper or cotton swab wet with the same solvent you used to clean the surfaces in Paragraph 5.C.(1)(a). Do not let the solvent get into the bondline.

在粘合剂固化前,用干净的刷子或棉签蘸取第5.C.(1)(a)段中用于清洁表面的溶剂擦拭多余的粘合剂。不要让溶剂进入粘合线。

(f) Keep the pressure on, and cure at 70-80°F. for a minimum of 12 hours. This adhesive will not cure satisfactorily below 65°F. Maximum strength comes after a minimum of 7 days at 75°F. A full cure can also be made in 2 hours at 115-135°F., or in 1 hour at 190-210°F.

保持压力,在70-80°F的温度下固化至少12小时。低于65°F时,粘合剂无法达到理想的固化效果。在75°F下放置至少7天后,粘合剂强度达到最大。在115-135°F下放置2小时,或在190-210°F下放置1小时,粘合剂即可完全固化。

(2) EA901NA/B-1

(a) Mix 113 parts of EA901 Part A with 100 parts by weight Part B. The pot life of the mixture is approximately 1 hour at 75°F. Do not thin the EA901.

按重量比将113份EA901 A部分与100份B部分混合。在75°F时,混合物的可使用时间约为1小时。请勿稀释EA901。

(b) Mix 113 parts of Epibond 1539 Part A with 100 parts by weight Part B. The pot life of the mixture is approximately 1 hour at 75°F. Do not thin the Epibond 1539.

按重量比将113份Epibond 1539 A部分与100份B部分混合。在75°F时,混合物的可使用时间约为1小时。不要稀释Epibond 1539。

(c) Apply a layer of mixed adhesive, not more than 0.005 inch thick, to each mating surface.

在每个配合表面涂上一层混合粘合剂,厚度不超过0.005英寸。

(d) Put the parts together and apply 2-6 psi pressure to make sure the surfaces fully touch. A continuous bead of adhesive at the edges is usually a good sign of sufficient contact.

将零件放在一起,施加2-6磅/平方英寸的压力,确保表面完全接触。边缘出现连续的胶条通常是充分接触的良好迹象。

(e) Wipe off unwanted adhesive, before it cures, with a clean wiper or cotton swab wet with the same solvent you used to clean the surfaces in Paragraph 5.C.(2)(a). Do not let the solvent get into the bondline.

在粘合剂固化之前,用干净的刷子或棉签将其擦去,棉签应蘸取与第5.C.(2)(a)段中用于清洁表面的溶剂相同的溶剂。不要让溶剂进入粘合线。

(f) Keep the pressure on, and cure at 70-80°F. for a minimum of 12 hours. This adhesive will not cure satisfactorily below 65°F. Maximum strength comes after a minimum of 7 days at 75°F. A full cure can also be made in 2 hours at 115-135°F., or in 1 hour at 190-210°F.

保持压力,在70-80°F的温度下固化至少12小时。低于65°F时,该粘合剂无法达到理想的固化效果。在75°F的温度下至少放置7天后,粘合剂强度达到最大。在115-135°F的温度下,粘合剂可在2小时内完全固化;在190-210°F的温度下,粘合剂可在1小时内完全固化。

(3) Optional method (BMS 5-92) — Use the same procedure as in Paragraph 5.B. for BMS 5-92, above.

可选方法(BMS 5-92)——使用与上述第5.B.段中BMS 5-92相同的步骤。

D. Method 6

方法6

(1) Preferred procedure

首选步骤

(a) Mix 113 parts of Epibond 1539 Part A with 100 parts by weight Part B. The pot life of the mixture is approximately 1 hour at 75°F. Do not thin the Epibond 1539.

按重量比例将 113 份 Epibond 1539 A 部分与 100 份 B 部分混合。在 75°F 条件下,混合物的可使用时间约为 1 小时。请勿稀释 Epibond 1539。

(b) Mix the adhesive until smooth.

混合粘合剂直至均匀。

(c) Apply a thin layer of the mixed adhesive to each mating surface.

在每个配合表面涂上一层薄薄的混合粘合剂。

(d) Cut a piece of fiberglass fabric (scrim) to the exact size of the shim and put this against one of the prepared surfaces.

裁剪一块与垫片尺寸完全相同的玻璃纤维布(无纺布),并将其贴在准备好的表面之一上。

(e) Remove unwanted adhesive with solvent. Do not let the adhesive get into the bondline.

用溶剂清除多余的粘合剂。不要让粘合剂进入粘结线。

(2) Optional Procedure (BMS 5-92) — Use the same procedure as in Paragraph 5.B. for BMS 5-92, above.

可选程序(BMS 5-92)——使用与上述第5.B.段中BMS 5-92相同的程序。

E. Method 8

方法8

(1) Spray a very thin, smooth layer of adhesive to the mating surfaces of the shim only. Wait 30 seconds minimum for the adhesive to dry. Make a note of the time you applied the adhesive to the shim.

在垫片的配合面上喷上一层薄薄的、光滑的粘合剂。等待至少30秒,让粘合剂干燥。记录下你在垫片上涂抹粘合剂的时间。

(2) Put the shim on the part and apply pressure to the assembly within 15 minutes after you applied the adhesive to the shim.

在你给垫片上粘合剂后的15分钟内,将垫片放在零件上,并给组件加压。

(3) Cure the adhesive by the vendor’s instructions.

根据供应商的说明固化粘合剂。