飞机部件的保护、储存和处理PROTECTION, STORAGE AND HANDLING OF AIRPLANE COMPONENTS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5401, BAC5402, BAC5411 (obsolete) and BAC5485.

本主题中的数据来自波音工艺规范BAC5401、BAC5402、BAC5411(已过时)和BAC5485。

B. The data for BMS 3-11-filled hydraulic components comes from these Boeing service letters:

有关BMS 3-11填充液压部件的数据来自以下波音服务信函:

(1) 707-SL-29-025

(2) 727-SL-29-044

(3) 737-SL-29-106

(4) 747-SL-29-070

(5) 757-SL-29-050

(6) 767-SL-29-063

(7) 777-SL-29-029

C. The data is general. It is not about all situations or specific installations. Use this data to help you write minimum standards.

数据为通用数据。不适用于所有情况或特定安装。使用这些数据来帮助您制定最低标准。

D. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

有关所有供应商名称和地址的列表,请参阅 SOPM 20-00-00。

2. GENERAL 通用

A. Refer to SOPM 20-44-02 for data about temporary protective coatings.

临时保护涂层的相关数据请参考SOPM 20-44-02。

B. Give protection to the components and put them away by standard industry practices and the instructions in this subject.

按照标准行业惯例和本主题中的说明对部件进行保护并妥善存放。

C. If the overhaul instructions are different than the instructions in this subject, use the overhaul instructions.

如果大修说明与本主题中的说明不同,请使用大修说明。

3. GLASS WINDOWS 玻璃窗

A. Glass windows used on the airplane are easily damaged. Protection of windows includes covers or coatings applied to the glass and the correct containers and crates.

飞机上使用的玻璃窗很容易损坏。保护窗户包括在玻璃上覆盖保护层或涂层,以及使用正确的容器和板条箱。

B. Handling

处理

(1) Keep windows in their containers until you start to repair them, or until you install them on the airplane.

在开始修理或安装到飞机上之前,将窗户放在容器中。

(2) Do not remove the protective covering from the windows until you start to repair them or install them in the airplane. If the window will be repaired,remove the protective covering only from the area to be repaired,and replace the covering immediately after the repair work is completed.

在开始修理或安装到飞机上之前,不要取下窗户的保护罩。如果窗户需要修理,则只取下需要修理的部分的保护罩,修理工作完成后立即更换保护罩。

(3) If you remove the protective covering, be sure to keep the bare window surface away from the work table or other objects that could cause damage.

如果取下保护罩,确保裸露的窗户表面远离工作台或其他可能造成损坏的物体。

(4) Do not slide the window, with or without protection, across the work table.

无论是否带有保护装置,都不要将窗户滑过工作台。

(5) Do not hold the window up on the plastic around the edge of the window.

不要用窗户边缘的塑料条支撑窗户。

(6) Be careful not to bump or hit the edges of the window panes, or the plastic around them, or let them touch something that can cause damage.

小心不要碰撞或撞击窗玻璃边缘或周围的塑料条,也不要让它们接触可能造成损坏的物体。

C. Protection and Packaging

保护和包装

(1) Clean the window fully with a wiper wet with Glyst concentrate, Glasswax or aliphatic naphtha. Use only these cleaners, unless the overhaul instructions are different. Dry and polish with a dry wiper.

用蘸有 Glyst 浓缩液、玻璃蜡或脂肪烃的刷子彻底清洁窗户。除非大修说明另有规定,否则只能使用这些清洁剂。用干刷子擦干并抛光。

(2) Clean the window only before you apply the protective cover to prevent unwanted material under the cover.

仅在安装保护罩前清洁窗户,以防止保护罩下出现不想要的物质。

(3) Apply protective covering by one of these methods.

通过以下方法之一安装保护罩。

CAUTION :BE VERY CAREFUL NOT TO CATCH UNWANTED MATERIAL BETWEEN THE PROTECTIVE COVERING AND THE GLASS SURFACE.

注意:请小心操作,不要让保护罩和玻璃表面之间夹入任何异物。

(a) Method No. 1 — Cellulose acetate sheeting cut to the size of the window

方法 1——将醋酸纤维板切割成与窗户相同的大小

CAUTION :DO NOT USE THIS METHOD ON PLASTIC OR PLASTIC-COATED GLASS WINDOWS OR WINDSHIELDS.

注意:请勿在塑料或塑料涂层玻璃窗或挡风玻璃上使用此方法。

1) Cut cellulose acetate sheeting to the same size and shape as the window pane. If the acetate sheeting was used before, be sure to first clean it carefully with aliphatic naphtha.

将醋酸纤维板切割成与窗户玻璃相同的大小和形状。如果以前使用过醋酸纤维板,请务必先用脂肪烃石脑油仔细清洁。

2) Put the acetate sheeting on the window pane and apply cloth tape all around the edges of the sheeting to fully keep out unwanted material.

将醋酸纤维板放在窗户玻璃上,并在纤维板边缘四周贴上布胶带,以完全防止不必要的材料进入。

3) Parts or assemblies given protection by this method can be kept in storage indoors up to 18 months.

通过这种方法保护的零件或组件可在室内存放长达18个月。

(b) Method No. 2 — Transparent polyester tape

方法 2——透明聚酯胶带

1) Apply transparent polyester tape to the surface of the glass to fully cover all of the glass. The tape can be cut to size before or after application.

在玻璃表面贴上透明聚酯胶带,完全覆盖玻璃。胶带可在粘贴前或粘贴后裁剪。

CAUTION :IF YOU CUT THE TAPE TO SIZE AFTER APPLICATION, BE VERY CAREFUL NOT TO DAMAGE THE WINDOW SURFACE OR ITS EDGES.

注意:如果粘贴后裁剪胶带,请小心操作,不要损坏窗户表面或边缘。

(c) Method No. 3 –Strippable temporary protective coating per SOPM 20-44-02.

方法 3——根据 SOPM 20-44-02 进行可剥离的临时保护涂层。

1) Apply a smooth, continuous layer, minimum thickness 0.008 inch, of protective coating to all of the surface of the glass. Cheesecloth can be applied with the coating to help you remove the coating subsequently.

在玻璃表面均匀涂抹一层厚度至少为 0.008 英寸的保护涂层。可在涂层上覆盖一层粗棉布,以便日后去除涂层。

(d) Method No. 4 — Die-cut cellulose acetate sheeting cut smaller than window

方法 4——将醋酸纤维素片材模切成比窗户更小的尺寸

1) Cut cellulose acetate sheeting one inch smaller than the glass size. If the acetate sheeting was used before, be sure to first clean it carefully with aliphatic naphtha.

将醋酸纤维板切割成比玻璃尺寸小一英寸。如果之前使用过醋酸纤维板,请务必先用脂肪烃石脑油仔细清洁。

2) Put the sheeting on the glass, adjust its position as necessary, and attach it with two or three small pieces of cloth tape.

将纤维板放在玻璃上,根据需要调整其位置,并用两到三小块布带固定。

CAUTION :IF YOU CUT THE TAPE TO SIZE AFTER APPLICATION, BE VERY CAREFUL NOT TO DAMAGE THE WINDOW SURFACE OR ITS EDGES.

注意:如果在使用后裁剪胶带,请格外小心,不要损坏窗户表面或边缘。

3) Apply strips of 3 inch wide cloth tape to fully seal the edges of the applied sheeting and cover all of the bare glass surface. Tape can be cut to length before or after application.

使用3英寸宽的布胶带条完全密封已粘贴的薄膜边缘,并覆盖所有裸露的玻璃表面。胶带可在使用前或使用后裁剪。

4) Parts or assemblies given protection by this method can be kept in storage up to 18 months.

通过这种方法保护的零件或组件可在仓库中保存长达18个月。

(4) Wrap the window per step (a) or (b):

按步骤 (a) 或 (b) 包裹窗户:

(a) Put the window in a polyethylene bag of wall thickness 0.006 inch, fold the open end of bag at least twice, then fully seal the folds with masking tape.

将窗户放入壁厚为 0.006 英寸的聚乙烯袋中,将袋子的开口折叠至少两次,然后用遮蔽胶带将折叠处完全密封。

(b) Wrap the window in greaseproof paper or 0.006 inch thick polyethylene film, fold all joints at least twice, then fully seal the folds with masking tape.

用防油纸或0.006英寸厚的聚乙烯薄膜包裹窗户,将所有接缝处至少折叠两次,然后用胶带将折叠处完全密封。

(5) Put each wrapped window in a fiberboard container, add padding as necessary, and seal the container with tape.

将每个包裹好的窗户放入纤维板容器中,必要时添加垫料,并用胶带密封容器。

(6) On the outside of the container, identify the contents, such as by part number, serial number, test date, etc. Include such precautions as “GLASS – HANDLE WITH CARE,” “KEEP DRY” and “THIS SIDE UP” on at least two sides.

在容器外部,注明内容物,例如件号、序号、测试日期等。至少在两面写上“玻璃——小心轻放”、“保持干燥”和“此面向上”等注意事项。

CAUTION :DO NOT LET THE CONTAINER BECOME WET. TESTS SHOW THAT SOME RESINS USED TO MAKE CONTAINERS, WHEN MIXED WITH WATER, WILL ETCH THE WINDOW GLASS.

注意:切勿让容器受潮。测试表明,一些用于制造容器的树脂与水混合后会腐蚀车窗玻璃。

(7) If you will send the window from one depot to another, put the fiberboard container in a wooden crate and put the same identification on the same markings on the crate that are on the container. During wet weather, be sure to give the crate protection from moisture.

如果要将窗户从一个仓库运送到另一个仓库,请将纤维板容器放入一个木箱中,并在木箱上贴上与容器上相同的标识。在潮湿的天气里,一定要给木箱防潮。

D. Storage of Glass Windows

玻璃窗的存放

(1) Windows must stay in their individual containers during storage.

存放时,窗户必须放在各自的容器中。

(2) The storage area must be clean, without metallic objects or other substances which could come through the surfaces of the container and damage the window. Do not let glass touch metal or glass touch glass.

存放区域必须干净,不能有金属物体或其他物质,否则可能穿过容器表面损坏窗户。不要让玻璃接触金属或玻璃。

CAUTION :CONTAINERS PUT ON EDGE PUTS WEIGHT ON WINDOW EDGES WHICH CAN CAUSE DEFORMATION OF THE PLASTIC AROUND THE OUTSIDE OF THE WINDOW.

注意:容器放在边缘会使窗户边缘承受重量,从而导致窗户外侧的塑料变形。

(3) Containers must be put down flat and not put on edge.

容器必须平放,不能放在边缘。

(4) Containers must not be stored near steam pipes, heater outlets or other sources of heat.

容器不得存放在靠近蒸汽管、加热器出口或其他热源的地方。

(5) The storage area must be dry. The air must have a low relative humidity.

存放区域必须干燥。空气的相对湿度必须低。

CAUTION :DO NOT LET THE CONTAINER BECOME WET. TESTS SHOW THAT SOME RESINS USED TO MAKE CONTAINERS, WHEN MIXED WITH WATER, WILL ETCH THE WINDOW GLASS.

注意:切勿让容器受潮。测试表明,用于制造容器的某些树脂与水混合后会腐蚀窗户玻璃。

E. Materials

材料

NOTE: Equivalent substitutes can be used.

注意:可以使用等效替代品。

(1) Protective Coating — Spraylat SC-1048, V87354.

防护涂层——Spraylat SC-1048,V87354。

(2) Cellulose Acetate Sheeting, Transparent, 0.020 inch gage — Kodapak No. E-463, V32153.

醋酸纤维素片材,透明,0.020英寸厚度——Kodapak No. E-463, V32153。

(3) Mylar polyester film, V18873.

聚酯薄膜,V18873。

(4) Polyester Transparent Tape — Pressure Sensitive, No. 850, V76381.

聚酯透明胶带——压敏,No. 850, V76381。

(5) Masking Tape — Scotch No. 202, V76381.

遮蔽胶带——Scotch No. 202, V76381.

(6) Cloth Tape — Permacel 692, V99742.

布带——Permacel 692, V99742.

(7) Cleaner — Glasswax, V53793.

清洁剂——玻璃蜡,V53793。

(8) Cleaner — Glyst Concentrate, V61102.

清洁剂——浓缩玻璃蜡,V61102。

(9) Wipers — BMS 15-5.

刷子——BMS 15-5。

(10) Aliphatic Naphtha — TT-N-95 (Flash point 20°F).

脂肪族石脑油——TT-N-95(闪点20°F)。

4. RUBBER OR RUBBER-LIKE MATERIALS 橡胶或类似橡胶的材料

A. Some elastomers (rubber and rubber-like materials) can get deterioration because of oxygen, ozone, sunlight, heat, rain, and other agents while the material is made or during storage. This could cause decreased serviceability or malfunction. Precautions during storage, and age control, will help prevent problems with rubber parts. Refer to BAC5401 for more data.

一些弹性体(橡胶和类似橡胶的材料)在制造或储存过程中会因氧气、臭氧、阳光、高温、雨水和其他因素而变质。这可能会导致零件的可用性降低或发生故障。在储存期间采取预防措施和实效控制,有助于防止橡胶零件出现问题。有关更多信息,请参阅 BAC5401。

B. Storage

储存

(1) Do not let different rubber materials touch each other.

不要让不同的橡胶材料相互接触。

(2) Keep parts away from steam pipes, heater outlets or other sources of heat, or where they could touch water, oils, grease, or other contamination.

零件应远离蒸汽管、加热器出口或其他热源,或可能接触水、油、油脂或其他污染物的区域。

(3) Store parts at 100°F maximum, unless higher temperatures are caused by temporary changes in the weather. Keep the relative humidity sufficiently low that condensation does not occur.

零件存放温度最高不得超过 100°F,除非天气临时变化导致温度升高。保持相对湿度足够低,以免发生冷凝。

(4) Do not put parts or assemblies in stacks or piles that could crush, kink, or deform rubber items. Long items can be tied in loose coils. If an item is in storage longer than 24 months, be sure to examine it for defects before you use it.

不要将零件或组件堆叠或堆放,以免压坏、扭结或弄变形橡胶制品。长件物品可以松散地盘绕在一起。如果物品存放时间超过24个月,请务必在使用前检查是否有缺陷。

(5) Cap or seal hoses with plugs per MIL-C-5501 and store without kinks or sharp bends.

按照MIL-C-5501用塞子盖住或密封软管,存放时不要扭结或急弯。

C. Age Control

时效控制

(1) Age control requirements apply only when specified by the part drawings, material standards, or other documents.

时效控制要求仅适用于零件图纸、材料标准或其他文件规定的情形。

(2) Cure Data Codes

固化数据代码

(a) The cure date code is the letter Q preceded by one digit and followed by two digits as follows:

固化日期代码为字母Q,前面是一个数字,后面是两个数字,如下所示:

1) The first digit indicates the applicable quarter of the year. Each year is divided into quarters as follows:

第一个数字表示适用季度。每年分为以下四个季度:

1st quarter – January, February, March

第一季度——1月、2月、3月

2nd quarter – April, May, June

第二季度——4月、5月、6月

3rd quarter – July , August, September

第三季度——7月、8月、9月

4th quarter – October, November, December

第四季度——10月、11月、12月

2) The last two digits indicate the year.

最后两位数字表示年份。

EXAMPLE: 3Q98 identifies a part cured in the third quarter of 1998; that is, sometime between July 1 and September 30, 1998.

例如:3Q98表示零件在1998年第三季度固化,即1998年7月1日至9月30日之间。

(b) You will find the cure date code on all parts made from rubber or rubber-like material unless the code is specified as not necessary in the applicable specification. Some items could have the cure date code adjacent to or below the part number or equivalent identification.

所有橡胶或类似橡胶材质的零件上都有固化日期代码,除非适用规范中规定无需此代码。有些零件的固化日期代码可能位于件号或同等标识的旁边或下方。

(3) Storage Expiration Dates

存储有效期

(a) The expiration date for an item is the last day of the quarter that is a specified number of quarters after the quarter identified in the cure date code. Thus, if an item has a maximum permitted age of 4 quarters and it was cured in the first quarter of the year, it is acceptable until the end of the first quarter, or March 31, of the following year.

零件的有效期是指固化日期代码中指定的季度数之后的最后一个季度的最后一天。因此,如果某零件的最大允许有效期为四个季度,且在第一季度进行固化处理,则该零件的有效期可延续至第一季度末或次年3月31日。

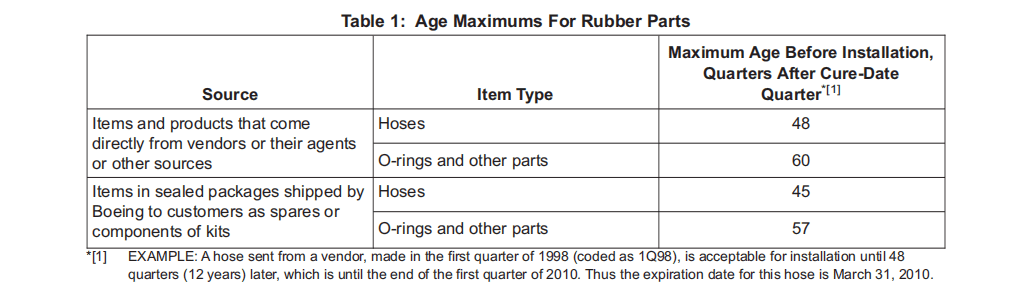

(b) For parts not yet installed, and bulk materials, Table 1 gives the maximum age, in quarters after the cure date quarter, that an item can have and be acceptable for installation.

对于尚未安装的零件和散装材料,表1给出了在固化日期所在季度后,某零件的最大允许有效期,即可以安装的期限。

(c) Age control is not necessary for rubber parts after they are installed.

橡胶零件安装后无需进行时效控制。

(4) Here are some examples of materials and parts not in the age control program. This list is only a guide. Refer to the part drawing, material standard or equivalent documents to see if the age control program applies.

以下是一些不在时效控制计划内的材料和零件示例。此列表仅供参考。请参考零件图纸、材料标准或同等文件,以确定是否适用老化控制计划。

(a) Silicone rubber

硅橡胶

(b) Ethylene propylene rubber

乙丙橡胶

(c) Butyl rubber

丁基橡胶

(d) Hydrin rubber

氢化丁腈橡胶

(e) Urethanes

聚氨酯

(f) Compressed asbestos-rubber sheet packing

压缩石棉橡胶板填料

(g) Vulcanized-in-place seals

就地硫化密封件

(h) Chlorosulfonated polyethylene

氯磺化聚乙烯

(i) Static seals when used with fasteners, such as sealing washers and permanently installed O-rings used with bolts, bulkhead fittings and dome nuts

与紧固件一起使用的静态密封件,例如密封垫圈和与螺栓、隔板配件和圆顶螺母一起使用的永久性安装的O形圈

(j) Fluorinated hydrocarbon such as Teflon, Viton, and Kel-F

氟化烃,例如特氟龙、氟橡胶和凯尔氟

(k) Cushion mountings, dust seals, and grommets installed as protection from damage to or by other parts.

缓冲垫、防尘密封圈和扣眼,用于保护其他零件免受损坏或防止损坏其他零件。

5. ELECTRICAL AND ELECTRONIC COMPONENTS 电气和电子零件

A. Electrical Wire Bundles

电线束

(1) Indicator lights, connectors, switches or other component permanently attached to wires of a bundle must be put in a plastic bag attached in position with tape.

指示灯、连接器、开关或其他永久连接到电线束的零件必须放在塑料袋中,并用胶带固定在适当的位置。

(2) Wire bundles with a large number of components permanently attached must be stored in cardboard boxes to give these components protection from damage.

带有大量永久连接组件的线束必须存放在纸板箱中,以保护这些组件免受损坏。

(3) Wire bundles must be kept in a dry area that does not have large changes of temperature which could cause condensation to collect on the bundle.

线束必须存放在干燥且温度变化不大的区域,以免线束上出现冷凝水。

(4) Wire bundles kept on shelves must be loosely coiled or distributed to keep attached components away from objects that could cause damage. If bundles are to be stacked, put cardboard separators between bundles.

放置在架子上的线束必须松散盘绕或分散放置,以使连接的部件远离可能造成损坏的物体。如果线束要堆叠,请在线束之间放置纸板隔板。

(5) If you hang wire bundles on a vertical surface, do not use only one support which can badly bend the wires. Use a sufficient number of supports to keep the bend radius a minimum of ten times the bundle diameter.

如果将线束悬挂在垂直表面上,不要只使用一个支撑物,否则可能会严重弯曲电线。使用足够数量的支撑物,使弯曲半径至少为线束直径的十倍。

B. Electronic Components

电子部件

(1) Keep circuit boards and electronic assemblies at temperatures of 60-100°F. Humidity control is not necessary, but make sure moisture does not collect on the components.

电路板和电子组件应保持在60-100°F的温度范围内。无需控制湿度,但应确保组件上不会积聚水汽。

(2) Put away small electronic components and assemblies as follows:

小型电子组件和组件的存放方法如下:

(a) Put the component in a plastic bag and seal the bag.

将组件放入塑料袋并密封。

(b) Wrap cushioning material around the outside of the plastic bag.

在塑料袋外层包裹缓冲材料。

(c) Put this in a paper bag or cardboard container.

将其放入纸袋或纸板箱中。

(d) Identify the package with the part number, test date and other important data.

在包装上标明件号、测试日期和其他重要数据。

6. OXYGEN SYSTEM COMPONENTS 氧气系统组件

A. Vapor degrease or aqueous degrease oxygen system components per SOPM 20-30-03 before you put them away. Use the general cleaning method before you install fittings. Use the special procedure for oxygen system components as a final cleaning after pressure tests and after sleeves or unions are installed on units not to be pressure tested. Refer to BAC5402 for more data.

按照 SOPM 20-30-03 的要求,对氧气系统部件进行蒸汽或水脱脂处理,然后再进行存放。在安装配件前,应使用通用清洁方法。在压力测试后,以及在不对设备进行压力测试的情况下安装套管或接头后,应使用特殊程序对氧气系统部件进行最终清洁。更多资料请参阅 BAC5402。

B. Wear clean lint-free gloves while you work with unpackaged oxygen system components after final cleaning.

在最终清洁后,使用未包装的氧气系统组件时,请佩戴干净的无绒手套。

C. Individually seal the cleaned BAC, NAS, AN and MS fittings in polyethylene bags or sleeves. Put the fittings in the bag within 10 minutes after you clean them if in an uncontrolled area, or within 8 hours if in a controlled work area.

将清洁后的BAC、NAS、AN和MS接头分别密封在聚乙烯袋或套管中。如果是在非受控区域,请在清洁后10分钟内将接头放入袋子中;如果是在受控工作区域,请在8小时内放入袋子中。

D. Install protective caps or plugs in all openings of tube assemblies. Visually-clean plastic caps can be used on B-nuts and other fittings if they do not engage the thread and let in plastic particles.

在所有管组件开口处安装保护帽或塞子。如果B型螺母和其他配件没有卡住螺纹,也不会让塑料颗粒进入,则可以使用目测干净的塑料帽。

(1) Protective metal caps or metal plugs can be used again after they are vapor degreased per SOPM 20-30-03 or immersion-cleaned with Freon TF solvent.

保护性金属帽或金属塞子在按照SOPM 20-30-03进行蒸汽脱脂处理或用氟利昂TF溶剂浸泡清洗后,可以再次使用。

(2) Keep protective caps and plugs in sealed polyethylene bags until immediately before you use them. After you open the bag and remove a supply sufficient for 5 minutes of work, immediately close the bag again.

将保护帽和塞子放在密封的聚乙烯袋中,直到马上要使用它们时再打开。打开袋子并取出足够5分钟使用的量后,立即将袋子重新密封。

E. Seal tube assemblies and tube assembly ends in new, clean polyethylene or nylon bags. Use 4-mil minimum thick polyethylene or 3-mil minimum thick transparent nylon on parts that weigh less than approximately one pound. Use 6-mil minimum thick polyethylene or 3-mil minimum thick transparent nylon bags or sleeves for all other parts. To seal the bags, fold twice and staple them. Other methods can be used to seal the bags if they do not catch dust or moisture in the bags.

将管组件和管组件末端密封在新的、干净的聚乙烯或尼龙袋中。重量小于约一磅的零件应使用至少4密耳厚的聚乙烯或至少3密耳厚的透明尼龙。对于所有其他零件,使用至少6密耳厚的聚乙烯或至少3密耳厚的透明尼龙袋或套管。为了密封袋子,将其折叠两次并用订书机装订。如果袋子不会沾染灰尘或湿气,也可以使用其他方法密封袋子。

F. Do not open the bags that hold oxygen system components until immediately before installation. If the bag is torn or unsealed during storage, clean the parts again.

不要打开装有氧气系统组件的袋子,直到即将安装时再打开。如果袋子在存放期间被撕裂或未密封,请再次清洁零件。

G. Identify all bags that contain cleaned oxygen system components and protective caps and plugs as Breathing Oxygen System Components. Include the part number and the date when the part was cleaned and sealed.

将所有装有清洁的氧气系统组件和防护帽、塞子的袋子标记为“呼吸氧气系统组件”。注明件号以及清洁和密封日期。

H. Put the sealed parts away where they will have protection from dust, moisture, lubricants or other contaminants and where the temperature will be 60-90°F and the relative humidity will be no higher than 90%.

将密封的零件存放在防尘、防潮、防润滑油或其他污染物的地方,温度保持在60-90°F,相对湿度不超过90%。

I. Keep oxygen modules in the same orientation as they are installed in the airplane.

保持氧气模块与飞机上安装时的方向一致。

7. BMS 3-11-FILLED HYDRAULIC COMPONENTS BMS3-11填充的液压元件

A. General

通用

(1) These general recommendations are superseded by any component-specific overhaul instructions.

这些通用建议被任何特定组件的大修说明所取代。

(2) Although these instructions are for BMS 3-11-filled components, they can be used for hydraulic components that use a different hydraulic fluid such as MIL-H-5606, MIL-H-6083, BMS 3-32, etc., but the fittings, seals and materials that you use must be specifically for that different hydraulic fluid.

虽然这些说明是针对 BMS 3-11 填充组件的,但它们也可用于使用不同液压油(如 MIL-H-5606、MIL-H-6083、BMS 3-32 等)的液压组件,但您使用的配件、密封件和材料必须专门用于该不同液压油。

B. Ports and Fittings

端口和接头

(1) Seal all ports and electrical connectors with caps and plugs that are resistant to BMS 3-11 hydraulic fluid.

用耐BMS 3-11液压油的盖子和塞子密封所有端口和电气连接器。

(a) Make sure the installed caps or plugs will not leak hydraulic fluid when the unit is filled with the fluid for storage.

确保在设备充满液压油进行储存时,安装的盖子或塞子不会泄漏液压油。

(b) Unless the overhaul instructions are different, you can use these caps or plugs, as applicable, for leak-free closure of hydraulic ports of components:

除非大修说明不同,否则您可以根据需要使用这些盖子或塞子,以无泄漏地封闭组件的液压端口:

1) BACC14AD pressure seal cap, flareless tube

BACC14AD压力密封盖,无扩口管

2) MS21913 plug, flareless tube

MS21913塞子,无扩口管

3) BACP20AU plug, flareless tube

BACP20AU塞子,无扩口管

4) AS4662 plug fitting, short flareless

AS4662塞子接头,短无扩口

5) AS4694 cap fitting assembly, hollow end, acorn, short flareless

AS4694盖子接头组件,空心端,无扩口,短

6) AS5169 port plug and bleeder fitting (for flareless boss ports only)

AS5169 端口塞子和引气接头(仅适用于无凸缘凸台端口)

(c) We recommend caps or plugs that have seals.

我们推荐使用带密封圈的盖子或塞子。

(2) Keep the caps and plugs installed in the components and hoses until immediately before installation.

在安装之前,请将盖子和塞子安装在组件和软管上。

(3) Be careful when you remove plastic plugs from the ports, to help prevent unwanted plastic pieces in the threads.

从端口上取下塑料塞子时,请小心操作,以免螺纹中混入不想要的塑料碎屑。

(4) Be careful to make sure paint near the port face does not chip off or get into the unit.

注意确保端口附近的油漆不会剥落或进入设备。

(5) Make sure the area around a port face (a sealing surface) has protection from dents, scratches, corrosion or contamination.

确保端口表面(密封表面)周围区域免受凹痕、划痕、腐蚀或污染。

(6) Keep the fittings that will be screwed into the port clean and lubricated .

保持将拧入端口的配件清洁和已润滑。

C. Preservation and Storage

保存和存放

(1) After you are done with the component tests, drain the hydraulic fluid from the unit, then refill it (90% minimum) with new, clean BMS 3-11 hydraulic fluid.

完成组件测试后,将液压油从设备中排出,然后重新注入(至少90%)新的、干净的BMS 3-11液压油。

(a) Add sufficient fluid to lubricate all internal seals.

添加足够的液压油,润滑所有内部密封件。

(b) Make sure there is sufficient air volume for thermal expansion during storage.

确保在储存期间有足够的空气量用于热膨胀。

(2) Flush hoses and tubes, then install protective caps and plugs, as applicable, on the end fittings, until immediately before the component is connected to the system.

冲洗软管和管道,然后在连接器上安装保护帽和塞子(如果适用),直到即将将组件连接到系统上。

(3) Do not use compressed air to blow out a tube, hose or reservoir, because the air supply could possibly not be clean.

不要使用压缩空气吹出管子、软管或储液器,因为压缩空气可能不干净。

(4) Keep filler caps clean.

保持加油口盖清洁。

(5) Clean the exterior of units with isopropyl alcohol, and blow these surfaces dry with compressed air.

用异丙醇清洁设备的外部,并用压缩空气吹干这些表面。

(6) Make sure hydraulic assembly areas are free of airborne contaminants.

确保液压组件区域没有空气污染物。

(7) Remove condensation that collects on a unit moved from a cold storage area into a warmer area.

清除从冷藏区移至较暖区域的设备上积聚的冷凝水。

(8) Apply corrosion inhibiting compounds on the exterior of units that will be in storage a long time.

在长期存放的设备外部涂抹防腐蚀化合物。

(9) Keep parts in a storeroom that will give protection from weather and direct sunlight. Ultraviolet radiation will cause deterioration of seals.

将零件存放在仓库中,避免天气和阳光直射。紫外线辐射会导致密封件老化。

(10) For storage conditions, we recommend a temperature range of 55-110°F (67°F is best) and a relative humidity of 40% or less.

储存条件方面,我们建议温度范围为55-110°F(最佳温度为67°F),相对湿度为40%或更低。

D. Packaging

包装

(1) When practical, seal the unit in a polyethylene barrier bag and include desiccant. Make sure the identification tag is visible.

如果可行,请将设备密封在聚乙烯隔离袋中,并放入干燥剂。确保识别标签清晰可见。

(2) Wrap the unit in nylon film, bubble wrap, or other padded, non-corrosive material to prevent damage to the component and its barrier bag.

用尼龙薄膜、气泡袋或其他填充性非腐蚀性材料包裹设备,以防止损坏组件及其隔离袋。

(3) Put the unit in a corrugated cardboard box or other superior protective container.

将设备放入瓦楞纸箱或其他高级保护容器中。

(4) Fill all empty space in the container around the unit with packing material.

用填充材料填满容器中设备周围的所有空隙。

(5) If the unit is not sealed in a polyethylene barrier bag, add desiccant and seal the box or container with packing tape or the closure mechanism.

如果设备没有密封在聚乙烯隔离袋中,请添加干燥剂并用包装胶带或封闭机构密封盒子或容器。

(6) Attach a tag to the package with the part number, nomenclature and maintenance date, as applicable.

在包装上贴上标签,注明件号、名称和维护日期(如适用)。

(7) When size or other factors let you pack more than one item in the same shipping or storage container, individually package each item first, then physically separate them, as with partitions, to help prevent external damage.

如果尺寸或其他因素导致您需要在同一运输或存储容器中包装多个物品,请先单独包装每个物品,然后用隔板等将其物理隔离,以防止外部损坏。

(8) Be sure to include in the package or container any special instructions necessary to prevent damage to the units when they are packed or unpacked.

请务必在包装或容器中附上必要的特殊说明,以防止在包装或拆包时损坏设备。

(9) If the units have springs or other items that have stored potential energy, be sure to pack the unit to prevent the risk of injury or damage.

如果设备有弹簧或其他具有潜在能量的部件,请务必妥善包装,防止造成人身伤害或设备损坏。

(10) Use tape, string, or something equivalent to hold loose pieces that could be damaged or lost.

使用胶带、绳子或其他类似物品固定可能损坏或丢失的松散部件。

(11) Give special protection to units that have electrical components sensitive to electrostatic discharge. Refer to SOPM 20-12-02 for details.

对具有静电放电敏感电子元件的设备进行特殊保护。详情请参阅SOPM 20-12-02。

E. Fluids

液体

(1) Unless specified differently in the overhaul instructions, use new hydraulic fluid, or filter the hydraulic fluid to NAS1638 Class 8 minimum standard, and 7500 ppm (0.75%) maximum water content.

除非大修说明书另有规定,否则应使用新的液压油,或按照NAS1638 Class 8最低标准和7500 ppm (0.75%)最高含水量标准对液压油进行过滤。

(2) Water is a chemical contamination. If you think the hydraulic fluid has water in it, drain the unit and refill it as specified.

水是一种化学污染物。如果您认为液压油中混有水分,请排空设备并按照说明重新注满。

(3) Make sure surfaces that will touch hydraulic fluid stay clean and dry.

确保接触液压油的表面保持清洁干燥。

F. Exposed Surfaces

暴露表面

(1) Be careful not to put scratches or dents in the surfaces of exposed cylinder rods or attachment bolts. Give protection to these surfaces as necessary.

注意不要在暴露的汽缸杆或连接螺栓表面留下划痕或凹痕。必要时为这些表面提供保护。

(2) Keep motor and pump shafts clean, and give them protection from physical damage.

保持电机和泵轴清洁,防止其受到物理损伤。

(3) Give splines protection from physical damage. Be sure to apply the applicable lubricant to them before assembly.

防止花键受到物理损伤。在组装之前,确保为其涂抹适当的润滑剂。

(4) Give tapered shafts and the inside diameters of couplings protection from physical damage.

保护锥形轴和联轴器的内径,防止物理损坏。

(5) Give special protection to critical and close-tolerance surfaces, and to sensitive and easily-damaged components.

对关键和公差小的表面以及敏感且易损坏的部件进行特殊保护。